Company details for:

Spraylat International

Quick Links:

Products / Services

Aerospace Coatings

Protectapeel® is the ideal solution for protecting aircraft as it is liquid applied. Simply spray or roll-on, Protectapeel® is perfect for the curved and uneven surfaces of the aircraft.

The protective coating dries to form a secure bond that will not lose adhesion −providing the ultimate aircraft protection for up to 24 months internally and up to 12 months externally.

When required, simply hand peel the protective coating away revealing clean and undamaged surfaces. The coating is condensed down into a small ball and can either be disposed of as domestic waste or returned to Spraylat International for recycling.

Aircraft Preservation

The Protectapeel® preservation system prevents corrosion and damage to the aircraft and paintwork. Simply apply by spray or roller directly to the surface.

When required, the temporary peelable coating is simply removed by hand peeling. Protectapeel® preservation system is a water-based, environmentally friendly coating. It can either be disposed of as domestic waste or returned to Spraylat for recycling.

Anti-Rust Coatings

Applied as a liquid by spray or roller, the Anti-Rust protective coating is ideal for uneven shapes and surfaces. Protectapeel® Anti-Rust dries to form a skin-tight bond. Through development trials, Protectapeel® Anti-Rust achieves zero flash rust.

The peelable protective coating is simply removed by hand, the coating is then condensed into a small ball and disposed of as non-hazardous waste. Or you can return it to Spraylat for recycling.

Protectapeel® Anti-Rust offers the best possible protection to most metal surfaces.

Automotive Coatings

Save time cutting to size by using Protectapeel® - a liquid-applied coating. Simply applied by spray or roller, Protectapeel® peelable protective coating is ideal for a quick solution to curved/uneven surface protection.

Protectapeel® protective coating is an environmentally-friendly coating that is simple to remove by hand peeling. Effortlessly condensed into a small ball, Protectapeel® is disposed of as domestic waste or can be returned for recycling.

Construction Coatings

Our liquid-applied, peelable, protective coating dries to form a skin-tight barrier. Applied as a liquid, Protectapeel® makes protecting curved/uneven surfaces effortless.

Protectapeel® provides the following protection during construction;

- Scratching protection

- Dust, dirt & debris protection

- Paint overspray protection

- Mortar protection

- Weathering protection

Before project handover, Protectapeel® peelable protective coating is simply removed by hand peeling. Surfaces are clean and damage-free preventing delays due to additional cleaning & replacements.

Protectapeel® is an environmentally friendly protective coating. Once removed the peelable coating is condensed into a small ball and disposed of as non-hazardous waste. Or you can return it to Spraylat International for recycling.

Custom Coatings

Spraylat International Ltd is the world leader in peelable coating technology. We can produce specific, bespoke products to suit your needs. (Subject to volume and requirements).

Spraylat International Ltd develops and controls the formulation of all new products in-house. We do occasionally consult with local universities that assist with specific projects.

If you have a unique or specific requirement that our range of coatings does not meet, contact us we can help.

Things To Consider;

What are your protection requirements?

Which surface(s) are you protecting?

How long does the coating need to protect for?

Do you need a permanent or temporary protective coating?

Do you have an existing formulation or do you require one to be formulated?

What volume is required?

What size packaging would you require?

Engineering Coatings

Liquid applied, protective, peelable coatings for preventing damage, rust and corrosion. Protectapeel® provides the best temporary surface protection for stainless steel, bare steel and other metals from damage during storage, fabrication, painting and despatch.

Protectapeel® will protect surfaces from damage such as weld spatter, flash rusting, abrasion, staining, dirt, saltwater and weathering.

Protectapeel® protective coating adheres to the surface via surface tension which means that it is simple to remove by hand peeling.

Protectapeel® is also Environmentally Smart, once removed the peelable coating is condensed into a small ball and disposed of as non-hazardous waste.

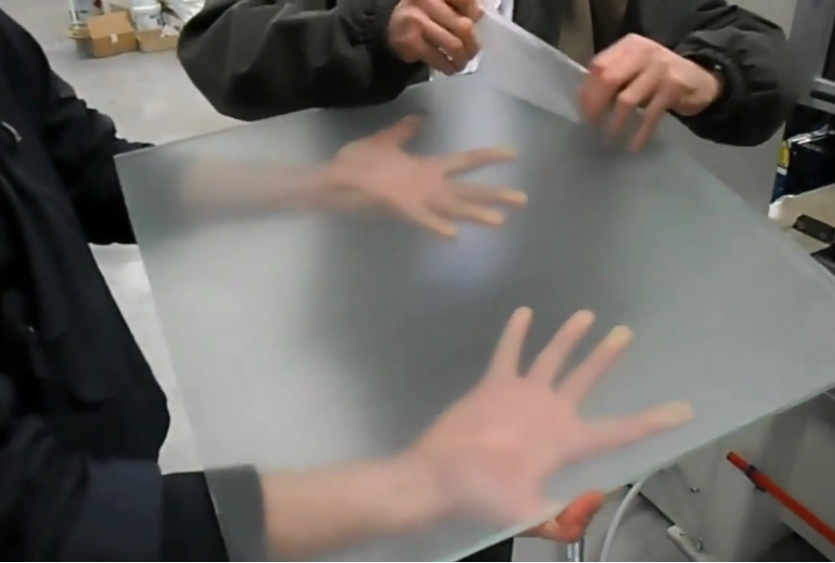

Glass & Window Coatings

Our spray-on window protection film will prevent the need to repair or replace glass and windows.

