Company details for:

Newton Waterproofing

Unit 17-19,

Sovereign Way,

Tonbridge,

Kent,

TN9 1RH,

United Kingdom

Quick Links:

Products

Newton CDM BaseDrain & FloorDrain - Drainage System

The 18 mm holes drilled in both sides of the profile, as well as to the top surface, allows water from beneath the CDM Fibran XPS-500C insulation boards and within the spacer zone to enter the drainage channels more easily.

Flexible, Reinforced Waterproof Coating and Gas Barrier for Basements - Newton HydroBond 2K-Flex

Environmentally friendly and solvent-free, HydroBond 2K-Flex consists of two components; a bitumen emulsion and a reactive powder. These two components chemically react when mixed to produce a firm, yet still highly flexible coating that can be applied by trowel or by airless spray machine. Adhering insulated panels to concrete, masonry and thoroughly dried thick bituminous coatings, 2K-Flex dries quickly and is rain-fast after a short period.

Newton CDM Fibran XPS-500C for Basement Waterproofing Systems

The product is manufactured in accordance with EN 13164 - "Thermal insulation products for buildings - Factory made products of extruded polystyrene (XPS)- specification."

Produced exclusively for Newton Waterproofing Ltd, CDM Fibran XPS-500C insulation boards are used to form a 50mm spacer adjacent to the CDM BaseDrain and CDM FloorDrain drainage channels within the Newton CDM System cavity drain waterproofing system. The insulation boards are rated at 500 kPa and feature specifically designed slots to the underside of the boards, that in combination with the perimeter and spine drainage channels of the Newton CDM System form a fully drained supporting spacer below the floor drainage membrane.

The insulation boards can also be used as a protection for Newton liquid applied waterproofing membranes applied externally to new earth retained structures or retained walls, uniquely offering protection, insulation and drainage within one product.

Newton CDM 508 - Basement Waterproofing Membrane for Waterproofing of Existing and New Build Basements

CDM 508 is suitable for waterproofing earth retained walls and vaulted soffits and floors. It is guaranteed against deterioration for 30 years, with a life expectancy of the design life of the building (DIN 9001:2000), and supported by BBA Agrément Certificate 22/6357.

CDM 508 is inert and non-polluting to drinking water, highly resistant to water, alkalines, saline solutions and organic acids, and not affected by minerals and hydrocarbons. It is also rot-proof, and resistant to bacteria, fungi and small organisms.

Rubber Waterproofing Membrane Newton HydroBond 109-LM

HydroBond 109-LM is extremely puncture resistant with elasticity of 850% and a 95% recovery memory. The membrane becomes fully engaged into the substrate to prevent water tracking and is suitable for all below ground and earth-retained structures, ranging from domestic basements to the largest civil engineering projects.

HydroBond 109-LM is available in two variants: Medium Viscosity, for use in warmer temperatures, and Low Viscosity, for when it is cooler. HydroBond 109-LM is also a constituent product of the Newton HydroBond System supported by BDA Agrement Certificate BAB 16-031/04/A and is accepted by the NHBC as a suitable waterproofing system for Type A Waterproofing to Grades 1a, 1b, 2 & 3 - BS 8102:2022.

Newton Newtonite 801 Sealing Mastic for Sealing Penetration and Preventing Bridging

Applied to the fixing plugs before they are fitted, Newtonite 801 Mastic serves so as to seal the penetration and stop the occurrence of a 'bridge' between the damp or stained substrate and the new internal surface. Newtonite 801 Mastic has a high resistance to both ageing and extremes of temperature, as well as achieving a high adhesive strength, without primer, on the majority of materials used in the building and engineering industries.

HydroSeal 107 Elastic 2KWaterproof Tanking Membrane for the protection of below ground structures with Newton HydroCoat 107 Elastic 2K

Features and benefits:

- Pre-packaged materials easily mixed on site.

- Tough, flexible coating which maintains its elastomeric properties even under immersed conditions to accommodate movement in cracks.

- Good abrasion and very high resistance to freeze/ thaw cycles and de-icing salts.

- Excellent adhesion to sound prepared concrete and masonry substrates, as well as steel.

- Dense matrix offers low permeability to water, even at 10 bar pressure, and very high diffusion resistance to carbon dioxide gas.

- Suitable for positive and negative waterproofing of earth-retaining structures as well as covered decks.

- A 2 mm coat provides the equivalent to 135 mm of good quality concrete cover.

- Can be applied to damp substrates in temperatures down to 5°C.

- Water-based product, free from hazardous solvents, ideal for use in confined spaces. Non-toxic when cured.

