Company details for:

Racaw Ltd

Unit 9,

Henley''s Business Park,

Manor Road, Abbotskerswell,

Newton Abbot,

Devon,

TQ12 5NF,

United Kingdom

Quick Links:

Products

Design Services

Integrated CAD, Drawing and Design Service

Project Management

Design Consultancy

Product Prototyping and Development

Small or large projects undertaken

Conversion of paper drawings to solid models and CAD drawings

Integrated CAD, Drawing & Design Service

Project Management

Design Consultancy

Product Prototyping & Development

Small or Large Projects Undertaken

Conversion of Drawings to Solid Models & CAD Drawings

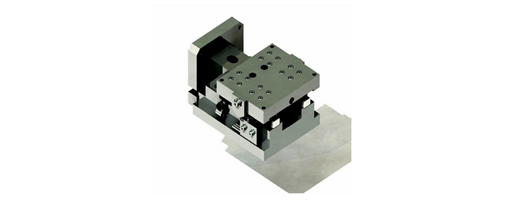

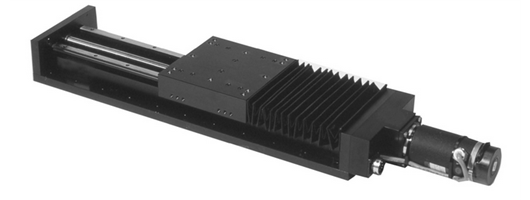

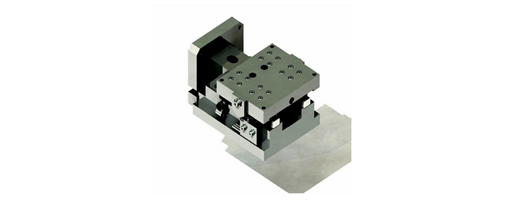

2000 Series Stage

Adjustable magnetic limit and datum switches are integral within the stage.

Stepper or servo motors are compatible with 2000 series stage.

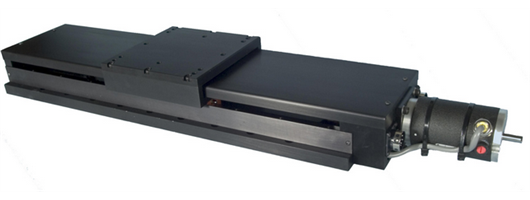

2500 Series Stage

Adjustable magnetic limit and datum switches are integral within the stage.

Stepper or servo motors are compatible with 2500 series stage.

3000 Series Stage

Both 17 frame size stepper and small servo motors with encoders are easily integrated onto the stage, offering resolutions to 0.1µm and better. Integrated mechanical datum and limit switches are common to all the models and connections are made by way of a secure 15 way D type connector.

