Company details for:

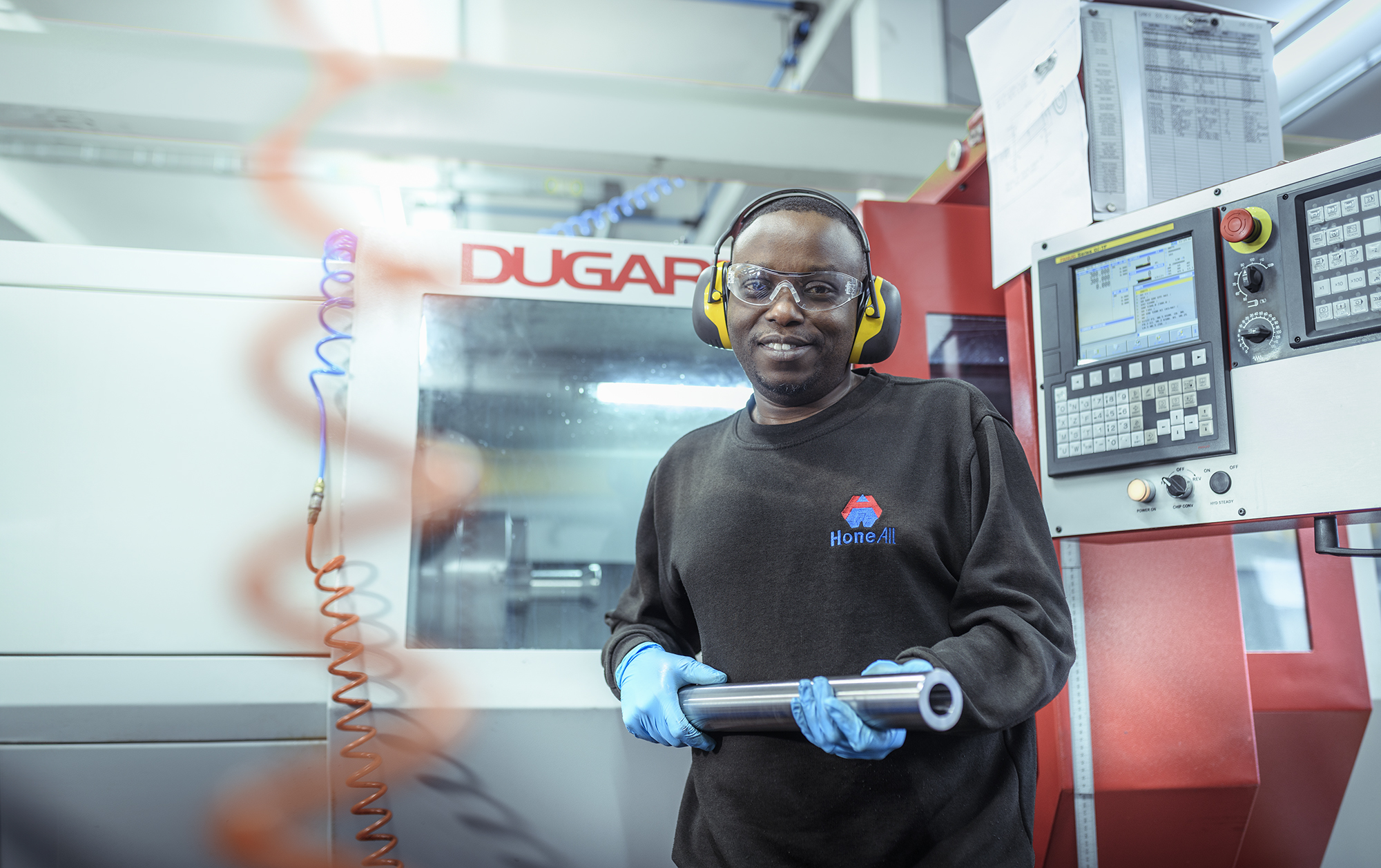

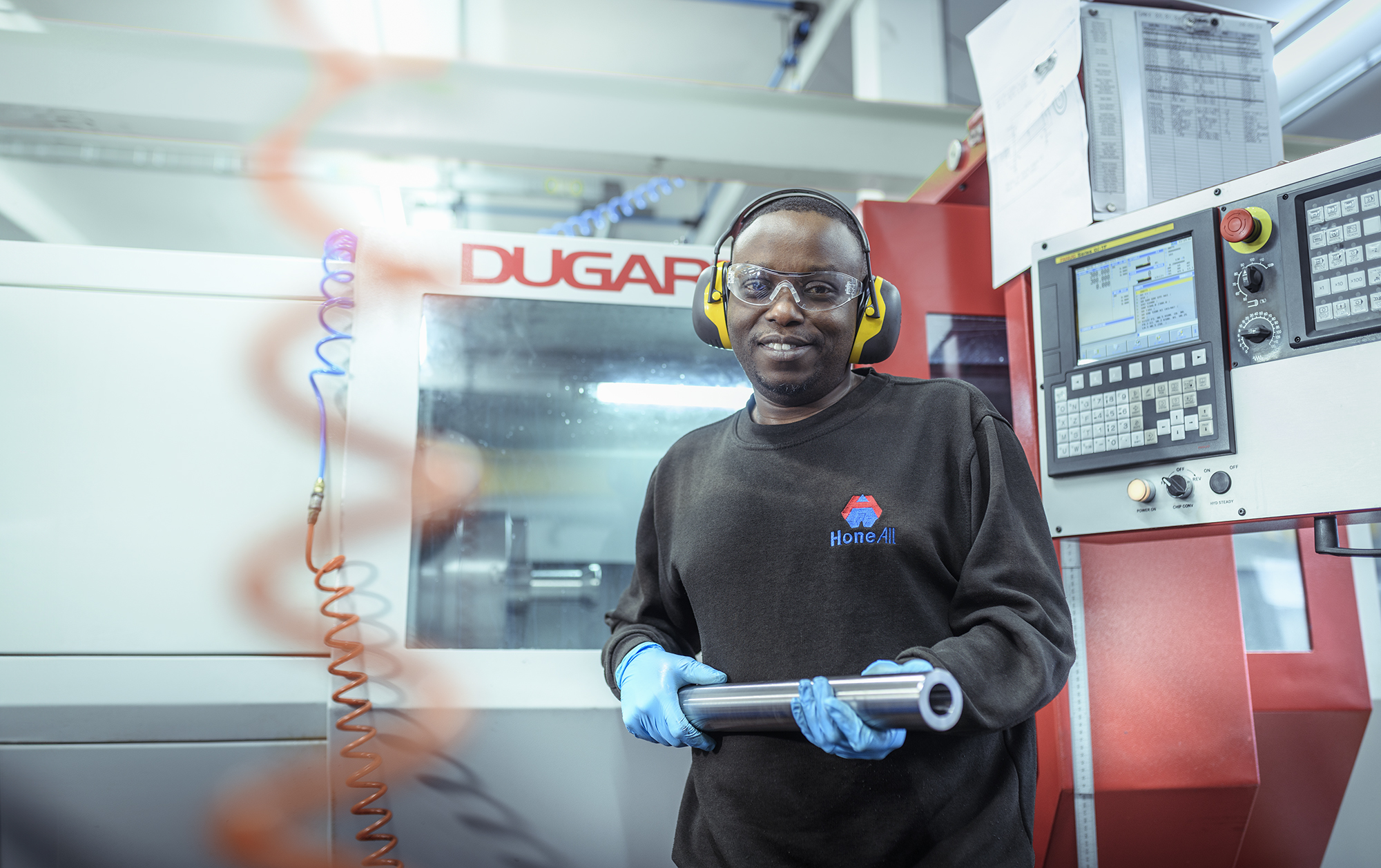

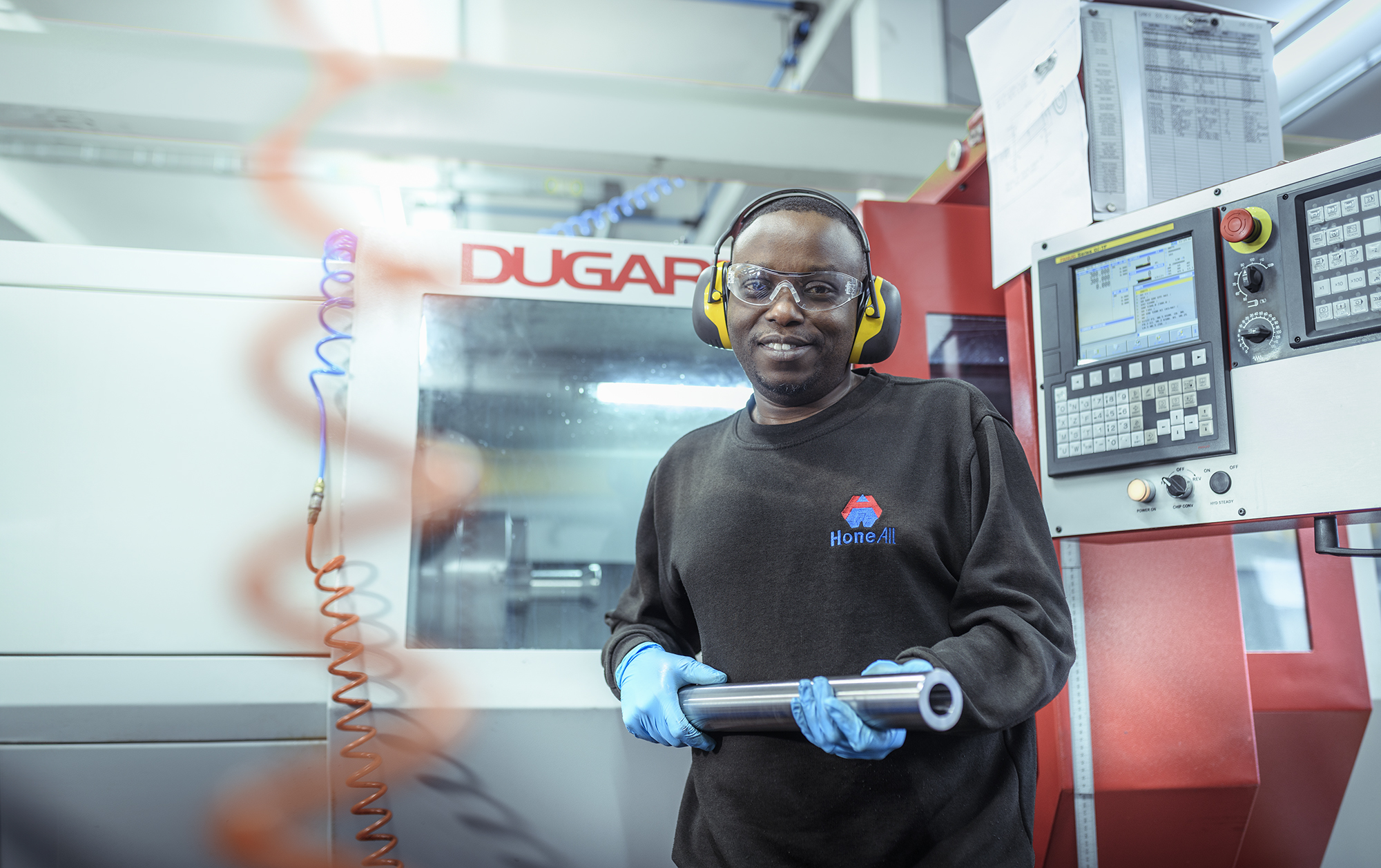

Hone All Precision Ltd