- Correctly prepared suitable substrates include concrete of at least 20 kN, steel, masonry and screed.

- Can be applied via squeegee, roller, airless spray, pin leveller, brush or trowel.

- CE marked and manufactured in accordance with EN 1504-2: 2004.

- Guaranteed to resist weathering for up to ten years.

Newton HydroBond 403 Plus - Pre-Applied External Waterproofing Membrane for Basement Waterproofing and Gas Protection

HydroBond 403 Plus provides a complete waterproof envelope to the structure to achieve Type A (barrier) waterproofing suitable for Grades 1,2 and 3 as defined by BS 8102:2022, are suitable for all below ground and earth-retained structures from domestic basements to the largest civil engineering projects, and can be used as part of the HydroBond System with HydroBond 108-LM which is sprayed to the exposed walls of the basement after the temporary formwork is removed. Where space is tight, HydroBond 109-LM can be applied by roller or brush or small airless spray machine.

HydroBond 403 Plus can be used in conjunction with other Newton products to provide a coordinated and combined approach to the waterproofing of the whole structure that includes protection against water ingress to the deck, through construction joints, through and around service entries and to movement joints.

Correctly protected, the Newton HydroBond System will provide, under normal service conditions, a durable waterproof barrier for the life of the building to which it is installed, the expected lifetime of the building itself should be at least 60 years. The Newton HydroBond System is supported by BDA Agrement Certificate BAB 16-03/03/A and is accepted by the NHBC as a suitable waterproofing system for Type A Waterproofing to Grades 1,2 & 3 -BS 8102:2022

Externally Applied Drainage Membrane Newton HydroBond 410 GeoDrain

The product provides drainage and protection to the outside face of basement walls to sloping sites, preventing the build-up of water pressure and protecting the structure from aggressive water, chemicals and toxins, and provides mechanical protection only when used against the ‘Type A’ waterproofing where the site is not sloping and so where ground water removal is not viable or recommended.

Consult manufacturer's literature for relevant installation information.

Features and benefits:

- Assists in moving water around and downhill of the structure to sloping sites to prevent water pressure from bearing against the structure.

- Resistant to all chemicals normally found in the ground and unaffected by soil, bacteria and fungi.

- Withstands stresses and movement acting as a slip membrane as the backfill settles.

- Allows for backfilling with excavated earth.

- Extremely strong material, minimising the risk of damage when backfilling even when no protection board is used.

- Very high compressive strength.

- Suspended soil particles (fines) are filtered out by the geotextile layer.

- Quick and easy to install with a range of ancillary fixing and installation products.

- CE marked, and manufactured in accordance with EN 13252: 2016.

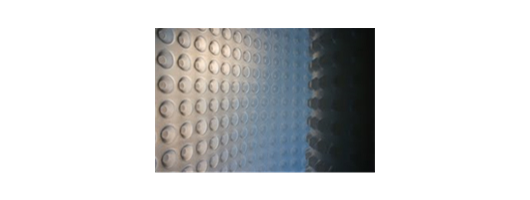

Newton CDM 520 eco Floor - Basement Waterproofing Membrane for Waterproofing of Existing and New Build Basements

Newton 520 eco is one of the main constituent parts of the Newton CDM System, our BBA Certified 'Type C' cavity drain system used for waterproofing earth-retained structures, including drainage channels sited below the membrane for increased drainage capacity.

With its 20mm deep stud profile, CDM 520 eco Floor is used within the CDM System as a high drainage capacity floor membrane and is generally specified where it is anticipated that there may be a risk of severe water penetration.

Newton CDM 503 - Basement Waterproofing Membrane for Waterproofing of Existing and New Build Basements

CDM 503 Mesh is suitable for the waterproofing of earth retained walls and vaulted soffits and is guaranteed against deterioration for 30 years, with a life expectancy of the design life of the building (DIN 9001:2000), and supported by BBA Agrément Certificate 22/6357.

CDM 503 Mesh is inert and non-polluting to drinking water, highly resistant to water, alkalines, saline solutions and organic acids, and not affected by minerals and hydrocarbons. It is also rot-proof, and resistant to bacteria, fungi and small organisms.

Newton HydroTank 315 Waterbar for Sealing Structures Against Water Leaks

The swelling is achieved through hydrophilic acrylate polymers, which are inseparably embedded within the butylene carrier material. This results in high elasticity and exceptional tensile strength, even when fully expanded within the joint.

Due to its high resistance to acids, alkalis and organic solutions, HydroTank 315 Waterbar can be used to seal joints where aggressive water is expected such as within sewage treatment plants, biogas plants and liquid waste holding tanks.

