Company details for:

Hanovia Ltd

780 Buckingham Avenue,

Slough,

Berkshire,

SL1 4LA,

United Kingdom

Quick Links:

Products / Services

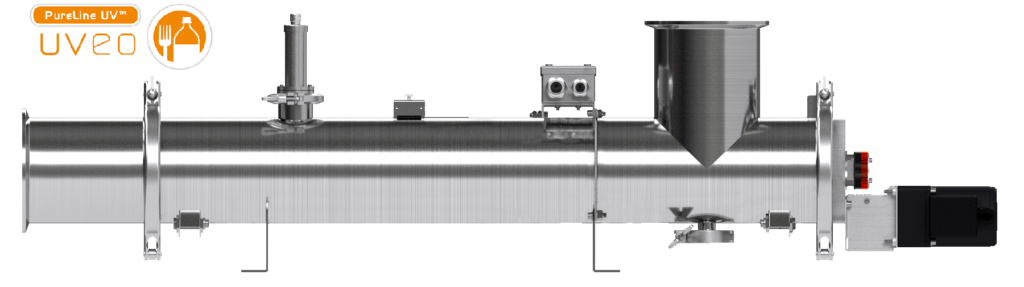

PureLine UVEO

An innovative single medium pressure lamp chamber design

Intelligent control technology to automatically deliver optimum disinfection performance with high operational efficiency.

The UV dose being produced will eliminate harmful microorganisms, reduce the bio-burden, protect against bio-fouling

A reduced CIP / SIP frequency and lower operating costs.

The intuitive control system will monitor external flow and transmittance meter inputs and ensure optimum UV system performance based on real time operating conditions.

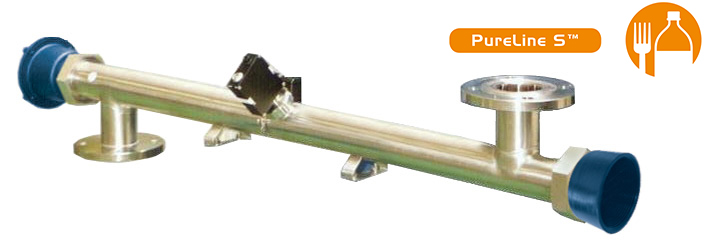

PureLine S

Medium pressure UV technology with higher wavelengths emitted by medium pressure, ideal to degrade Alicyclobacillus protein and enzymatic pathways in addition to its primary mode of inactivation through DNA degradation

A specially designed ‘thin’ chamber to maximise the contact time between the sugar syrup and UV light to optimise inactivation of moulds and spores.

A treatment design philosophy to cater for syrups with a BRIX content up to 67 (BRIX is the concentration of sucrose within the syrup)

