Company details for:

Prima Electronic Services Ltd

4 Harding Way,

St Ives,

Cambs,

PE27 3WR,

United Kingdom

Quick Links:

Products / Services

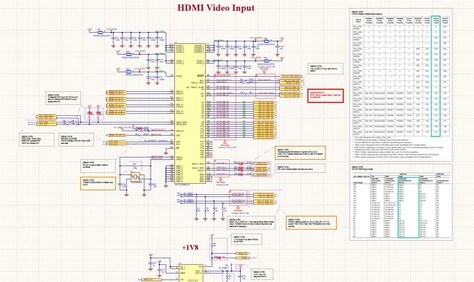

PCB Layout Design

Design for Manufacture

Obsolescence Management

Hardware/Software Design

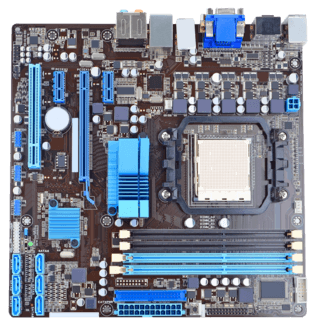

Surface Mount Assembly (SMA)

Through-Hole Build

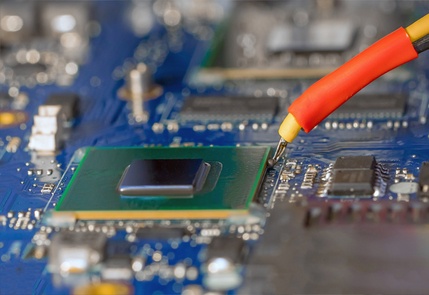

Advanced Rework

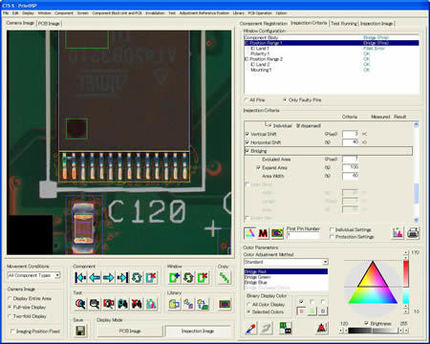

Automatic Optical Inspection (AOI)

X-Ray Inspection

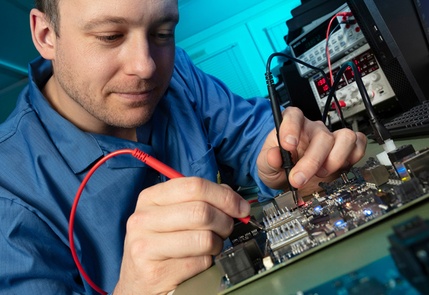

Functional Test

Comprehensive Product Testing

Shipping

Repair & Service

PCB Layout Design Service

About us

Here at Prima Electronic, our mission is to become the UK’s most trusted strategic partner and preferred contract manufacturer for high-end PCB solutions. We work closely with customers to build long-lasting collaborative relationships with them, therefore helping them expand their businesses effectively. We strive for continuous improvement, persistently engaging in more advanced management, production, process, quality and service delivery. We are widely recognised for our ability to listen to customers’ needs and exceed their expectations accordingly.

We as a company care a great deal about the local community, which is why we do our best to make a positive impact by reducing waste and emissions. We dispose of all waste ethically, legally and responsibly, ensuring that we stick to our environmental values. We specialise in a variety of services including PCB layout design, design for manufacture, obsolescence management, hardware/software design, surface mount assembly, through-hold build, advanced rework, automatic optical inspection, x-ray inspection, functional test, comprehensive testing and more.

Sponsored Links

Articles / Press Releases

Trade Associations