Company details for:

Griffiths & Johnson Ltd

Red Rose Works,

Shaw Road,

Royton,

Oldham,

Greater Manchester,

OL2 6EF,

United Kingdom

Quick Links:

Products

G&J Powder Coating

- Enclosed pre-treatment (Phosphating) hot water washing facility with - capacity of 1m x 1m x 2m which degreases and phosphates components prior to powder coating.

- A large powder coating booth with 2 x powder coating guns.

- A totally enclosed large oven 2m x 2m x 3m which is temperature controlled to ensure correct curing of powder.

- A team of 4 operators mean we can offer a quick turnaround.

- We powder coat any colour from white to black!

- Our own 1.5 tonne van for collecting and delivering to our UK mainland customers.

- All above to our exacting ISO 9001-2008 Quality Standards.

G&J Laser Cut

We have Press Brake, MIG Welding and Powder Coating facilities to

complement our Laser cutter.

Our Laser cutter capacity is:-

- Stainless · 304 · 316 · 430

- Mild Steel · Cold Reduced · Hot Rolled · Galvanised · Zintec

- Aluminium · 1050

- Tread plate · Aluminium · Stainless up to 10mm · mild steel/Aluminium/ tread plate up to 20mm.

- Cutting Medium · Oxygen · Oxygen · Nitrogen · Compressed Air

- CAD drawings can be processed in dxf format.

- All above to our exacting ISO 9001-2008 Quality Standards.

G&J Logistics

- CNC Press Brake capacity up to 80 tonnes.

- M.M.A, M.I.G, T.I.G. − welding facilities up to 8mm weld size.

- Tube bending up to 50mm diameter.

- Assembly facilities for our own bespoke healthcare products.

- Upholstery department − re-upholster seating, benches etc.

- Various folding machines, deep drawing press, 100 tonne hydraulic press and associated equipment.

- Sawing machines to 50 ∅ capacity

- Miscellaneous drilling, linishing and finishing machines.

- 1.5 tonne van for collecting and delivering to our UK mainland customers.

- All above to our exacting ISO 9001 − 2008 Quality Standards.

