Company details for:

Robinson Pattern Equipment Ltd

Rabone Lane,

Smethwick,

Warley,

West Midlands,

B66 3JH,

United Kingdom

Quick Links:

Products / Services

Core Competences

Complex Assembly Fixtures for all industries with Poka yoke capabilities where required

Computer Aided Design and Manufacture (we can take Catia, Iges Step and other proprietary formats)

Computer Aided Inspection and Measurement Facilities

Resin & Composite tooling

General and precision Engineering

Spray Metal Tooling and Models

Vacuum Forming Tools

Foam Mould Tools

Assembly Fixtures

Trim Fixtures

Checking Fixtures

Architectural Patterns and Castings

On Site Tooling Repair/Maintenance Service

Rapid Prototyping Service

Computer Aided and traditional modelmaking

Turnkey Projects and Project Management

Prototype Parts

Autoclave tools

Re production of classic car parts/Mould tools

Resin moulded parts

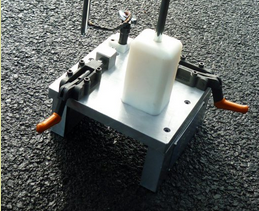

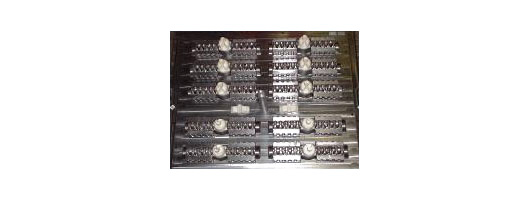

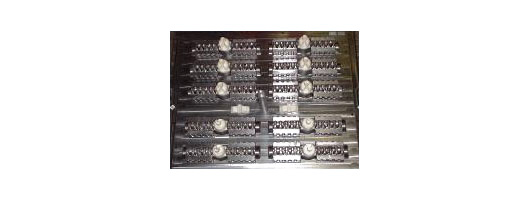

Jigs, Fixtures & Nests

•Trim and pierce and router fixtures

•Assembly and checking Fixtures

•Welding and Machining Fixtures

•Fixtures with gauging and Statistical Process Control capabilities

•Jigs with Poka Yoke capabilities to check the presence or absence of parts to ensure that the final part is correct before delivery to the customer, with PLC control if required.

•Vacuum Fixtures for mounting parts on water jet and router cutters

Fixture & Models

Trim and pierce and router fixtures

Assembly and checking Fixtures

Welding and Machining Fixtures

Fixtures with gauging and Statistical Process Control capabilities

Fixtures with Poka Yoke capabilities to check the presence or absence of parts to ensure that the final part is correct before delivery to the customer.

Vacuum Fixtures for mounting parts on water jet and router cutters

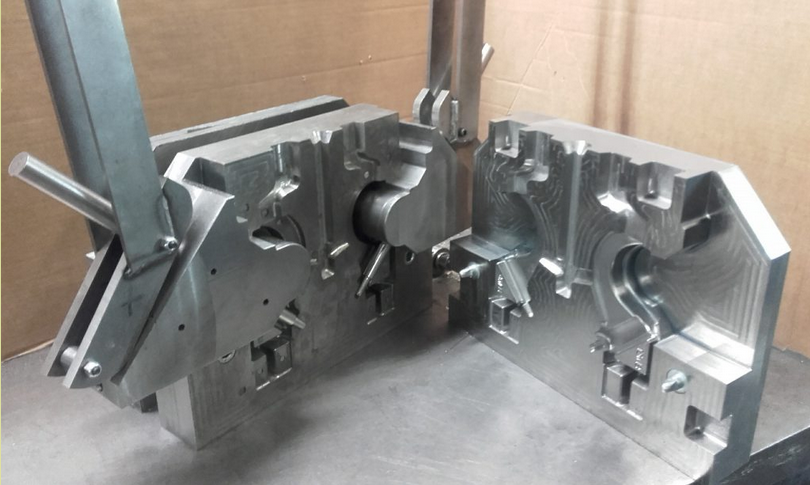

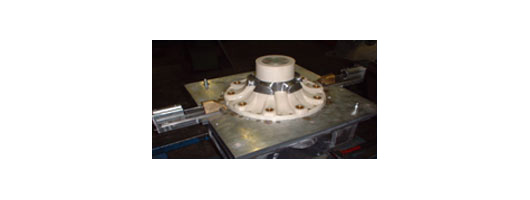

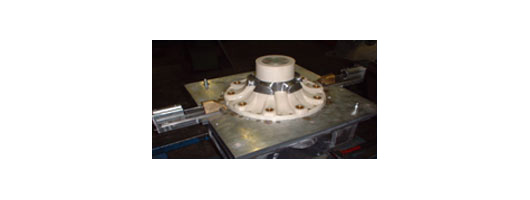

Mould & Vacuum Form Tools

We can also make short run mould tools for prototype parts

For industries as diverse as packaging, automotive etc.

