Company details for:

QFS Manufacturing Ltd

Unit 3, Chelmsley Wood Industrial Estate,

Waterloo Avenue,

Birmingham,

West Midlands,

B37 6QQ,

United Kingdom

Quick Links:

Products / Services

2-Axis & 5-Axis Laser Cutting

2 x Trumpf 5030 5-Axis Laser

Maximum Pressing − 4mm Aluminium, 6mm Mild Steel

High-Speed Cutting

Cutting Tolerance 0.2mm

Laser Etching

Amada Ventis 3015 Fibre Laser

High-Speed Cutting with Locus Beam Control.

Maximum Processing − 25mm Mild Steel, 20mm Stainless Steel, 18mm Aluminium, 10mm Brass, 8mm Copper.

Blank CAM Software

Laser Etching

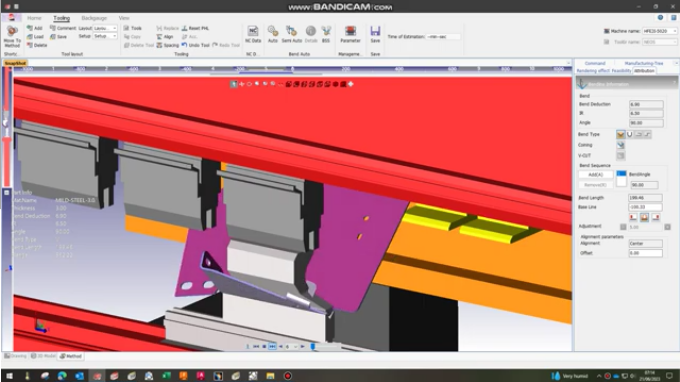

Bending, Folding & Pressing

Amada HFE 3i 5020 Hydraulic Press Brake

Maximum Processing 2000mm (L)

High Accuracy Rapid Development with Bend CAM & Production Designer Software.

2 x Reha 600T Hydraulic Press

Working Environment 2500mm x 1600mm

Open Height 790mm

Shut Height 245mm

Weld & Robotic Welding

Hi-Spot 2000 Robotic Mig Weld Cell

Lifting Capacity − 165Kg

British Fed WS4000 Weld Control with Turntable System

Working Environment 2000mm (X) x 1300mm (Y) x 1500mm (Z)

Pro-Spot Spot Weld Cell

Lifting Capacity − 165Kg

Fanuc System R-30iA Robot Control with Turntable System

Working Environment 2500mm (X) x 2500mm (Y) x 2000mm (Z)

Sheet Metal, Metal Finishing & Fabrication

QFS Manufacturing Ltd stands as an industry leader in the world of metalworking, offering a comprehensive suite of services encompassing sheet metal fabrication, metal finishing, and general metal fabrication. With a relentless commitment to quality, our company has earned a sterling reputation as a reliable partner for clients seeking top-notch metal solutions. Equipped with state-of-the-art facilities and a team of skilled professionals, we excel in delivering precision and innovation to every project we undertake. From creating custom sheet metal components to providing flawless metal finishing touches, our expertise is unrivaled. We take pride in our ability to meet a wide spectrum of metal fabrication requirements, delivering solutions that cater to diverse industries and applications. At QFS Manufacturing Ltd, our unwavering focus on quality, timeliness, and customer satisfaction ensures that we are your go-to source for all your sheet metal, metal finishing, and fabrication needs.

Tox Pressotechnik CEC008

Max Press Force − 82,4 Kn

Total Stroke 150mm

Eckold KF330

Max Thickness Stainless − 1.5mm

Max Thickness Aluminium − 2.5mm

Horizontal − Vertical Throat − 340mm x 245mm

Motorised Ram Adjustment − 80

CNC Machining & Tool Room

Soraluce TA-25

Hartford HCMC − 1270

Meyer SB1036 Precision Gap Bed Centre Lathe

Length − 1000mm

Quality & Inspection

Romer Absolute Arm

Part/Tooling/Fixture Inspection Reporting

Measuring Tolerance 0.1mm over 2m (7 Microns)