Quick Links:

Products / Services

CNC Turning

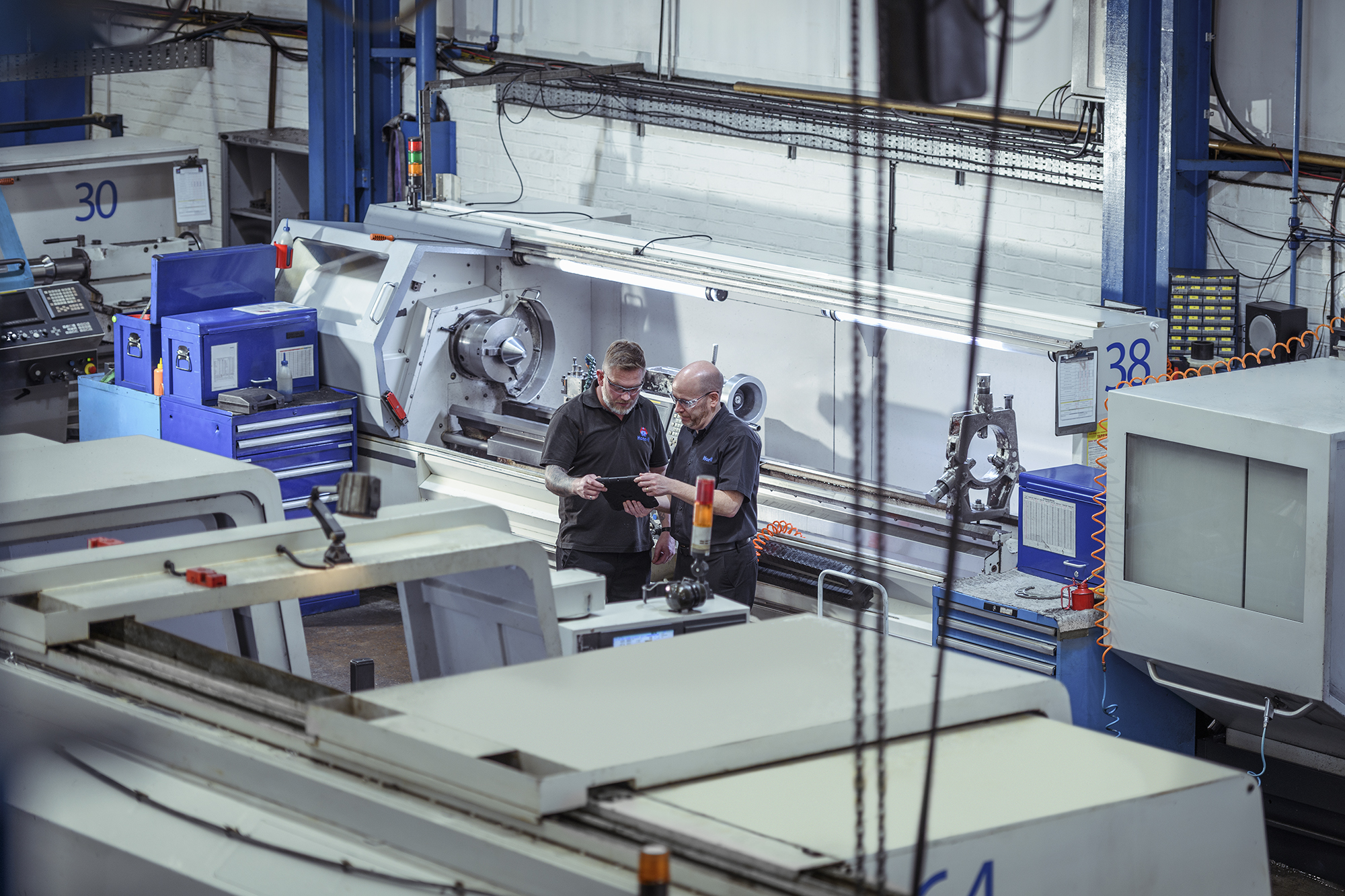

Our state of the art and professionally maintained equipment allows us to offer immediate capacity for turning, boring and trepanning to exacting tolerances and is just one element of our unique, single source supply package available.

