Company details for:

Lumasense Technologies GmbH

Kelsterbacher Strasse 14,

Raunheim,

65479,

Germany

Quick Links:

Products / Services

IMPAC Pyrometer Series 5

IMPAC Pyrometer Series 6

Portable Infrared Thermometers (Pyrometers)

IMPAC Pyrometer Series 12

With optical fiber: Offers 2-color design (switchable to mono mode), with long fiber optic cable lengths up to 30 m, different optical heads, and laser targeting.

Without fiber optics: Offers through lens sighting and/or laser targeting. Includes versions with integrated scanners and for special materials (e.g. Aluminum or Silicon). Highly accurate Transfer-Standard-Versions are also available.

All instruments feature a display, very small spot sizes, analog output and digital interface, and maximum value storage.

IMPAC Pyrometer Series 50

IMPAC Pyrometer Series 140

This series includes special instrument versions for special applications / materials, e.g. extremely short wavelength pyrometers (metal measurements with high emissivity), measurement of CO2, measurement through flames, measurement of very thin PE- and PP-foils, and measurement of glass surfaces, etc.

IMPAC Pyrometer Series 320

Small and very fast digital pyrometers with fixed focus. Models are available with LED targeting light and fiber optics for temperature measurement on metals. This series includes versions for low temperature metal measurements and also includes a ratio pyrometer version.

Sulfur Recovery Unit (SRU) Monitoring

Of particular importance is control of the furnace process temperatures to prevent damage to the furnace refractory and assurance that reaction or destruction temperatures are reached and maintained.

Flare Monitor Quasar 2 M8100-EXP

FlareSpection™

Given the unique demands of monitoring flares from a distance, the FlareSpection camera is robust, easy to deploy, and designed for continuous duty monitoring in classified hazardous areas. LumaSense has developed specific image analysis tools with years of experience to provide direct and trusted integration to the plant’s distributed control system (DCS).

FurnaceSpection™

FurnaceSpection™ helps operators monitor and control process temperature uniformity through streaming images and powerful software for analysis and historical trending, outputs to automation and DCS, and a real-time web server to broadcast images on the plant’s local network.

ThermalSpection™ CVM system

ThermalSpection™ 724 system

MIKRON Thermal Imager MCS640

Thermal Imagers MC320 Series

Photoacoustic Gas Monitor - INNOVA 1314i

Its measurement principle is based on the photoacoustic detection method. Extremely versatile by design, the 1314i can measure at trace levels almost any gas that absorbs infrared light.

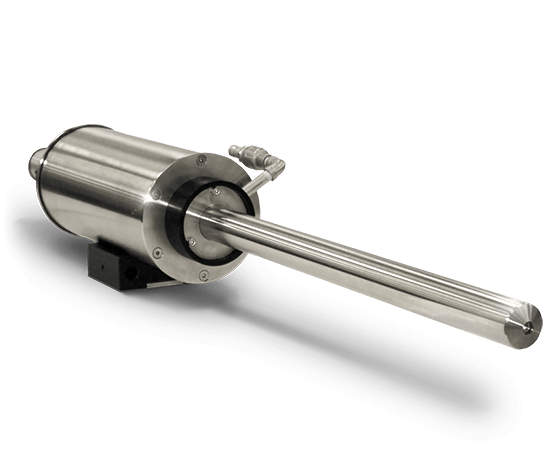

Photoacoustic Gas Monitor - INNOVA 1512

Tracer Gas Systems - 3750-2 / 3750-5

Supervises the tracer gas methods:

Concentration Decay

Constant injection

Multipoint Sampler and Doser INNOVA 1403

Multipoint Sampler - INNOVA 1409

The INNOVA 1409 greatly increases the monitoring capabilities of the gas monitors by drawing air-samples through tubing from up to 24 different points according to an automated and programmable sampling sequence, and delivering the samples to the monitor.

It is available in 6-, 12-, or 24-channel configuration.

SF6 Leak Detection System - 3731

The SF6 Leak Detection products from LumaSense offer an unmatched combination of performance and convenience. Based on the company’s Photoacoustic Spectroscopy (PAS) technology, they offer highly accurate, repeatable, and reliable quantitative gas analysis and detection. The growing environmental requirements and pressures regarding the use of SF6 make LumaSense’s leak monitors a coveted tool designed for routine testing or continuous monitoring at minimal costs.

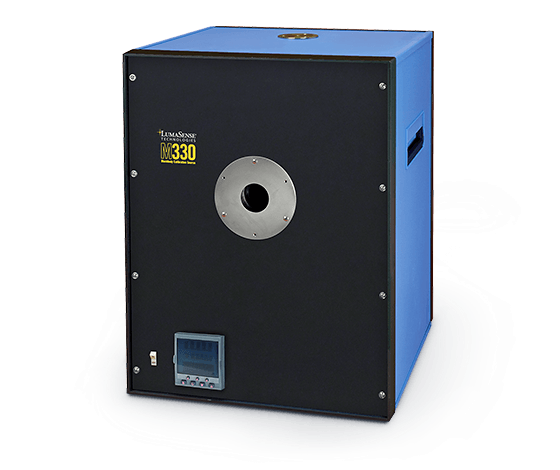

Calibration Source M330-US / M330-EU

Calibration Source M340

Calibration Source M390

Fiber Optic Temperature Sensors for OEM Applications

About us

Lumasense Technologies GmbH in RAunheim, Germany is manufacturing and distributing a wide range of infrared instruments for non-contact measurement of temperatures. Products include Impac pyrometers and temerature switches, Mikron thermal imaging products and blackbody calibration sources, Luxtron Fiberoptic measurement solutions and more.

In all industries, temperature is a basic requirement for the control of production processes. Our thermal imaging supplies can support you in improving your production processes.

Lumasense Technologies' non contact infrared instruments are able to measure temperatures ranging from -50 to 4000°C and operate efficiently even under the toughest of conditions. By focusing on our clients' requirements and thanks to our systematically developed sales organization, Lumasense has become a leading manufacturer of pyrometers.

Temperature measurement instruments include;

- Fixed and portable Impac Pyrometers

- Impac temerarure switches

- Mikron Calibration sources

- Mikron thermal imaging cameras and systems

- Luxtron Fiberoptic solutions

- Sekidenko pyrometers for SemConductor applications

- E2T Pyrometers for petrochemical markets

- Innova photoacoustic multi-gas monitors and samplers