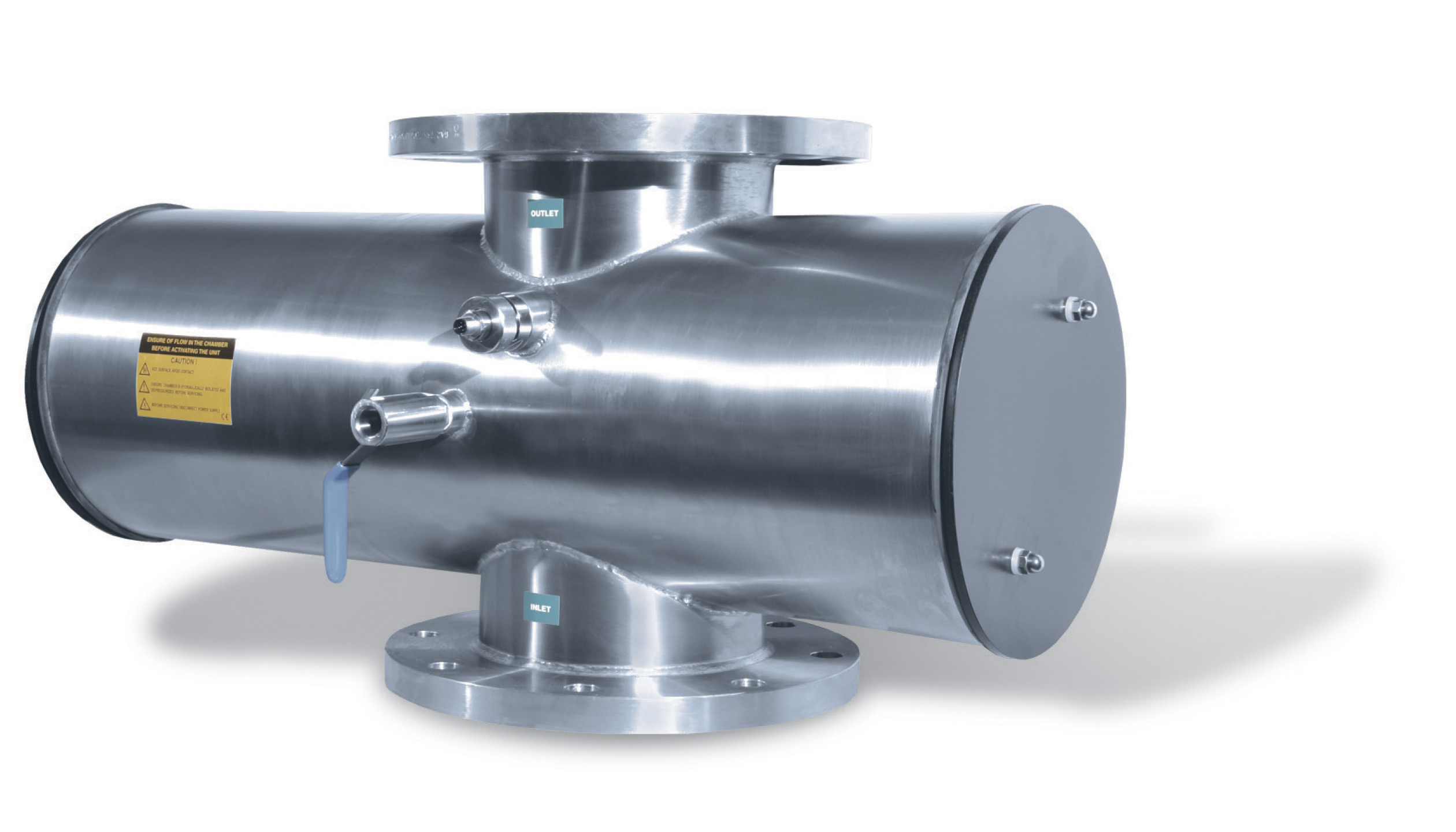

PureLine PQ

the UV dose being produced will disinfect the water, eliminate harmful micro-organisms, reduce the bio-burden and protect against bio-fouling

you will require fewer CIP / SIP cycles and lower operating costs.

The DVGW certified dry sensor will accurately measure the germicidal output of the UV system and calculate and display a validated a UV dose making it easy to monitor and log performance.

The intuitive control system will monitor external flow and transmittance meter inputs and ensure optimum UV system performance based on real time operating conditions.

