Company details for:

Habia Cable Ltd

Shortway,

Thornbury Industrial Estate,

Thornbury,

Bristol,

Avon,

BS35 3UT,

United Kingdom

Quick Links:

Products / Services

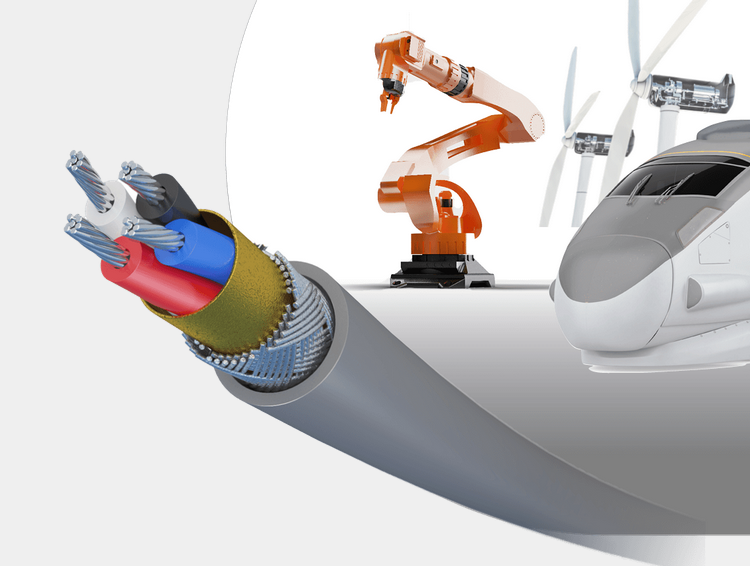

Custom Cables

Every aspect of the conductor, screen, insulation and jacket can be tailored to meet your specific needs − whether that be simple wires in non-standard sizes, coaxial cables with odd impedance requirements or complex multi-core hybrid cables.

By choosing Habia custom cables, you don’t just get purpose-built solutions with functional properties such as greater durability, more flexibility or smaller size. You’ll also see the benefits through your applications, including improved performance, cost-effectiveness and sustainability.

Whatever your cable needs, we can build your perfect match.

Custom Cable Harnesses & Systems

We regularly design custom cable harnesses for a variety of different applications, including:

remotely operated underwater vehicles (ROVs)

or gas turbines

submarine sonars

radar systems

weapon stations

and many more.

Find out more below about our capabilities, the services and techniques we offer for designing, manufacturing and testing your ideal cable harness or system.

