Company details for:

NTG Northern Tool & Gear Company Ltd

John Street West,

Arbroath,

Angus,

DD11 1RT,

United Kingdom

Quick Links:

Products

Spur Gears

Helical Gears

Northern Tool & Gear produce helical gears and mating pinions, both finish cut and gear ground, utilising the latest technology CNC machinery, sizes ranging from 50mm to 1200mm PCD, supported with full CNC gear inspection capability and our in-house heat treatment facility.

Straight Bevel Gears

Spiral Bevel Gears

Hypoid Bevel Gears

Northern Tool and Gear have the capacity to produce high quality hypoid gears, on high technology “Gleason” CNC machinery in both high and low volume, supported by in house heat treatment, with quench press to control quality during heat treatment

Precision Ground Gears

Gear Manufacture

Gleason-Pfauter P600,

Gleason-Phoenix 400GH,

Gleason G-Tech 782 CNC Hobber,

Pfauter P250,

Pfauter P901,

Pfauter RS9 Spline Hobber,

Pfauter PSA500 CNC Gear Shaper,

Lorenz 1000mm Gear Shaper (2 off),

Pfauter Worm Miller.

Bevel Gear Manufacture

Gleason Phoenix 800HC CNC.

Gleason Phoenix 450HC Hypoid Cutting Machine.

Gleason Bevel testers (3 off).

Gleason Auto Lapper.

Straight:

Gleason 104.

Heat Treatment:

Oerliken Quench Press for controlling distortion of bevels during heat treatment.

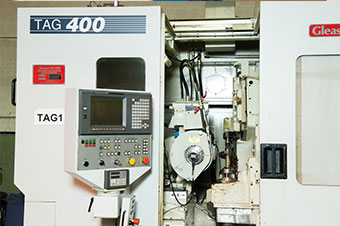

Gear Finishing

with full on machine gear checking

Gleason TAG 400 CNC Gear Grinder

Gleason Hurth TWG 300 CNC Gear Grinder

Reishauer RZ300E CNC

Reishauer Thread / Worm Grinder

Matrix Spline Grinder

Churchill Gear Shaver

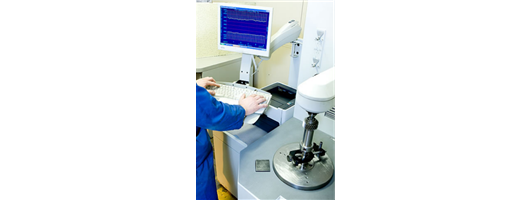

Gear Inspection

Grinding

Up to 350mm diameter, 1500mm long.

Internal:

Up to 600mm diameter bore, 150mm long.

Honing:

Up to 100mm diameter bore, 100mm long.

Worm / Thread grinding:

Up to 150mm diameter, 750mm long.

Turning

Mazak Integrex i200 X/M.

Mazak Quickturn 40,

Mazak Quickturn 35,

Mazak Super Quickturn 15m,

Mazak Quickturn N20B Lathe,

Mazak NEXUS 250,

Massa MV1200ATC CNC Vertical Lathe,

Swedturn ST10 CNC,

Swedturn ST20 CNC,

Center Lathe 1500mm.

Doosan 480L 2 meter bed

Doosan Lynx 220

Milling

Mazak MTV-655 Machining Centre with pallet changer,

Edgwick 50″ Broach , Matrix XL20 Broach,

Burdept Slotter + Cabe 350 ST Slotter,

Heckert Radial Drill.

Heat Treatment

Hardening.

Tempering.

Annealing.

Normalising.

Straightening.

Quench pressing.

Shot blasting.

General Engineering

About us

NTG serves a wide range of industries, including printing machines, mining equipment, defence, diesel engines, marine, agricultural machinery, and the specialist automotive sector. We are open to expanding into additional areas. Our current contracts have helped us achieve a turnover of £5 million.

Our Products Include:

Spur Gears

Spur gears, which have straight teeth, operate in boxes with parallel shafting. Northern Tool & Gear manufactures spur gears, both finish cut and gear ground, ranging from 50mm PCD to 1200mm PCD. These are produced using the latest CNC hobbers and gear grinders, with full CNC gear inspection and in-house heat treatment capabilities.

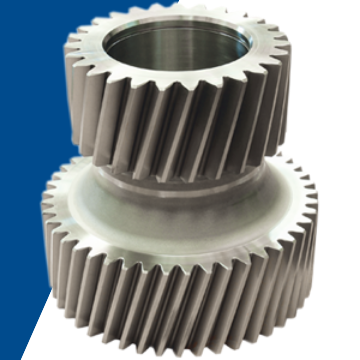

Helical Gears

Helical gears have angled teeth, known as the helix angle, which enables parallel axis gears to transmit power more efficiently and quietly than equivalent spur gears, thanks to improved contact transmission. Northern Tool & Gear manufactures helical gears and matching pinions, both finish cut and gear ground, using advanced CNC machinery. We produce sizes ranging from 50mm to 1200mm PCD, with full CNC gear inspection and in-house heat treatment support.

Straight Bevel Gears

Straight bevels, as the name indicates, are bevel gears with straight teeth, providing a straightforward and reliable way to transfer drive through an angle, typically 90 degrees. Northern Tool & Gear can produce straight bevel gears up to 215 PCD with a 35mm face width, offering on-site heat treatment and utilising a full Gleason test facility to ensure strict quality control.

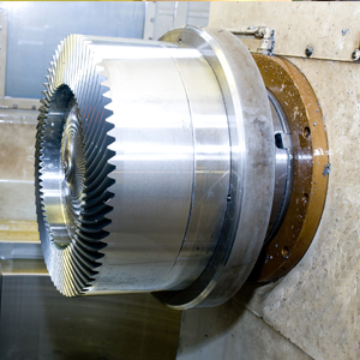

Spiral Bevel Gears

Spiral bevels feature "curved" teeth, offering an efficient, quiet, smooth, and durable way to transmit drive through an angle.

Hypoid Bevel Gears

Spur gears, characterised by straight teeth, operate within boxes with parallel shafts. Northern Tool & Gear can produce spur gears, both finish cut and gear ground, in sizes from 50mm to 1200mm PCD. Production utilizes state-of-the-art CNC hobbers and gear grinders, supported by full CNC gear inspection and an in-house heat treatment facility.

In 1989, NTG earned the BS5750 Part 2 certification and currently holds the ISO 9001:2008 standard, reflecting our commitment to quality manufacturing for diverse clients using advanced machinery. NTG takes pride in maintaining high standards and excellent customer service. To uphold these goals, we have made significant investments in the latest CNC gear manufacturing and inspection machines. For a full view of our capabilities, please see our Plant List showcasing the extensive range of machinery used in our gear production.

For more information, feel free to reach out to us at the address above or through our contact page on our website.

Images

Trade Associations