Company details for:

Sovereign Labelling Machines Ltd

Unit 5,

Wild Close,

Oakwood Business Park,

Clacton-on-Sea,

Essex,

CO15 4BB,

United Kingdom

Quick Links:

Products / Services

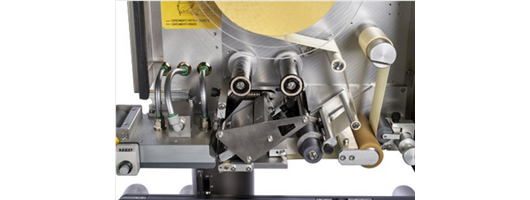

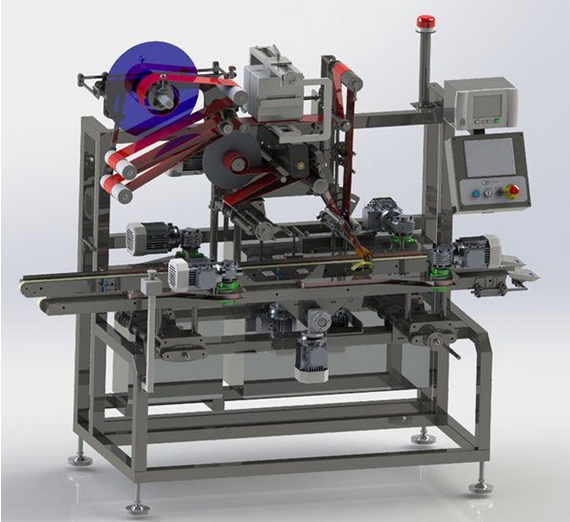

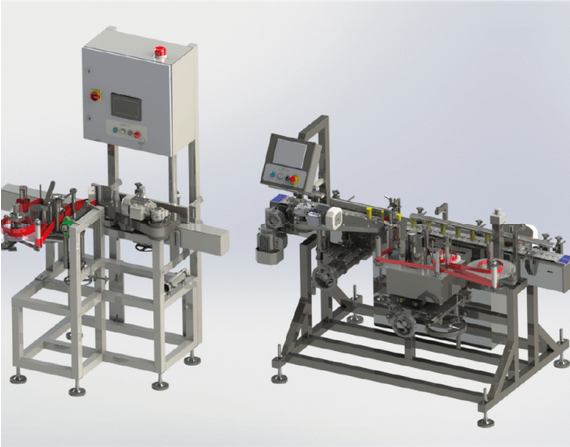

Labelling Machines

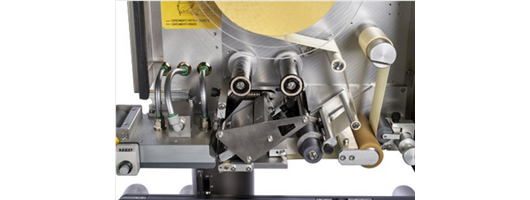

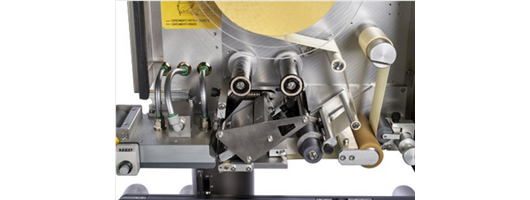

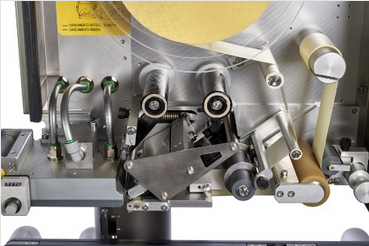

Sovereign Labelling manufactures a range from small units to complete production lines to apply any type of self-adhesive label to just about any product face in any orientation and configuration conceivable.

Our systems work to the highest degree of precision, speed, flexibility, security and hygiene. Our range of labelling machine add-ons allows us to completely adapt and tailor our machines to your specific needs. You can find your style of label below and find out which labelling machine is right for you.

