Company details for:

Incotech Ltd

Quick Links:

Products / Services

Capabilities

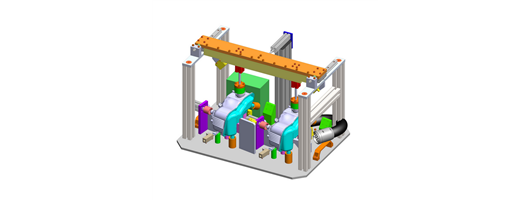

Assembly Machines & Fixtures

Assembly machines can include Poka Yoke features, vision systems and assembly sequence prompts on a HMI screen to help ensure that the components are being assembled correctly and in the right order.

Over many years we have manufactured assembly machines for a large variety of products including: − automotive drive shafts, sunshine roofs, interior trim, door hinges, clutch plates, gearboxes, glass panels, body jewellery, radiators, etc.

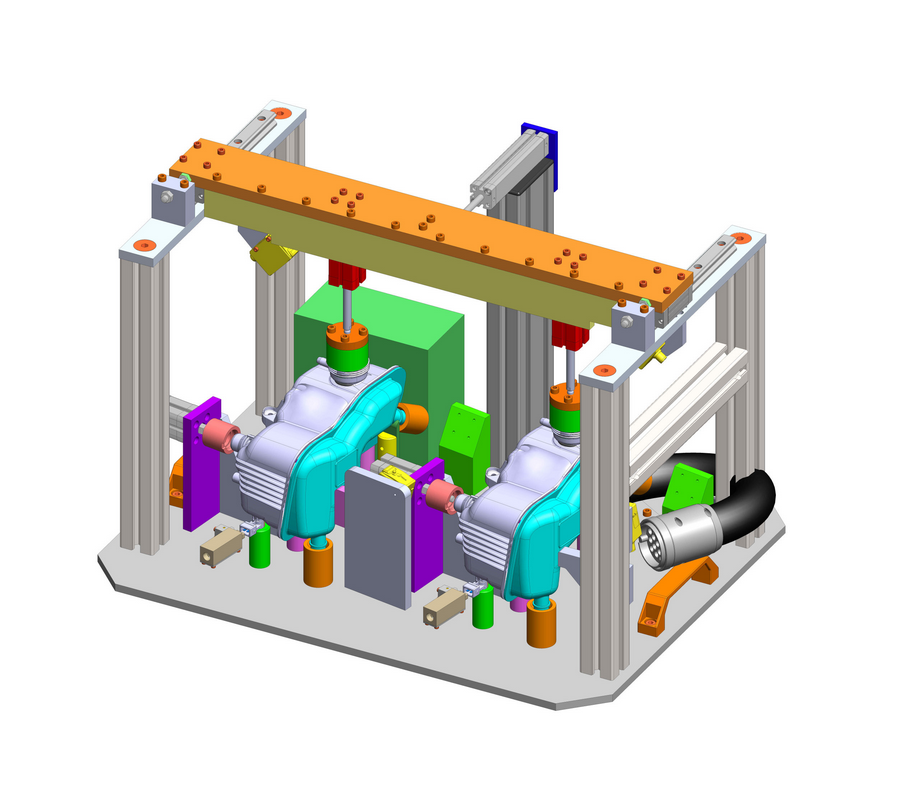

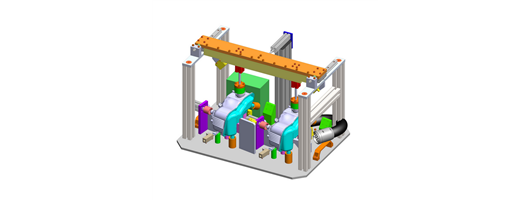

Aerospace Shaft Assembly Machine

The machine was National Instrument Labview controlled, programmed in house. The machine was mechanically designed, electrically designed, panel built, assembled, wired, and project managed from conception to installation.

