Company details for:

RAD Additive Ltd

164-170 High Street,

Crowthorne,

Berkshire,

RG45 7AT ,

United Kingdom

Quick Links:

Products / Services

Sectors We Operate In:

No matter the sector, whether you are a manufacturer, engineer, technical developer, or creative entrepreneur, RAD Additive can be the ideal partner for you.

We are dedicated to collaborating with you throughout the entire process, regardless of your specific needs. Our attentive approach involves actively listening to you and your requirements, offering valuable insights based on our extensive expertise and passion for the project.

Even if your industry is not listed below, we want to assure you that our services are not confined to those mentioned. We are committed to assisting all clients, regardless of their sector. Please feel free to reach out to us, and we will gladly discuss how RAD Additive can help bring your vision to life.

Supporting the Engineering Sector

Do you need to enhance the speed of your production processes while also reducing costs? Perhaps you need to lower your annual investment in jigs? Or is there a requirement to print moulds with a high degree of precision?

Whatever your challenges, we listen to your needs, learn about your business, and understand the problem you need to solve. Using our passion and extensive expertise in design and printing, we then work to find the right solution for you, customising it to ensure the optimal outcome.

Do you require small production runs, possibly with each part customised? At RAD Additive, we have specialised tools to meet your requirements. For our engineering clients, we can assist with material/part traceability and the creation of robust products such as flame-retardant enclosures.

We are happy to discuss any other ideas you may have. Please do not hesitate to get in touch.

Inventors & Entrepreneurs

RAD Additive can transform your visions into reality through our comprehensive step-by-step process.

With our 3D printing technology and expertise, the only limit is your imagination. We are committed to doing everything we can to turn your ideas into reality.

Companies often seek promotional products, customised specifically for their business, and we can assist in designing and manufacturing these items, including pens, phone stands, beer mats, and more.

Whatever your needs as inventors and entrepreneurs, we begin by listening to you−your concept, your vision. Our deep-seated passion for creation, combined with our dedication to understanding your needs, allows us to partner with you to achieve your goals.

Our expertise is unparalleled, with 60 years of combined experience in design and production among our founders.

Our process guides you from design to development, creating production-ready plans. Once these are approved, we move into prototype production, refining and perfecting until we reach the final design. From there, we can assist you in producing the final product and even take it to market through our fulfilment services.

Technology Prototyping

We start by understanding your idea and what you’re looking to achieve. We then develop your plans into a print-ready format, ensuring we capture any nuances and details of your design.

With that approved, we move through to creating the prototype itself, customising the output to meet your needs. The agile process allows for multiple versions and comparisons to be made to reach the optimal final design.

The difference at RAD Additive is that we have a huge passion for design. We bring this to bear on every new prototype - coupling this with our extensive expertise in both design and printing.

With our end-to-end service, we are also able to help you move forward. Move from prototype into production and into fulfilment - at the right time for you.

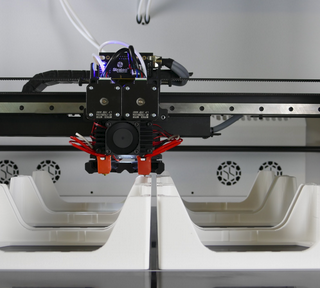

3D Printers

At RAD Additive, we can support fellow 3D printing companies.

In the event of machine outages, we can provide the necessary tools and parts to get you back up and running. Additionally, we can handle your printing needs during this period, ensuring you don't experience any downtime.

Have you taken on a large project that you can't fulfil in-house? We can partner with you to help deliver it seamlessly.

We also offer an end-to-end service, from design to fulfilment. For 3D printers that focus solely on printing, we can support you and your clients at every stage of the process. This includes offering advice and design at the early stages, manufacturing parts, and providing fulfilment services at the later stages.

RAD Additive Logo Architecture

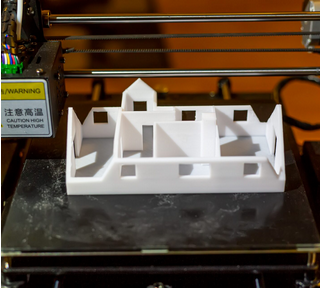

We understand the need to get it right, down to every last detail.

This is why many architects now create 3D models of their designs; a tangible solution to explain their thinking. 3D Printing is a cost- and time-efficient solution to showcasing your vision to your clients.

We are driven by our passion to produce the outcome that is right for you, so listening is at the heart of our processes - right from your initial brief to us through to the end result. Our extensive expertise means we can customise your designs with the highest level of precision, ensuring a premium quality result - one that does your idea justice.

Giving you the best chance of selling your idea to your client, first time.

