Company details for:

Joseph Ash Galvanizing

Quick Links:

Products / Services

Galvanizing

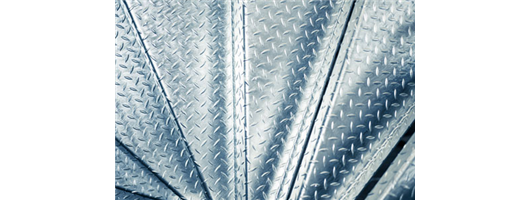

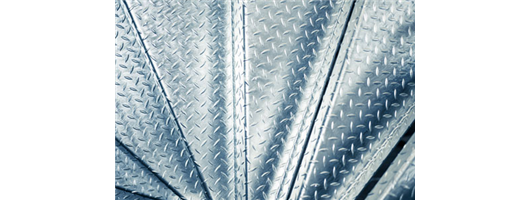

Hot dip galvanising has been used worldwide for well over a century because it provides a long-life, low-maintenance corrosion protection which safeguards steel from atmospheric attack.

With a number of different bath sizes at our various plants, we galvanize everything from lighting columns to bridges, fencing products to industrial flooring, structural sections to access support steelwork, and motorway guardrails to bracketry and fixings.

When it comes to corrosion protection, our dedicated and expert workforce and large and modern HGV fleet enable us to provide the highest standards of hot dip galvanising quality and service available.

Additionally, our dedication to adding value at every step ensures we deliver the optimal possible results and service. For example, we never forget that hot dip galvanising is a hands-on process - the final quality of which rests on the skill of our technical galvanising operatives.

All galvanising at Joseph Ash plants adhere to the coatings requirements of BS EN ISO 1461:2009 and BS EN ISO 9000 quality assurance specifications.

Spin Galvanizing

Powder Coating

Shot Blasting

Before steel or other metals are galvanized they need to be cleaned of rust and other uneven/dirty particles using a process called shot blasting. Shot blasting cleans metal and gives it a smooth surface by firing a high pressure/high speed spray of abrasive materials onto a rough metal surface.

Joseph Ash Galvanizing uses fully approved top of the range heavy duty shot blasting cabinets as well as highly skilled shot blasting operators, to shot blast and strip all architectural and structural steel such as gates, fences, vehicle chassis, railings, sculptures, agricultural equipment, steel pipes, bridge components etc.

The shot blasting cabinets allow us to clean large metal surfaces on behalf of metal fabricators from many different industries across the UK. They are also fully approved and meet all COSSH, health and safety and environmental regulations.

With both an automatic loading and shot reclaim system, the process is an incredibly efficient and fast way to remove surface contaminants, without chemically altering a fabrication.

No other process is more suited to removing undesired layers or coatings.

Get in touch with Joseph Ash Galvanizing today for a free shot blasting quotation. We can also provide a galvanizing and powder coating quote too, if necessary.

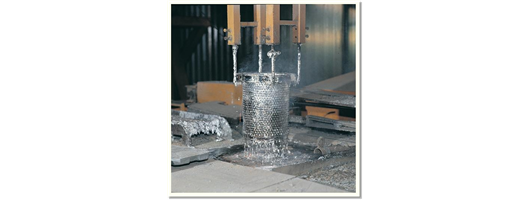

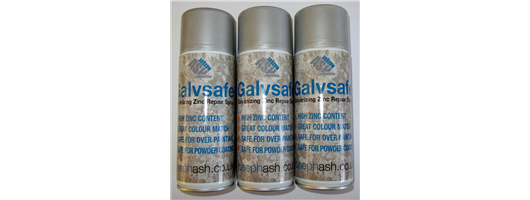

Galvsafe Zinc Spray

Despite its inherent toughness and abrasion resistance, hot-dipped galvanized coatings can still get damaged or need repair after on-site alteration*. To provide further metal protection for steel parts that are altered or damaged after galvanization, Joseph Ash Galvanizing sells an own-brand galvanizing zinc repair spray called Galvsafe. Galvsafe can simply be sprayed onto fabrications from about 12 inches away, as long as the surface of those fabrications have been cleaned to remove wax, dirt, polish or grease etc.

Galvsafe was developed by Joseph Ash Galvanizing in response to many customers asking for an alternative spray to the branded products that are currently available on the market.

Galvsafe has the following important features:

High zinc content which contains 88% zinc in the dry film. (Zinc dust content conforms with BS EN ISO 3549)

Great colour match with most galvanized coatings

Good adhesion

Safe for over painting

Safe for use on products due to be powder coated after galvanizing as Galvsafe contains high temperature resins.