PureLine DO

PureLine D

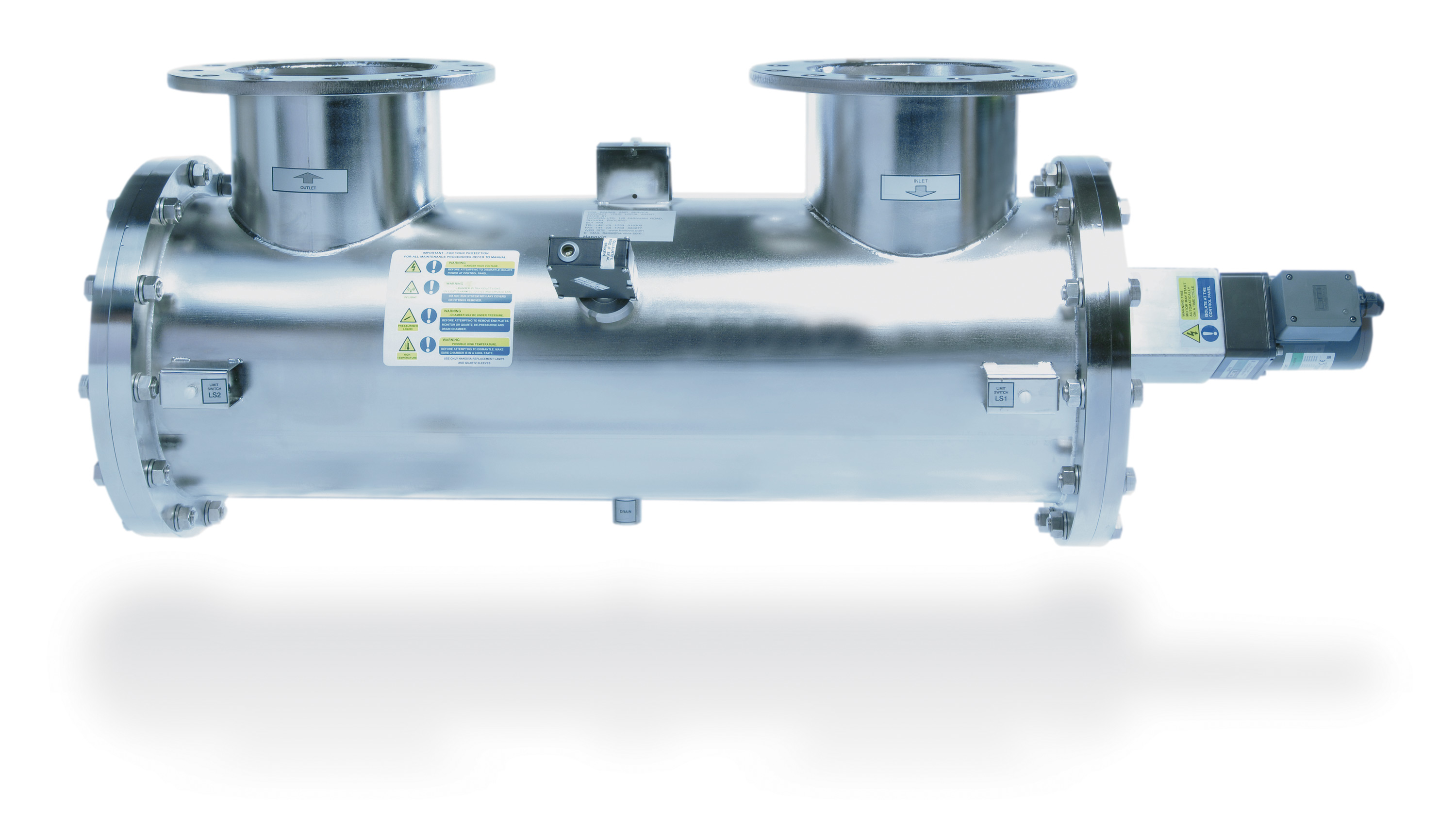

PureLine DC

Reverse Osmosis (RO) membrane protection from both residual chlorine and bio-fouling without chemicals or water wastage

An effective alternative to Activated Carbon filtration and Sodium bi-sulphite dosing without the issues of microorganism build-up or plant downtime for backwashing / chemical cleaning

A lowest lifetime cost solution with minimum operator intervention and small footprint.

PharmaLine DC

Reverse Osmosis (RO) membrane and Electro-deionisation (EDI) protection from residual chlorine and bio-fouling through strong disinfection without chemicals or water wastage

An effective alternative to Activated Carbon filtration and Sodium bi-sulphite dosing without the issues of microorganism build-up or plant downtime for backwashing / chemical cleaning

A lowest lifetime cost solution with minimum operator intervention and small footprint.

PharmaLine DL

PharmaLine DO

remove residual ozone dosed into the water to maintain microbiological integrity before the points of use

interlock with the distribution control system to switch off and on during a planned sanitisation procedure

Measure UV lamp intensity using a wet UV monitor to make it easy for the operator to assess and log performance.

