Company details for:

Richards Engineering Leeds Ltd

Unit 10,

Wortley Moor Lane,

Leeds,

West Yorkshire,

LS12 4HX,

United Kingdom

Quick Links:

Products / Services

Engineering Services

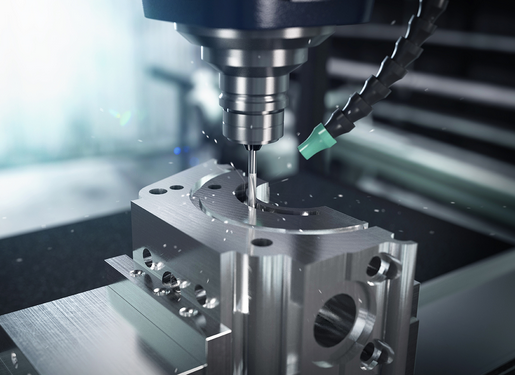

CNC Milling Including 4th Axis

CNC Turning

CAD-CAM Services

Milling Services

Turning Services

Sawing Services

Drilling Services

Broaching Services

Engineering Machinery

Doosan DNM 650 with Nikken 4th Axis

Doosan DNM 5700

Matchmaker VMC 1000

Dugard Lunan 500A

CNC Lathes:

Doosan Puma GT2100

Mazak Quickturn 28

Mazak Quickturn 10

Hyundia HiT 28

Mori Seiki SL-35

Milling:

Birdgeport Verticle Miller

Elliot Sturdimill horizontal miller

Lathes:

Colchester Triumph

Colchester Master

Colchester Mastiff

Measuring:

Mitutoyo Co-ordinate Measuring Machine 600 x 200 x 400

Sawing:

Super Brown 300 cut off saw

Qualters and Smith automatic band saw

Slotting:

Butler 8” Toolroom Slotter.

About us

We are a family-owned business, founded in 1947 and located in Leeds. We offer top-quality precision engineering services across a wide range of industries, including oil, valves, food packaging, motor production, furniture, shop fitting, and more.

At Richards Engineering, our expert team of engineers provides a broad array of services, from traditional milling and turning to advanced CNC machinery, CAD CAM design, and reverse engineering with CMM technology.

Our Services Include:

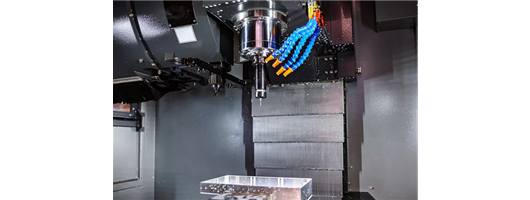

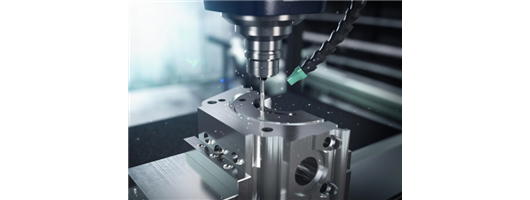

CNC Milling Including 4th Axis

By integrating a 4th axis, which allows rotation of the workpiece around a secondary axis, this advanced process enables the creation of intricate shapes and features that would be difficult or impossible to achieve with standard 3-axis milling. This added functionality improves efficiency, reduces setup time, and increases machining accuracy, making it ideal for producing detailed components with high geometric complexity.

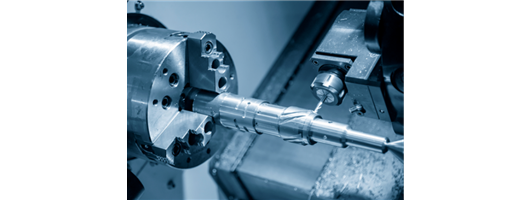

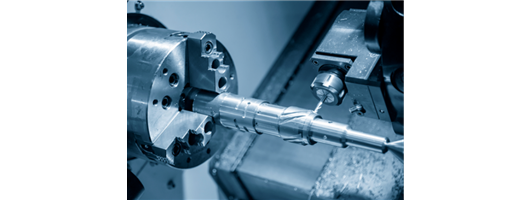

CNC Turning

This technique is ideal for producing cylindrical parts with tight tolerances and smooth finishes, including shafts, bushings, and gears. CNC turning allows for high repeatability and accuracy, making it perfect for both small batch runs and high-volume production.

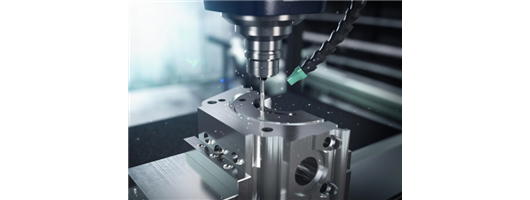

CAD-CAM Services

CAD-CAM services are essential for industries that require complex parts with high precision, such as aerospace, automotive, and medical devices. By utilising these technologies, manufacturers can optimise designs, reduce errors, and ensure high-quality outcomes for both prototype and production runs.

Sawing Services

Sawing is commonly used for applications requiring straight cuts, such as cutting bars, tubes, or plates into smaller sections for further processing. Whether for one-off components or large production volumes, sawing services are crucial in industries such as manufacturing, construction, and engineering, offering cost-effective solutions that ensure high precision and fast turnaround times.

Drilling Services

Whether for simple pilot holes or complex multi-stage drilling operations, drilling services provide versatile solutions for both prototype and production runs. With the ability to handle small to large batches, these services ensure efficient and cost-effective manufacturing with minimal downtime.

… And more.

In today's market, our customers demand complete traceability of material specifications and non-destructive testing. Therefore, we work exclusively with suppliers who can provide materials that meet our rigorous quality standards, certified to ISO 9001:2015.

Our customers span various industries, from components for the oil and motor sectors to the repair and maintenance of original parts for kitchen and bedroom manufacturers. We work with customers' drawings or samples to meet any application, whether for one-off or batch production.

We provide a fully traceable, quality-assured service, sourcing materials only from suppliers who can provide the necessary documentation and test certificates. This ensures that we meet our customers' requirements and maintain full compliance.

Images