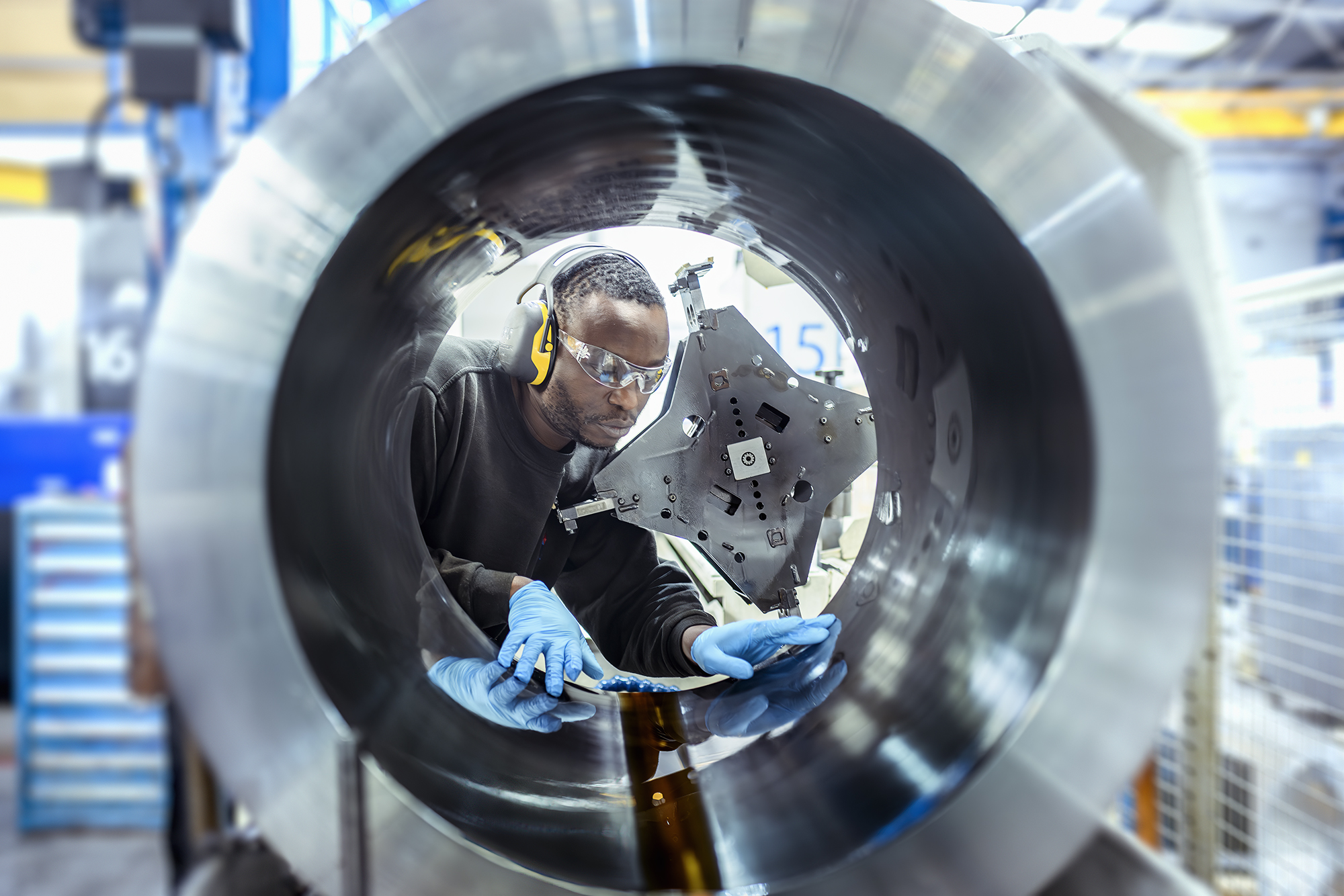

CNC Honing

Decades of honing expertise continues to be enhanced through ourinvestment in the latest CNC technology enabling much higher stock removal, whilst maintaining the exacting quality standards of surface finish and geometry on which our excellent reputation has been built.