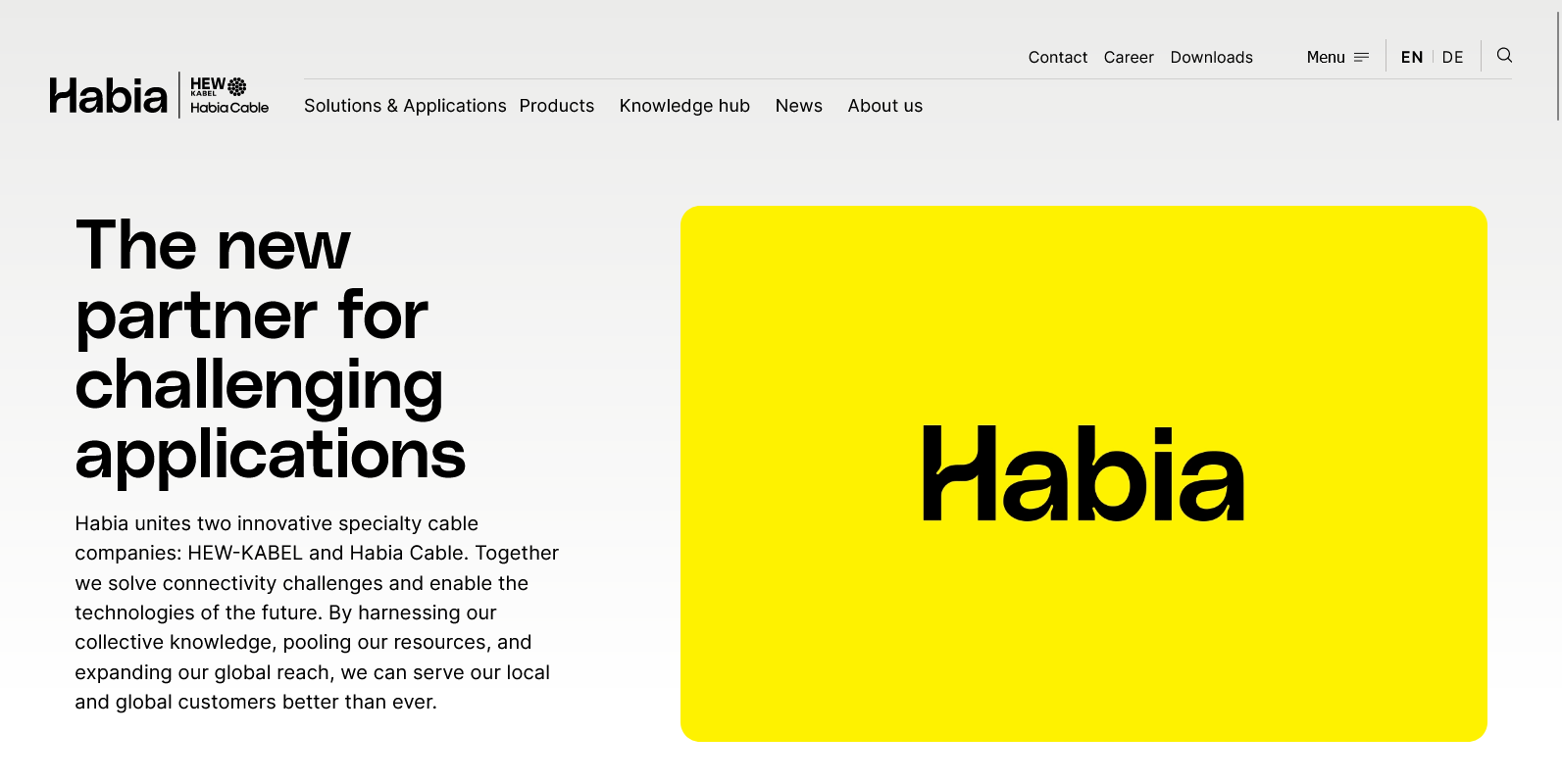

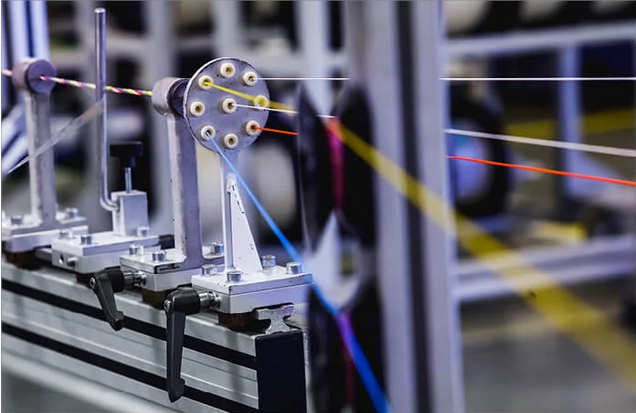

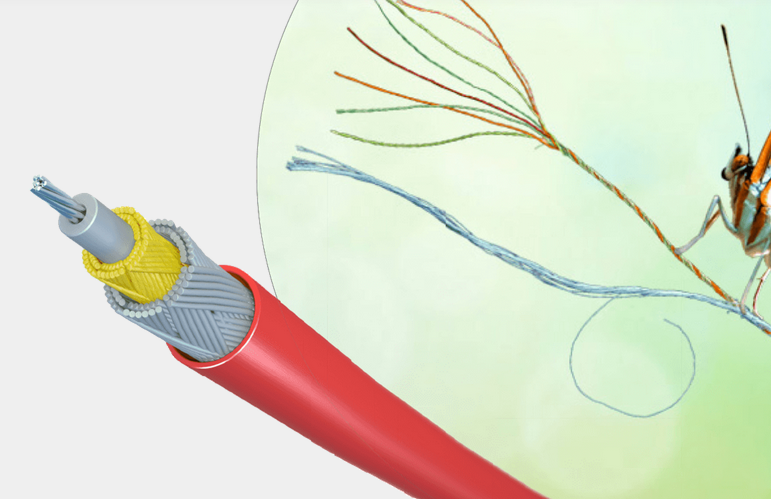

Fibre Optic Cable Systems

Fibre optic cable systems work by transmitting information in the form of pulses of light - or photons - along a glass or plastic fibre, no thicker than a hair shaft in diameter, and can offer greater speed and bandwidth than copper cable solutions. Fibre optics also experience less interference and signal degradation than copper, while being both thinner and lighter.

At Habia Cable, we offer pure fibre or hybrid harnesses (made with both fibre optics and copper) to ensure high-quality connectivity over long distances. The manufacturing of fibre optic harnesses is demanding, requiring a high level of precision and care to prevent contamination by dust and other particles.

Development & Testing

From prototype development to the final manufactured cable harnesses, we have the resources and infrastructure to undertake all the necessary tests to assure premium quality cable-connector integration. All the required equipment - including pressure tanks and tools for mechanical resistance tests - are in place to perform the inspections.

We also have a number of manual, computerised, and automatic appliances to perform electrical testing and evaluation. Electrical testing and visual inspection are both performed as standard practice on each and every finalised product.

Moulding & Surface Treatment

We have also developed different surface treatment techniques (including plasma and chemical treatment) for polyethylene and polyurethane based materials.

These methods allow us to design reliable underwater harnesses for medium and high depths with complex geometry and functionality. It’s also possible to use FEP moulding and various potting materials for the sealing of connectors, protecting against different environmental conditions.

Custom Spiral Cable Solutions

As well as being visually appealing, the spring form of coiled cables allows them to be extended and retracted repeatedly without causing damage to the wires inside - a perfect solution for connecting free-moving parts or objects.

