Company details for:

SI Protech (UK) Ltd

Unit 20-23 Eldon Way,

Wick,

Littlehampton,

West Sussex,

BN17 7HE,

United Kingdom

Quick Links:

Products / Services

Manufacturing Services

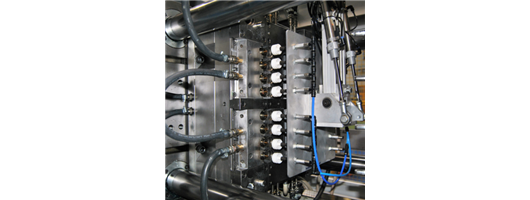

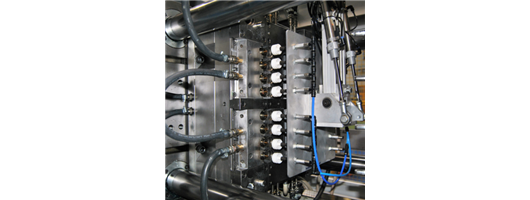

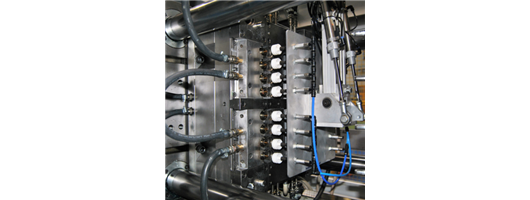

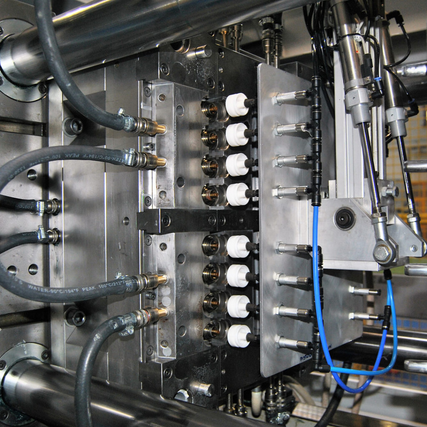

All machines include specialised ancillary injection moulding equipment such as moulds heaters, dryers, hot runner controllers, conveyors, sprue pickers, individual water chillers for optimum temperature control and various automated assembly equipment.

Additional Manufacturing Facilities

Automated assembly machinery

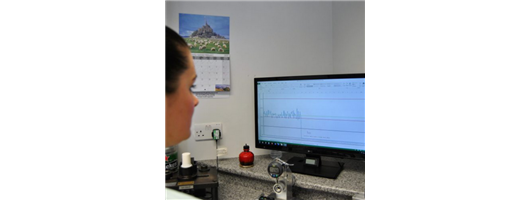

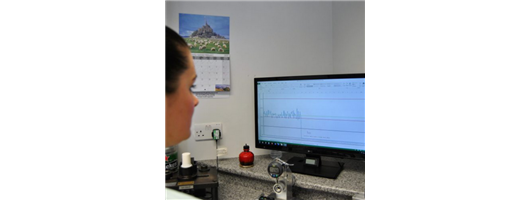

In-line inspection stations to verify the quality of parts and assemblies

Comprehensive Quality Assurance and Control Systems: online & offline

Detailed maintenance programs for machinery, process equipment and tooling

Research and Development facilities in UK and USA and Academic Research partners

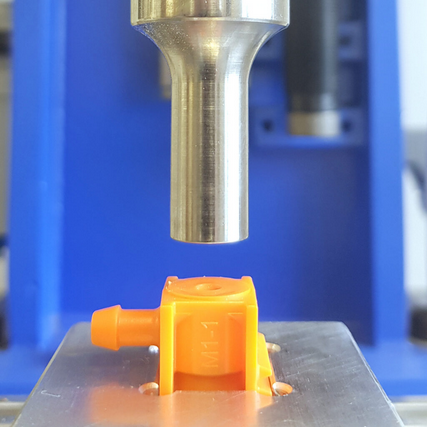

Design & Development Services

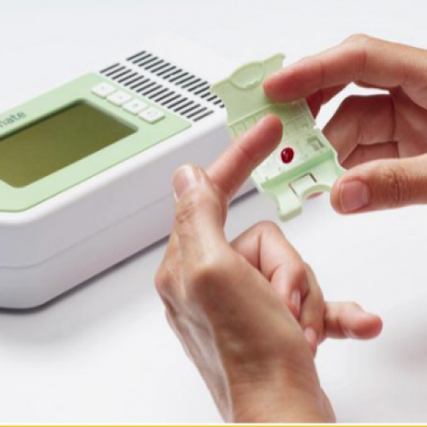

Our products feature predominantly in the Beverages, Consumer Goods, Cosmetic, Medical and Retail sectors. Our experience in these sectors allows us to understand and adapt to your unique requirements and expectations, and we provide the same professional service for high and low annual volumes.

