Company details for:

KW Engineering (Poole) Ltd

Unit 1, Ency Park,

7 Abingdon Road,

Nuffield Industrial Estate,

Poole,

Dorset,

BH17 0UH,

United Kingdom

Quick Links:

Products

Precision CNC Machinery

Precision CNC Turning

We can offer multi axis turning capability including the latest in sliding head technology delivering low batch and high-volume output to close tolerances.

A high quality, smooth finish.

CNC Turning capabilities:

Boring

Drilling

Reaming

Taper turning

Materials suitable for CNC Turning:

Aluminium

Steel

Titanium

Copper

Brass

Non-metallics

We’ll look at the design and advise which engineering is the best to consider.

Offline Programming & CAD

Concepts into Creation - ACCURATE COSTING

Our CAD software enables us to interrogate components at the quotation stage.

We can then advise costs accurately, create our own models, stage drawings for production, and drawings for tooling and fixtures.

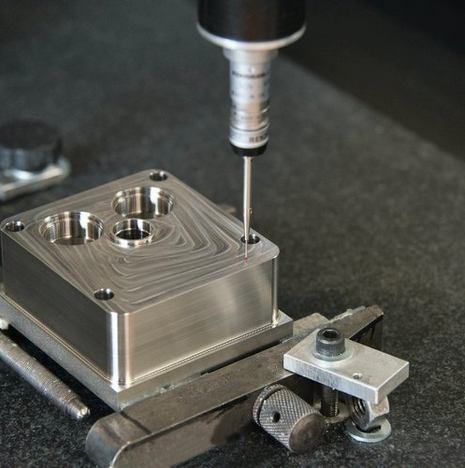

CNC Milling - Multi-Point Cutting Tools

We are able to utilise 3/4/5 axis milling and mill turn technology to create solutions to complex engineering challenges.

Up to 800x800x900mm and Ø406x600mm in length - whilst maintaining exceptionally tight tolerances and ensuring surface finish requirements are maintained.

Materials suitable for CNC Milling:

Aluminium

Steel

Stainless Steel

Titanium

Brass

Alloy Steel

Copper

Nickel

Non-metallics

We’ll always talk to our clients about which process is the best option.

Durable, strong parts machined with precision accuracy.

Quality Engineering

Our robust Contract Review process takes into consideration PFMEA on all product, and where applicable PPAP and APQP.

We use these tools to engineer quality into the manufacturing process to reduce the likelihood of non-conforming product.

It ensures that the customer requirement is understood and achieved.

To further establish this ethos, KWE’s strategy is to move towards a zero defects culture, utilising the tools that are currently being used, including Process Control Plans, SPC, lean tools and problem-solving methodologies.

We invest in technology and further processes that will enable us to achieve this target.

About us

The primary focus of our business is providing complex machined components and assemblies to the aerospace and defence sectors. We achieve this by using the latest machine tools and continuously investing in technology, our team, and our processes.

We work with a diverse range of clients, from small businesses seeking prototype work to internationally recognised companies needing high-volume engineering for specific parts.

Our Services Include:

CNC Turning

We offer advanced multi-axis turning capabilities, including the latest sliding head technology, for high-volume and low-batch production with tight tolerances and a smooth, high-quality finish. Our CNC turning services include boring, drilling, reaming, and taper turning, and we work with a variety of materials such as aluminium, steel, titanium, copper, brass, and non-metallics. We also provide expert advice on the best engineering approaches based on your design requirements.

Offline Programming & CAD

We use the latest CAD/CAM (Mastercam) software to efficiently program production parts offline, optimising lead times for first-time manufacturing. Our CAD capabilities allow us to analyse components during the quotation stage, providing accurate cost estimates, creating models, and generating detailed production, tooling, and fixture drawings.

CNC Milling

We utilise advanced 3/4/5 axis milling and mill-turn technology to tackle complex engineering challenges, producing durable, precision-machined parts with tight tolerances and excellent surface finishes. Our capabilities include machining parts up to 800x800x900mm and Ø406x600mm in length. We work with a variety of materials, including aluminium, steel, stainless steel, titanium, brass, alloy steel, copper, nickel, and non-metallics. We always consult with clients to determine the best process for their specific needs.

Our combination of extensive experience, a loyal and highly skilled team, and ongoing investment in modern machinery and techniques enables us to maintain a competitive edge, deliver high-quality results, and retain long-term client relationships.

Our experienced engineers collaborate with customers on design-for-manufacture processes to ensure the most cost-effective solution is reached.

We efficiently oversee the entire manufacturing process, from raw material procurement to testing and treatments, leveraging our diverse and reliable supply chain to meet customer needs.

Images

Reviews

Trade Associations