Company details for:

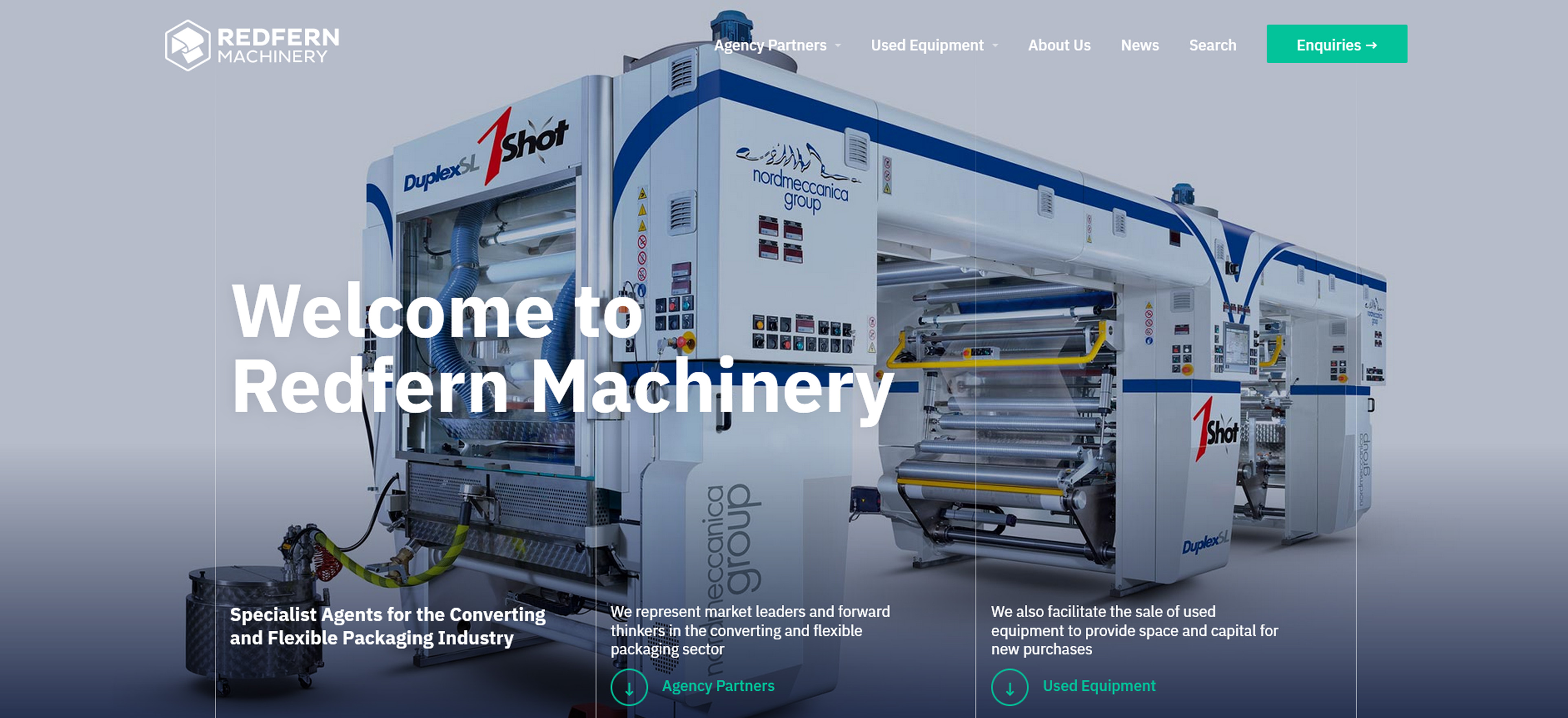

Redfern Machinery

12 Kayfields,

Harwood,

Bolton,

Greater Manchester,

BL2 4DY,

United Kingdom

Quick Links:

Products / Services

Nordmeccanica Simplex SL

Laminating machine for the production of two-layer laminates with solventless adhesives.

PRODUCTIVITY.

Productivity and reliability growing in perfect harmony through machine design.