Dynamometers

Dynamometers can feature various motor types including DC, AC and servo which are selected to suit the application specification. We have supplied dynamometers with output speeds up to 70,000 rpm and power outputs of 90kW. Data acquisition is generally via National Instruments hardware in conjunction with LabVIEW software. We also use VMC for data acquisition as required by some of our mass production customers

End of Line Test Machines

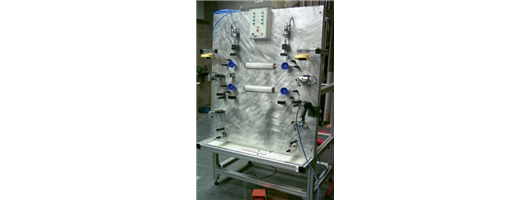

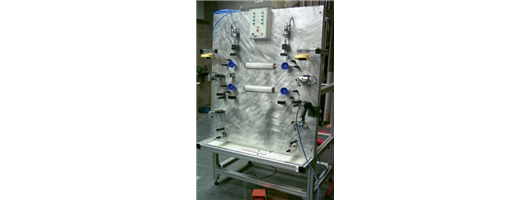

Leak Test Machines & Fixtures

Automated leak test machines can incorporate fixtures to hold and clamp the component, actuated sealing devices to close off any fixed openings in the component, safety enclosure and test pass/fail indication or part marking.

Alternative leak testing media are available depending on the test requirements e.g. water, oil, nitrogen, helium.

Incotech also manufacture our own basic leak testing instrument, which is generally used for manual offline testing of standalone components.

Environmental Testing of Automotive Generator

Incotech led the complete project and installed a suite of 3 identical test machines.

An environmental chamber was modified for our purposes.

A fixture was placed into each machine, made from stainless steel so as to not rust with the harsh atmosphere.

A drive motor was placed outside the environmental chamber and tested the unit under test (UUT).

A chiller unit was required to keep the UUT at a safe temperature like it would in real life.

The machine control was by Labview, which controlled the UUT, motor, and CANbus as well as other systems on the machine. Not an easy task!

Glass Roof Curvature Checking & Test Machines

Either as a final check or as a in process check, the glass has to be measured for the correct curvature. It is important it is correct so that it fits the body in white (BIW) car body correctly.

The pictures below so several of our machines. Mostly the piece of glass is heavy and is loaded with a manipulator.

Once loaded the operator either pushes go and a completely automated, or a manual process of measurement occurs.

LVDTs measure the roof and report back on to a display their findings. The panel can then be passed or failed, or in some cases bent to make it correct.

A passed panel receives a printed label with date/time/operator/type included in a barcode.

The whole process takes around 60 seconds.

Gearbox Test Rigs

All gearbox test rigs are supplied with a high specification oil lubrication system that enables the oil used in the gearboxes to be tested for particles and filtered. Oil flows, pressures and temperatures are measured and all variables are monitored to be within preset limits.

The gearboxes test rigs feature variable speed electric drive, output load application, hydraulic clamping, manual or automatic gear change, automatic drive engagement and output speed measurement.

Data acquisition and machine control is via a Windows based industrial PC.

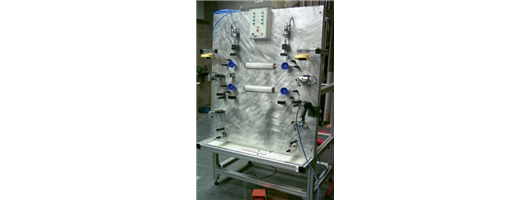

Endurance Test Machines

Control could be via simple pneumatic logic with a basic cycle counter or a PLC and HMI screen giving the option to produce test data tables.

An example is shown which is used for endurance testing of door locks in accordance with British Standards.

About us

We offer solutions ranging from fixtures and workpiece holding to semi-automated and fully automated assembly lines. Our systems include in-process testing, poka-yoke mechanisms, end-of-line production acceptance, critical feature inspection, data recording and reporting, as well as electrical panel construction and complete PLC or PC control.