PharmaLine DP

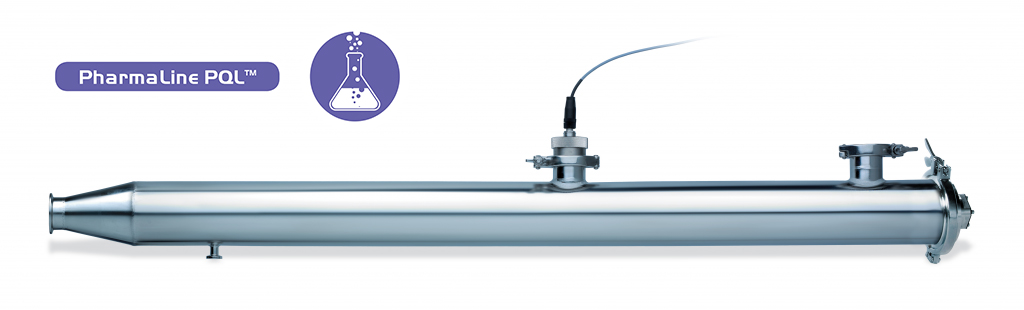

PharmaLine PQL

The UV dose being produced will disinfect the water, eliminate objectionable organisms, reduce the bio-burden and protect against bio-fouling within the storage and distribution system.

You will require less downtime for distribution SIP cycles and experience lower operating costs.

The DVGW certified dry sensor will accurately measure the germicidal output of the UV system and calculate and display a validated a UV dose making it easy to monitor and log performance.

The intuitive control system will monitor external flow and transmittance meter inputs and ensure optimum UV system performance based on real time operating conditions.

PharmaLine PQP

The UV dose being produced will disinfect the water, eliminate objectionable organisms, reduce the bio-burden, protect against bio-fouling in pre-treatment technologies such as softeners and reverse osmosis membranes

You will require less downtime for pre-treatment CIP / SIP cycles and experience lower operating costs.

The DVGW certified dry sensor will accurately measure the germicidal output of the UV system and calculate and display a validated a UV dose making it easy to monitor and log performance.

The intuitive control system will monitor external flow and transmittance meter inputs and ensure optimum UV system performance based on real time operating conditions.

