Company details for:

Multigas Installations Ltd

Unit 3, CMA Industrial Park,

Howfield Lane,

Chartham Hatch,

Canterbury,

Kent,

CT4 7LZ,

United Kingdom

Quick Links:

Products / Services

Laboratory Gases Installation

Laboratory gases installation refers to systems designed to provide various gases required for scientific experiments, research, and analytical work within a laboratory setting.

These gases are essential for a wide range of purposes, from providing a controlled atmosphere for experiments to powering analytical instruments and equipment.

A well-designed and maintained gases installation is critical for the safety and efficiency of laboratory operations.

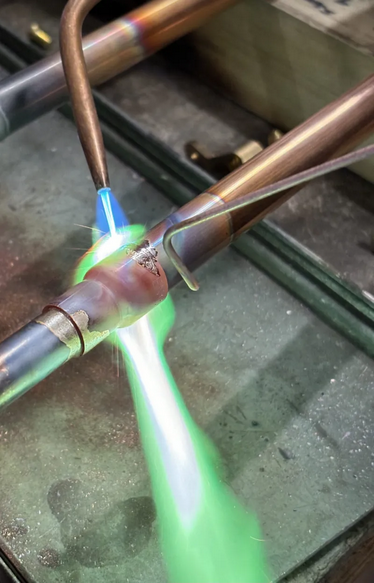

De-Greased Copper Pipework

De-greased copper pipes are particularly important in applications where cleanliness and the absence of contaminants are critical, such as in medical pipeline installations and equipment, semiconductor manufacturing, and food processing industries.

Copper pipes are commonly used in plumbing and other applications due to their excellent corrosion resistance and heat conductivity. However, during the manufacturing or handling of copper pipes, they may come into contact with oils or greases, which can be detrimental to their performance in certain applications

Removing grease and oil residues ensures that the copper pipe can function effectively and maintain the purity of the substances it carries.

Degreased copper pipe must meet the highest of levels conforming to the following with BS EN 13348, BS EN 1057, BS 2871 Part 1 Table X, EN 7396, and HTM 02-01.

Stainless Steel Pipework

Stainless steel pipework is a common choice for high-purity systems in various industries, such as pharmaceuticals, food processing, semiconductor manufacturing, and chemical processing.

The use of stainless steel offers several advantages for these applications, primarily due to its corrosion resistance, cleanliness, and durability.

Orbital Welding

At MultiGas, we are proud to offer high-quality and reliable orbitally welded stainless steel pipework solutions. Whether you’re in the pharmaceutical, food and beverage, semiconductor, or any other industry requiring sanitary and precise piping systems, our orbitally welded stainless steel pipework is designed to meet your specific needs.

What is orbitally welded stainless steel pipework, you may ask? It is a specialised welding technique that ensures the highest level of purity, integrity, and consistency in the welded joints. This method is commonly used in industries where cleanliness and contamination control are critical.

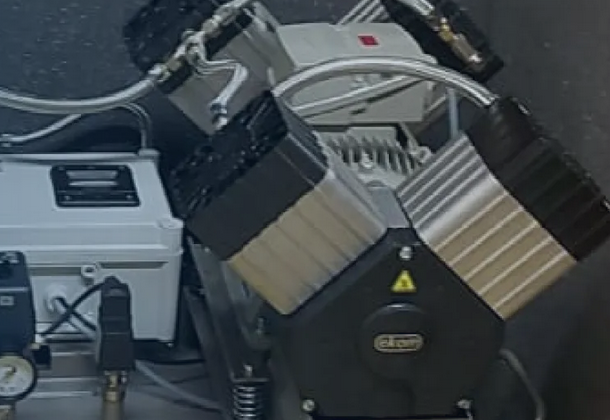

Compressed Air Plant

Compressor technology has evolved considerably in recent decades.

Compressors today are more efficient, cleaner and better controlled than ever before. These developments are all designed to help customers save money through energy savings, whilst still providing the necessary compressed air, critical for their needs. The most common types of compressor we supply are defined as fixed /variable speed and oil lubricated/oil free.

Vacuum Plant

All vacuum systems are designed to a bespoke specification for each application to create and maintain the desired vacuum level for the system, within the design an element of future proofing is considered for potential increase in demand and extension of the system.

Common types of vacuum pumps include rotary vane pumps, turbo pumps, cryogenic pumps, and ion pumps. These pumps work in tandem or in series to achieve the necessary pressure levels.

The Vacuum plant is often located within a controlled environment known as a cleanroom, to minimise contamination and maintain the purity of the gases being processed.

Regular maintenance and servicing of the equipment are essential to ensure optimal performance and longevity of the vacuum plant system. This includes routine inspections, lubrication, and replacement of worn components.

