Company details for:

Summit Process Cooling

Quick Links:

Products / Services

Small − Medium Duty Air Cooled Chillers

- Cooling capacities 1 − 130 kW

- Internal water pump & tank

- Non ferrous water circuits

- Close Temperature Control

- Ozone friendly refrigerant

- High pressure pumps

- Indoor/Outdoor version

- Energy Saving

High Duty Air Cooled & Water Cooled Chillers

Standard & Low Noise available

Indoor installation

Semi-hermetic Screw Compressors

Shell & Tube Condenser Coils

Double Passage Hydraulic Circuit

Expansion Vale

Shell & Tube Evaporator

Full Metal Structure

Electrical Panel

C2020 electronic controller with digital display

Flat Bed Air Blast Coolers

No Clean and Chlorination

Sealed System

No Water Losses Through evaporation

Low Operating Noise Levels

Minimal Plan Area

Low Operating Costs

Energy Saving Inverters

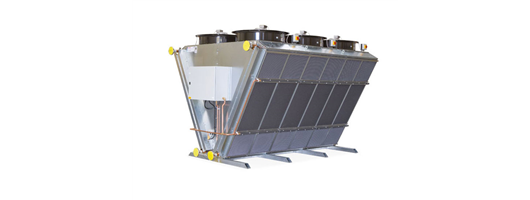

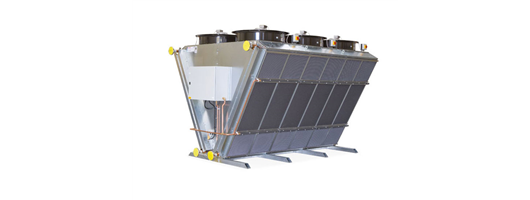

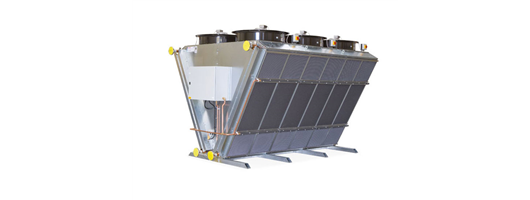

V-Type Air Blast Coolers

V-Type Air Blast Coolers provide a highly efficient cooling solution with a minimal footprint, making them ideal for applications where space is limited but high-performance cooling is required. With cooling capacities starting from 100kW and scalable to meet larger demands, these units are designed to deliver reliable and consistent thermal management across a wide range of industrial processes.

Each cooler is equipped with an advanced control panel, offering seamless integration into existing systems. Depending on specific operational requirements, units can feature either staged fan control or an energy-efficient inverter drive, ensuring precise temperature regulation while significantly reducing energy consumption and running costs.

- No chemical water treatment

- No clean chlorination

- Sealed system

- No water losses through evaporation

- Low operating noise levels

- Minimal plan area

- Low operating costs

- Energy saving inverters

Get in touch with Summit Process Cooling for more information.

Packaged Air Blast Coolers

The Advantages of Air Blast Coolers

These systems provide numerous benefits. They’re easy to install and require less maintenance compared to chiller units, which significantly reduces operational costs. This cost-effectiveness comes without sacrificing performance, as they offer efficient solutions in a compact size. Their reduced footprint is a major advantage, offering an optimal balance between performance and utility.

Moreover, these coolers do not have a refrigeration circuit. This reduces maintenance requirements and eliminates the challenges associated with managing refrigerants.

When you buy your system from Summit Process Cooling, you can also expect:

- Units built with high-quality leading brand components.

- A proven repeat performance.

- An optional 24-month warranty.

- Rapid response through Summit's service network.

The Applications

Air Blast Coolers are integral components in various industries due to their proficiency in reducing excessive heat and maintaining optimal temperatures. They find utility in:

- The oil and gas industry, ensuring efficient operations in extremely hot environments.

- Chemical processing plants, to manage and reduce the high heat produced during reactions, preventing potential hazards and maintaining a safe working environment.

- Power generation plants, where they cool down machines and transformers. This improves the efficiency of power generation and extends the lifespan of the equipment.

- The food and beverage industry, where they're used for the rapid cooling of products. This preserves the quality of the food or beverages and extends their shelf life.

- Data centres, to regulate the heat generated by servers. This helps maintain operational efficiency and prevents overheating that could lead to data loss or equipment damage.

Some other notable applications include the metallurgical industry for cooling molten metals, or the automotive industry for cooling engines and maintaining optimal performance.