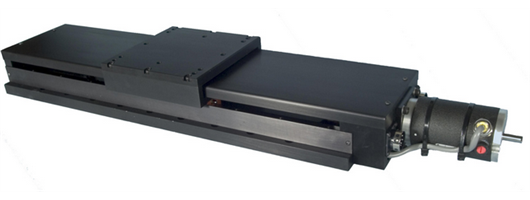

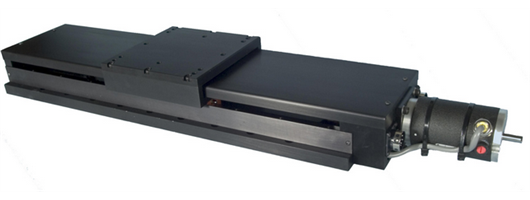

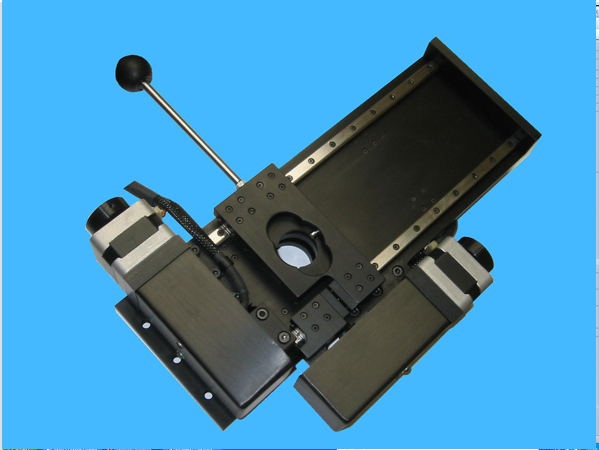

4000 Series Stage

This design allows the mounting of high accuracy linear scales, protected, within the stage assembly, on the side opposite the ballscrew. The ratio of base thickness to stage envelope ensures a superior trajectory performance. Limit and datum switches are also integrated within the stage. High resolution stepping motors or servo motors are mounted to an adaptable motor mount assembly. All connections are securely made through a single 25 way D connector.

9000 Series Stage

The compact design allows installation in tight spaces for remote adjustment of focusing, tension, sensor position and many other continuousmovement applications.

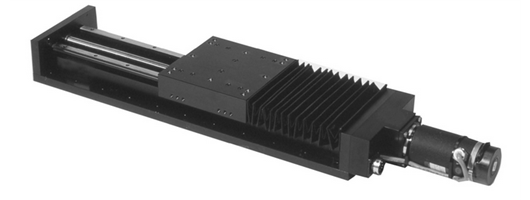

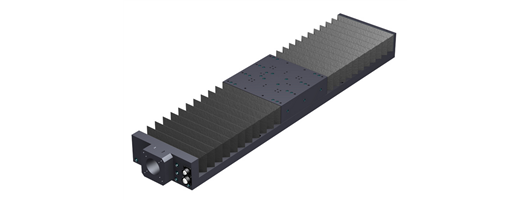

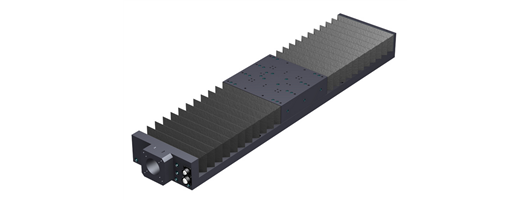

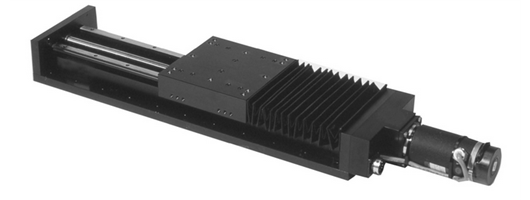

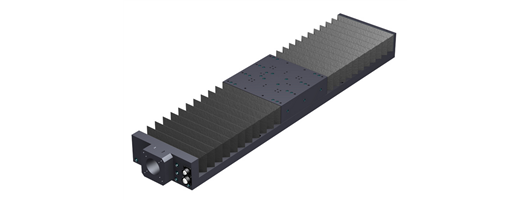

12000 Series Stage

Using high load capacity, four journal rail bearings and a high precision ground ballscrew, these stages offer accurate control of position suited to laser machining and optical positioning systems. Limit and Datum switches are fitted. Switch, motor and encoder connections are made through QM connectors.

Available with stepping or servo motors with encoders. Linear encoders internally fitted are an option. Protective bellows fitted as standard.

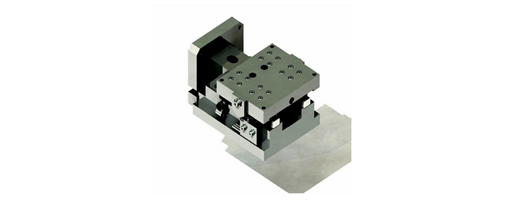

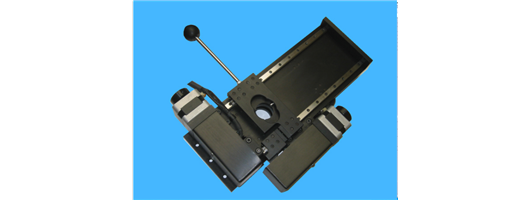

29000 Series Stage

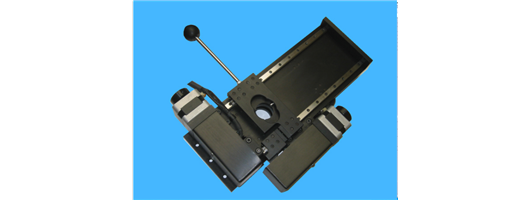

Using ground ballscrews or optional leadscrews for economy, this compact XY stage is available in 50x50, 100x100 or 150x150 travels. Stepping motors are standard but servo motors are optional. Crossed roller bearings are used for good stability, within an economical design.