Automotive 3D Printing Specialists

Fully customisable and accessible, we can assist in designing essential tools required for your automotive projects. Whether it's jigs or intricate parts and components, we can manufacture according to your specific requirements.

Additionally, we can support with prototyping, replacing hard-to-find parts, and product design, followed by manufacturing.

We begin by understanding your needs - whether it's solving a problem or achieving a particular benefit. Then, we leverage our expertise and passion to identify the ideal solution for you.

With our comprehensive service, we can guide you through the entire process, from design and development to production and fulfilment, at the most suitable time for your project.

Meeting Diverse 3D Printing Opportunities

If you're uncertain whether 3D printing opportunities are suitable for your business, we're glad to offer sincere advice and the essential information to aid in your decision-making.

Our approach revolves around attentive listening to our clients and utilising our expertise and passion to assist them. Therefore, regardless of your query, we'll approach it with an open mind and a commitment to help.

Get in touch with a member of our team to commence your journey.

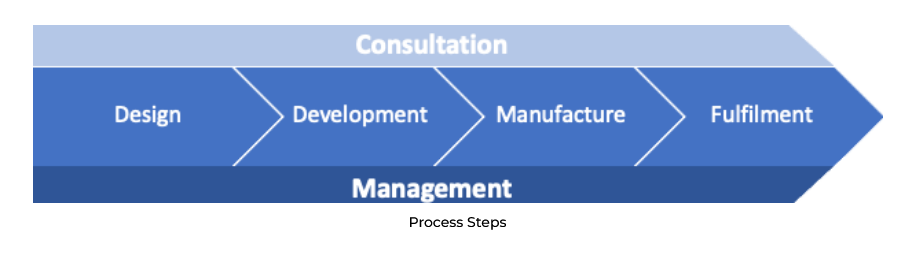

Revolutionise Your Production

Design, Development, Production and Fulfilment.

Because we like to make things happen, we offer an end-to-end service. From initial designs, through to production-ready plans, then into production and fulfilment. Clients join or leave the process at any point, making use of the service, or services, that they need. We always offer clients honest advice, so that they can select the services that are right for them.

The right service for you will vary depending on your sector and your needs. You can read more about who we work with here. Contact us and let’s discuss how we can help.

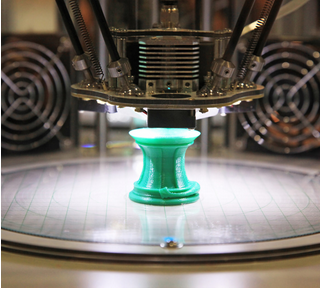

3D Printing Services: Infinite Possibilities

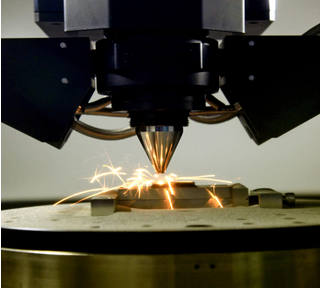

Discover the transformative power of 3D printing services at RAD Additive. From precision engineering for industrial applications to hobbies, crafting intricate models and miniatures, our 3D printing services redefine what's possible.

3D-Printed Jigs & Fixtures: Enhance Your Operations

Step into the forefront of contemporary manufacturing innovation! At RAD Additive, we're not merely experts; we're trailblazers in creating exacting 3D-printed jigs, fixtures, and an extensive array of tooling solutions aimed at transforming your production methods fundamentally. Our proficient team, comprising experienced engineers and forward-thinking designers, employs inventive design concepts paired with state-of-the-art 3D printing technology to significantly enhance your operational effectiveness and productivity.

Project Portfolios Collection:

Manga Stand Arrow: A Private Commission

If you have an interest in Manga items, such as this Stand Arrow, please share your preferences with us. Although a stand wasn't initially requested, we're open to designing something for printing or creating a compatible accessory based on your needs.

This project entailed a private commission for 3D printing the Stand Arrow derived from Manga. The client provided us with the STL 3D definition file. The level of detail is exceptional and remains unaffected by the gold paint on the body and aluminium paint on the edges. The arrow underwent spray painting and received a clear protective spray finish. We printed the arrow shaft separately and meticulously hand-painted it to achieve a natural dark wood effect, also applying a clear protective spray.

Design to Production: Motorcycle Coil Removal Tools

If you're interested in collaborating with us on one of your projects, please reach out to us to discuss your requirements.

3D Printing: A Revolution in Education

The transformative impact of education, particularly in manufacturing careers, is underscored by the significant role played by 3D printing. It facilitates the acquisition of basic skills necessary for the workforce.