Mechanics and electronics developed expressly to comply with higher production speed and increased productivity.

EXTREMELY ACCURATE.

The industry standard in the achievement of the most stringent accuracy in coating weight control.

SAFETY.

Utmost care to operator’s safety with mechanical/electrical/functional solutions CE certified. CSA/UL certified for North America.

ENERGY EFFICIENCY.

Every Nordmeccanica product is developed in accordance to the most stringent energy ef ciency criteria and the use of state of the art technology.

In particular the Simplex family of products features extremely low energy consumption, regenerative drives and the utmost attention to energy exploitation in general.

UNSURPASSED WEB HANDLING TECHNOLOGY.

Nordmeccanica through the years developed first and continued to perfect the web handling technology that allows a reliable solventless lamination process control.

Nordmeccanica Super Simplex SL

Laminating machine for the conversion

of two-layer laminates with solventless adhesives.

Patented Solventless coating unit.

Shaftless unwinds and rewind, quick job changeover.

Digital vector motors and drives for the ultimate web handling accuracy.

EXTREMELY ACCURATE.

The industry standard in the achievement of the most stringent accuracy in coating weight control.

UNSURPASSED WEB HANDLING TECHNOLOGY.

Nordmeccanica through the years developed first and continued to perfect the web handling technology that allows a reliable solventless lamination process control.

PRODUCTIVITY.

The ultimate achievement in converting equipment.

In the Simplex family productivity is achieved through the combination of reliability, know how, simplicity, high tech, quick set up integration and ease of handling.

OPERATOR FRIENDLY.

A high productivity equipment must feature operator friendly design.This is what the Simplex family is all about.The most efficient laminator in the industry that brought the concept of “operator friendly” to the highest peaks in the industry.

SAFETY.

Utmost care to operator’s safety with mechanical/electrical/functional solutions CE certified. CSA/UL certified for North America.

ENERGY EFFICIENCY.

Every Nordmeccanica product is developed in accordance to the most stringent energy efficiency criteria and the use of state of the art technology. In particular the Simplex family of products features extremely low energy consumption, regenerative drives and the utmost attention to energy handling in general.

SUPERVISION.

Electronics controlled by a powerful PLC connected to a pleasant “user-friendly” interface.

Nordmeccanica Super Simplex SL HD

Patented Solventless coating unit.

Shaftless unwinds and rewind, quick job changeover.

Motors controlled by vectorial drives and tension control made by dancing rollers.

SUPERVISION.

Electronics controlled by a powerful PLC connected to a pleasant “user-friendly” interface.

SEPARATE ELECTRIC CABINET.

Trouble-shooting and repairing done easily and safely, due to the separate electric cabinet (self-ventilated or conditioned on request).

POWERFUL MOTORS.

Reliable and powerful motors, controlled by the latest generation electronic vectorial drives.

ELIMINATION OF HARMFUL EMISSIONS.

Floating exhaust hood with direct suction for elimination of the harmful emissions.

TECHNICAL SOLUTIONS.

Reliable technical solutions to make easy cleaning operations, job changeover operations and regulations.

MIXING UNIT COMPATIBILITY.

Mechanical adapters for any type of mixing units available on the market and pneumatic control for adhesive claiming.

CORONA TREATER.

Collaboration with main Corona treater manufacturers enables successful satisfaction of all requirements worldwide.

WEB GUIDE SYSTEM.

Web guide system with ultrasonic sensors

for transparent and non-transparent materials.

SAFETY.

Utmost care to operator’s safety with mechanical/electrical/functional solutions certified CE or CSA/UL on demand.

HEAVY DUTY SHAFTLESS.

Heavy duty shaftless unwinds/rewind manufactured to accept high weight reels.

Nordmeccanica Duplex SL 450 / Duplex SL 600 HD

The machine is equipped with the Nordmeccanica patented coating unit.

The technology of this unit guarantees the extreme simplicity of operation and the most constant coating weight even during speed ramp.

Tension control throughout the machine is highly accurate.

The quality of components and the raw materials used in the manufacturing are at the maximum technological levels.

