Company details for:

Morgan Rushworth Ltd

St. Albans Road,

Stafford,

Staffordshire,

ST16 3DR,

United Kingdom

Quick Links:

Products / Services

Servo Electric Press Brakes

Hybrid Press Brakes

Hydraulic Press Brakes

Mechanical Guillotines

Hydraulic Guillotines

Corner Notchers

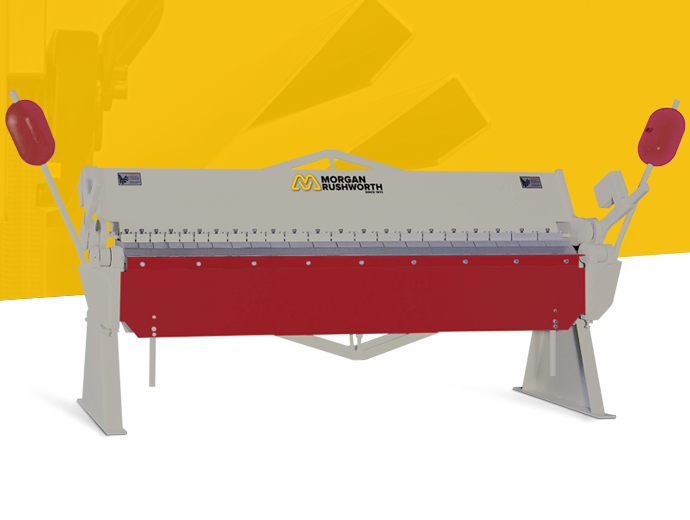

Manual Folders

Hydraulic Folders

CNC Folders

Manual Bending Rolls

Powered Bending Rolls

Hydraulic Bending Rolls

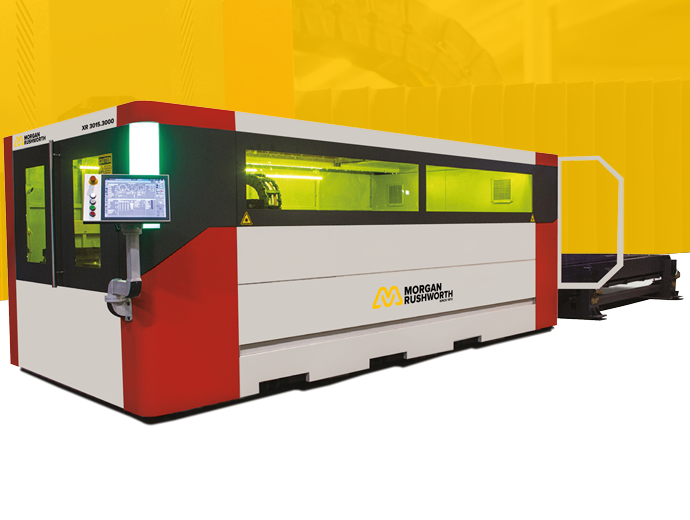

Compact Fibre Lasers

The range covers from 1.5kw up to 3kw with the Fuji motors and drives for the X & Y axis and a rigid gantry and frame structure, resulting in fast acceleration, fast positioning speeds and fast cutting times. The control is by Cypcut and includes software for drawing parts or importing DXF files. Class leading components ensure superior cut quality, high reliability and reduced down time

Production Fibre Lasers

Compact Plasma

High Definition Plasma

Powered Section Benders

Hydraulic Section Benders

Hydraulic Steelworkers

Hydraulic Punching Machines

H-Frame Presses

H-Frame Hydraulic Press Brakes

Horizontal Bending Presses

Deburring Machines

Swaging Machines

About us

Morgan Rushworth has grown from humble beginnings manufacturing plate working machines in 1872 to become one of the leading manufacturers of high quality, high performance, specialist sheet metal and fabrication machinery.

Across the UK, Morgan Rushworth is the machine partner of choice for metal fabrication, engineering, and manufacturing businesses because of its top-notch machinery and excellent customer service.

Our Product Range Includes:

- Press Brakes

- Guillotines & Corner Notchers

- Folding Machines

- Bending Rolls

- Fibre Laser Cutting Machines

- Plasma Cutting Machines

- Section Benders

- Steelworkers & Punches

- Bending & Forming Presses

- Other Sheetmetal Machines

With Morgan Rushworth's state-of-the-art press brakes, laser cutters, plasma cutters and guillotines, we offer superior precision, performance, and longevity for a more competitive price. We also provide expert advice and outstanding service as standard.

- Technology-advanced and innovative options

- Advice on the best solution for your business from a specialist

- Our UK showroom offers live machinery demonstrations and hands-on buyer experiences

- From specification to delivery and installation, we offer market-leading customer service

- Team of expert commissioning engineers and service engineers

- Availability of in-stock items and short manufacturing lead times

- All Morgan Rushworth machinery comes with a three-year warranty

- After-sales and service packages with fixed costs

- Machinery and components with high performance, high value, cost-effectiveness, reducing downtime, waste, and environmental impact

Images