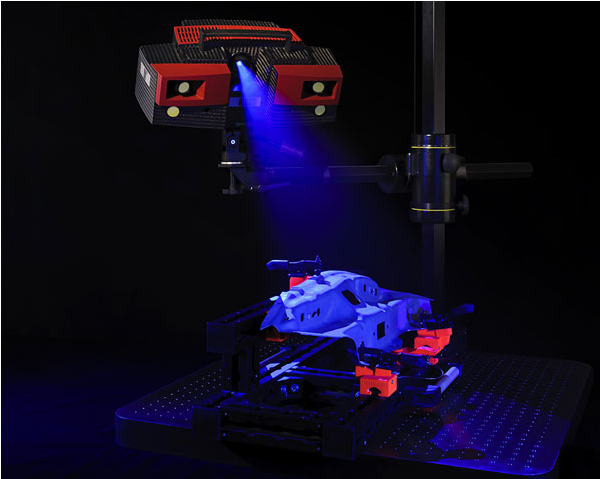

GOM Scanner

3D Laser Scanning

Reverse Engineering

0-30 Microns

Tool Design

Tool Development

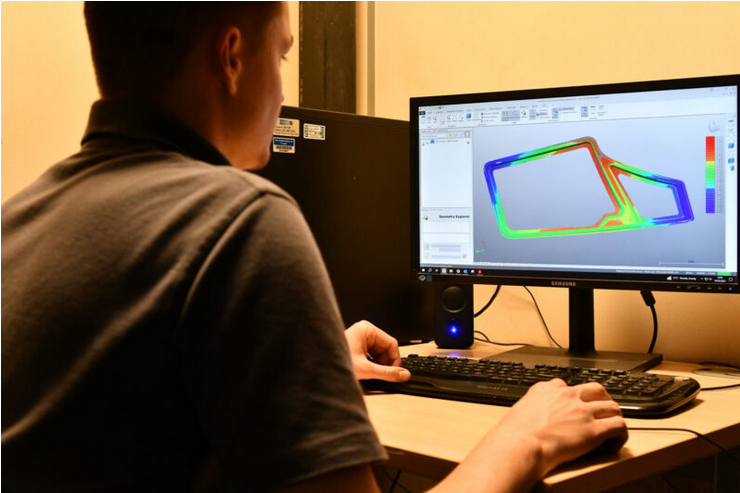

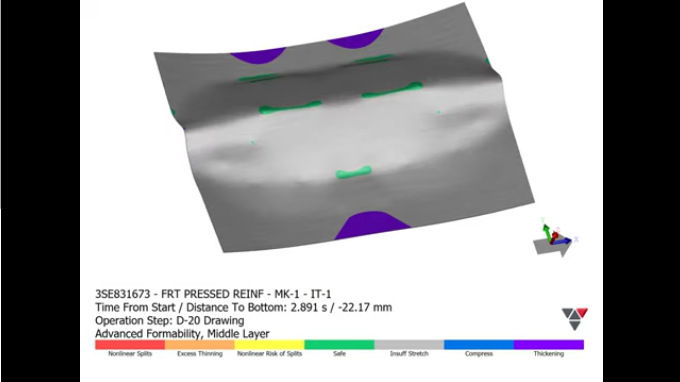

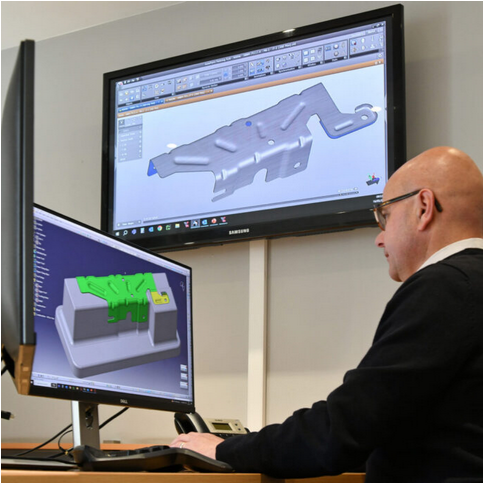

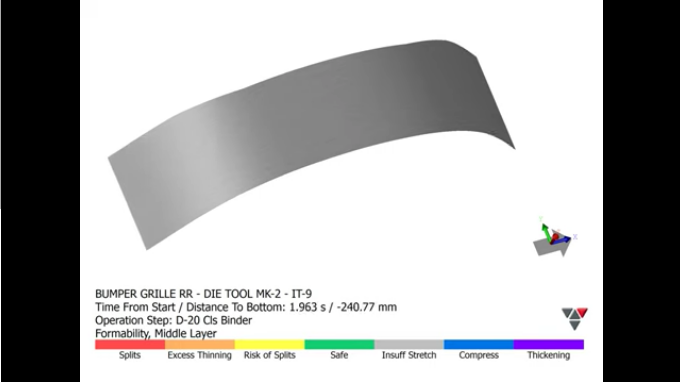

Autoform Simulation

QFS Manufacturing Ltd is a recognised leader in the realm of precision engineering, offering specialised services in Autoform simulation. Our commitment to excellence and innovation has positioned us as a trusted partner for clients in need of top-notch simulation solutions for metal forming and related processes. With our team of skilled professionals and cutting-edge technology, we excel in providing accurate and reliable Autoform simulations that ensure optimal performance and product quality. Whether it's predicting and optimising complex metal forming operations or enhancing tool and die design, QFS Manufacturing Ltd is well-equipped to meet the most demanding simulation requirements. Our dedication to precision and client satisfaction ensures that we are your go-to source for all your Autoform simulation needs, allowing you to make informed decisions and drive efficiency in your manufacturing processes.

Rapid Turnkey Solutions

Wide-Ranging Flexibility

Offering a Wide Range of Services

About us

We've commenced a process of elevating our overall capabilities, thanks to the backing of our investors. This involves investments in cutting-edge technologies like Mig and Spot Robotic Welding. Furthermore, our dedication extends to nurturing our employees' expertise by implementing comprehensive training and development programs across all our facilities.

QFS Manufacturing Ltd offers an extensive spectrum of services, encompassing in-house design and advanced simulation software, guaranteeing the smooth integration and prompt delivery of top-quality components to our clientele.

Our Services Include:

- 2-Axis & 5-Axis Laser Cutting

- Bending, Folding & Pressing

- Weld & Robotic Welding

- Sheet Metal, Metal Finishing & Fabrication

- CNC Machining & Tool Room

- Quality & Inspection

- Tool Design, Development & Simulation

In the future, our entire management team is dedicated to nurturing the business's growth opportunities, and we have strategies in motion to accomplish this objective. At QFS Manufacturing, we are unwavering in our commitment to providing top-notch products and services to our clients, and we eagerly anticipate maintaining this commitment for many years to come.