Each machine is manufactured according to the customer’s needs and based on a large availability of accessories.

TURRETS.

Production process without intermediate stops. Automatic reel splice at high speed.

MOTORS WITH ‘VECTORIAL’ DRIVES.

High performance powerful motors controlled by regenerative vector drives.

SUPERVISION.

The electronic system is managed by a powerful computer, which provides complete Supervision functions and is interfaced with a “user-friendly” touch screen.

Nordmeccanica Duplex Compact SL 450 / Duplex Compact SL 600 HD

The machine is equipped with the Nordmeccanica patented coating unit.

The technology of this unit guarantees the extreme simplicity of operation and the most constant coating weight even during speed ramp.

Tension control throughout the machine is highly accurate.

The quality of components and the raw materials used in the manufacturing are at the maximum technological levels.

Each machine is manufactured according to the customer’s needs and based on a large availability of accessories.

TURRETS.

Production process without intermediate stops. Automatic reel splice at high speed.

MOTORS WITH ‘VECTORIAL’ DRIVES.

High performance powerful motors controlled by regenerative vector drives.

SUPERVISION.

The electronic system is managed by a powerful computer, which provides complete Supervision functions and is interfaced with a “user-friendly” touch screen.

Nordmeccanica Triplex SL One Shot

Triplex laminator for solventless adhesives equipped with shaftless, single position reel change or with automatic splicing with particularly contained dimensions: the only machine in the world able to laminate with solventless adhesives three layers in a single passage, with a perfect control of pressure, temperature and web tension during the production process.

Nip.

Variable position of the lamination nip for stepless regulation of the infeed angle.

Solventless No-Limits.

The unique Nordmeccanica “Solventless” coating process.

Powerful motors.

Reliable and powerful motors, controlled by the latest generation electronic vectorial drives.

Rewinder.

New lay-on roller design for improved rewinding performances.

Automatic reel change.

Turret non-stop reel-stands are also available on request.

Supervision.

The electronic system is controlled by a powerful computer, which provides complete Supervision functions and is interfaced with a “user-friendly” touch screen.

Triplex laminator for solventless adhesives.

The machine is equipped with a coating unit patented by Nordmeccanica.

The technology of this unit guarantees the extreme simplicity of operation and the most constant coating weight even during speed ramp.

Tension control throughout the machine is highly accurate.

The quality of components and the raw materials used in the manufacturing are at the maximum technological levels.

Each machine is manufactured according to the customer’s needs and based on a large availability of accessories.

Nordmeccanica World Mixer SL

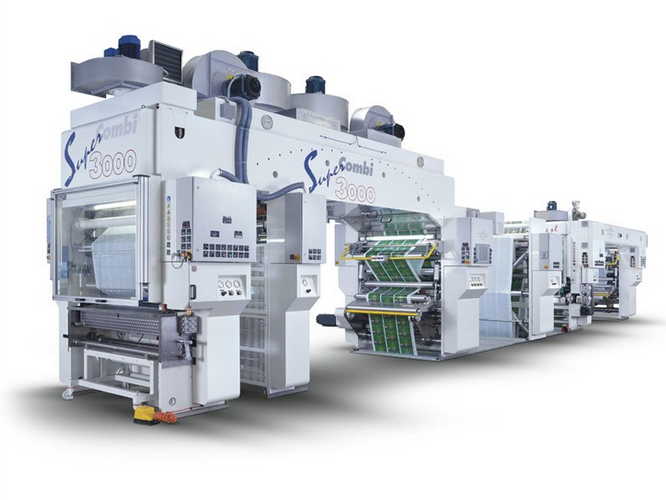

Nordmeccanica Super Combi 5000

An unmatched machine design that evolves at an even higher level.

In the new SUPER COMBI 5000 productivity is fuelled by a combination of reliability, know-how, simplicity, high tech, quality, quick set up, ease of handling.

