Company details for:

Scantron Industrial Products Ltd

Monarch Centre,

Venture Way,

Priorswood Industrial Estate,

Taunton,

Somerset,

TA2 8DE,

United Kingdom

Quick Links:

Products / Services

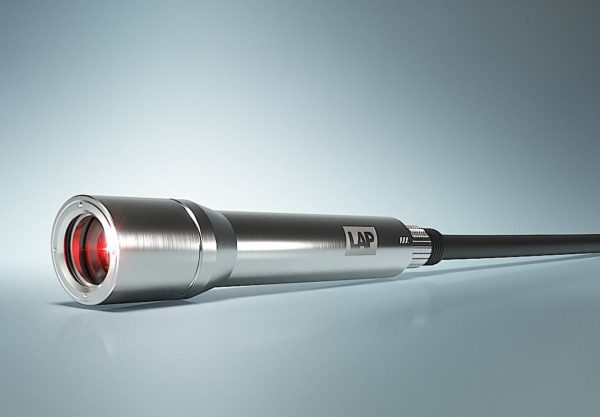

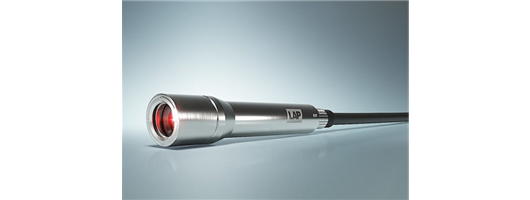

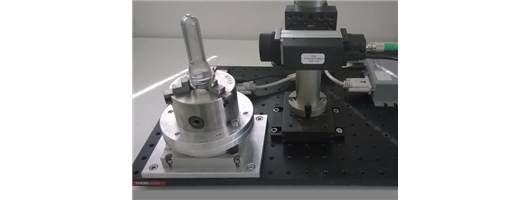

Laser Triangulation Displacement Sensors

The laser triangulation sensors can be used to measure soft, sticky or hot surfaces as well as other sensitive surfaces that require the utmost care to maintain quality. Optical measurement is independent of the material, which ensures that there will be no influence of chemical or material properties, colour or reflectivity, owing to the excellent dynamic behaviour of the sensors.

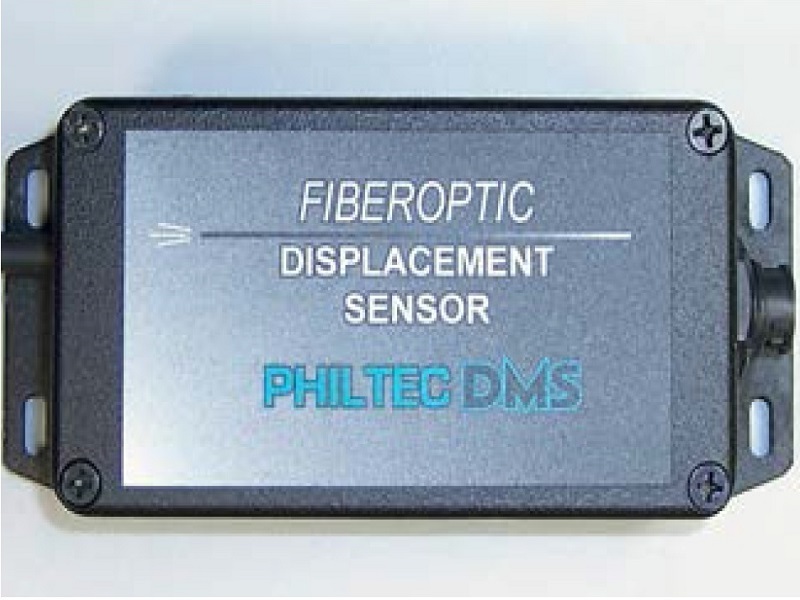

Fibre Optic Displacement Sensors

These are retro-reflective optical devices that use sensors with bundled glass or quartz fibres that transmit light to targeted surfaces and in return also receive light from such surfaces. The intensity of the reflected light is then processed to identify and provide the distance between the sensor tip and targeted surface. They are designed to be robust and withstand extreme temperatures without fail while also operating at a high frequency capacity up to 200 kHz.