Adiabatic Coolers

Adiabatic coolers are an efficient and environmentally friendly solution for maintaining optimal temperatures in various industrial and commercial settings. Designed to minimise both energy consumption and customised footprint, these industrial coolers provide a highly effective alternative to traditional cooling methods, offering reliable performance with significantly reduced water usage. Whether you're looking to lower operational costs or enhance sustainability, adiabatic coolers are a versatile and dependable choice.

Our premium adiabatic coolers take this efficiency a step further by operating without the use of external aerosols. This innovative design keeps the coil blocks dry, preventing scaling and keeping the local area dry. With these advanced features, our premium coolers ensure not only superior performance but also enhanced safety and hygiene, making them the ideal solution for environments where cleanliness and reliability are paramount.

- Low operating costs

- No chemical water treatment

- No chlorination

- No water loss through evaporation

- Modular design for easy expansion

- Low-noise options

- EC fan control

Get in touch with Summit Process Cooling or visit our website for more information.

Open & Closed Cooling Towers

Cooling towers are essential systems used to dissipate excess heat from buildings and industrial processes. Cooling towers absorb heat via water that has been circulated through machinery and release it into the atmosphere through evaporation, lowering the water’s temperature before it’s recirculated.

Cooling towers are available in a number of designs, including open and closed systems and are a cost-effective, sustainable solution that enhances system efficiency. By keeping equipment at optimal temperatures, cooling towers help extend machinery life, minimise maintenance needs and improve overall operational stability.

- Open cooling towers with high efficiency packing

- Closed cooling towers with tube bundle in steel or stainless steel

- Closed cooling towers with plate type heat exchanger

- Induced draught or forced draught design

- Galvanised steel, stainless steel and GRP construction

- Access doors, ladders and rails available

Get in touch with Summit Process Cooling or visit our website for more information.

Free Cooling

Free cooling technology presents an innovative and sustainable solution that can dramatically improve the efficiency of your cooling systems. By reducing the reliance on traditional, energy-intensive compressors, free cooling harnesses the power of ambient air to maintain optimal temperatures. This approach lowers electricity consumption, extends the lifespan of critical equipment, and reduces carbon emissions. It’s a smart, environmentally friendly investment that delivers exceptional return on investment (ROI) and helps companies move towards a more sustainable future.

The Benefits Speak for Themselves:

- Reduced energy consumption: Utilises ambient air to minimise reliance on mechanical cooling.

- Lower maintenance needs: Less strain on compressors results in fewer breakdowns and reduced maintenance costs.

- Fast ROI: Typical payback period of just 6-12 months.

- Eco-friendly: Contributes to a reduced carbon footprint and supports improved sustainability.

Get in touch or visit our website for more information.