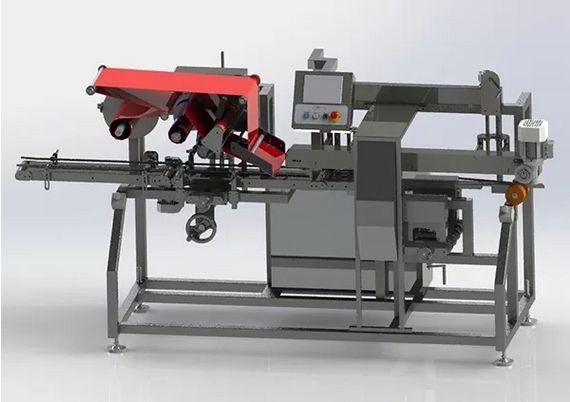

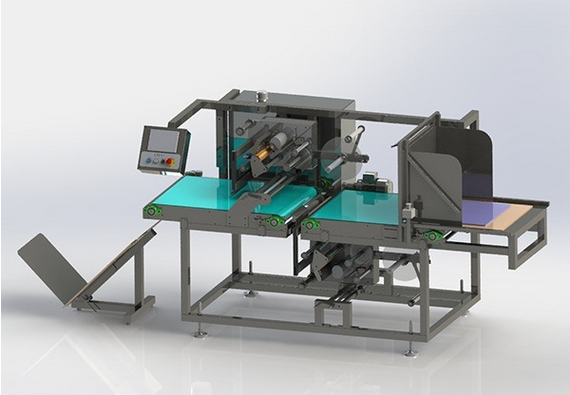

C Wrap Labeller

The C Wrap labeller is an extremely popular range of machines. The quality of the packaging is so important in the ready meals, salads, prepared products and confectionery sectors. Fact !… a perfectly good product will remain rejected on a supermarket shelf because of a creased or poorly applied label.

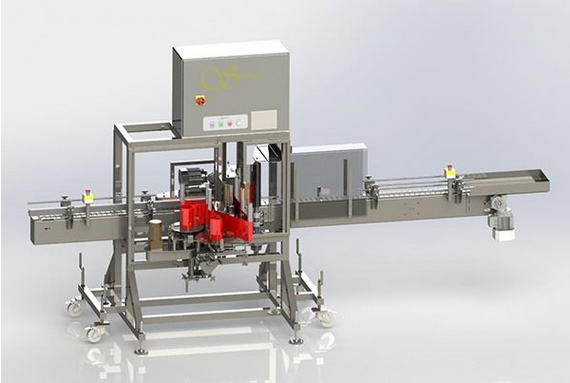

Round Bottle Labeller

The round bottle labeller range is offered in standard build and Monarch (extreme environment) versions. A single long label is applied and wrapped around the entire circumference of the predominantly circular product. The result is 360° product decoration.

Tamper Labeller

This tamper-proof labelling machine model serves to apply a narrow label attached to the lid and body of a product. Clearly, to open the product the label must be broken and so tamper-evidence is achieved.

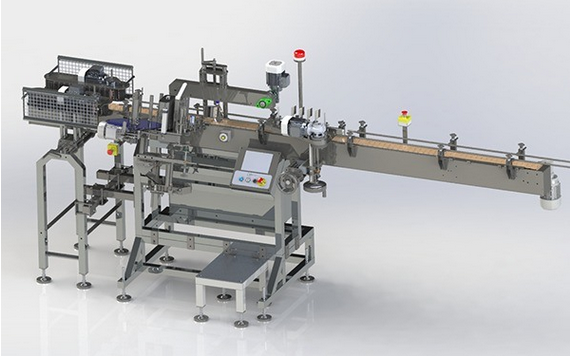

Front & Back with Wrap Labeller

Top & Base Labeller

The Top & Base labelling machine can be used to apply labels to a variety of different surfaces to a variety of products. Sovereign are the only UK manufacturer of Stainless Steel Labelling machinery, Pick and place feeders and Shrink Sleeve application machinery. This fact is pivotal in the choice of machinery that is ‘fit for purpose.

Corner Labeller

The corner labelling machine is a specialised system for over-labelling pre-printed flat-pack cartons. A pivotal tool in the operation of large volume ‘special offer’ campaigns. Used to be that reduced cost offers were simply to encourage the sale of near dated fresh produce. Nowadays ‘buy one get one free offer are often huge volume pre-planned and managed campaigns.