In simple terms, we create automation, assembly, and testing machinery tailored specifically to your requirements.

Our Capabilities Include:

Assembly Machines & Fixtures

Incotech can design and produce assembly machines and fixtures tailored to a customer's specifications and components. Our assembly solutions can vary from basic work-holding fixtures to standalone fully automated stations and complete assembly cells with multiple machines.

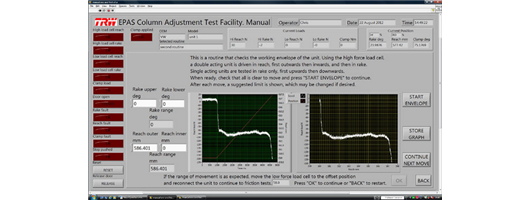

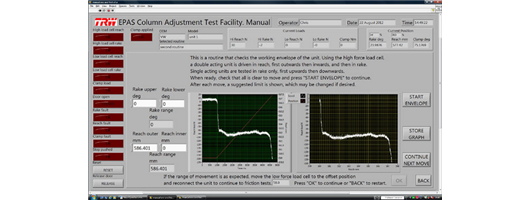

Control Panels & Systems

Incotech designs and constructs control panels and systems for our machines, as well as for upgrades to existing machines and plants, including those from third-party manufacturers. We specialise in PLC control, ranging from relay logic to mimic panels and HMI operator interfaces. Our expertise also includes PLC programming and data acquisition using National Instruments LabVIEW, enabling us to deliver optimal and competitive solutions tailored to your needs.

Dynamometers

Incotech designs and manufactures custom dynamometers to measure various parameters, including force, torque, power, pressure, temperature, and vibration. These dynamometers can be equipped with different motor types, such as DC, AC, and servo, chosen based on the specific application requirements. We have delivered dynamometers with output speeds reaching 70,000 rpm and power outputs of up to 90 kW. Typically, data acquisition is done using National Instruments hardware alongside LabVIEW software, and we also utilise VMC for data acquisition as needed by some of our mass production clients.

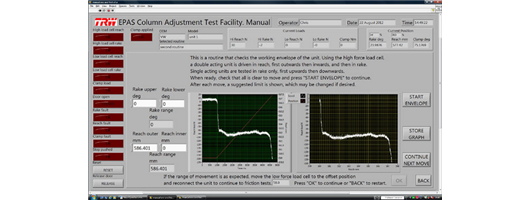

End of Line Test Machines

End-of-line test machines conduct final assessments on completed products to verify proper assembly and functionality within specified parameters. The requirements and functions of these test machines can vary based on the product, including product cycle testing, earth continuity testing, pressure testing, force and load measurement, speed testing, leak testing, dimension measurement, and flow measurement. These testing systems can provide simple pass/fail indicators, print test reports, and support full data acquisition, data logging, and product marking.

Leak Test Machines & Fixtures

Incotech manufactures custom leak testing machines and fixtures that typically use the pressure decay method. This process involves pressurising the component with low-pressure compressed air, sealing it off, and then monitoring any drop in pressure. The results are compared against established criteria to determine whether the test passes or fails.

With many years of experience, we specialise in delivering solutions for component and product assembly and testing. Incotech offers mechanical and electrical design, as well as the manufacture and installation of custom machines and systems. Our expertise enables us to provide technically sound solutions for various engineering and manufacturing challenges.

Whether it’s your machine specifications or a production challenge, Incotech has the expertise to deliver a fully functional solution that meets your needs. We offer everything from advanced turnkey end-of-line automated test facilities with comprehensive data acquisition to simple assembly tooling fixtures, ensuring competitive and dependable solutions.

At Incotech, we have the capabilities to deliver a fully functional solution that meets your specifications or addresses your production issues. Whether you need a complex turnkey end-of-line automated test facility with complete data acquisition or a simple assembly tooling fixture, we can offer a competitive and reliable solution.

Images

Reviews

Trade Associations