Applied as a liquid, the spray-on window protection film dries to form a skin-tight bond. Curved/uneven surfaces are protected easily, without the need of cutting to size.

Glass and windows can be protected during manufacture, storage, transportation & installation.

Protectapeel® glass protection spray will protect glass and frames from;

- Dirt

- Damage

- Weathering

- UV attack

Protectapeel® peelable glass protection is simple to remove by hand peeling. Once peeled, the glass is clean and damage-free, preventing delays and disputes.

As an environmentally-friendly coating, Protectapeel® can be disposed of as domestic waste or returned for recycling.

Hotpeel Coatings

Protectapeel® Hotpeel is a peelable protective coating supplied in pellets and is applied by a roller coater directly onto the surface. Protectapeel® Hotpeel cures in 3-5 seconds providing instant protection.

The equipment can be integrated into the production line. Enabling manufacturers to protect their products without affecting production cycle times.

Providing protection for glass, metal and other flat, non-porous surfaces against damage during;

- Manufacture

- Transportation

- Storage

- Installation

When required, Protectapeel® Hotpeel is quickly removed by hand peeling, revealing clean and undamaged surfaces.

Marine Coatings

Besides providing protection, Protectapeel® will also reduce the need for cleaning.

Protectapeel® is easy to apply by roller or airless spray. There is no need to cut or trim the coating to size, eliminating extra work and wasted material.

The skin-tight protective film will prevent damage for up to 12 months from;

- Saltwater

- UV rays

- Weathering

- High winds

- Staining

- Paint overspray

- Scratching

- Dirt

Protectapeel® peelable coating provides outstanding protection both internally and externally. When required the environmentally friendly protective coating is simply peeled away by hand.

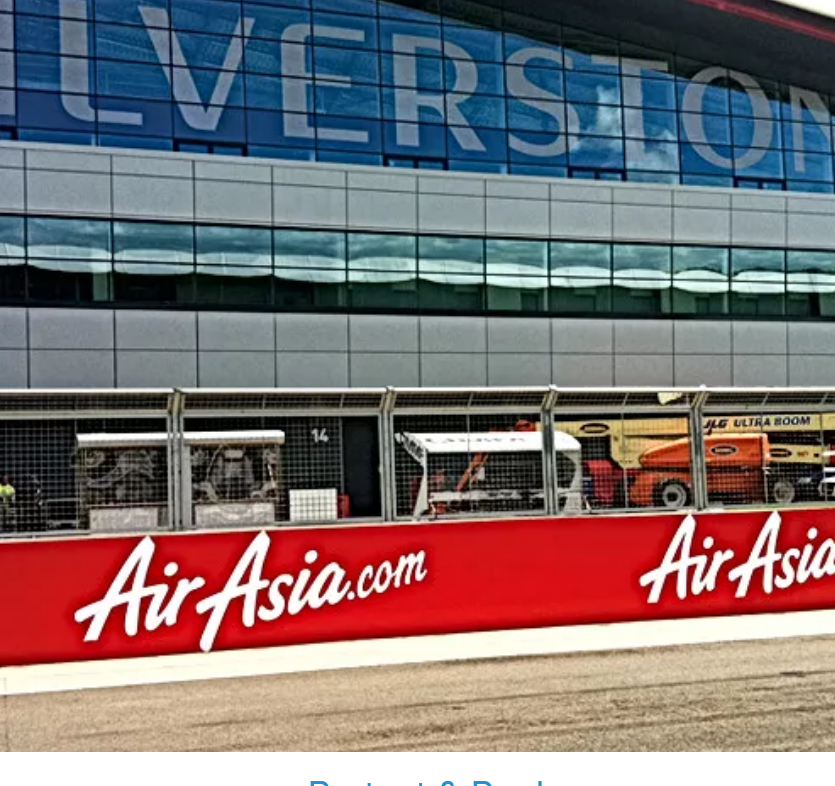

Sign & Studio Coatings

Protectapeel® is a liquid applied peelable coating that can be applied to any non-porous surface. It dries to form a tough protective layer that not only provides an attractive look but also offers protection against damage.

Protectapeel® has been used on;

- Silverstone Racetrack

- The Olympic Games

- Soccer World Cup

- Euro 96

- Euro 2000

- Rugby World Cup

- QVC UK

- Channel 4 Television Corporation

- BBC Television Centre

Protectapeel® peelable coating adheres to the surface via surface tension meaning it is simple to remove by hand peeling. The coating is also environmentally smart, once removed it is condensed into a small ball and disposed of as non-hazardous waste.

Spray Booth Coatings

No matter the size or shape of the surface Protectapeel® offers a smart protective solution. Easily apply Protectapeel® to your spray booth by airless spray or roller. There is no need to cut to size, no offcuts and no wastage.