Laser Phase Shift

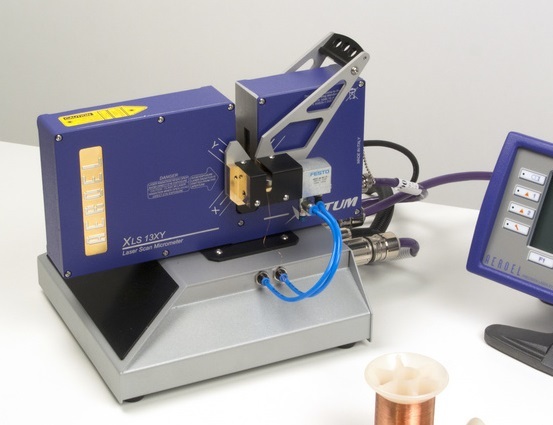

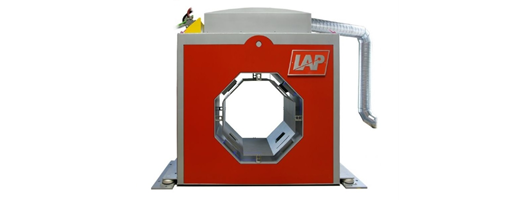

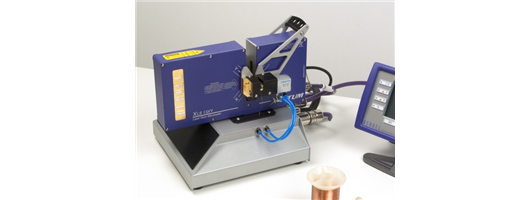

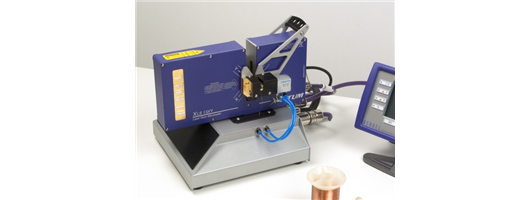

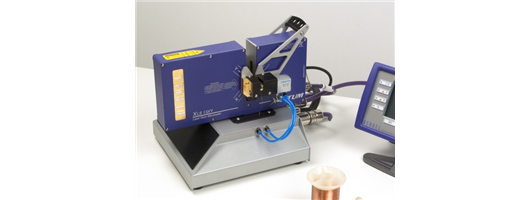

Laser Micrometers

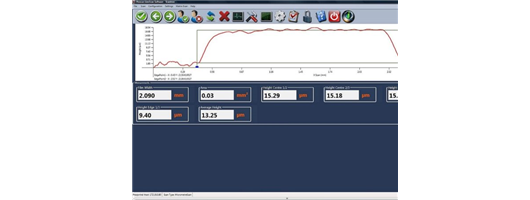

Aeroel’s line of Xactum laser micrometers is our preferred choice thanks to its industry-leading repeatability and warranty length. Every gauge features Aeroel’s patented ‘NO-VAR’ active thermal compensation which ensures correct diameter measurement in any condition, as well as built-in references to further guarantee enduring performance and remove the need to remaster the gauge for varying product size.

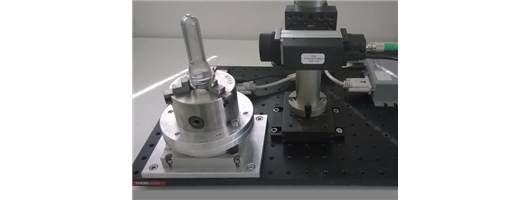

Offline Tube & Sheet Measurement

Transparent, semi-transparent and soft materials can be difficult to quality check and control. Scantron can offer non-contact sensors and standalone benchtop systems. These allow for quick and easy laboratory quality control and certification to be performed across a number of products within the laboratory environment.

Flat & Multi-Layered Materials

With a 1.8 − 4 mm measurement range, our flat multi-layered materials non-contact surface measurement systems come with easy to use software and have a number of applications.

The thickness of transparent or semi-transparent polymer sheets and membranes can be measured online using state-of-the-art interferometric technology with a single point sensor, a multi-track system, or scanning sensors. It is even possible to measure the thickness of complex multilayer materials and thin films, such as those used for food packaging purposes, diffusion barriers, protective wrapping, or medical films.

Plastic, Rubber & Glass Tube

Offline Laser Micrometers

As an industry-leader in this field, the product can provide the highest level of repeatability and accuracy, something that is crucial when working to fine tolerances. All of this is complemented by a built-in calibration cycle to ensure consistent performance.