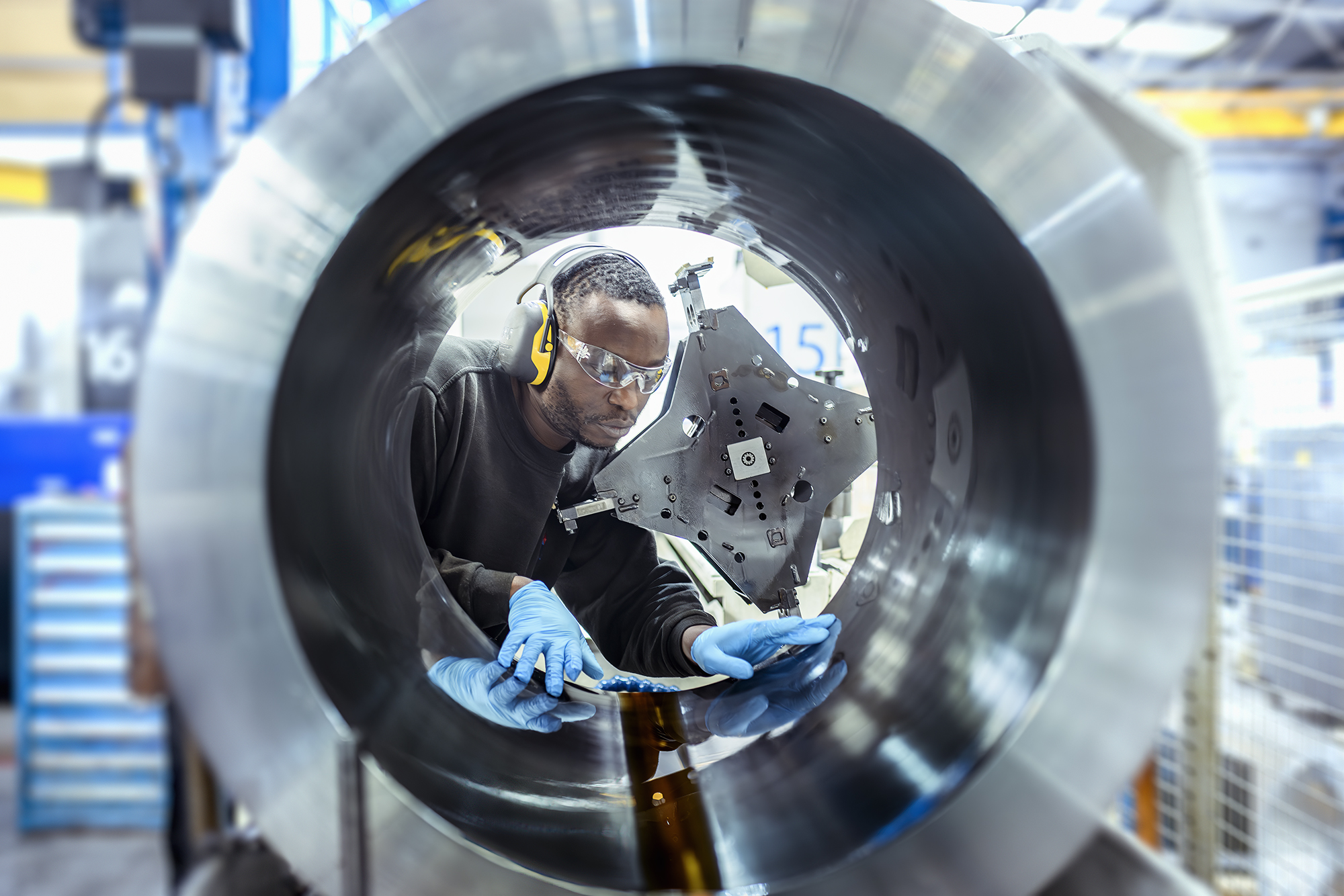

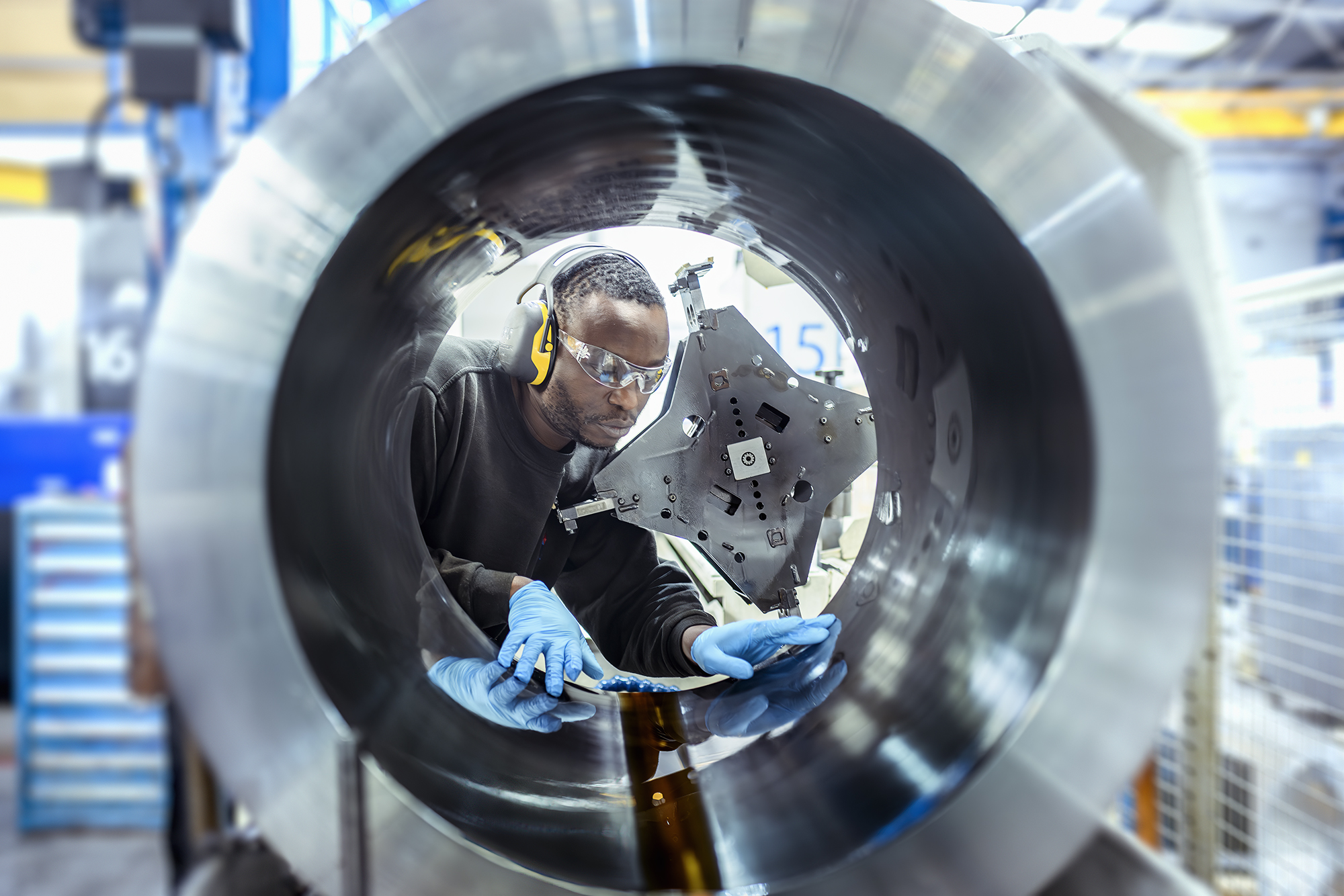

Deep Hole Boring

Utilising the latest in cutting and machine tool technology we achieve close tolerances, excellent accuracy and surface finishes second to none.

CNC Gundrilling

Our efficient and effective management of the process is continually meeting and exceeding the demands of the petrochemical, aerospace, automotive and medical sectors, where demand for deep holes between 3 and 25mm continues to grow.

CNC technology enables us to offer the highest degrees of accuracy on PCD, angled and positional drilling on a wide variety of components both in tubular and block form.

Hone-All Precision Rollers and Shafts

Perfectly balanced and machined to the highest quality within our own unique facility, we can guarantee quality and service whilst maintaining a competitive cost due to all machining processes being completed and controlled in-house.

