Company details for:

Pillarhouse International

Pillarhouse International Ltd.,

Rodney Way,

Widford Industrial Estate,

Chelmsford,

Essex,

CM1 3BY,

United Kingdom

Quick Links:

Products / Services

Pilot

The all-new ultra-low-cost Pilot machine has been designed as an entry-level, handload, benchtop machine for small to medium batch manufacturers, combining high levels of production flexibility with economic running costs.

Offered with two universal, quick change tooling carriers, each one can be exchanged to optimise cycle time. Each carrier is capable of handling a board size up to 330mm x 250mm (13″ x 10″).

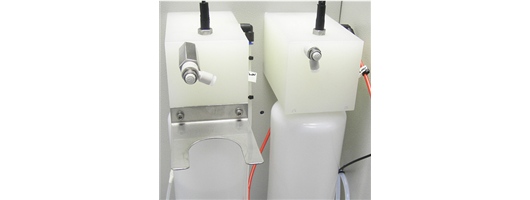

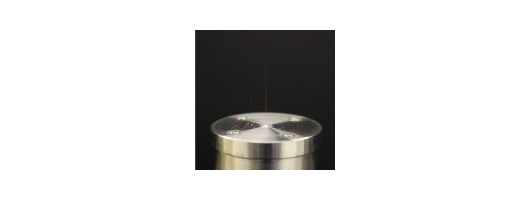

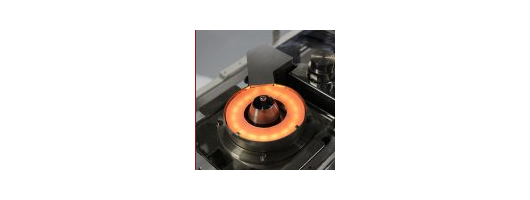

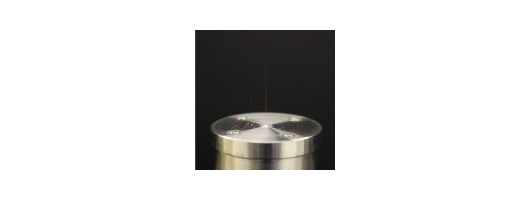

The Pilot incorporates, as standard, our patented Drop-Jet fluxer for quick, accurate flux deposition. An optional bottom side IR pre-heat is also available; this is particularly useful when processing multi-layer PCBs or using water-based flux types.

Jade MKII

Designed to meet the needs of the small/medium batch manufacturer who requires high levels of production flexibility, the Jade MKll entry-level system offers uncompromised selective soldering quality at a very low cost.

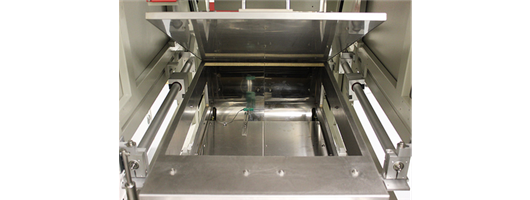

The Jade MKII is a handload system, incorporating a universally adjustable tooling carrier capable of accommodating PCBs or pallets up to 457 x 508mm (18″ x 20″).

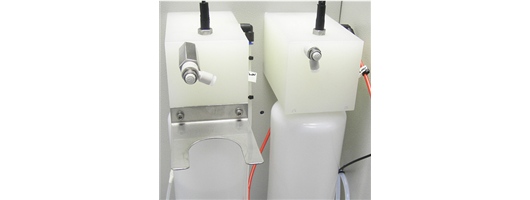

Our patented Drop-Jet design fluxer offers quick and effective flushing of the pressurised flux chamber. This helps to keep maintenance levels to a minimum whilst enabling use of higher solid content fluxes as well as water-soluble fluxes.

Jade MKIV

With all the proven features of the Jade MKII, the Jade MKIV sets even higher standards of performance.

Designed to meet the needs of the small/medium batch manufacturer who requires high levels of production flexibility, the Jade MKIV offers uncompromised selective soldering quality at a very low cost.

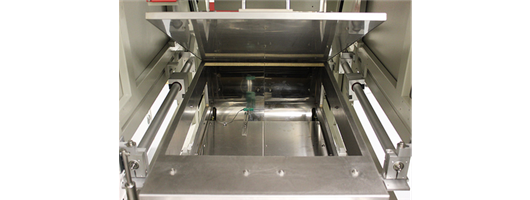

The Jade MKIV is a handload system, incorporating a universally adjustable tooling carrier capable of accommodating PCB’s or pallets up to 508 x 610mm (20″ x 24″).

