Company details for:

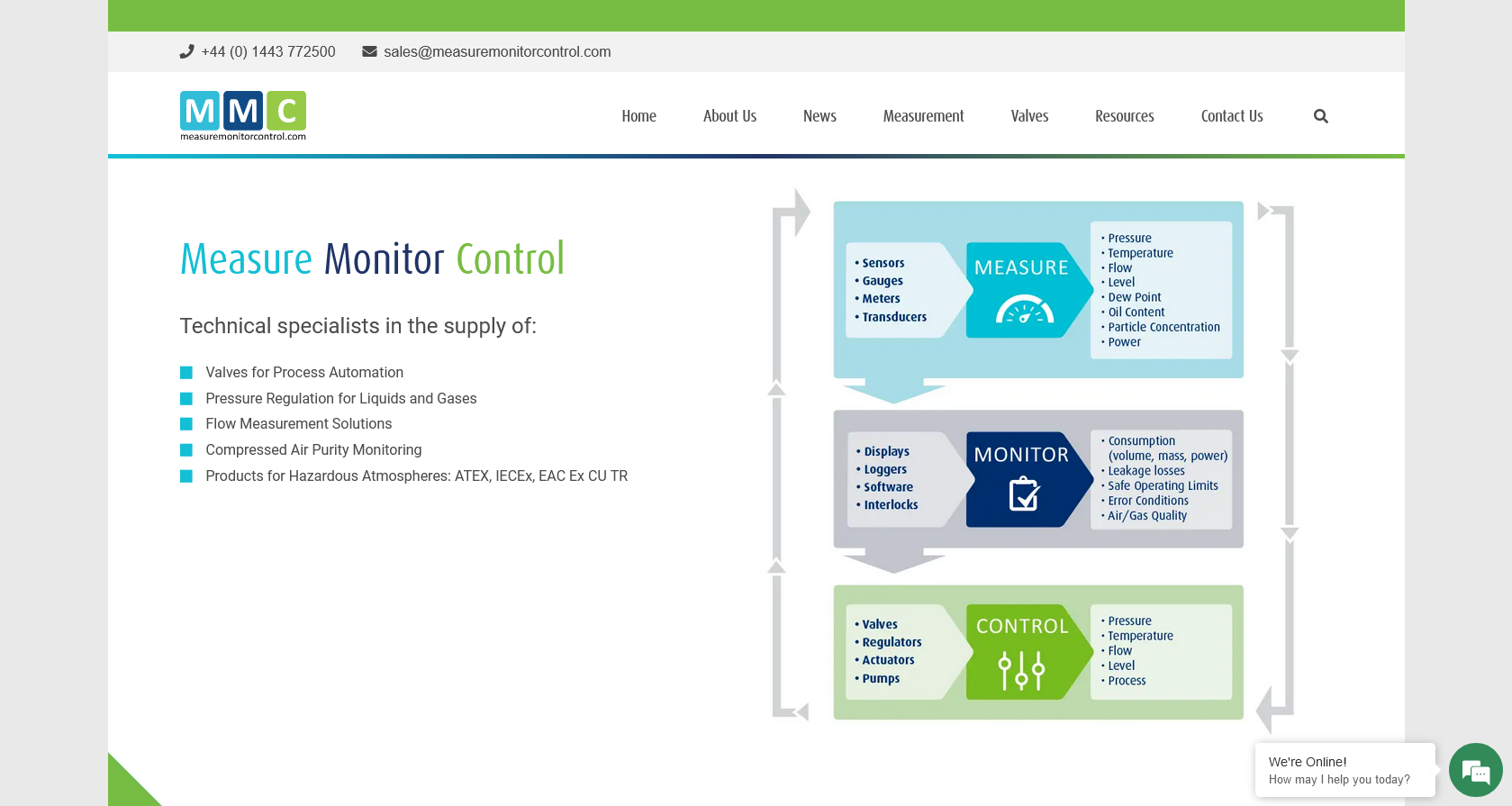

Measure Monitor Control

Unit 15,

Abergorki Industrial Estate,

Treorchy,

Glamorgan,

CF42 6DL,

United Kingdom

Quick Links:

Products / Services

Pressure Regulators up to 50bar

Low Pressure Regulators from 5mbar

Direct Acting Pressure Reducing Valves

Reducing range: 1-6bar, 4-10bar & 8-13bar

Body pressure range: 25bar

Maximum operating temperature: 85 degrees C

Body: 316 stainless steel

Seals: EPDM O rings and diaphragm

Ports: 1/2″, 3/4″, 1″, 1 1/2″, 2″ BSP

DN15, DN20, DN25, DN40, DN50, DN65, DN80, DN100 & DN150 flanged PN16

Pressure Sustaining Valves

Filters for Compressed Air, Gas & Liquids

Water Hammer Arrestors

EN161 Compliant Valves for Natural Gas

Two Way Solenoid Valves

2-way solenoid valves are suitable for a wide range of applications, including: isolation / shut off, release, distribution, dosing and mixing.

