Company details for:

Mid Anglia Engineering Ltd

90 Wetmore Road,

Burton-on-Trent,

Staffordshire,

DE14 1SN,

United Kingdom

Quick Links:

Products / Services

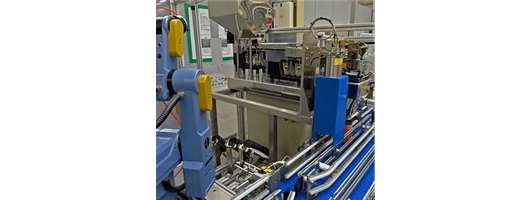

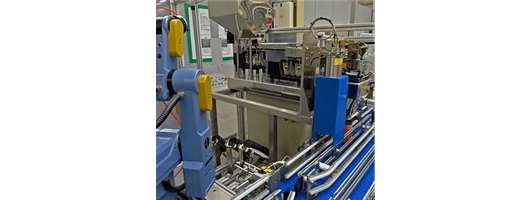

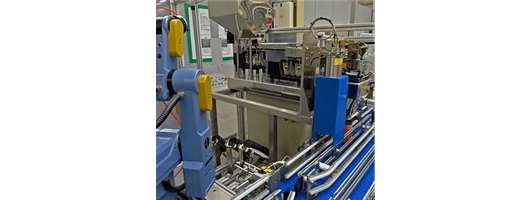

Special Purpose Machinery

Process Automation Services

Research & Development Services

Full Proof-of-Concept Prototyping

Servicing & Repairs

Sewing Machines

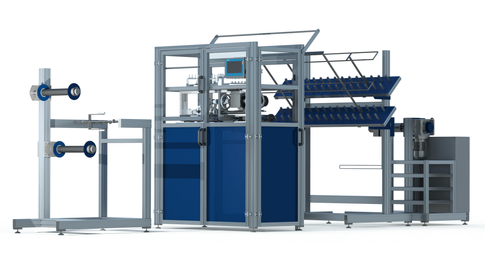

Gauntlet Machines

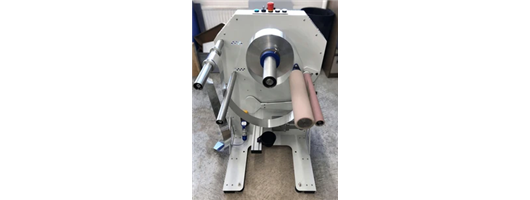

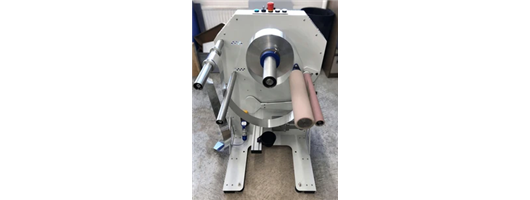

Our Gauntlet Forming machines are designed to allow for the accurate and consistent forming of gauntlets (tubular bags) from sewn non-woven polyester fabric, which are used in industrial batteries.