HydroTank 315 Waterbar swells up to 9 times its original size when in contact with water, sealing the joint fully and reliably. The product is particularly suited to sealing non-compressed joints such as at the junction between slab and wall.

Tanking Membrane Newton HydroCoat 103 2K

Capable of resisting extremely high positive and negative water pressure, HydroSeal 103 2K forms a hard, highly alkaline coating with a degree of elasticity which has greatly enhanced chemical resistance and so is particularly suited for the protection of concrete within sulphate contaminated ground.

It has excellence resistance to the ingress of acid gases, moisture and chlorides to enhance the durability of reinforced concrete and protect highway and coastal structures from chloride attack. HydroSeal 103 2K is reinforced over static joints and at details and changes of direction with HydroSeal 912-RT.

Flexible Construction Joint Waterproofing System - Newton FlexProof 106

The FlexProof 106 System is composed of two variants of the product, plus ancillaries:

- X1 − A thixotropic variant that is applied as a paste and so is suitable as a surface sealant over joints.

- NV − A lower viscosity variant that can be poured and is typically used within movement joints.

- FlexProof 106 Primer (Product code: 916) − Improves adhesion to porous surfaces.

- FoamStop (Product codes: FS1 to FS8) − Foam backing rod for movement joints.

High Strength Newton HydroCoat 203 Repair Mortar for Reparation of Concrete

The mortar can be used as supplied up to 100 mm deep, or it can be bulked out with sharp sand to form a high-performance screed or for floor or deck repairs up to maximum depth of 300 mm.

Surface preparation is required, as is protection after application - consult manufacturer for details.

Features and benefits:

- Incorporates the latest proven cement chemistry, fibre and styrene acrylic copolymer technology.

- Reliable strength development, even at sub-zero temperatures, gives rapid return to service.

- Pre-packaged material only requires mixing with clean water. Can be bulked out with sand or aggregate.

- High bond strength exceeds tensile strength of concrete, thus ensuring monolithic performance of the repair.

- Sets in 10 minutes at 20°C yielding a durable, high strength mortar.

- Dense matrix resists 10 bar water pressure. Very high diffusion resistance to acid gases and chloride ions.

- Sulphate resistance to class DS-5/5m of BRE Special Digest 1 and ideally suited for sewage and wastewater applications.

- Portland cement base with physical properties of cured material similar to base concrete.

- Non-toxic when cured and is listed as authorised under Regulation 31 for use in the supply of drinking water.

Below-Ground External Waterproofing Membrane and Ground Level Damp Proof Membrane - Newton HydroBond 402-CSSM

A composite of LDPE and a non-woven geotextile fleece, the membrane has excellent crack-bridging capabilities at places where cracks occur within the concrete, the wet concrete is absorbed into the fleece, integrally bonding it to the membrane. This results in a high-strength bond with exceptional peel adhesion qualities, preventing water migration between the concrete and the membrane, even when damaged.

HydroBond 402-CCSM can also be post-applied to the wall surface, and can be used alongside other Newton products to provide a coordinated and combined approach to the waterproofing of the whole structure that includes protection against water penetrating through construction joints, through and around service entries and to movement joints.

Newton HydroTank 301-EP Metal Construction Joint Waterbar

Installation is quick and easy with the waterbar fitted in place to the reinforcement steel with special clips so that after the placement of the concrete, the waterbar is fully embedded within the two adjoining elements, completely blocking the passage of water through the joint.

Because HydroTank 301-EP Metal Waterbar is not fixed to one of the concrete elements as is the case with conventional waterbars, the forming of a kicker is not necessary. Where the walls are formed above a kicker joint, use 315 Polymer Waterbar.

Newton HydroTank 301-EP Metal Waterbar is certified to resist water pressure of up to 5 bar (50m) and is resistant to all types of naturally occurring ground water types.

Flat Loose Laid Flooring Membrane Newton DampSafe 601 Slimline

Damp Tolerable, Vapour Barrier and Primer for Porous Services Newton Epoxy Primer

The high-quality, epoxy formulation allows for application onto damp surfaces, whilst the low-viscosity penetrates deep into porous substrates to effectively seal the surface ready for the main primer application.

Newton Epoxy Primer is quick and simple to apply by brush or roller and can be applied over cementitious screeds and concrete just 7 days after placement.

Features and benefits:

Very damp-tolerable.

Can be applied to concrete and screed seven days after placement.

Low viscosity.

Solvent free.

Provides an excellent vapour barrier.

High-bond damp proof membrane (DPM) that provides a barrier to vapour and to prevent osmotic blistering.