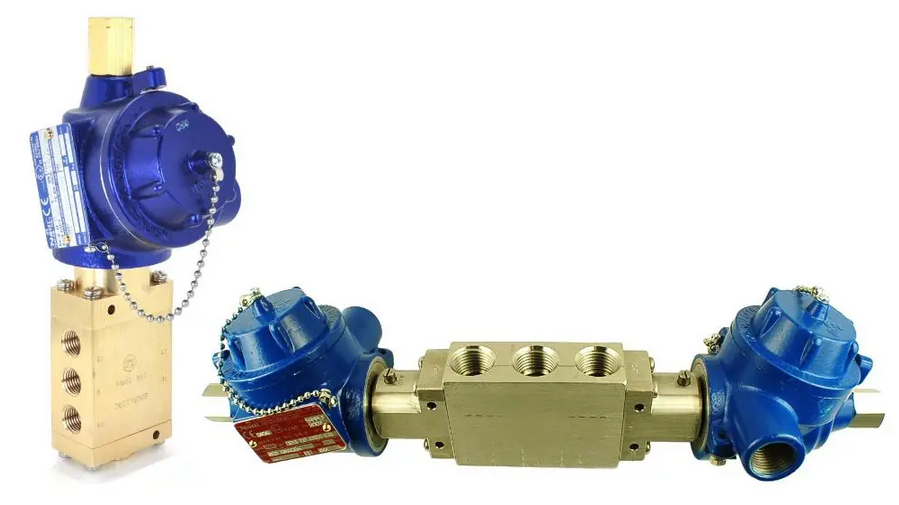

Three / Two Way Solenoid Valves

3 Way or 3 port solenoid valves refer to the line connections in that there are 3 ports which makes them ideal for diverting flow from one path to another. Unlike 2 way valves that are intended for isolation purposes, 3 way valves are used for directional control and have 3 function variants − normally closed (NC), normally open (NO) and universal (U).

3 way solenoid valves are used with liquid or gaseous media and can incorporate a huge variety of options:

Environmental − IP65, IP67, ATEX, IECEx, …

Functional − manual override, manual reset…

In addition to material options for the valve body and elastomers for compatibility with a wide range of gases and liquids.

Five Way Solenoid Valves

Two Way Air Pilot Operated Valves

Pilot operation is the main force required to open the valve is provided by the media pressure. The pilot can be very small as it only controls the flow of a small diameter impulse line that allows the fluid to open the main diaphragm or piston.

What does 2 way mean?

2 Way or 2 port air operated valves refer to the line connections in that there is a single inlet and outlet which makes them ideal for flow isolation. For most of these valves, the flow direction through the valve must be from the inlet to the outlet as reverse flow will cause the valves to fail or operate unreliably.

Depending on the model, 2 way pilot operated valves are used with liquid or gaseous media and can incorporate many varieties of options:

Functional − normally open or normally closed

Feedback − limit switches, visual position indicators

Various elastomers for compatibility with a wide range of gases and liquids

LK Series Lock-Up Valves

VB Series Volume Booster

316L Stainless Steel or epoxy coated copper free aluminium

ATEX, GOST EAC & Ex, SIL3

Up to 10bar max inlet pressure

Threaded exhaust option

1/4″, 1/2″, 3/4″ and 1″NPT

Pneumatic Air Preparation

Our Products Include:

Fr Series Filter Regulators

R Series Pneumatic Pressure Regulators

F Series Filters

… And many more.

Measurement - Dew Point

The Dew Point is the lowest temperature that allows water vapour to remain in a gas without condensing to a liquid state. As the air or gas temperature drops, its ability to absorb water vapour drops until it becomes completely saturated and below this dew point temperature, water droplets will start to form.

In pressurised systems such as compressed air distribution networks, the dew point is directly related to the temperature AND system pressure. As pressure increases, the dew point temperature also rises meaning that the potential for vapour to condense out occurs at a higher temperature. In practice this can mean that instead of the condensing temperature being quite low, the dew point could be at or above ambient temperature.

Measurement - Leak Detection

Measuring leakage can sometimes be confused with detecting leakage but although the two are complementary, don't be confused with claims of devices that can tell you how much a leak is costing. There is only one accurate way of measuring leakage and we can help with that too. Contact us today to discuss the options available.

Ultrasonic Flow Measurement

Compressed Air Purity Measurement

Compressed air for breathing regulators falls under the EN 12021 standard and requires not only contaminants to be measured but also gases to ensure that the air is safe to breathe. Breathing air testers allow the user to monitor Oxygen (O2), Carbon Monoxide (CO) and Carbon Dioxide (CO2) with dew point/humidity and oil or VOC contents.

Thermal Mass Flow Measurement

Oil Measurement in Compressed Air

ISO 8573-1 states that the total oil liquid, aerosol and vapour concentration figures must be combined to attribute a purity class but if you need to achieve class 1 or 2, how can this be achieved?

ISO 8573-2 gives two ways of measuring aerosols but only one that is also suitable for liquid oil − Method A. This requires the use of ISO 12500-1 class coalescent filters in series to collect oil from the airstream during the test period and the volume collected is measured to calculate the concentration in mg/m³.