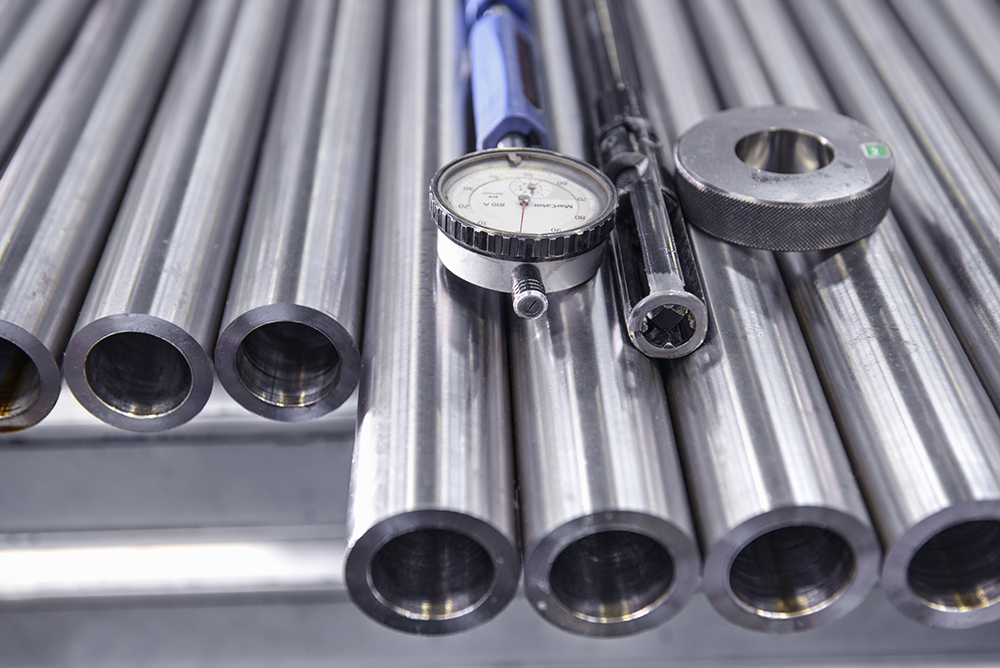

Tubing Supply & Manufacture

Based in Leighton Buzzard, the 9100:Rev D & 9001:2015 approved company offer a range of engineering services including material supply & full manufacture to drawing.

Excellent quality, customer service & a flexible approach ensure that Hone-All meet & exceed your requirements for the supply and machining of precision tubing utilising our expertise in deep hole boring, deep hole drilling, CNC Turning & CNC Honing up to 3 metres long.

From prototype to production batch, our approach to engineering excellence and exemplar customer service guarantees a quality product from start to perfect finish. We serve a variety of industries including Petrochemical, Aerospace & Defence, Hydraulics, Medical and Motorsport.