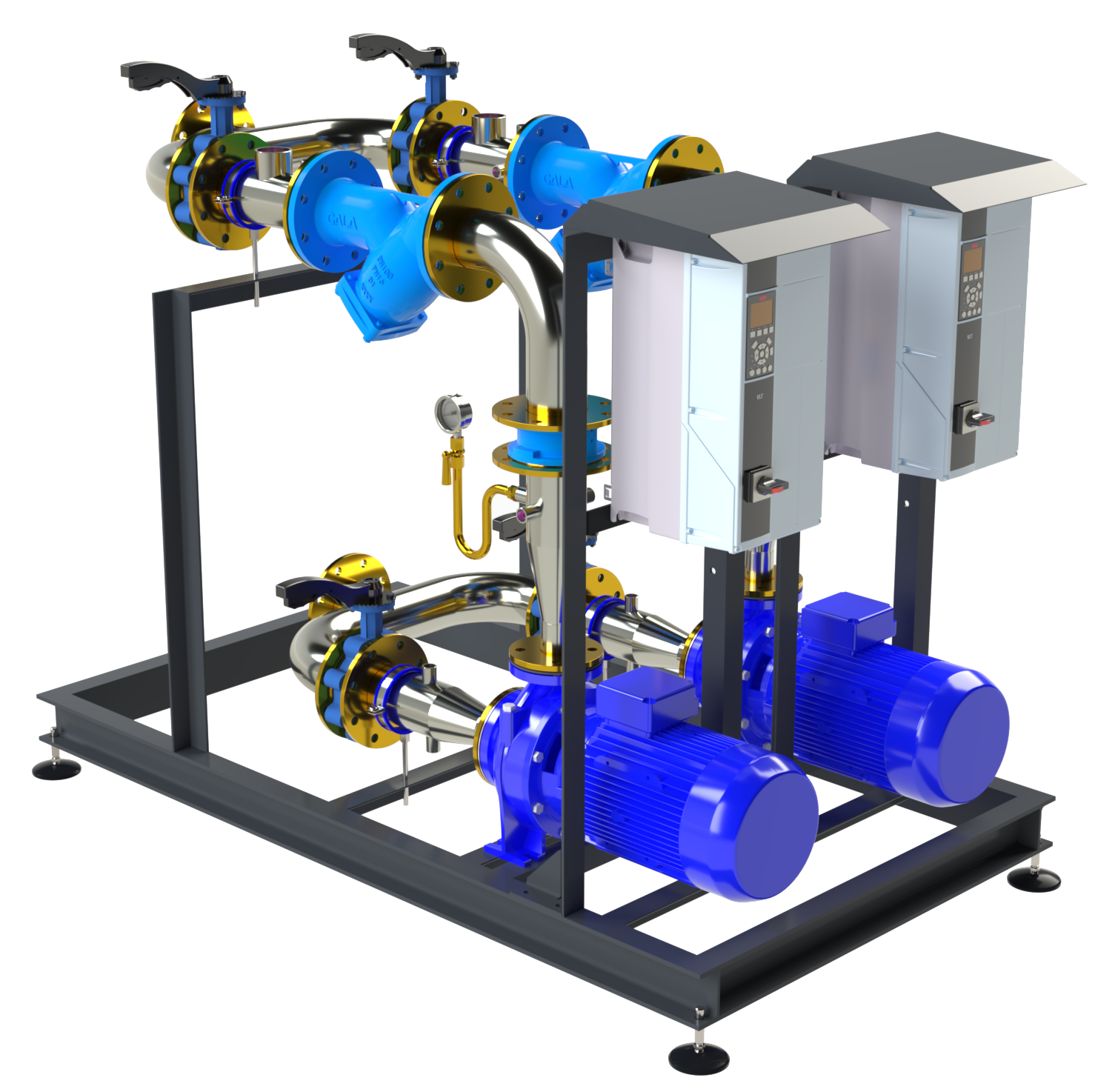

Pump Stations

Our Pump Skids/Pump Stations offer a versatile and efficient solution for complex fluid handling needs across various industries. They can be fully customised, allowing us to tailor each unit to meet your specific operational requirements, ensuring optimal performance and efficiency. With over 30 years of experience in plastic automation and process cooling, we offer unparalleled expertise to the fabrication of high-quality, durable pump skids. Our state-of-the-art technical capabilities, including precision engineering with advanced tools like SolidWorks, guarantee that every pump skid is designed and built to the highest standards.

Our commitment to quality doesn't end with the sale; we provide comprehensive after-sales support, including routine maintenance, repairs, and access to genuine spare parts. Whether you need a pump skid for industrial cooling, chemical processing, water treatment, oil and gas applications, or pharmaceutical manufacturing, we have the expertise and technology to deliver reliable and efficient solutions. Choose Summit for tailored, high-performance systems backed by decades of industry experience and a dedication to customer satisfaction.

Summit has a well-established fabrication department with over 30 years of experience in plastic automation and fabrications. Our expertise now extends to process cooling, supported by an advanced technical design team using innovative tools such as SolidWorks for precision engineering. We continually invest in new technologies and methods to stay at the forefront of the industry, ensuring our products are of the highest quality and performance standards.

- Customisable fluid handling solutions

- Effective handling for fluid circulation

- Run & Standby (N+1) design

- SolidWorks customised modelling

- Short lead times

- UK manufactured

Sealed Dual Pumpset

Open Dual Pumpset

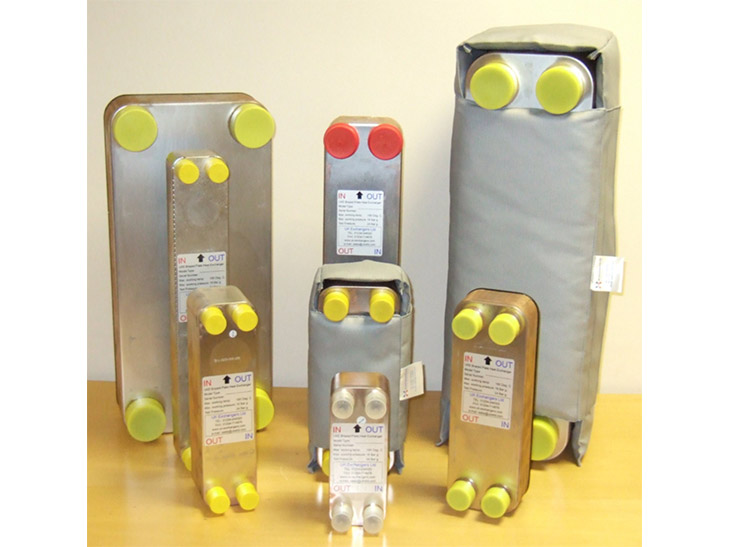

Brazed Plate Heat Exchanger

Shell & Tube Heat Exchanger

Gasketed Plate Heat Exchanger

Summit Process Cooling plate type, brazed and shell and tube heat exchangers for heat transfer of fluids that need separate cooling circuits.