ISO 8573-5 covers the sampling of oil vapour and subsequent analysis by gas chromatography to determine the vapour concentration.

The results of these two methods then need to be added together and compared with the purity class table in ISO 8573-1 to determine the actual purity class achieved.

S531 Advanced Ultrasonic Leak Detector

The S531 leak detector can collate additional contextual data such as voice recordings and photographs with the integral camera that show the exact leak location for inclusion in a leak survey report. When the user inputs the sensing distance for each leak and the site air generation cost per unit, the S531 will also display and record the leak flow rate and cost for every location.

S531 ultrasonic leak detector is compatible with the SUTO Leak Management System software (LMS below) and data can be downloaded through Bluetooth or USB when compiling reports.

How to Measure Compressor Efficiency and FAD

The distribution of compressed air in industrial plants is prone to efficiency losses through pressure drops and leakage but the largest inefficiency is at the point of generation. Compressor units are most commonly run with electrical induction motors driving piston or screw compressors. Depending on the scale of the installation, the electrical consumption of these compressor plants can be a significant part of the overall plant electric bill as they are always responding to system demands to maintain pressure. The mechanical compression process is very inefficient with over 90% of the electrical energy lost as heat and noise. Cooling or heat reclamation systems can have an influence on the overall efficiency but it is still very costly to produce compressed air.

Compressed Air Leak Detection

In regards to compressed air and gases, leakage refers to unintentional venting of the gas to atmosphere. Leaks can arise from corrosion, vibration or material failure and most commonly at joints or component junctions in the pneumatic circuit. Note that leakage is normally considered separate to the venting of compressed air through the action of valves and actuators where the air energy has already been partially used.

Compressed air systems are large users of electricity and can be a significant proportion of the overall plant electricity consumption. It is generally accepted unlikely that perfect sealing can be maintained in pneumatic systems and up to 10% leakage may be deemed acceptable. This sounds like a high percentage but leakage is often much higher than expected with figures up to 40 or 50% not being unusual. This makes maintenance of compression and distribution systems an important part of the plant maintenance scheme.

S430 Pitot Tube Flow Sensor

S430 has a new 3 line colour display displaying flow, velocity and pressure with bluetooth interface for remote sensor configuration. S 430 offers a choice of communication options including 4-20mA, pulse and SDI (SUTO Digital Interface), Modbus/RTU and MBUS.

Pressure range up to 1.6MPa

Output 4-20mA, SDI, Modbus/RTU, MBUS

Optional colour display

Bluetooth interface

S430 is ideal for measuring at the compressor outlet as the pitot tube design is not damaged by the very wet gas unlike thermal mass flow sensors which cannot be used here. S 430 offers FAD calculation facilities for accurate measurement of compressor performance.

Self-Contained Portable Breathing Air Tester

S605 has electrochemical gas sensors for oxygen (O2), carbon dioxide (CO2) and carbon monoxide (CO) in addition to the uniquely capable SUTO dual QCM & polymer dew point sensor, PID VOC sensor and pressure sensor. Combining these with a simple to use touchscreen display that clearly shows the readings in an easy to understand manner and an integral data logger, provides an elegant solution to breathing air testing that does not rely on subjective measurements or user interpretation. The S605 will produce the PDF report at the end of every test and it can easily be downloaded via USB for printing or emailing.

SUTO recommend an annual calibration for this unit and simplify the process by the availability of exchange pre-calibrated sensor modules that are simple for the user to swap and return the old sensors through the supply chain so that they can be recycled at the factory. This removes the need for the instrument to be off-site for a period of time and testing can resume the same day once the modules are exchanged knowing that it will be twelve months till the next time it is required.

About us

As a family-owned business, honesty and integrity are at the forefront of everything we do. As a company, we care about our customers and are excited about making their lives easier as a result of our actions.

Some of Our Products Include:

Compressed Air Purity Measurement

Ensure compliance with plant operating standards and ensure optimal conditions for your processes by measuring compressed air purity. By maintaining the compressed air or gas purity to ISO 8573 standards, plant reliability can also be improved, and regular monitoring can provide advance notice of problems requiring maintenance or overhaul.

Dew Point Measurement

Dew Point is the lowest temperature at which water vapour does not condense into liquid. Under the dew point temperature, water droplets will form as the temperature of the air or gas drops. As this happens, the ability of the air or gas to absorb water vapour decreases until it becomes completely saturated.

Displays & Data Loggers

For users to see measured process variables locally or remotely, displays are essential. Data logging and onboard graphical displays may be included in these displays, which can connect to a wide range of analogue or digital sensor inputs.

Valves

From large ball and butterfly valves to tiny needle valves, we can offer a wide range of process, pneumatic, and instrumentation valves. Once the design requirements have been evaluated, we can provide specialist valves and bespoke solutions.

We consider the supply chain an integral part of the success of any business, and the way in which we interact, the ease with which we do business, and the reliability of the same throughout the chain are fundamental to our success. Our close partnerships with our manufacturers give our clients confidence that we can deliver what we promise.

The importance of choosing a reliable supply partner cannot be overstated today. We'll demonstrate how much we can help you if you let us know what you need. Our services are likely to exceed your expectations.