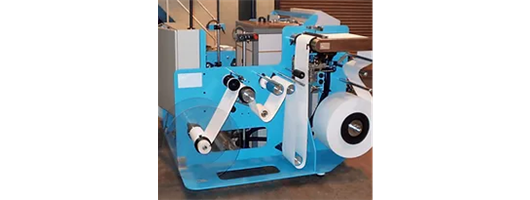

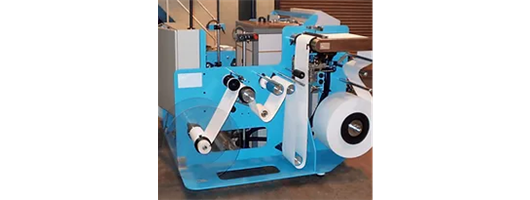

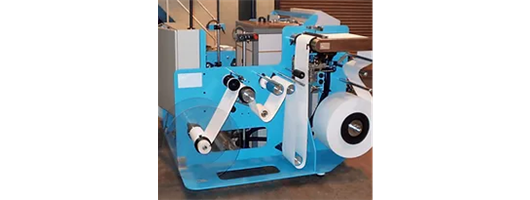

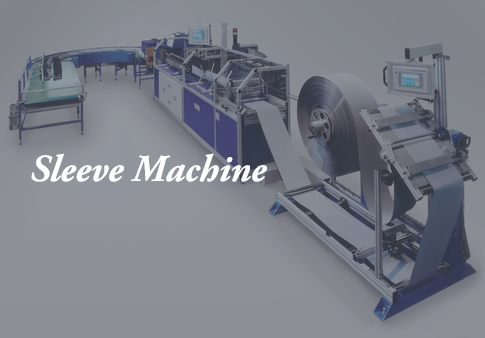

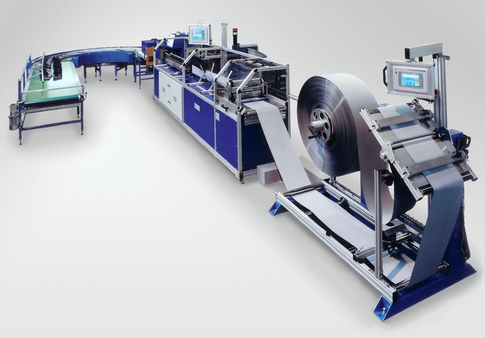

Sleeve Machines

Our automatic battery sleeve forming machines are designed to rapidly produce BS size, DIN size, and other sizes of sleeves, with minimum operator intervention.

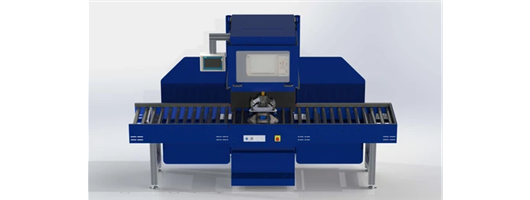

Linear Refilling Stations

Mould Machines

Powder Handling Sieves

Owing to a tried and tested design and build quality, the vast majority of the sieves we’ve made over the years are still in frontline use. They’re in active use within rapid prototyping, 3D printing, metallurgy, motorsport, automotive, and aerospace companies.

Our sieves are 400mm in diameter as standard, and can be made to 500mm in diameter on request