At Habia, we use custom coiled cables in many of our cable harness designs, for applications such as communication headsets, extendible radio masts or in the connections between trucks and trailers.

HEW Flat Cables

Heating Cables

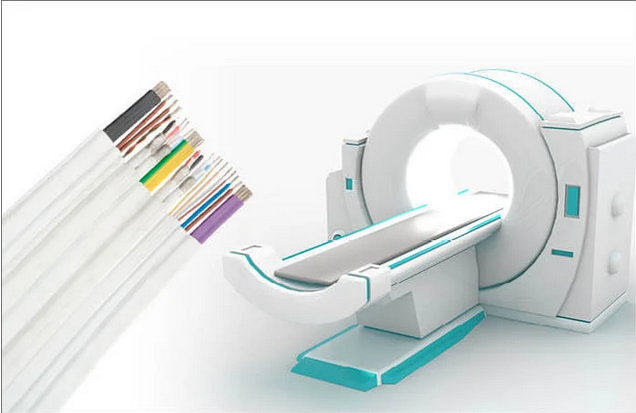

For these purposes, HEW offers a wide range of heating cables, heating lines and pipe trace heating systems for a wide variety of applications. By converting energy into heat, our heating cables primarily protect fluid-carrying lines from frost. Our heating cables are also able to maintain constant temperatures in heat engineering processes.

High-Temperature Cables

While the temperatures mentioned above are of natural origin, the temperatures to which cables and wires are exposed in industrial environments often reach similar ranges in the environment of welding robots, inside production plants or heating elements. Here, particularly heat-resistant cables and wires are required that can fulfill their intended purpose to 100%, even under harsh and adverse conditions

Ultra-Flex Cables

Based on 50 years of experience in development and production, we offer our customers individual solutions based on the latest state of the art in material and production technology. With 50 years of experience in production and development, our customers benefit from state-of-the-art materials and technology tailored to their unique situation.

High-Voltage Cables

Our HV cables are extremely flexible, extraordinarily temperature-resistant and mechanically highly resilient. The wide range of possible cross-sections makes possible a variety of many different applications.

HEW Hybrid Cables

Instead of handling different individual cables, our hybrid cables enable multifunctional combinations of different types of cables under a common sheath. Thus, for example, energy, optical and electrical data, signals, gases or liquids can be transmitted simultaneously in a hybrid cable specially designed for you.

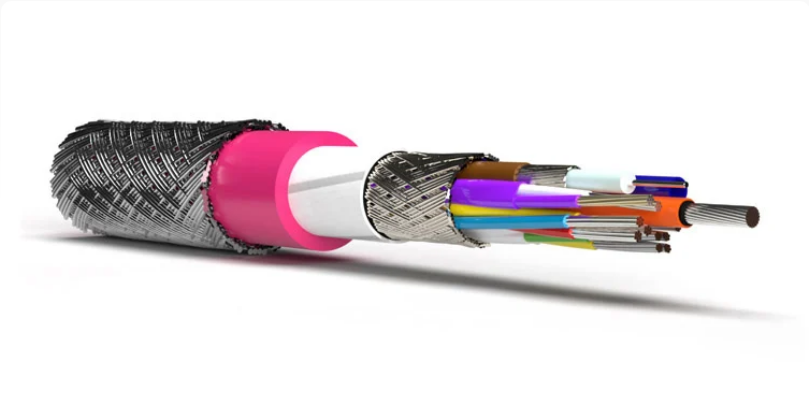

Medical Cables

HEW Miniature Cables

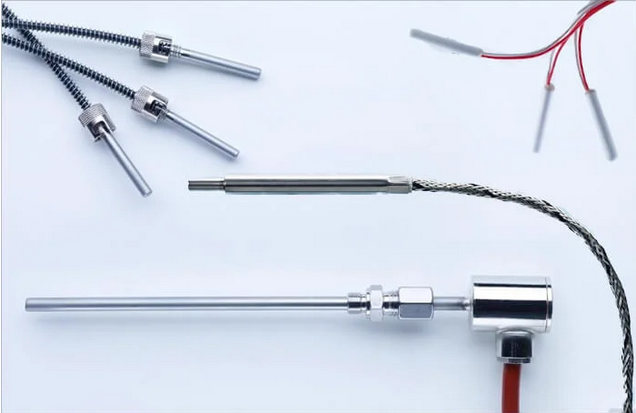

Sensor Cables

A prerequisite for the absolute reliability of the overall system is the quality of the individual components. For example, the measurement results of the sensors must be transmitted through the sensor cable to the processing system without interference.

About us

- Coaxial cables

- Custom design cable systems and harnesses

- Custom design cables

- Custom design coaxial

- Custom design cores

- Custom design multicores

- Equipment wires and hook up wire

- Shielded signal cables

- Signal cables

- Thermocouple cables

- Triaxial cables

- Twisted wires and twisted pairs and triples

With minimum order quantities as little as 500m for bespoke cable that is made to order, and quick delivery timescales, give us a ring for your specialist cable requirements!