Also used for adding additional or corrective information labels such as alternative languages, barcode, vignette (pharmaceutical), tactile safety information (triangle), or money off voucher labels.

Watch Strap Labeller

The watch strap labelling machine applies labels to a variety of different surface, including, but not limited to, fresh produce, salads, ready meals and confectionery.

Taper Neck Labeller

Modular Add-ons Available

To this basic machine, we can supply multiple modular add-ons. For instance, an additional label applicator and special wipe-down to attach and position a tamper-evident label to the cap and body… or a form of product spacing devices, such as a scroll or spacing wheel.

Cosmetics Labeller

Flat Carton Labeller

Ready meals

Meat packs

Fruit and vegetable trays

Direct application to fruit and veg

Where this machine differs from all others is the fact that it can apply labels to undulating, sloped, curved, spherical surfaces. And to top it all… the labels can be applied to the top of the pack at any angle/orientation regardless of their orientation on the backing web.

Milk Bottle Labeller

All stainless steel construction.

300 bottle per minute

No bug traps (open design to suit wash down).

Designed specifically for the dairy industry.

0-90 metres per minute web speed (tested to 240 metres per minute web speed, 600 PPM delivery speed).

Consistent and constant product pitching device.

Designed and manufactured for minimal service requirements.

Software compatible with coders and scanners, and configurable to suit customers’ specific requirements.

Single or twin heads with auto change over.

Extremely simple to operate.

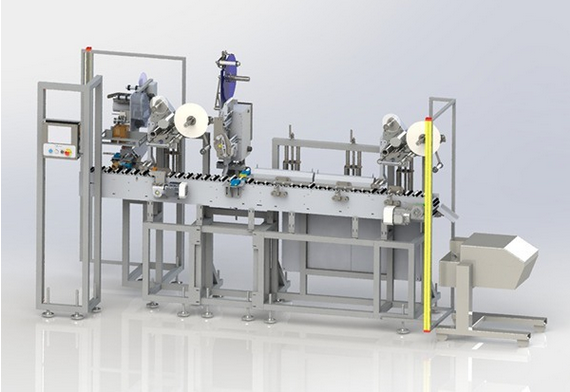

Pharmaceutical Outsert Labeller

Outserts are folded paper leaflets usually associated with pharmaceutical drug information. They attach directly to a container using an adhesive, applied during the delivery cycle. The resultant container/leaflet assembly alleviates the need for any further packaging and is therefore environmentally beneficial.

The requirement for large amounts of pharmaceutical information has resulted in the size of outserts steadily increasing and this trend will continue. Sovereign Labelling has addressed and resolved all the shortcomings currently associated with the processing of the folded paper outserts size, adhesive application and accurate placement onto products.

Paint Can Labeller

Tri Roller Full Wrap & Patch System

Sleeving Machines

Sovereign offers a number of variations of sleeve labelling machines, including heat shrink tamper-proofing, full-body product labelling and stretch sleeve labelling. Our systems work to the highest degree of precision, speed, flexibility, security and hygiene. Our range of machinery and add-ons allows you to fully customise your build to suit your products’ needs. All our systems are built of a stainless steel frame and are compact and simple in their design, making them reliable, hygienic and easy to use.

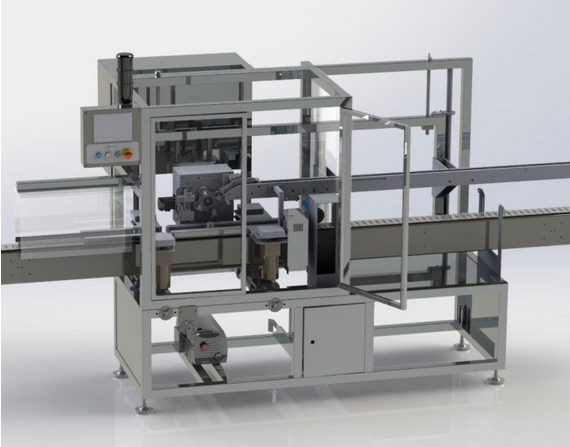

Heat Shrink Sleever

The tamper neckband system applies a heat shrink sleeve to the lid and neck of the product meaning it must be removed to open. This anti-theft application protects your product leaving you with peace of mind.