Vacuum forming tools can be made for forming complex 3D forms in resins or aluminium or for blister packs as used in the packaging industries.

Mould Tools for the composites industries incorporating heating/cooling channels suitable for autoclaves etc

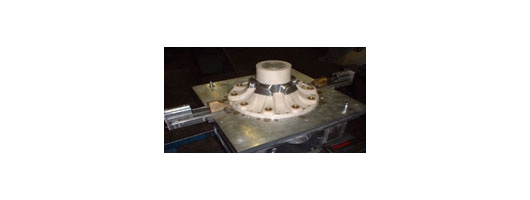

Composite Parts & Castings

Parts can be manufactured using conventional pattern making and fully machined castings.

Spray metal tooling technologies for producing parts or moulds

Digitising and then creating CAD surfaces from existing parts to make new or modified parts.

Resins can be cast in various forms e.g. hard, soft etc. to create prototype or small batch parts.

We can also supply castings in various materials either cast or fully machined.

We can also supply composite mouldings and RTM mouldings

Re production of Classic car parts via digitizing and making new mould/vac tools

Prototyping & Rapid Parts

• Parts can be manufactured using conventional pattern making and fully machined castings.

• Spray metal tooling technologies for producing parts or moulds

• Digitising and then creating CAD surfaces from existing parts to make new or modified parts.

• Resins can be cast in various forms e.g. hard, soft etc. to create prototype or small batch parts.

• We can also supply castings in various materials either cast or fully machined.

• We can also supply composite mouldings and RTM mouldings

• Re production of Classic car parts via digitizing and making new mould/vac tools

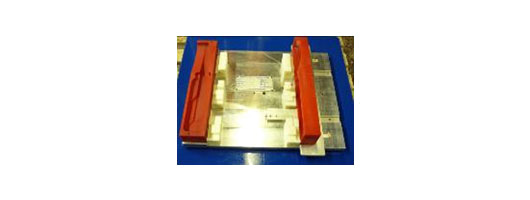

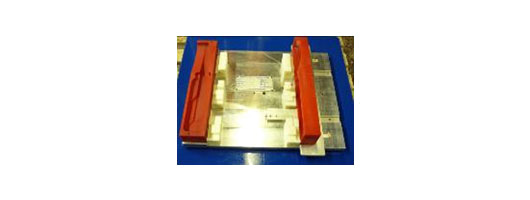

Machined Parts & Assemblies

We can then build these up into assemblies with hydraulics, pneumatics PLC control etc.

We can wood turn up to 2.00 meters diameter

Foundry Patterns

For the following Processes:-

Shell mould, Disa matic, Green Sand, Hot box and cold box in the following materials:-

Wood, Cast epoxy resin, Polyurethane, Spray Metal, Aluminium, Tool Steel and Cast Iron and also for high and low volume production.

Foundry Core Boxes

In the following materials:-

Wood, Epoxy, Polyurethane, Spray Metal, Aluminium and Cast Iron and tool steel for wear parts.

With loose pieces and core lifting assisters, manually and pneumatically operated to aid the core making process.

Gravity Dies

About us

Robinson Pattern Equipment Ltd has 45 years of experience in traditional pattern making, providing a comprehensive service to the foundry industry, as well as technical engineering services to all sorts of businesses.

Facilities include CAD services, composite tooling, general engineering, vacuum forming tools, trim fixtures, rapid prototyping and much more.

Fixture & Models: Router fixtures, assembly and checking fixtures, welding and machining fixtures and various other fixtures with specific capabilities and features.

Mould & Vacuum Form Tools: For various industries we manufacture mould tools in materials such as aluminium, steel and many more with additional options available.

Composite Parts, Castings, Prototyping and Rapid Parts: Made using fully machined castings, spray metal tooling technology, CAD surfaces, with castings available in many materials and forms.

Machined Parts & Assemblies: CNC machining to 1500x700 available, can be built up into assemblies with PLC control, hydraulics, etc.

Foundry Patterns: For processes such as shell mould, hot box, cold box and so on, made from materials such as wood, resin, aluminium, cast iron and more.

Foundry Core Boxes: Available in wood, spray metal, polyurethane and many other materials with manual and pneumatic operated loose pieces and core lifting assisters to help the core making process.

Efficiency, top of the range technology and product, cost effectiveness and dedication to quality in both product and customer service, Robinson Pattern Equipment is the right choice. Contact us for more details.

Images

Articles / Press Releases

Reviews

Trade Associations