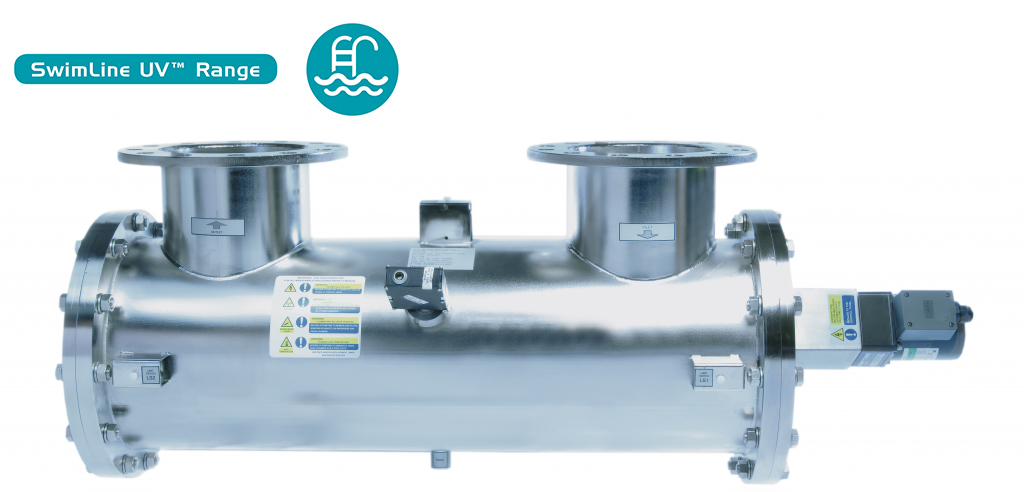

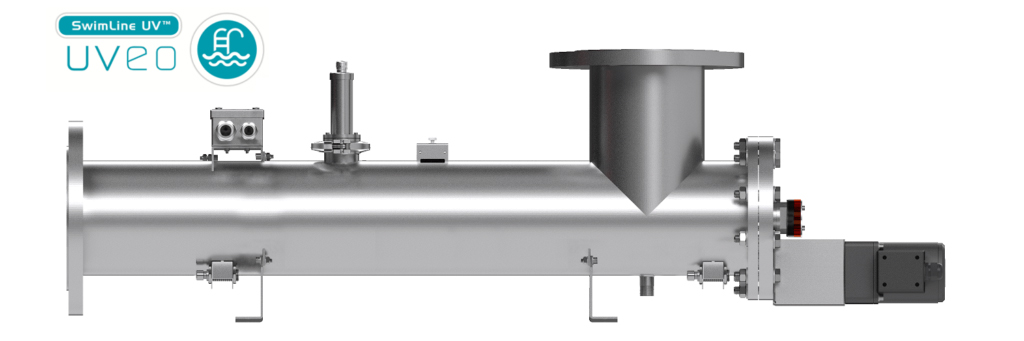

SwimLine

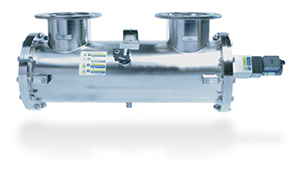

SwimLine UVEO

Single lamp technology delivering high treatment capacity (4 log cryptosporidium reduction at 330m3/hour flow rate)

Effective break down of not only monochloramine but also di- and trichloramine which are responsible for eye and skin irritation, headaches and unpleasant odours.

30 − 100% Step-less power control providing enhanced operation flexibility and energy savings

UVGuard and UV Shield unique safety features ensures maximum operator protection

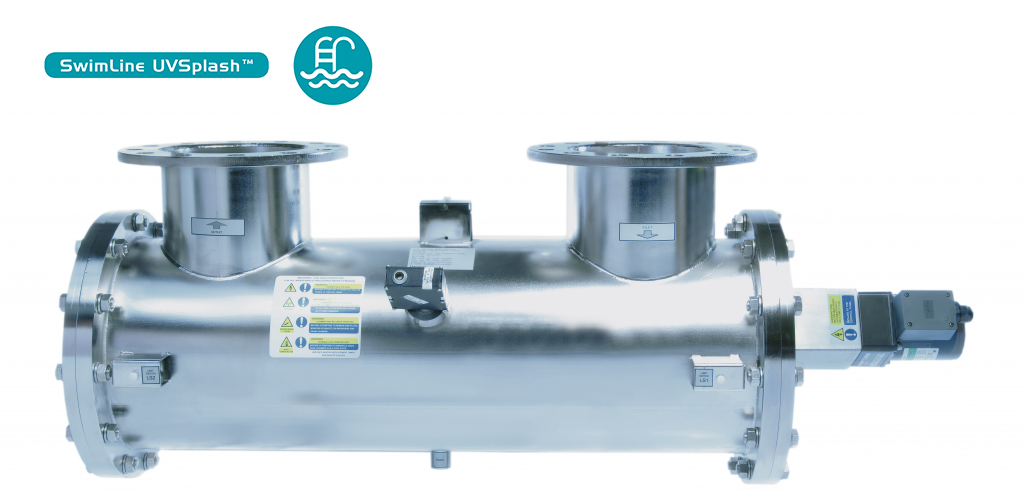

SwimLine UVSplash

About us

Hanovia Ltd has been developing and manufacturing UV (ultraviolet) products for the non-chemical treatment of water and air for over 90 years. We are the only UV system supplier of UV lamps and monitors and are recognized as the technology leader in this specified area. Our ranges of UV lamps are manufactured with enhanced spectral outputs for disinfection, dechlormaination, pesticide photolysis and NDMA photolysis.

Based in Slough, Berkshire, Hanovia has been committed to supplying many thousands of companies worldwide our range of UV systems, which can be used for a wide range of applications including; municipal drinking water, waste water, process industries, hospitals and swimming pools. Our commitment is to deliver top quality UV Systems that meet all our clients’ needs. Our UV reactors are designed using the most advanced Computerized Fluid Dynamic (CFD) software applying the latest UV technology.

In conjunction with Aquionics INC, based in the USA and Berson Milieutechnic in Holland we are able to provide our complete UV lamp range worldwide. Our global network of distributors and highly trained technicians ensure that the highest standards of service are provided locally. Visit the Hanovia website for more details.

Sponsored Links

Articles / Press Releases

Trade Associations