Increased production speed is functional to an harmonic growth of machine specifications to include structure, mechanics electrics and electronics. The machine offers a wide range of options that allow a variety of productive configurations for coating and laminating: Solvent-less; Solvent-based; Water-based; UV; EB; One colour printing; Water/Solvent-based lacquering; In register coating on pre-printed rolls.

Nordmeccanica Super Combi 5000 Wet

Nordmeccanica Super Combi 5000 Matic

Nordmeccanica Super Combi 5000 Heavy Duty

Nordmeccanica Super Combi 5000 Tandem with Super Simplex SL

Nordmeccanica Super Combi 5000 Tandem with Super Combi 5000

Nordmeccanica Duplex Combi Linear

Nordmeccanica Duplex Combi Horizontal

Nordmeccanica Triplex Combi Horizontal

SOMA OPTIMA2

Print decks 8

Print Width 880/1050/1270/1450mm

Repeat Length 300/330/360/400 up to 800mm

Design speed 400/500/600m/min

Printing Inks Solvent/ Water-based

SOMA S_MOUNT

Print Length − up to 1250mm

Operation − manual/ semi-auto/ fully auto

SOMA FLEXMONT

Print lengths − 250-800/ 300-1300 mm

Cameras/ Monitors − 2

Magnification <100 x

Mounting & Positioning − manual

SOMA Optima1

Print decks 8

Print Width 620/880/1050mm

Repeat Length 240/260/330/up to 650mm

Design speed 350m/min

Printing Inks Solvent/ Water-based/ UV/ UV LED

SOMA OPTIMA2 10C/ 8CL

Print decks 10 or (8)

Print Width 1050/1270/1450mm

Repeat Length 300/360/400 up to 800mm (1300)mm

Design speed 400/500/600m/min

Roll diam 800/1000/1300/1500mm

Printing Inks Solvent/ Water-based/ UV/ UV-LED Ultra technology · SOMA (soma-eng.com)

SOMA PLUTO III.2

Design speed 650m/min

Rewind diam 650mm

Slit width 35/25mm

Unwind diam 1000mm

Parent roll weight 1200kg

SOMA VENUS III

Design speed 800m/min

Rewind diam 820mm

Slit width 35/25mm

Unwind diam 1300/1500mm

Parent roll weight 1500/2000kg

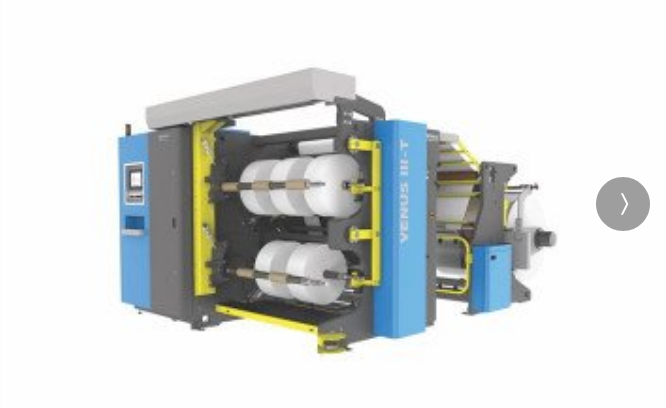

SOMA VENUS III.T

Design speed 800m/min

Rewind diam 635mm

Slit width 35/25mm

Unwind diam 1300/1500mm

Parent roll weight 1500/2000kg

SOMA BULLDOG

Roll diam 450mm

Strokes/min 250

Feed 15-150mm steps

About us

Our agency partners are Nordmeccanica and SOMA, and we work closely with them to deliver exceptional quality products that are durable, professional and efficient. We employ a team of dedicated specialists who will work with clients to ensure that their needs are being met. We offer an extensive range of flexographic presses, coaters, laminators, metallizers and slitter rewinders.

Widely recognised on a global scale for our impressive product range as well as our outstanding customer service, our company has gained an excellent reputation over the years. We represent market leaders and forward thinkers all over the world by catering primarily to the converting and flexible packaging sector. We strive for excellence here at Redfern and pride ourselves on our ability to exceed the expectations of customers.

We facilitate the sale of used equipment as this can provide space for new purchases. Contact our team for more information.

Images