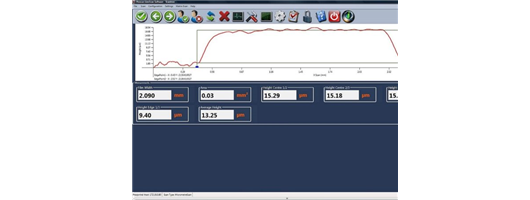

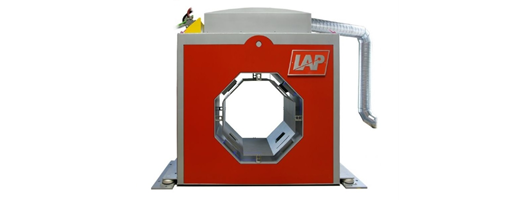

Online Laser Micrometers

Some of the additional accessories include: product guides for alignment of wire or cable in the measurement range of the gauge; air purge protection to prevent ingress of dust or oil; cleaning rings to remove light emulsion or moisture from the bar prior to measurement; frames for added stability; and warning or traffic lights to signal quickly to the operator that the production is out of tolerance or at a pre-alarm stage.

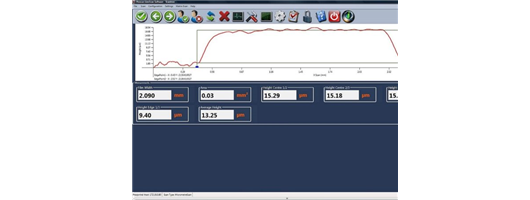

Hot Metal

Gauges have been equipped with intelligent software that contributes to their ability to identify, classify and acknowledge specific defects in production or rolling and is designed to alert operators to act fast to solve such production issues before they result in product scrappage. Diagnosable rolling defects include roller offset, shift, eccentricity, over and under filling, partial fill, inhomogeneous material, varying temperature distribution, blisters, roll strands, cracks and broken out areas, scoring and symmetry control which could be considered out of square, out of hex or ovality.

Laser Speed & Length Measurement

FD Series Laser

HD Laser

In fact, diode lasers in the HD green series are designed to withstand day-to-day use in harsh industrial environments. Scantron supplies these lasers across many industrial applications, including for use in the automotive sector, metal production, tyres and the concrete industry.

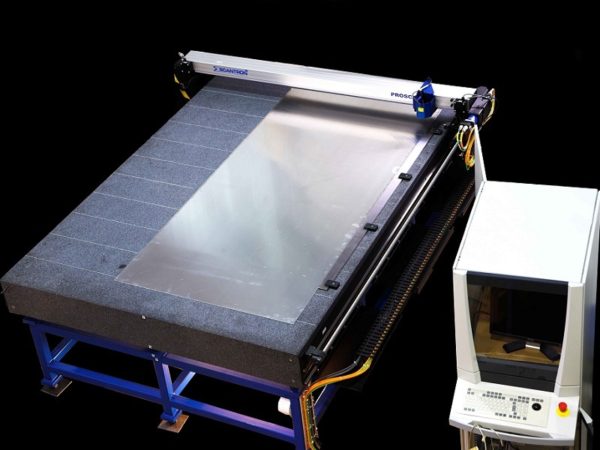

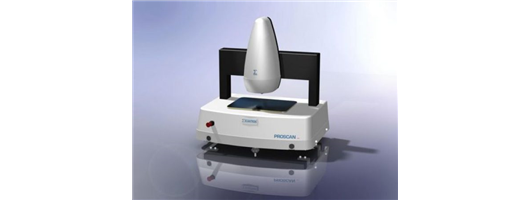

Proscan MasterTrak

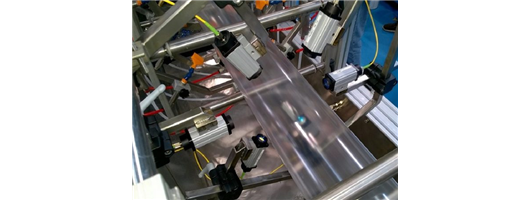

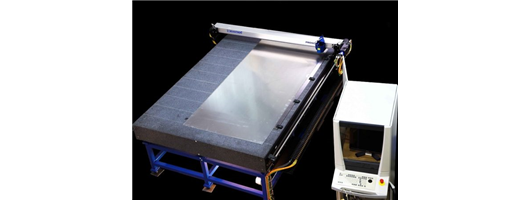

The Proscan MasterTrak uses a non-contact measurement technique to accurately measure the thickness or width profile of continuous or piece products as they are being produced. When used to measure thickness, the system can be supplied either to measure single or multiple points across the width of the product.