Extra Services

At Joseph Ash, we want to make our customers' lives easier, and we do this by providing a range of useful additional services which include:

Passivation post galvanizing

Collection and delivery

On-site storage

Bundling, packing and labeling of all steelwork

A range of different bath sizes and lifting capabilities

Full technical

A one-stop-shop service incorporating shot blasting, galvanizing, and powder coating

Gates & Closers

At Joseph Ash Medway, we not only manufacture the Mono Hinge Self Closing Gate® − the well established, most popular, and proven play gate − but we also supply a range of safety gates and closers that have evolved into a market standard and are used by hundreds of organisations and businesses across the UK.

The Joseph Ash Medway gate range includes:

Mono Hinge Self Closing Gate® (Single or Double Gates)

Indoor Play Safety Gate

Medway Gate Closer

Safety P-Gate

Gates and closers from Joseph Ash Medway are cost effective, resilient, and fully galvanized as standard. The gates can also be powder coated in a wide range of vibrant colours and feature enclosed vandal resistant mechanisms.

For more information about our gates and closers, visit www.monohingegates.com.

Duplex Coatings

About us

Joseph Ash are the UK’s leading experts in a complete range of steel finishing services including galvanising, shot blasting and powder coating.

Joseph Ash Galvanizing has been trusted to protect the UK’s steel against corrosion for over 165 years. With 9 sites across the UK, we’re never too far away to assist with your project – from Widnes and Hull in the north to Medway in the south and Bridgend in Wales.

Founded in 1857, Joseph Ash can now be found in 9 locations across the UK, operating from Bilston, Bridgend, Chesterfield, Corby, Hull, Medway, Telford, Walsall & Widnes.

We’re involved throughout the supply chain, from working with architects specifying materials through to sub-contractors and self-employed fabricators – and we can assist with technical knowledge and guidance at all stages. Added to this, we have the deepest and widest baths in the UK at Bilston and Telford, can double dip up to 18m at our Chesterfield site, and have a specialist spin galvanizing facility at Telford for your small items such as brackets and fasteners. We really can solve all your galvanizing requirements no matter the shape or size of your steel.

HOT DIP GALVANIZING

Hot dip galvanizing is a reliable and real-world proven solution for protecting steel fabrications against corrosion, extending their lifespan and reducing their whole-life cost. Galvanized steel can reliably last for over 60 years depending on environment, with document cases exceeding 00 years. Additionally, it requires little to no maintenance, making it ideal for fabrications where access is difficult or represents health and safety challenges.

Our services today protect your steel for the future.

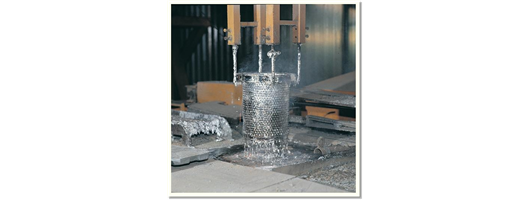

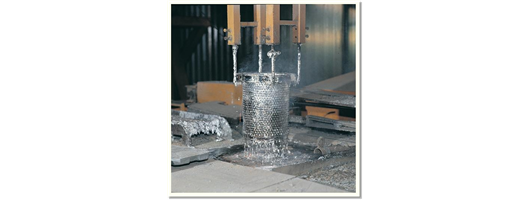

SPIN GALVANIZING

For small steel items such as brackets, bolts, and fasteners that may otherwise get lost in the galvanizing bath, we have a specialist facility ensuring they can also benefit from corrosion protection. Instead of being hung on a jig, the items are placed into a basket before submersion in a special zinc bath. The basket is then spun at high speed to remove the excess zinc.

Spin galvanizing is available at our Joseph Ash Telford site with a basket size of 250mm diameter by 500mm long.

POWDER COATING

Powder coating is a popular choice among architects for architectural steel such as balconies and balustrades.

Powder coating is available at our Medway site, in the South East of England. Joseph Ash Medway is an AkzoNobel Approved powder coating applicator for galvanized steel and is ideally located for those in London and the surrounding areas. The site acts as a one-stop-shop, offering shot blasting, hot dip galvanizing, and powder coating all in one location, reducing the risk and uncertainty that comes with using multiple service providers and guaranteeing a consistent high standard of quality and service.

Both steel and aluminium can be powder coated at Joseph Ash Medway.

ADDITIONAL SERVICES

We can also offer a range of extra services including on-site storage, full technical support and collection & delivery.

WHY JOSEPH ASH?

- Work galvanized to BS EN ISO 1461 specifications

- AkzoNobel approved powder coaters

- Widest and deepest galvanizing baths in the UK, and can dip steel up to 18m at our Chesterfield site

- Specialist spin galvanizing facility at Joseph Ash Telford

- Fit for Nuclear (F4N) status at Joseph Ash Chesterfield - the first and only galvanizing company to achieve this

Images

Articles / Press Releases

Brochures

Reviews

Trade Associations