Full Body Sleever

Stretch Sleever

The Sovereign stretch sleever is of stainless steel construction, designed for round, square and rectangular containers to operate at up to 20 placements per minute. Individual sleeves are separated from a layflat roll by breaking apart perforations between sleeves. The sleeve is then stretch open and lowered over the product forming a close semi-permanent fit around it. The mechanism to apply the sleeve is servo-controlled to precisely position it on the product, while a touch screen interface is provided to make operational adjustments and to display the current machine status. Audio/visual low and end of film alarms, as well as multiple-machine monitoring facilities, are also fitted as standard. The unit is supplied with fully interlocked guarding to comply with current regulations

Conveyors

We offer a wide range of new and used conveyor belts that provide proven solutions in corrugated, automotive, food and packaging applications as well as bakery, meat, snack food and vegetable preparation. Our conveying systems are ergonomically designed, fulfilling all manual handling requirements. We have modular belts available for drying, proving, cooling, chilling or freezing applications.

Our specialist team of engineers are also on standby to carry out conveyor servicing and repairs, which guarantees your conveyor systems are kept in the best condition possible.

Stock Machinery: New & Used

Pre-owned/stock sleeving machines

Pre-owned/stock labelling machines

and plenty more

At Sovereign Labelling, we boast the best of new and pre-owned machines, all of which come with ‘The Sovereign Standard’, meaning they have been subject to the most rigorous and meticulous testing and quality checks possible. So, this gives you the peace of mind that even our pre-used machines still meet our high standards of engineering and are, therefore, built to last.

Pre-Owned Machines

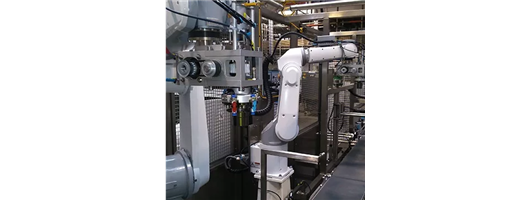

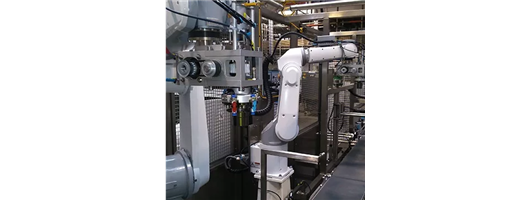

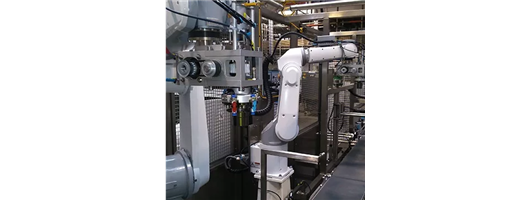

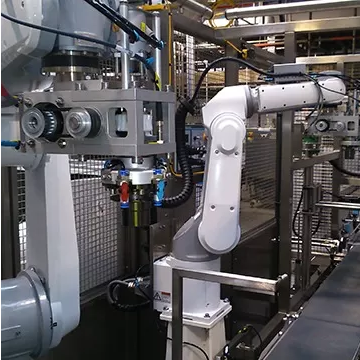

Robotic Handling

We have used both SCARA and 6-AXIS robots for loading/unloading product or using the robots to orientate and present difficult to handle components to the labelling system.

Each robotic machines is fully integrated into the machine control system making setup and change-overs both quick and exact.

Maintenance is a huge part in making such a big purchase so not only do we build some of the most advanced robotic handling machines in the business; we also provide robotic handling machine repairs and servicing to help keep the machines in tip-top condition so you never get left behind.

Get in touch and find yours today by speaking to one of our engineering specialists.

Sovereign Check Weigher

Selecta automatically weighs all the products on the production line, rejecting those falling outside the established limits and indicating the irregularities.