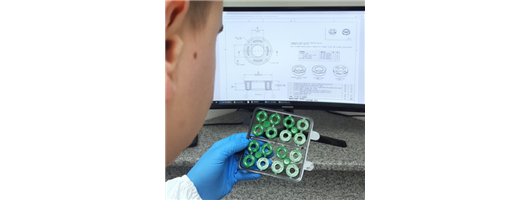

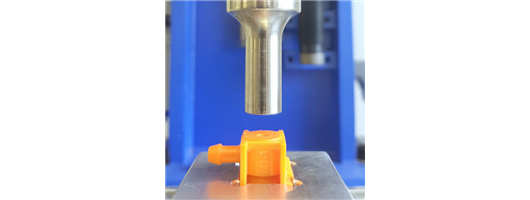

Additional Design & Development services

Material Consultancy

Project Feasibility studies

3D Component Design and Modelling

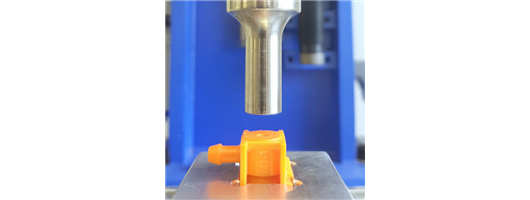

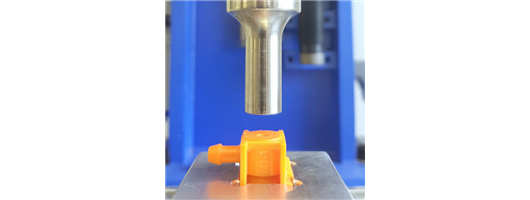

Fast Prototyping (SLA/3D Printing)

DFM (Design for Manufacture )

Pilot Tooling & Production for Market testing

Manufacturing Tool procurement (UK, Europe, China)

Project management

Product and Process validation using SPC

Injection Moulding Specialists

We serve some of the world’s most demanding customers. Our products feature predominantly in the automotive, beverages, consumer goods, cosmetic, electrical, medical and retail sectors. Our experience in these sectors allows us to understand and adapt to your unique requirements and expectations, and we provide the same professional service for high and low annual volumes.

IM Services

Insert and Over Moulding

Multi-material and Additive Injection Moulding

Co − Injection Moulding

Rapid-Prototype Injection Moulding

Manumould Injection Moulding

Auto & Manual Assembly

Welding & Printing

Components ranging from 1mm − 500mm

Shot weights ranging from 1 − 1000g

Knowledge Leaders in Plastics

Our flexible assembly operations provide a way to supply products to the market quickly, as well as reduce the up-front start-up costs associated with complex components. We can provide completed assemblies or sub-assemblies using a wide range of techniques.

We specialize in developing in-house assembly jigs and fixtures aimed at increasing your product quality and repeatability, whilst reducing operational costs.