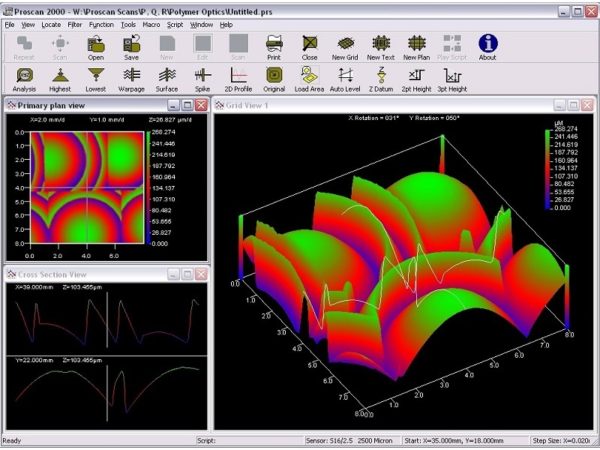

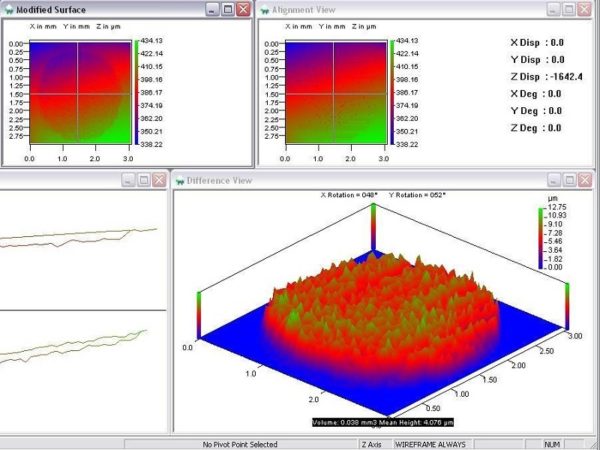

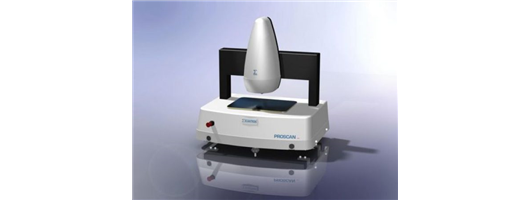

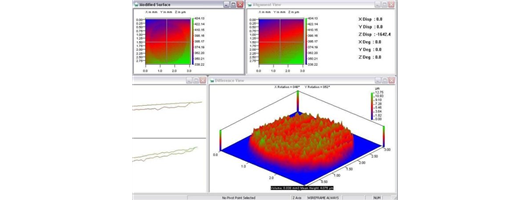

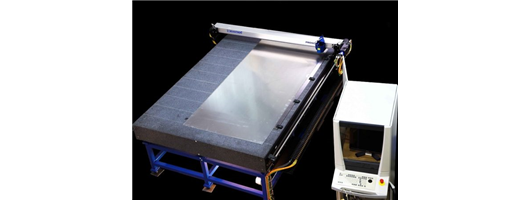

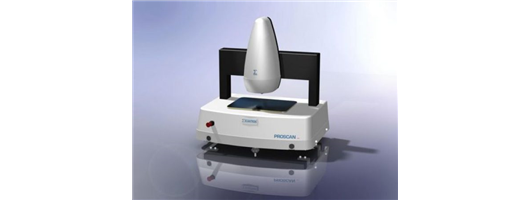

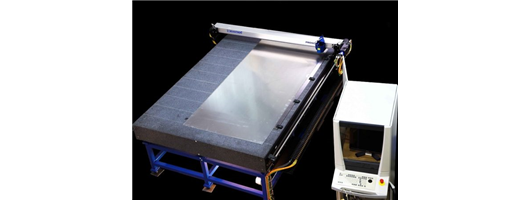

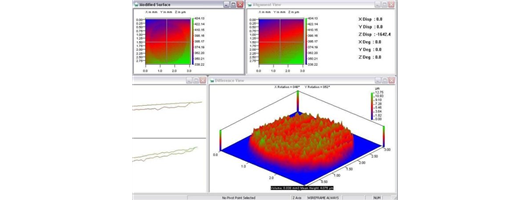

Proscan 2D Laser Profilometer

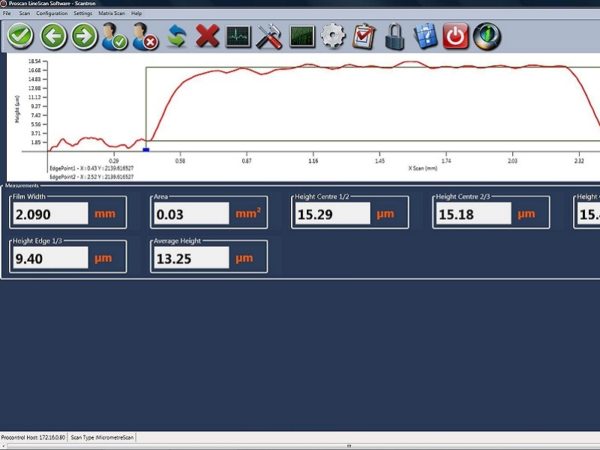

Developed by Scantron, the Proscan 2D is a popular solution with clients looking for a non-contact solution for offline sample inspection. It facilitates the measurement of roughness, flatness, shape, width, taper and bow on boards, panels and strip.

The Proscan 2D surface profilometer is an essential addition to any production environment where the analysis of a surface is critical to the performance, productivity or yield of the product.

LineScan Software

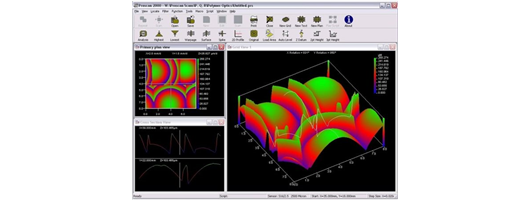

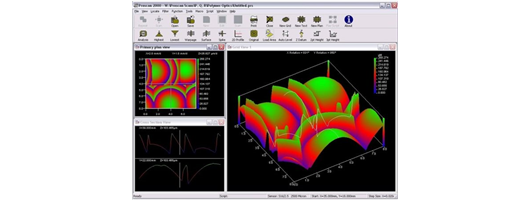

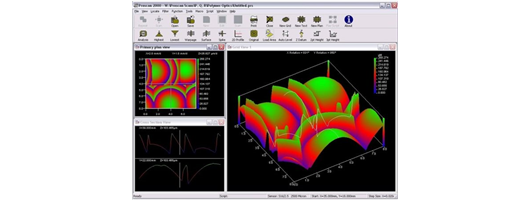

Proscan Software

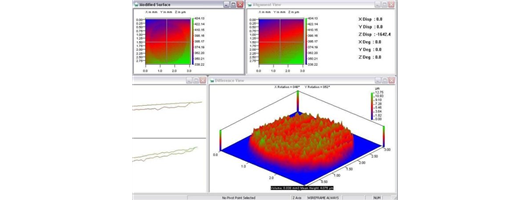

Proform Software

Proscan DDMS

Proscan Magnum

The Proscan Magnum accurately measures and quantifies the latent shape in the sample proving absolute values of wave heights, waves per meter and ‘I’ units. Offline measurement is the most accurate method of measuring shape as there is no tension or stress in the material during the measuring process. This makes the Proscan Magnum particularly suited for measuring thin gauge material with very high flatness specification such as lithographic aluminium coil. This system provides the user with full 2D & 3D mapping of the surface flatness.

About us

Based in Somerset, our company has over 35 years’ experience in the design and distribution of dimensional non-contact measurement systems that can be utilised for a variety of applications. We have installed countless offline and in-process systems over the years and continue to expand our services on a global scale.

Since establishment, we as a company have catered to a vast array of sectors including steel and metals, electronics, medical, dental research, aerospace, defence and the nuclear industry. We have also extended our services to various universities across the globe. We believe firmly in achieving the perfect solution, which is why we have decided to work closely with our customers in order to achieve excellent results every time.

Our main philosophy as a company is to combine our unique experience and knowledge with the knowledge presented by our customers, which has led to a significant boost in reputation.

Some of our main products here at Scantron include;

- Displacement / Distance Sensors

- Glass / Plastic Thickness Measurement

- Laser Micrometers

- Laser Speed & Length Measurement

- Line Lasers

- Measurement / Metrology Software

- Offline Precision Measurement

- Online Shape, Profile & Thickness Measurement

Images

Articles / Press Releases

Brochures

Trade Associations