3D printing has revolutionised education, fostering a hands-on and innovative learning approach. In the field of engineering design, it presents unique opportunities. The following is a comprehensive list, covering various topics suitable for different age groups. Encouraging student curiosity and providing access to appropriate tools are vital.

Mechanical Design: 3D Printing Integration

Precision and Complexity

One of the primary merits of integrating 3D printing into mechanical design workflows is its unmatched precision. Conventional manufacturing techniques often encounter challenges when dealing with intricate geometries and complex designs. In contrast, 3D printing excels in handling complexity, capable of producing geometries that would be either extremely difficult or prohibitively expensive using other methods. Engineers now have the ability to fabricate detailed prototypes with precision levels previously thought unachievable.

Empowering Growth: SMAs & SMEs in Manufacturing

Managing to Get Things Done in a Downturn

As a manufacturer, are you preparing for a potential sharp decline in activity? Are you still required to complete tasks or maintain your production lines?

3D printing tools, jigs, and fixtures often offer cost advantages over traditional subtractive fabrication methods. This is typically due to reduced time and material expenses.

When properly designed and using suitable materials and printing processes, 3D printed parts can be as durable as machined parts. There are instances of 3D printed lifting grippers being tested to withstand loads of up to 1000kg or four times the maximum. Don't overlook 3D printed tools, jigs, or fixtures as they can provide cost-effective alternatives. We would be delighted to assist you.

The Hazards of In-House Additive Manufacturing

We've come across several articles cautioning about the decision to pursue Additive Manufacturing (AM).

They offer wise advice, and we'll outline some of the recommendations within the following LINK:

3D Printing & Progress in Surgery

3D Printing for Excellence & Longevity

3D Printing: Manufacturing Efficiency

Designing Furniture with 3D Printing

A Guide to 3D Printing Filament Materials

For 3D Printing Services: Contact Us

We trust you found it informative.

Kindly click the LINK to access our 'Contact Us' page on our website for further assistance.

About us

Our 3D Print Service (including Additive Manufacturing) and Engineering Design Service are here to help you. It could be a model of a building or your favourite character as a miniature; a specialist tool, jig or fixture; perhaps a robot end effector. Perhaps you need a custom enclosure. We will be happy to take a look for you. Our dedication to and listening to your needs sets us apart from the rest.

Whether you require a solution to a problem or want to bring a new innovative idea to fruition, we are here to help. We believe that communication is key, and we are always ready to start a conversation with you. Best of all, it won’t cost you a penny to get started. So why wait? Let us help you turn your vision into a reality today! We like to think that the way we work sets us apart here at RAD Additive, from proposal to production, our experience, dedication to client needs and passion lead the way.

Our Services Include:

At RAD Additive, we provide comprehensive services covering Design, Development, Production, and Fulfilment. With our end-to-end approach, we guide clients from initial designs to production and delivery, allowing flexibility for clients to engage with the services they require. Our honest advice ensures clients can choose the right services tailored to their needs and sector. Our Design service includes conception, consulting, prototyping, and environmental assessment. Development involves rapid design preparation, material selection, and sustainability considerations. Manufacturing encompasses plastic extrusion, resin printing, surface finishing, assembly, and quality control. Fulfilment covers packaging, shipping, and various fulfilment routes. Contact us to explore how we can assist you further.

3D Printing Services

RAD Additive offers transformative 3D printing services, redefining possibilities from industrial precision engineering to crafting intricate models and miniatures. Their expertise in FDM and resin printing ensures selection of materials tailored to project requirements, providing custom solutions for diverse needs across industries such as aerospace, healthcare, and hobbies. Agile services cater to SMEs, enabling cost-effective innovation, while direct communication fosters seamless collaboration. RAD Additive serves as a comprehensive solution provider, offering everything from precision robotics to high-quality 3D printing under one roof.

3D-Printed Jigs & Fixtures

Our team pioneers precision 3D-printed jigs, fixtures, and tooling solutions, tailored to revolutionize your production processes. Experience unmatched efficiency with customized solutions designed to address your unique challenges while reducing costs through additive manufacturing. Unlock new design possibilities, accelerate prototyping, and enhance productivity with durable, eco-friendly solutions. Book a complimentary Manufacturing Process Review today and witness the future of manufacturing firsthand.

At RAD Additive, creativity propels us forward. Founder Robert Urry, a committed maker, imbues our projects with a philosophy of simplicity and experimentation.

We offer comprehensive 3D printing and design services tailored to benefit businesses across various industries. Whether you're an engineer, a technology developer, or a creative entrepreneur, we serve as your ideal partner. Our dedicated team collaborates closely with you, providing guidance, expertise, and unwavering support throughout the project.

If you don't fit into a predefined category, reach out to us, and let's discuss how RAD Additive can bring your ideas to life.

Images