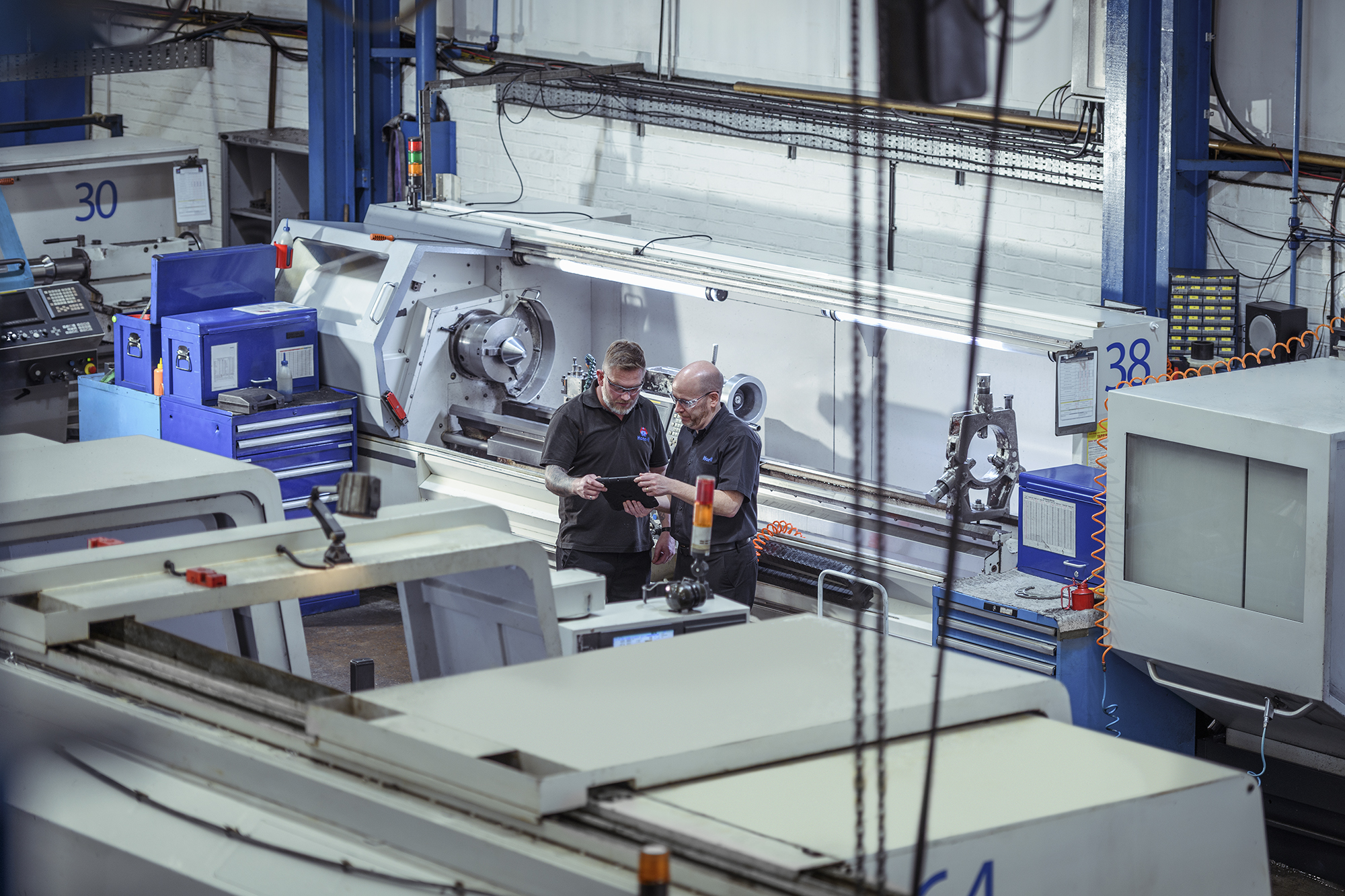

About us

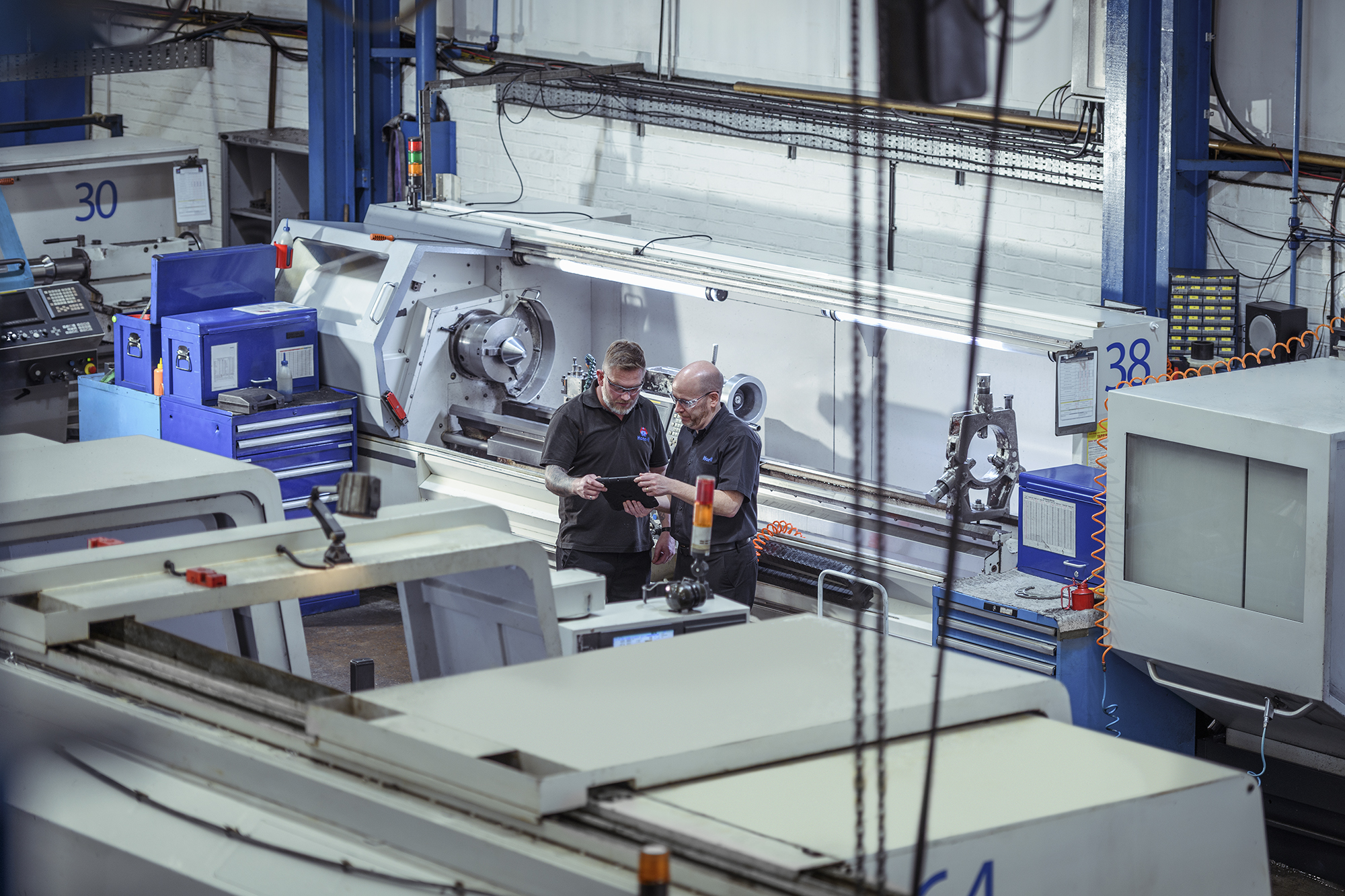

Hone-All Precision Ltd are the market leaders in the machining and manufacture of precision, tubular components.

Services include; CNC Gundrilling, CNC Honing, Deep Hole Boring & Drilling and Precision Roller Manufacturing.

We have a team of experienced engineers who undertake all services at our facility in Leighton Buzzard.

Through complete control over our supply chain, procurement and lead times we are able to provide the best customer service experience possible.

We are also able to offer very competitive pricing. We work with companies in the UK and across the world.

Hone-All Precision have experience working within a wide range of sectors including Automotive, Aerospace, Printing, Packaging, Medical, Pharmaceutical, Oil & Gas, Hydraulics, Defence & Motorsport. We fulfil the needs of many international clients machining requirements.

Our Services

CNC Turning

Minimum Over Cross Slide - 550mm 21.653”

Between Centres - 4000mm 157.480”

Minimum Trepanning Diameter - 100mm 3.937”

Maximum Trepanning Diameter - 195mm 7.677”

CNC Honing