Sovereign Weigh Price Labeller

The weigh price labeller is an automatic industrial system that allows to:

Weigh with a variable weight, print and apply labels on products

Check that products respect the pre-requisites in terms of weight tolerance, for use with preset weight

Manage both preset weight and variable-weight products according to the set weight ranges

Manage and print labels of cartons and pallets

About us

Since joining the ENE Group in 2018, Sovereign has expanded its capabilities and expertise. Our custom labelling machinery is produced at our advanced facility in Banbridge, Northern Ireland, outfitted with cutting-edge CNC laser cutting, milling, turning, and punching equipment. Additionally, we have a top-notch stainless-steel fabrication facility that exemplifies bespoke engineering. This enables us to offer clients a wide range of solutions for all production line requirements, encompassing conveying, labelling, sleeving, and robotic handling, tailored to individual units or complete customised production lines.

We also offer fully customised conveyor systems and conveyor belting through our affiliated companies within the ENE Group.

Our Products Include:

Labelling Machines

Sovereign Labelling produces a variety of machinery, from individual units to entire production lines, capable of applying self-adhesive labels to virtually any product surface, regardless of orientation or configuration. Our systems are engineered for utmost precision, speed, flexibility, security, and hygiene standards. With a range of add-ons available for our labelling machines, we can fully customise and tailor them to meet your unique requirements. Explore our selection of label styles below to determine the perfect labelling machine for your needs.

Sleeving Machines

Sovereign provides several types of sleeve labelling machines, such as heat shrink tamper-proofing, full-body product labelling, and stretch sleeve labelling. Our systems are engineered for top-notch precision, speed, flexibility, security, and hygiene. With a variety of machinery options and add-ons available, you can fully tailor your setup to match your product requirements. All our systems feature stainless steel frames and are designed to be compact and straightforward, ensuring reliability, hygiene, and ease of use.

Conveyors

Drawing on extensive engineering expertise in conveying and automated handling, our Sovereign conveyors are custom-crafted, produced, and installed to optimise product flow and enhance workload efficiency. Our end-of-line conveyors are tailored to complement all your conveying needs. We offer a diverse selection of new and pre-owned conveyor belts that deliver proven performance across a range of industries, including corrugated, automotive, food and packaging, bakery, meat, snack food, and vegetable preparation. Our conveying systems are designed with ergonomics in mind, meeting manual handling requirements. We also provide modular belts for various applications such as drying, proving, cooling, chilling, or freezing. Additionally, our dedicated team of engineers is available for prompt conveyor servicing and repairs, ensuring your conveyor systems remain in optimal condition.

Robotic Handling Systems

With extensive expertise in automated robotic handling, Sovereign Labelling serves as a TOSHIBA Robot integrating partner, having successfully installed numerous systems worldwide. We utilise both SCARA and 6-AXIS robots for tasks such as loading/unloading products or orienting and presenting challenging components to the labelling system. Each robotic machine is seamlessly integrated into the control system of the machine, ensuring swift and precise setup and changeovers. Recognising the significance of maintenance in safeguarding such substantial investments, we not only engineer some of the most advanced robotic handling machines in the industry but also offer repair and servicing for robotic handling machines, ensuring they remain in optimal condition and keeping you ahead of the curve.

Check Weighers

Crafted and engineered for manufacturing environments characterised by elevated humidity levels or requiring frequent sanitisation. Selecta automatically assesses the weight of all items on the production line, dismissing those that deviate from predetermined parameters and signalling any irregularities detected.

Weigh Price Labellers

Galaxi represents the contemporary series of weigh-price labelling systems designed specifically for the food industry. Featuring an AISI304 stainless steel framework and conveyor belts equipped with a rapid-release system, it facilitates effortless cleaning and maintenance procedures.

All of our machinery is produced at our facility in Banbridge, Northern Ireland, outfitted with state-of-the-art CNC laser cutting, milling, turning, and punching equipment. Additionally, we have one of the most exceptional stainless-steel fabrication facilities in the nation, enabling us to offer clients a comprehensive range that encompasses everything from individual units to fully customised production lines.

We manufacture all of our machinery at our facility in Banbridge, Northern Ireland, which is equipped with advanced CNC laser cutting, milling, turning, and punching machinery. Moreover, our outstanding stainless-steel fabrication facility allows us to provide clients with a diverse range of options, from standalone units to tailor-made production lines.

Alongside our labelling and sleeving systems, we provide a comprehensive selection of Conveyors, Conveyor Belting, and Components that comply with FDA and HACCP standards.

Images