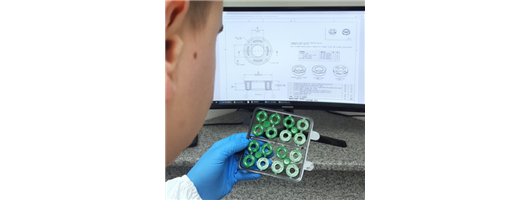

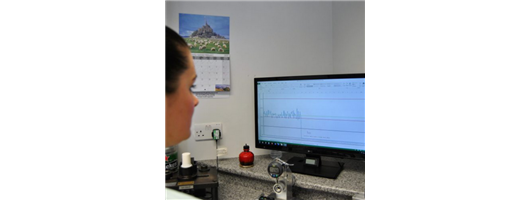

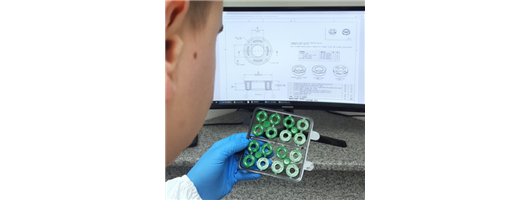

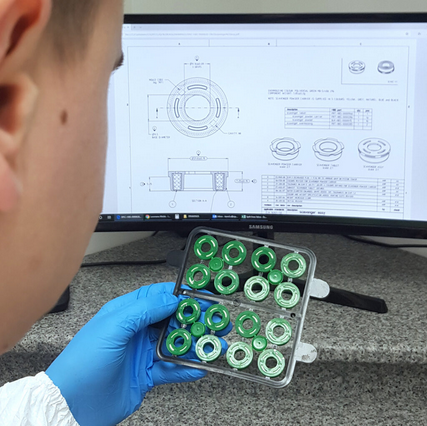

Quality Control Services

All of our Quality Systems are externally validated by the BSI (British Standards Institute to the international standards: ISO 9001 for Quality Management, ISO 14001 for Environmental Management and ISO 22000 Food /Drink Packaging Safety, Hygiene & Security Management.

Recycling & Waste Management

Comprehensive Recycling Programs: We have established robust recycling programs throughout our facilities to ensure the responsible disposal and reuse of materials.

Waste Reduction Strategies: Through continuous improvement and innovation, we actively seek ways to minimise waste generation at every stage of production.

Partnering for Sustainability: We collaborate with certified recycling partners to ensure that our waste materials are efficiently processed and diverted from landfills.

Sustainable Materials

We recognise the importance of using eco-friendly materials in our manufacturing processes. Our efforts include:

Selection of Sustainable Materials: We prioritise the use of recyclable and biodegradable materials whenever feasible, ensuring that our products are environmentally responsible from conception to completion.

Certified Eco-friendly Materials: We source materials from suppliers who adhere to rigorous environmental standards, verifying the sustainability credentials of each component used in our production.

Innovation in Material Science: We invest in research and development to explore alternative materials that offer improved environmental performance without compromising on quality or functionality.

About us

We possess vast experience in product development, mould tooling, plastic injection moulding, and final production. Our company caters to various industries, including Beverage, Pharmaceutical, Personal Products, and Automotive.

As a technical injection moulding company, we specialise in producing high-specification products and solutions. We offer expert guidance on material selection, production feasibility, mould design, packaging, and more during the critical product development phase.

Our Services Include:

Research & Innovation

Research and innovation are key to SI Protech, driving creative and sustainable solutions for our customers. Through generating new knowledge, research plays a vital role in developing innovative products, processes, and services that enhance our customers' productivity, competitiveness, and overall success.

Product Development

We provide development support for those with limited experience in thermoplastics, offering services such as IP reviews, 3D component design and modelling, rapid prototyping, and material consultancy.

Design & Development

SI Protech (UK) Ltd is your trusted partner for material selection, production feasibility, product design, mould manufacturing, assembly systems, and technical packaging solutions. We assist customers with established products, those needing improvement or replacement, as well as new projects for companies and developers.

Manufacturing

We run a 28,000 square ft. facility, operating 24/7, 5-7 days a week. This includes 'white room assembly' for food and beverage products. Our manufacturing approach focuses on prevention rather than detection, emphasizing the development of a reliable process from the start, which is then maintained throughout batch production.

Injection Moulding

We specialise in working with a variety of polymers, including Polypropylene, Polycarbonate, Nylon, LDPE/HDPE, PBT, ABS, PC, SAN, GPPS, TPE, TPU, POM, and others.

Quality Assurance & Control

Quality is fostered and enhanced internally through the use of Six Sigma and Lean methodologies. Additionally, all of our Quality Systems are externally certified by the BSI (British Standards Institute) to meet international standards, including ISO 9001 for Quality Management, ISO 14001 for Environmental Management, and ISO 22000 for Food and Drink Packaging Safety, Hygiene, and Security Management. SI Protech (UK) Ltd has established a strong reputation in the markets it serves.

SI Protech (UK) Ltd has built a great name within the markets it serves.

Widely recognised as an innovative and high-quality design, development, injection moulding, and assembly company in both multinational and UK market sectors.

Collaborating with numerous top companies, including Heineken, Anheuser-Busch InBev, Colep, Parker Hannifin, Honeywell, and others...

Got a project in mind? Reach out to us, and let's get started!

Images