Company details for:

MARK Compressors UK

Unit 5 Westway 21,

Chesford Grange,

Warrington,

Cheshire,

WA1 4SZ,

United Kingdom

Quick Links:

Products

MSA Series - Belt-Driven Screw Compressor

MSD Series - Belt-Driven Screw Compressor

MSL Series - Belt-Driven Screw Compressor

They are up to 35% less energy-consuming than piston technology, have lower noise levels, and higher efficiency and reliability. The optimized design offers an easy-to-use control panel, leads to smaller footprints, and takes up less space to keep.

Improved accessibility allows quicker and trouble-free maintenance with innovative maintenance kits facilitating usage and lowering service costs.

MSM Series - Belt Driven Screw Compressor

RMA/RMB/RMC IVR Series - Direct-Driven Screw Compressor

Combined with the innovative direct driven transmission, this allows these compressors to achieve up to 35% of energy savings. In addition, it drastically lowers the lifecycle cost of the compressors by up to 25%.

The highly efficient and flexible IVR oil-injected screw compressors bring new energy to your production and provide you with the strong performance and high efficiency you demand.

RMD IVR PM Series - Direct-Driven Screw Compressor

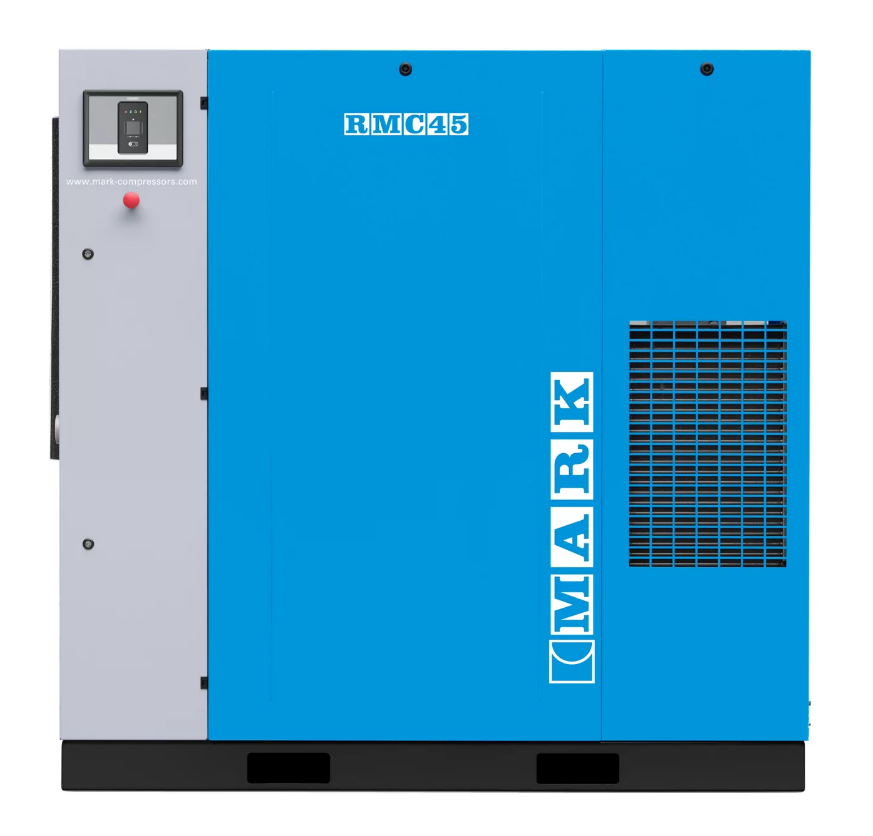

RMB/RMC Series - Gear-Driven Screw Compressor

RMD Series - Gear-Driven Screw Compressor

Each selection guarantees remarkable performance with its high standard components and ensures the easy operation by its design synergy, you are looking for.

RME (IVR) Series - Gear-driven screw compressor

RMF (IVR) Series - Gear-driven screw compressor

Mark RMF (IVR) 110-160 kW screw compressors are designed and built to give you that essential combination of reliability and efficiency. Easy to install, use and service, you can count on the RMF to produce the quality air that keeps your production going.

RMM Series - Gear-Driven Screw Compressor

Fonostop Series - Belt-Driven Piston Compressor

Stormy Pro Series - Belt-Driven Piston Compressor

Bluewind Series - Direct-Driven Piston Compressor

ADS Series - Desiccant Dryer

Cool MK Series - Refrigerated Dryer

As a result, the refrigeration technology is by far the most used dryer technology, complying for more than 95% of industrial applications. Refrigerant dryers are commonly used with pneumatic applications and in the general industry (e.g. engineering, steel, paper, tannery, garage).

MDX Series - Refrigerated Dryer

Compressed Air Line Filters

WS Series - Cyclonic Separator

D-ES Series - Oil Water Separator

Treating the oil in the condensate is not only good practice but most often a legal requirement. The D-ES helps you ensure that your wastewater archives high purity of oil content as low as 5 ppm at the outlet.

The D-ES Series is innovative and feature a cartage technology that makes oil-water separation easier and more efficient.

About us

We have a global customer base, with dedicated local customer centres positioned around the globe allowing us to provide the industry with compressors that are tailored to the needs of light industry and assembly production.

During our reign in the compressor market, MARK Compressors has developed and manufactured new products that meet our customers’ needs not only today but tomorrow as well.

From our branch in Warrington, the MARK Compressors team manage and support an authorised network thought out the UK. In partnership with our distributors, we can offer our customers compressed air systems and products that are optimised for cost effective products and fit for purpose. MARK Compressors mission is to guarantee the satisfaction and trust ALL of our customers. Our product range includes;

Piston Compressors

The MARK piston compressor range consists of multiple models that are suitable for industrial requirements as well as professional use.

Screw Compressors

Using the very latest screw technology, the MARK screw compressor range is available for customers wanting a very broad power range, whether it’s a single unit to much larger applications. Recently we have launched an oil injected screw compressor range from 30 to 90kW.

Refrigerant Dryers

MARK Compressors also offers a range of refrigerant air dryers from 350 to 70.000 l/sec so there is no need for harmful humidity or moisture in your compressed air.

Adsorption Dryers

To promote clean air, our range of Adsorption dryers provides perfect clean, dry air with clever dew point management.

Line Filters

MARK Compressors’ line filter range, ranges from 1000 to 40.000l/min. Filtration range for dry air, free of oil and dust. The MARK filters extend the lifetime of your air distribution network and pneumatic tools.

Oil-Water Separators

The MARK FOD 21 - 1440 Oil-Water Separator is the perfect system to separate oil from water in your compressed air system helping protect the environment as well as saving costs.

Condensate Drain

Our automatic condensate drain LD range includes LD200, LD202 and LD203 removing all condensate from your compressed air system.