Company details for:

Standish Engineering Co Ltd

Mayflower Works,

Bradley Lane,

Standish,

Wigan,

Lancashire,

WN6 0XF,

United Kingdom

Quick Links:

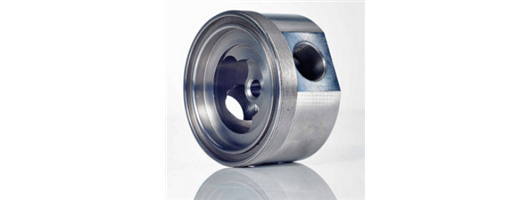

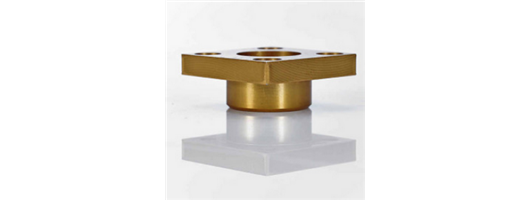

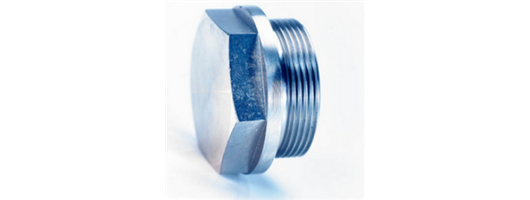

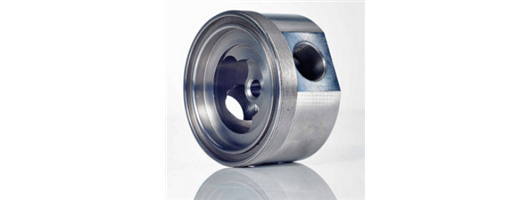

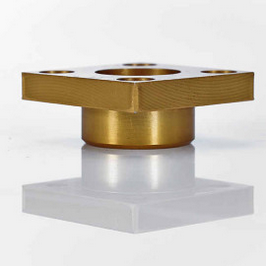

Products / Services

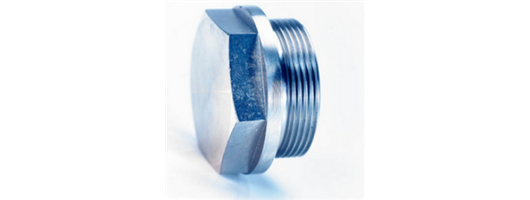

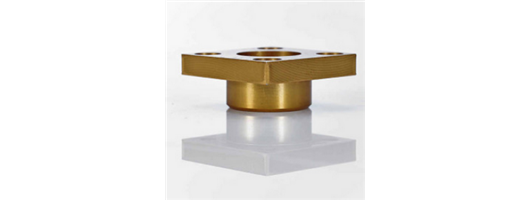

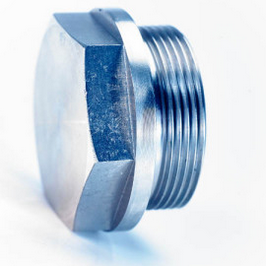

Subcontract Machining

The combination of precision engineering skill, state of the art machinery and the total flexibility of our workforce ensure that we have the ability to fulfil your requirements.

Precision CNC Machining Experts

Batch Quantity Production Specialists

High-Volume CNC Bar Fed Lathes

Advanced CNC Chuck Lathes for Large Parts

Full 5-Axis Machining Capabilities

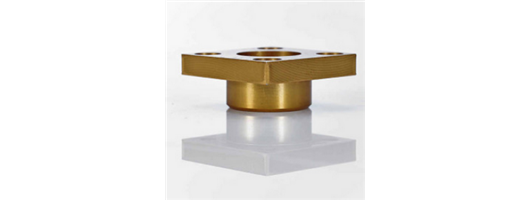

Expert Machining in Stainless Steel & Aluminium

Specialists in Exotic Alloys: Super Duplex, Inconel®, Monel®, Hastelloy®

ISO9001 Compliant Machining Services

RISQS Verified Engineering Solutions

Rapid Quote Turnaround

Timely Delivery of Machined Parts

Flexible Workforce for Customised Needs

State-of-the-Art Machining Technology

Family-Run Precision Engineering Since 1950

Comprehensive Subcontract Machining Support

Complex Parts Machining Within Tolerance

Global Supply Network: UK, Europe, America, Canada, Far East

Expertise in High-Precision Engineering

Investment in Modern Machining Equipment

Versatile Machining Solutions

Experienced in High-Tolerance Machining

Flexible Production Capabilities for Diverse Requirements

Dedicated to Exceptional Service Standards

Outstanding Customer Service & Relationship Building

About us

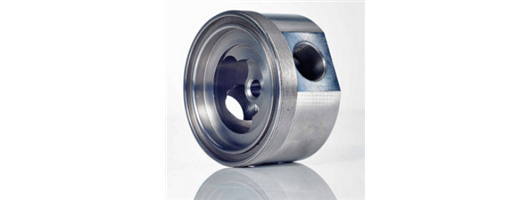

We combine the latest precision engineering equipment with a highly skilled workforce to handle both large-scale projects and custom prototypes. Our services cater to clients across the UK, Europe, America, Canada, and the Far East, specialising in producing batch quantities for a diverse range of industries.

Notable clients include British Rail, GE Oil & Gas, and the NHS, showcasing our capability to deliver high-quality components for some of the most demanding sectors.

Our expertise spans a variety of precision engineering methods, including CNC turning, grinding, machining, and milling. We serve industries such as pharmaceuticals, aerospace, and automotive, providing components that are both cost-effective and of superior quality. Our commitment to utilising state-of-the-art technology and adhering to stringent quality standards ensures that every project is executed with precision and efficiency. We take pride in our ability to quickly and effectively meet diverse requirements, delivering products that consistently meet or exceed client expectations.

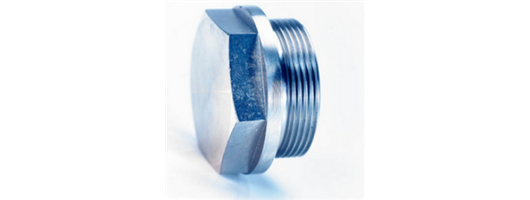

At Standish Engineering, we uphold rigorous quality control measures, supported by our ISO 9001:2015 and RISQS certifications. Our quality management system guarantees the accuracy and durability of every part we produce, with each component undergoing thorough inspection.

Our employees receive extensive training in quality control, machining techniques, and health and safety, ensuring that we maintain the highest standards throughout the engineering process. By focusing on cost, quality, and timely delivery, we provide a comprehensive precision engineering service from design to delivery, reinforcing our reputation as a trusted partner in the industry.

Images