Our patented Drop-Jet design fluxer offers quick and effective flushing of the pressurised flux chamber. This helps to keep maintenance levels to a minimum whilst enabling the use of higher solid content fluxes as well as water-soluble fluxes.

Jade Handex

The Jade Handex is equipped with a revolutionary twin PCB rotary table transport system to allow simultaneous load/unload during product processing.

Jade Pro

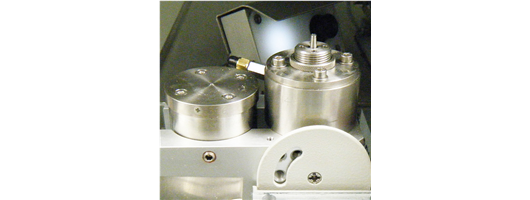

Designed to meet the needs of the small batch manufacturer who requires high levels of production flexibility. The Jade Pro offers the ability to regularly change solder alloys without incurring expensive down time, whilst the solder bath cools down and heats up during a regular manual changeover process.

Jade Prodex

Designed to meet the needs of the small batch manufacturer who requires high levels of production flexibility. The Jade Prodex offers the ability to regularly change solder alloys without incurring expensive down time, whilst the solder bath cools down and heats up during a regular manual changeover process.

The Jade Prodex is an offline system, incorporating a quick load, twin PCB, universally adjustable, rotary table transport system to allow simultaneous load/unload during product processing.

Orissa Synchrodex

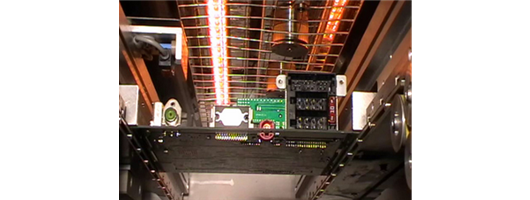

Designed as a modular system, the Synchrodex range of in-line equipment offers the ultimate in flexibility with the ability to upgrade to high-speed throughput when multiple modules are placed together.

Orissa Synchrodex Pro

Designed as a modular system, the Synchrodex Pro range of in-line equipment offers the ultimate in flexibility with the ability to upgrade to high-speed throughput when multiple modules are placed together.

Orissa Synchrodex Combo

This compact, modular, in-line system utilises the same design concept as the new generation Synchrodex soldering cell, and offers the user significantly reduced process time when compared to using a single soldering unit with on-board fluxing and pre-heat functions. It also provides a reduced footprint and cost savings over the conventional three module, fluxing, pre-heat and selective soldering work cell.

Orissa Fusion

Incorporating high-speed PCB transfer, the Orissa Fusion platform offers the ultimate in flexibility, coupled with reduced line length at a lower cost compared to current market offerings.

Quadron (PLC)

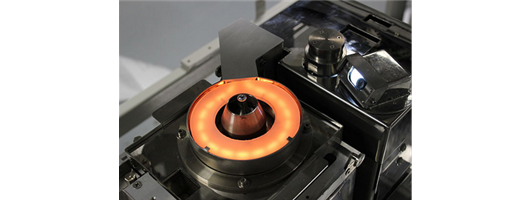

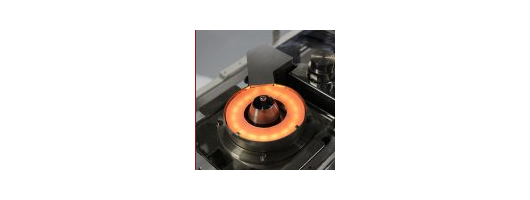

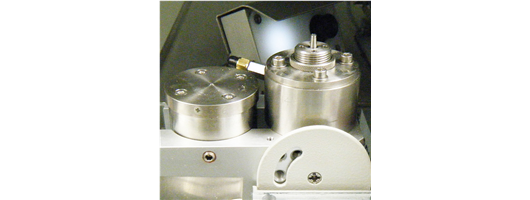

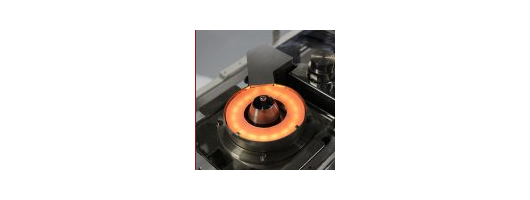

A versatile four station rotary bench top soldering machine, ideally suited for high or low volume production, the Quadron combines well proven pumped soldering techniques with advanced PLC-controlled movement technology.