Limit and Datum switches are optional. A linear encoder with integral Limit and Datum switch function can be optionally fitted.

5000 Series Stage

A magnetic Datum switch is included. Stepping or servo motor control with a rear- mounted encoder ensures accurate indexing. All connections are made through a secure QM 19 way connector. A through-hole feature is standard on all Series 5000 rotary stages.

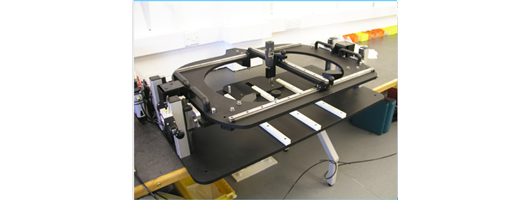

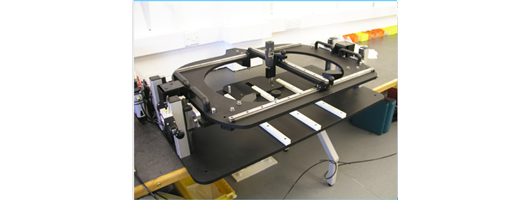

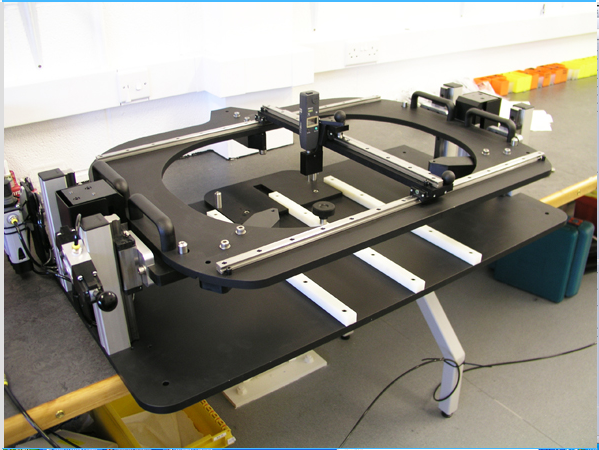

Systems

We have access to a number of different platforms for motion control of our stages and systems. Ranges from simple stepper motor or servo motors through to highly complex positioning needs can be accommodated. We offer flexibility to ensure that our customers get what they need.

We have supplied many stand-alone packages including:

PCs

Vision systems

Machining devices

About us

Established in 2003, Racaw Ltd is a mechanical design engineering firm specialising in the design and production of precision mechanical equipment and systems.

Our Services Include:

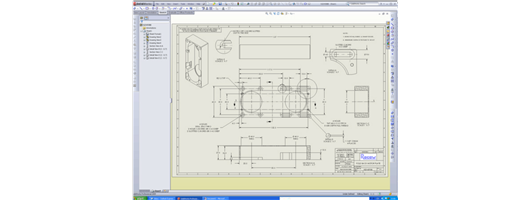

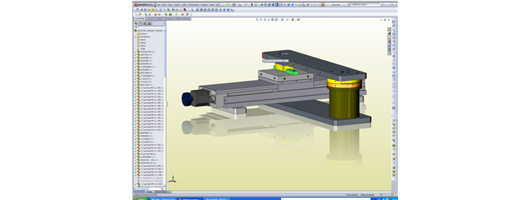

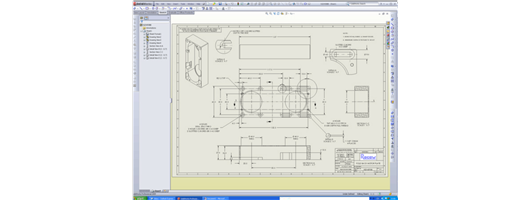

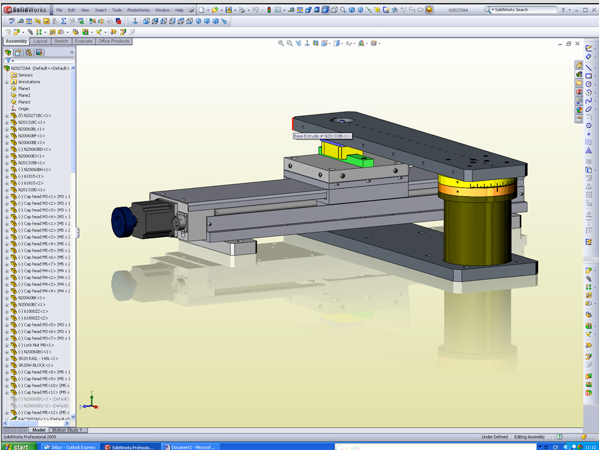

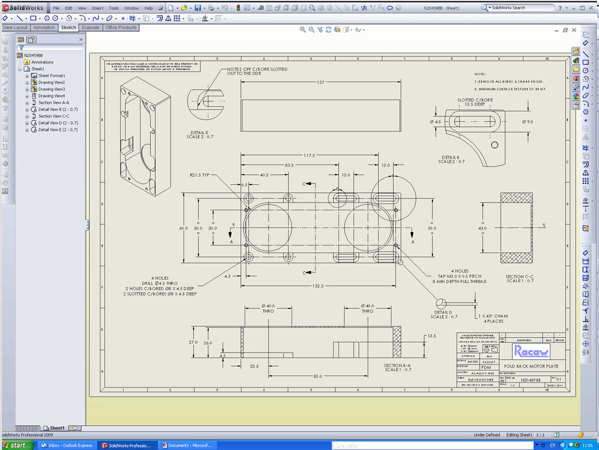

Design

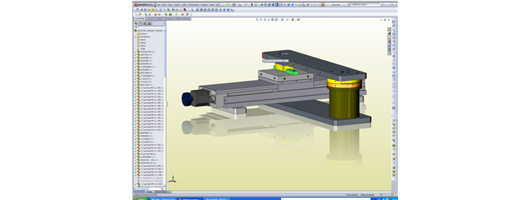

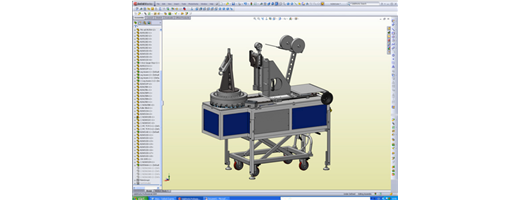

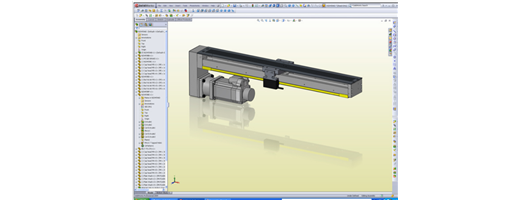

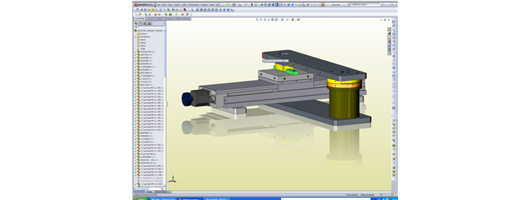

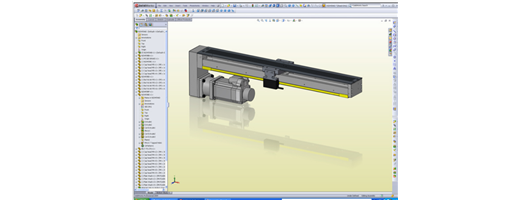

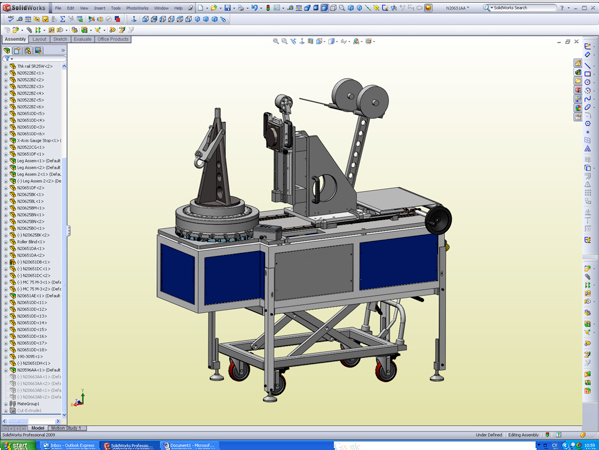

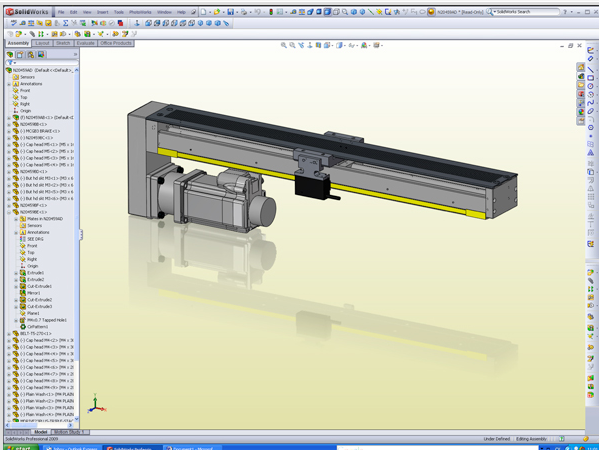

Racaw takes pride in its flexible, customer-focused design approach, utilising Solidworks™ CAD solid modelling and drafting to provide cost-effective solutions for projects of all sizes.

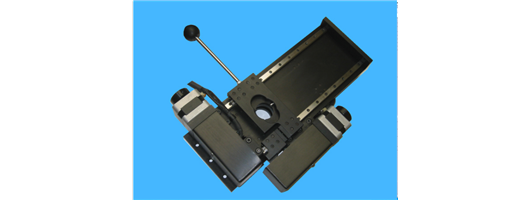