Spare Parts

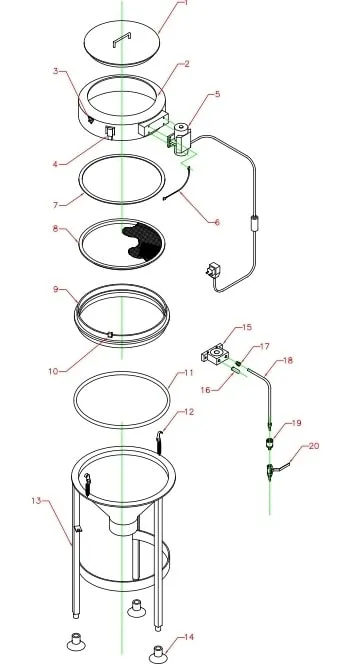

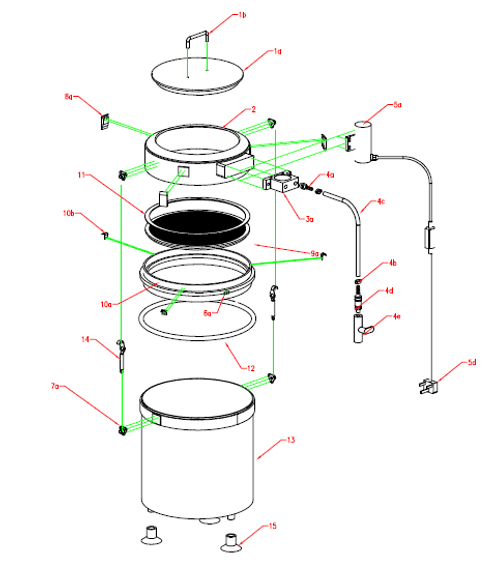

VS 400 2 - Polypropylene Sieve body

VS 400 3 - Anchor plates for spring fasteners

VS 400 4 - Spring latch

EVS 400 5 - 110V / 240V Electric vibrator

VS 400 6 - Grounding strip

VS 400 7 - Flat Nitrile seal

VS 400 8 - Stainless steel mesh

VS 400 9 - Polypropylene retaining ring

VS 400 10 - Latch plate

VS 400 11 - Polyurethane ring

VS 400 12 - Spring fastener

VS 400 13 - Powder coated steel stand

VS 400 14 - Rubber suction feet

PVS 400 15 - Pneumatic vibrator

PVS 400 16 - Silencer

PVS 400 17 - Hose coupling

PVS 400 18 - Hose

PVS 400 19 - Quick coupling

PVS 400 20 - Hand valve

EVD 400 / PVD 400

Additional drums with lids can be ordered

Top vibrated by a rotational pneumatic (PVS) or electric (EVS) vibrator

Stabilised on anti-vibration suction feet

Meshes can be changed to suit different applications or powder types

Can be dismantled for cleaning

Meshes

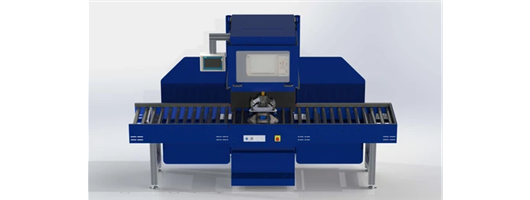

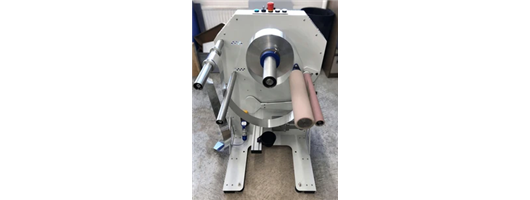

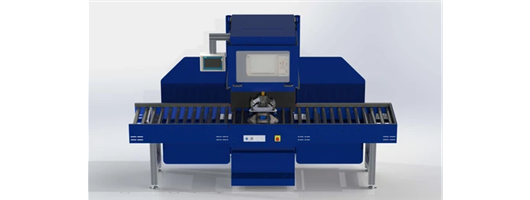

Breakout Stations

Our stations are commonly used in SLS 3D printing for breaking out parts from build volumes.

Our standard E500 station accommodates our standard sieves.

About us

At Mid-Anglia, we specialise in delivering a comprehensive design and engineering service. We have collaborated with clients of varying sizes on more than 2000 projects since our establishment in 1970.

We specialise in designing and manufacturing custom machinery and equipment, conducting research and development, and providing repair and servicing expertise.

Our Areas of Expertise Include:

Special Purpose Machinery

Mid-Anglia Engineering Ltd is a premier provider of Special Purpose Machinery, offering a wide array of customised solutions designed to meet the unique needs of various industries. Their expertise includes advanced Process Automation, enhancing efficiency and precision in industrial production lines. They specialise in the creation of bespoke jigs and fixtures, tailored to streamline manufacturing processes and ensure high-quality outcomes. The company also excels in designing Powder Sieves and material handling systems, crucial for optimising workflow in sectors like pharmaceuticals and food processing. Additionally, Mid-Anglia Engineering Ltd develops sophisticated testing and inspection equipment to maintain stringent quality control standards. Their innovative approach extends to creating eye-catching motor show displays and unique one-off machines, demonstrating their versatility and commitment to excellence. With a focus on innovation, quality, and customer satisfaction, Mid-Anglia Engineering Ltd is a trusted partner for businesses seeking reliable and efficient machinery solutions.

Research & Development Services

Mid-Anglia Engineering Ltd excels in providing comprehensive Research & Development (R&D) services, driving innovation from concept to reality. Their offerings encompass the entire spectrum of product development, starting with concept invention, where they collaborate closely with clients to generate groundbreaking ideas tailored to market needs. The design phase involves meticulous planning and advanced engineering to ensure functionality and feasibility. Mid-Anglia Engineering Ltd also specialises in full proof-of-concept prototyping, creating detailed and functional prototypes that allow for thorough testing and validation. This iterative process ensures that each concept is viable and optimised before moving to full-scale production. With a strong focus on precision, quality, and customer collaboration, Mid-Anglia Engineering Ltd’s R&D services enable businesses to develop cutting-edge products, reduce time-to-market, and maintain a competitive edge in their industries.

Servicing & Repairs

Mid-Anglia Engineering Ltd is a versatile provider renowned for its expertise in servicing both Mid-Anglia and non-Mid-Anglia machines, offering tailored solutions that enhance performance and extend operational lifespan. They specialise in modifications and performance optimisation, ensuring machines meet evolving industry standards and operational requirements. The company excels in part sourcing, leveraging a robust network to procure components efficiently, reducing downtime and enhancing reliability. Additionally, Mid-Anglia Engineering Ltd is adept at legacy part creation, manufacturing components that are no longer commercially available, thus preserving the functionality of older machinery. Their commitment to precision engineering and customer satisfaction makes them a trusted partner for businesses seeking comprehensive machine servicing, modification, and parts supply solutions.

We have assisted clients spanning individuals, local businesses, and authorities, all the way to national and global organisations.

Our specialised machinery is widely deployed across the UK, various European nations, North America, the Middle East, and the Far East.

Images