Life expectancy is equal to that of the surface it is applied to.

Suitable substrates:

Indoor or outdoor floors of correctly formed, compacted and prepared:

Concrete, at least seven days old;

Screed, at least seven days old.

Energy-Efficient Ground Water NP Eco Pumps

The pumps are compact, lightweight, easy to handle and exhibit excellent durability and corrosion resistance. The use of food-grade paraffin for lubricating oil also enhances the pumps eco-friendly credentials.

Capable of continuous duty for many years, Newton NP eco Pumps are available with two motor sizes, 0.4 kW and 0.75 kW and are available in both automatic and manual versions, with the automatic pumps featuring ubiquitous vertical float switch, fitted to Newton NP automatic pumps since 2003.

Crystalline Waterproofing of Concrete Newton HydroCoat 104 Super

The active chemicals combine with the free lime and moisture present within the capillaries to form insoluble crystalline complexes which effectively block the capillaries and any minor shrinkage cracks to prevent any further movement of moisture to provide a totally dry surface to the concrete.

Large areas can be quickly treated with HydroCoat 104. The speed of application and the low material application rate (1 kg/m²) makes this product a very low-cost option for various scenarios.

Because HydroCoat / HydroTank 104 penetrates deep into the concrete, it does not leave a physical membrane to the surface of the concrete element and so is completely unaffected by loadings imposed by further elements of the build. New concrete elements are placed ‘concrete to concrete’ with no potential for slip or separation as is the case with physical membranes.

Features and benefits:

- Single component.

- Ease of application − sprinkled onto new concrete and applied as a simple slurry to vertical and cured concrete.

- Permeates deep into the concrete to form a barrier against moisture that cannot be damaged or punctured.

- Loading capabilities only limited by the strength of the concrete.

- No physical membrane − subsequent concrete placement is ‘concrete to concrete’.

Single-component, Cement-based, Waterproof Tanking Slurry - Newton HydroCoat 105 1K

Features and benefits:

- 2 mm slurry coat is fully waterproof and resists 10 bar positive and negative water pressure.

- Can be applied to damp substrate.

- Can be part-mixed.

- Can be applied as a mortar to 6 mm thickness and so can be used to waterproof, smooth and/or repair rough and uneven surfaces in just one application.

- Environmentally friendly product that is ideal for confined spaces.

- Strong with quick strength gain - 13 MPa within one day.

- Quick drying times - rain tight within one hour.

- Odourless and VOC-free.

- CE marked to EN 1504-3:2005.

Newton HydroTank 302 Resin Injection Hose Waterbar System

HydroTank 302 Injection Hose features micro-ports equally spaced over the entire circumference of the house, and when injected with injection resin at 1-bar of pressure or above the microscopic ports open and the low-viscosity resin penetrates deeply into the concrete surrounding the construction joint.

The injection hose is compatible with both polyurethane and acrylic injection resins, and when installed and injected correctly HydroTank 302 Injection Hose improves the water tightness of the ‘Type B’ waterproof structure by sealing the joints and encouraging improvements in the quality of the concrete placement.

About us

Our company is a family-owned business with a long history of designing quality waterproofing materials and a passion for providing the best technical advice and support for those who require our assistance.

Our projects range from small and domestic to high-end residential city and country properties, commercial buildings and extensive civil projects. Here at Newton Waterproofing Systems, we pride ourselves on our ability to provide comprehensive technical design, superior materials and expert installation.

Newton Waterproofing provides various applications, both domestic and commercial;

Basement waterproofing, which involves transforming a basement/cellar into a comfortable living space, therefore increasing the property value.

Structural waterproofing, providing a full solution for either brand new builds or renovations and protecting the structure from water ingress.

Deck waterproofing, ensuring that areas such as decks and balconies are completely invulnerable to water ingress as well as meeting the client’s requirements often involving expanding the available space.

Damp floor treatments, supplying a complete range of floor membranes which can be used either as a standalone product or a full below ground waterproofing solution.

Basement pumps, used to manage clear ground water, grey water, effluent or sewage.

Drainage membranes, extracting any ground water from basements while also sustaining walls or rafts.

Ground Gas Waterproofing & Radon Protection, which manages water and gas levels within both below ground and retaining structures through the use of a combined system that involves basement waterproofing, ground gas waterproofing and mitigation.

Damp proofing, which prevents any condensation, rising or penetrating damp within the environment, creating a more comfortable living space for the client.

Concrete waterproofing, which provides a range of products that are used to waterproof both retained structures and covered/uncovered decks.

Images

Articles / Press Releases

Brochures

Reviews

Trade Associations