Much of its versatility is owed to the specially designed programming system which allows the user access to all fluxing and soldering parameters at any time. In addition, rapid product changeover is achieved quickly and easily through simple tooling design and program identification.

The machine is at home both processing coils/sub-assemblies/transformers or small PCBs, in either small or large batches. Cycle times as low as 5 seconds can be achieved.

Optical Flux Plume System

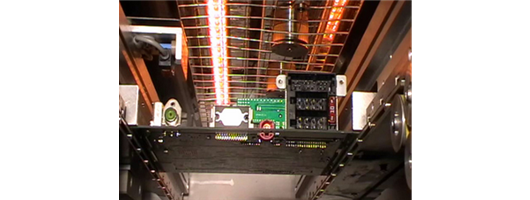

Thermal Flux Sensing

Flux Flow Monitoring

Auto-Nozzle Conditioning

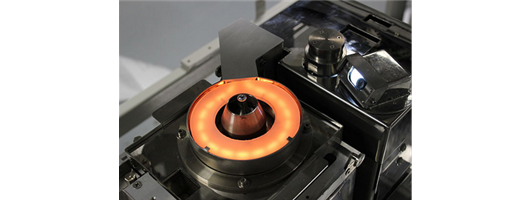

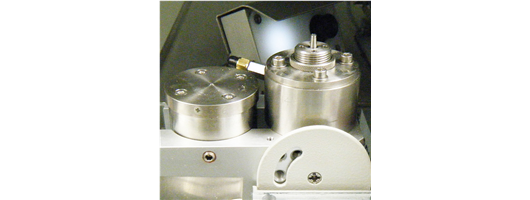

Dual Solder Pots

Heated Trollies

Nitrogen Purity Analyser

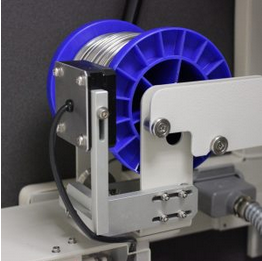

Pot Coding/Solder Reel Coding

Solder Level Detect/Top-up

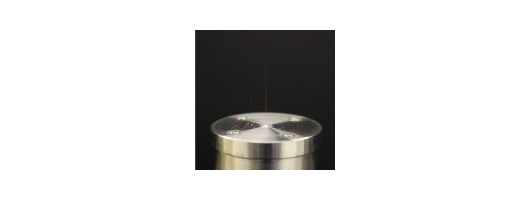

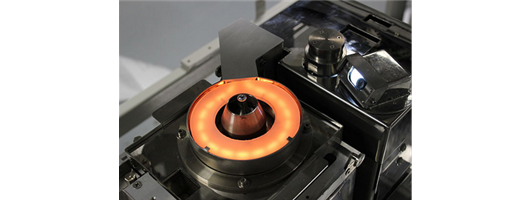

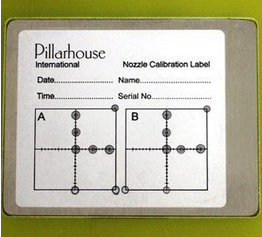

Thermal Nozzle Calibration

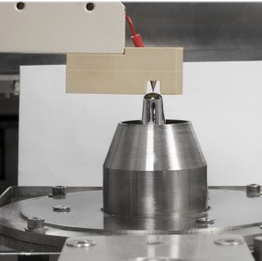

Wave Height Correction

Pump RPM Meter

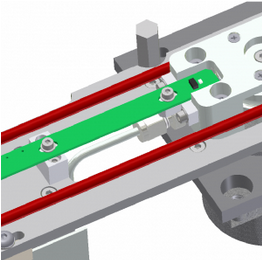

Board Warp

Barcodes & Board Traceability

About us

Pillarhouse International produced its first production soldering system in 1984, and with continued growth throughout the 1980s, used this technology to develop the world’s first selective soldering machine in 1994.

Our mission statement is to produce high engineering standard products with a focus on innovation and cutting-edge development. This practice has led to Pillarhouse International holding several important patents that have been key to our continued success over many years and growing into a global company with sales and service facilities in over 50 countries.

We offer a wide range of selective soldering machines, covering the complexity of global demand for production across electronics, aerospace, and PCB contract manufacturing.

Pillarhouse International has its Design & Manufacturing headquarters in Chelmsford − UK; with Sales & Service Support facilities in Suzhou − China; Chicago − USA; and Guadalajara − Mexico.

Images