Minimum Bore Diameter - 1.5mm 0.059"

Maximum Bore Diameter - 500mm 19.685"

Maximum O.A.L. - 3000mm 118.110"

Bore Tolerance - ± 0.05mm ± 0.002"

Surface Finish (Drilling Only) - 0.05μ 2√

Deep Hole Boring

Minimum Bore Diameter - 20mm 0.787"

Maximum Bore Diameter - 250mm 9.842"

Maximum O.A.L. - 3100mm 122.047"

Bore Tolerance under 76.2mm/3”- - ± 0.1mm ± 0.004”

Bore Tolerance over 76.2mm/3”- - -± 0.15mm ± 0.006”

Surface Finish (Drilling Only) - 3.2μ 125CLA

Accuracy (Drill Wander / T.I.R) - 0.025mm per 25.4mm 0.001”per 1”drilled

Deep Hole Drilling

Minimum Bore Diameter - 3mm 0.118"

Maximum Bore Diameter - 28mm 1.102"

Maximum O.A.L. - 2000mm 78.740"

Bore Tolerance - -± 0.5mm ± 0.002”

Surface Finish (Drilling Only) - 1.6μ 63√

Accuracy (Drill Wander / T.I.R) - -0.025mm per 25.4mm 0.001”per 1”drilled

CNC Gundrilling

Minimum Bore Diameter - 3mm 0.118"

Maximum Bore Diameter - 28mm 1.102"

Maximum O.A.L. - 2000mm 78.740"

Bore Tolerance - -± 0.5mm ± 0.002”

Surface Finish (Drilling Only) - 1.6μ 63√

Accuracy (Drill Wander / T.I.R) - -0.025mm per 25.4mm 0.001”per 1”drilled

Precision Rollers

Maximum Diameter - 550mm 21.653"

Maximum Length - 4000mm 157.480"

Images