Protectapeel® protective coating is used to protect against damage such as overspray and contamination from;

- Spray booth walls

- Spray booth floors

- Work surfaces

Protectapeel® can be applied onto surfaces such as;

- Plastic

- Aluminium

- Stainless steel

- Glass

- Painted surfaces

Once dry, Protectapeel® forms a skintight bond with the surface guaranteeing your spray booth is protected. The coating can withstand temperatures of up to 80°C and has a reflective surface for better working conditions.

The Protectapeel® peelable coating can be overcoated several times, and when required simply hand peel to reveal a clean and undamaged spray booth.

Storage & Preservation Coatings

Unlike traditional methods of protection such as films, Protectapeel® is applied as a liquid directly onto the surface, using either an airless spray gun, roller or dip - making it an ideal way to protect small, intricate components and complex shapes.

The material will dry to form a skin-tight film that protects the surface from damage for up to 12 months.

Protectapeel® peelable protective coating protects from;

- Abrasion Protection

- Acid Rain Protection

- Corrosion Protection

- Flash Rusting Protection

- Grinding Spark Protection

- Paint Overspray Protection

- Rust Protection

- Salt Water Protection

- Scratching Protection

- Shot Blasting Protection

- Weathering Protection

- Weld Spatter Protection

Protectapeel® is quickly removed by hand peeling when required.

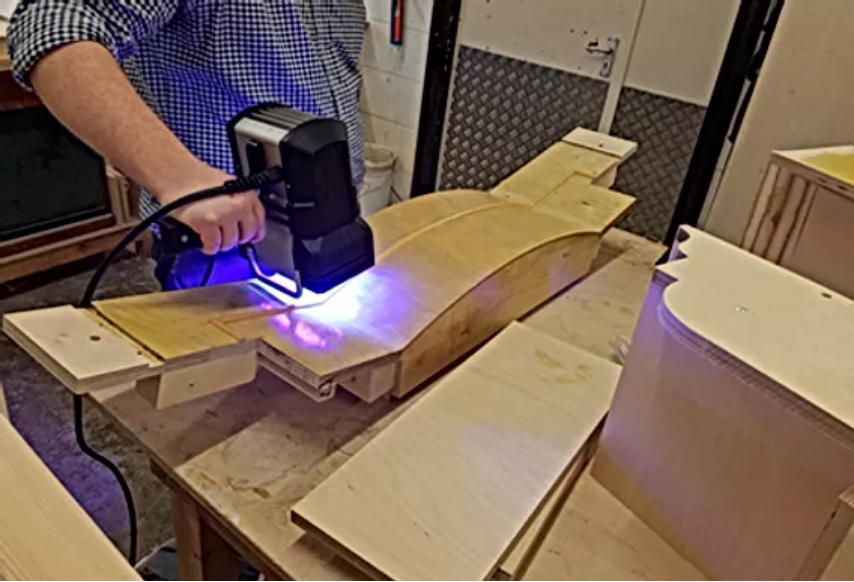

UV Cure Coatings

Photocure is a UV-curing peelable protective coating that can be applied by spray, roller or brush. The coating forms a skin-tight protective layer, preventing damage to flat, shaped or uneven surfaces.

There is no need to wait for the coating to dry as Photocure cures immediately under a UV lamp. Surfaces can be stacked, as Photocure is tack-free, reducing processing time & saving space.

Photocure can be implemented in any continuous flow manufacturing line. Providing protection for frames, cills, glass and other non-porous surfaces on the production line. Photocure can remain on the surface through storage, transportation and installation.

The peelable coating is easily removed by hand, condensed down & disposed of as domestic waste.

About us

With over 30 years’ experience within the liquid applied peelable coatings industry, Spraylat International, also commonly referred to as Protectapeel, are widely recognised for providing high-end products and solutions that have been utilised across multiple sectors.

Since 1992, our company has delivered exceptional service both nationally and internationally, catering for a vast array of industries including aerospace, aircraft preservation, automotive, chemical milling, construction, house building, engineering, glass and window protection, marine, signage, storage and various others.

Here at Spraylat, we pride ourselves on our range of easy and fast to apply coatings that form skin-tight protection across all projects, no matter how big or small. Our solutions are perfect for uneven shapes and surfaces and will result in no further cleaning expenses. Offering 12 months external protection and 24 months internal protection, we as a company can guarantee a service that is reliable, effective and professional.

Protectapeel is used and trusted on a global scale, benefitting countless clients who have praised our services for almost three decades. Our liquid-applied protective coating dries to form a tough protective film, which is achieved through advanced technology.

We at Spraylat have continued to expand our services by discovering new and innovative solutions that have been thoroughly tested to ensure maximum quality. Our team of professional coating experts have enough knowledge and experience to provide demonstrations, samples and application training for all clients, as well as regular visits to ensure that customers are receiving the very best from their solution.

We have catered for a vast array of well-known brands over the years, some of which include Yuanda Group, Bae Systems, Cammell Laird, BBC, Doosan and Ardmore. We understand that temporary surface protection is absolutely essential and are dedicated to providing exactly that.

Images