Products

A standard selection of precision rotary and linear stages, as well as electric linear actuators, designed for seamless integration into applications requiring sub-micron accuracy.

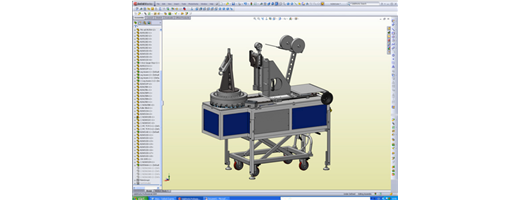

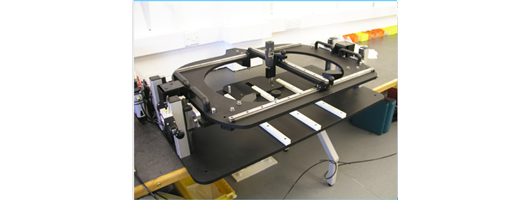

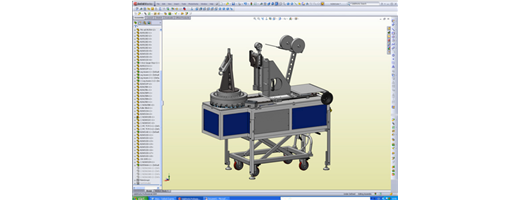

Systems

Racaw focuses on integrating design and manufacturing to create complete or partial systems customised to meet customer requirements.

Design work is carried out on modern CAD stations using the latest Solidworks™ software, integrated with a PDM drawing management system.

Collaborating closely with clients is central to Racaw’s approach, ensuring that projects meet desired outcomes, timelines, and specifications.

Images