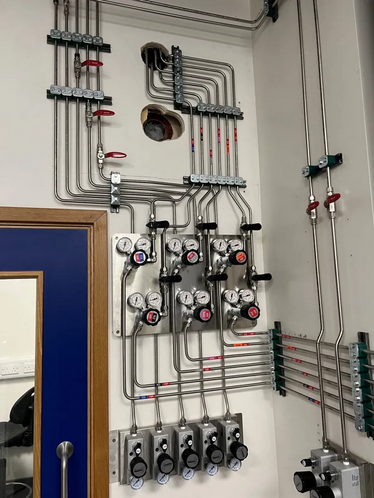

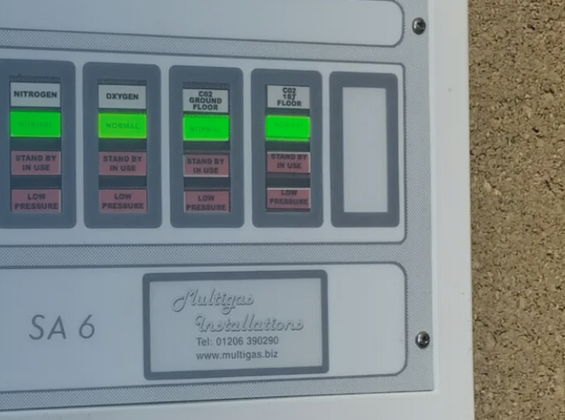

Gas Cylinder Manifolds / Control Panel

The manifold assembly is the central hub of the system where multiple gas cylinders are connected. It typically consists of a series of valves, regulators, gauges, and interconnecting piping. These systems are installed in varied settings, industrial, laboratories, medical facilities, and other environments where precise control and distribution of gases are required.

The control panel provides a user interface for operating and monitoring the gas distribution system. It may include controls for adjusting gas flow rates, switching between different gas sources, and safety features such as emergency shut-off valves.

Within the design of a manifold system often an alarm system may be incorporated to alert operators of abnormal conditions such as pressure fluctuations, leaks, or other potential hazards.

Gas Cylinder Change Alarm

A gas manifold system relies on a cylinder changeover alarm which is integrated into the gas distribution system. Where uninterrupted supply is required, a backup or reserve group of cylinders are incorporated which contain the same gas as the primary supply.

This system ensures a continuous and reliable gas supply by automatically switching between multiple gas cylinders when one depletes, while also providing audible or visual alerts to notify staff of the changeover.

Gas Detection Systems

The gas detection systems incorporate sensors designed to detect specific gases or vapours. These sensors can be electrochemical, catalytic, infrared, or semiconductor-based, depending on the type of gas they are designed to detect. Common gases monitored include methane, carbon monoxide, hydrogen sulphide, oxygen, and volatile organic compounds (VOCs).

The detection of this gases is monitored by the integration of a central control system which received data and continually evaluates the quantity of gases in the working environment from gas detection sensors and sampling pumps. These systems designed with preset thresholds bespoke to the environment setting and gases used. If the gas concentration exceeds the preset thresholds the alarm system will activate with audible and visual alarms, to alert personnel to the presence of hazardous gases. The gas detection systems also incorporate remote alarm panels located in areas to inform trained staff in the event of an failure or emergency.

Commissioning & Testing

Commissioning of laboratory and industrial gas systems is a crucial process that ensures the safe, efficient, and reliable operation of these systems. Whether it’s in a research laboratory, manufacturing facility, or any other industrial setting, commissioning involves a series of steps to verify that the gas systems are designed, installed, and functioning correctly.

Generally Multigas commission installations in accordance with BCGA CP4 guidance. Other guidance is followed when appropriate.

Maintenance

Understanding the regulations and your obligations for multiple systems can be a difficult task.

Here at MultiGas we are able to advise you on the relevant legal regulations and identify further appropriate guidance. Together we can develop a process to incorporate the necessary inspection and maintenance along with the paperwork to clearly demonstrate compliance.

About us

Our in-house team includes design and project management experts, along with contract managers and field-based engineers dedicated to ensuring the highest levels of client engagement and satisfaction.

We oversee all installation and maintenance projects from inception through testing, commissioning, and final client handover.

After completing our work, we provide comprehensive installation aftercare, which includes ongoing support such as system validation, maintenance, emergency response, and annual WSE inspections.

Our Services Include:

Installation

Installing high purity gas systems demands specialised expertise from highly skilled engineers. These systems typically utilise materials like stainless steel and degreased copper for pipelines, with stainless steel requiring orbital welding, and degreased copper pipelines necessitating brazing and purging with nitrogen gas.

Maintenance

Proper maintenance of pressurised gas supply and distribution systems is crucial. It can be challenging to navigate the regulations and responsibilities associated with managing multiple systems.

Over the past 25 years, we have worked closely with numerous prestigious and high-profile clients, whom we proudly consider long-term partners.

At Multigas, we firmly believe that education and industry-recognised accreditations are essential for maintaining the highest standards, providing quality assurance to our clients.

For all your high purity gas needs, please get in touch with Multigas Installations at 01634 249 988 or email us at admin@multigas.biz.

Images

Trade Associations