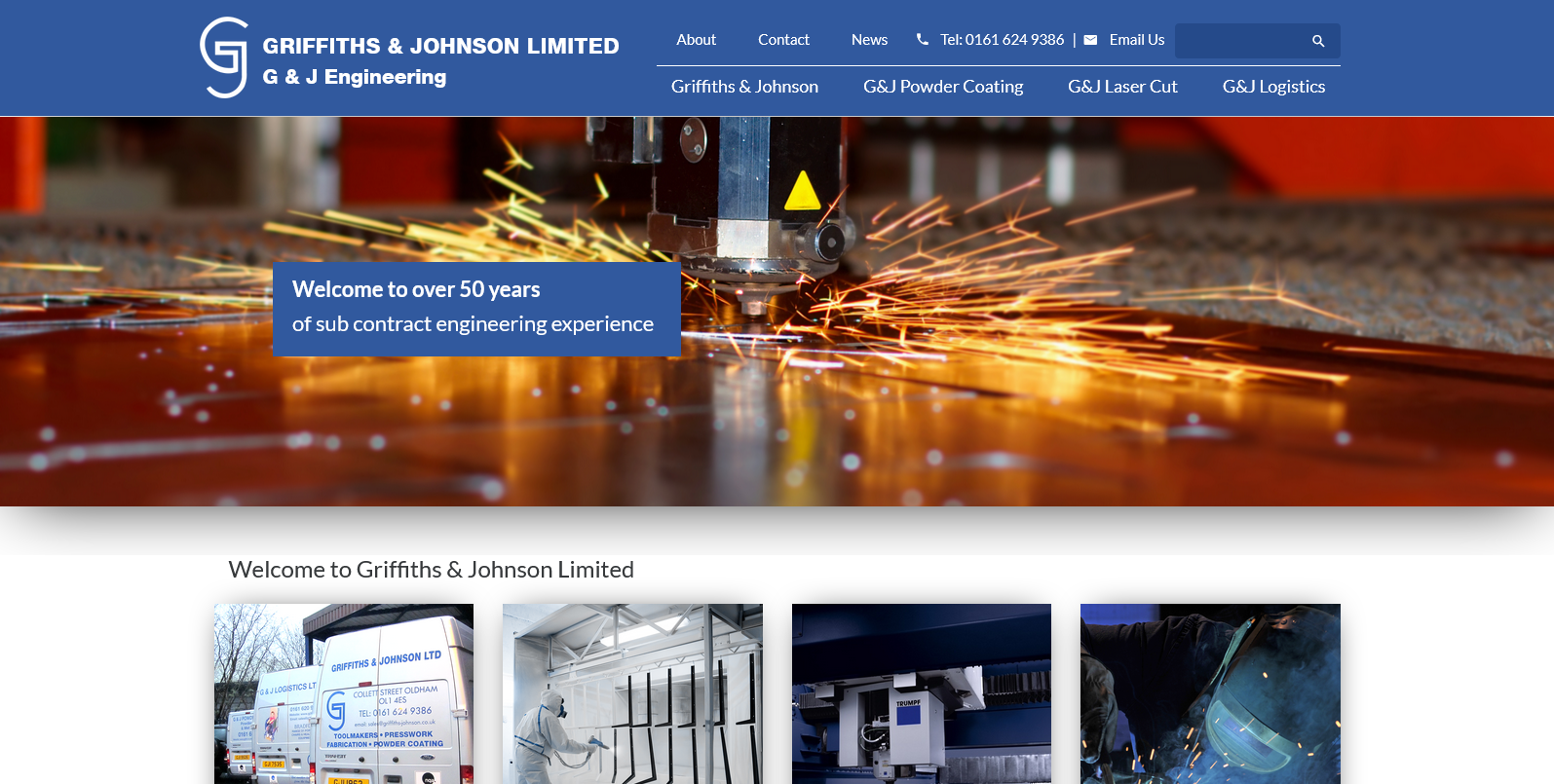

About us

Griffiths & Johnson can manufacture components from your designs or samples at one of our sites in Oldham, Lancashire. All work is carried out to meet ISO 9001-2008 Standards. Griffiths offer a delivery service to any location within UK Mainland in one of our very own fleet of vans.

G&J Powder Coating

G&J Powder Coating site is located at Unit 5, Moss Lane Industrial Estate, Oldham OL2 6HR

- Enclosed pre-treatment (Phosphating) hot water washing facility with capacity of 1m x 1m x 2m which degreases and phosphates components prior to powder coating.

- A large powder coating booth with 2 x powder coating guns.

- A totally enclosed large oven 2m x 2m x 3m which is temperature controlled to ensure correct curing of powder.

- A team of 4 operators meaning quick turnaround.

- We powder coat any colour from white to black!

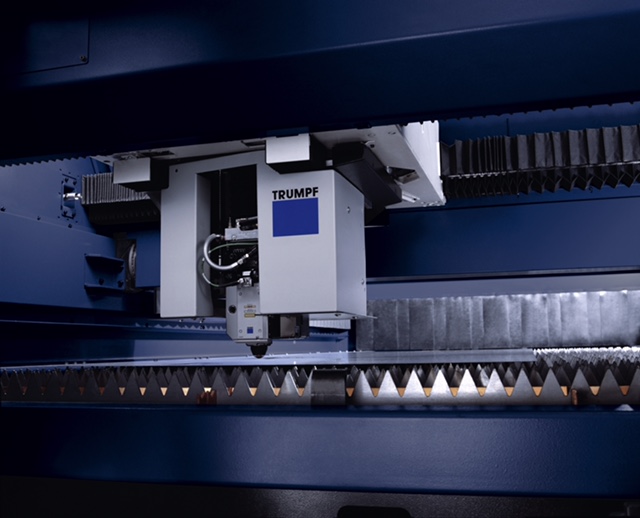

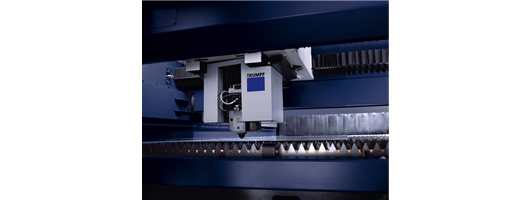

G&J Laser Cutting Service is provided using a state of the art Trumpf 3530 Laser Cutting Machine. We can provide a complete component from your drawing and/or sample.

We have Press Brake, MIG Welding and Powder Coating facilities to complement our Laser cutter.

Our Laser Cutter Capacity is:-

• Stainless · 304 · 316 · 430

• Mild Steel · Cold Reduced · Hot Rolled · Galvanised · Zintec

• Aluminium · 1050

• Tread plate · Aluminium · Stainless up to 10mm · mild steel/Aluminium/ tread plate up to 20mm.

• Cutting Medium · Oxygen · Oxygen · Nitrogen · Compressed Air

• CAD drawings can be processed in dxf format.

G&J Logistics

G&J Logistics site is located at Units 5 & 5B, Moss Lane Industrial Estate, Oldham OL2 6HR. This site specialises in a manufacturing ‘one stop’ site.

- CNC Press Brake capacity up to 80 tonnes.

- M.M.A, M.I.G, T.I.G. − welding facilities up to 8mm weld size.

- Tube bending up to 50mm diameter.

- Assembly facilities for our own bespoke healthcare products.

- Upholstery department − re-upholster seating, benches etc.

- Various folding machines, deep drawing press, 100 tonne hydraulic press and associated equipment.

- Sawing machines to 50 ∅ capacity

- Miscellaneous drilling, linishing and finishing machines.

Images

Trade Associations