Gasket type units have the advantage of a small footprint with their compact design, they can be fitted with 304, 316 stainless or titanium plates and there are a range of alternative gaskets to suit specific applications available. They are easily cleaned and additional plates can be added to the frame.

- Highly efficient heat exchangers for water to water and oil to water processes

- Compact brazed heat exchangers can be copper or nickel brazed

- Can be fitted with 304, 316 stainless or titanium plates

- Shell & tube heat exchangers are ideal for higher operating pressures and lower pressure drops

- Heat exchangers can be built onto Summit Process Cooling’s packaged heat exchanger pumpset

Get in touch or visit our website for more information.

Cabinet Coolers

Maintenance & Repair Services

At Summit Process Cooling, we provide expert chiller repair services designed to restore optimal performance and efficiency to your cooling systems. Our team of highly skilled engineers is equipped to handle all makes and models of chillers, addressing both common and complex issues. We utilise advanced diagnostic tools and techniques to quickly identify problems and implement effective solutions, ensuring minimal downtime and disruption to your operations.

- National / International Support Network

- Rapid Call Out Service

- Routine Preventative Maintenance Plans

- Installation and Commissioning

- All Makes & Models

- Chiller repair - no matter the make

Get in touch or visit our website for more information.

Energy Saving

Using standard Stage Control, fans are switched on and off at full speed to match cooling requirements and the cooler input power increases or decreases in direct proportion to the number of fans in operation. This wastes a great deal of power and creates unnecessary noise.

However, using Summit-TPC’s Inverter Control, cooler capacity is matched to load by changing the speed of all fans in unison. Power consumption and operating noise level falls dramatically with any reduction of load or ambient.

Microgel Temperature Control Unit

The Microgel, a temperature control unit from Frigel, is a super compact mould cooling unit specifically designed for cycle cooling time reduction. Single and dual zone temperature control units with integral water-cooled chiller and booster pumps are available.

Microgel are designed to deliver constant high pressure and flow to process, resulting in optimal heat transfer. 3-way modulating valves provide the ultimate in temperature control accuracy to ±0.5°C (±1°F).

- Single or dual zone Temperature Control Units

- Temperature from -5°C to 90°C

- High flow process pumps ΔT as low as 1°C

- Integral free-cooling valve for operation with Frigel Ecodry (or other clean water) systems

- Automatic shut-down of the compressors for large energy savings, depending on ambient and set point condition

- Stainless steel reservoirs, evaporators and condensers, and corrosion-free piping throughout

- Space saving design

Get in touch or visit our website for more information.

Turbogel

Thermogel TBX Temperature Controller

The Thermogel TBX Temperature Control Unit from Frigel, was designed to operate up to a maximum temperature of 90°C and for running also in vacuum mode. Indirect cooling through a high efficiency heat exchanger provides for a high cooling capacity.

The compact design of the temperature controllers offers reduced footprint and height. Each unit is equipped with two rear wheels for easy handling.

- Simple and competitive

- Reversible pump for continuous running in vacuum mode

- High resistance to corrosion

- High temperature accuracy

- Indirect cooling through a high efficiency heat exchangers

- Low specific heating elements in stainless steel

Thermogel TDK

The Thermogel TDK Temperature Control Unit from Frigel, was designed to deliver constant pressure and flow to process, providing optimal heat transfer.

Temperature Controllers are designed to control automatically and to keep diathermic fluids at the required temperatures in the industrial processes.

The TDK is suitable for small to medium sized injection moulding machines with a large working temperature range, thanks to the direct cooling and the possibility to operate with pressurised water up to 120°C.

- High accuracy: ± 0.1°C of the set value

- Simple and functional user interface

- High resistance to corrosion

- High accessibility for easy maintenance

- Compact dimensions and easy to install

- Peripheral pump common to all versions

- Self-tuning PID electronic control instrument

- Solid state relay

Rentals

Here at Summit Process Cooling we understand there are many different reason’s companies will require hire equipment, rather than purchase and we have built our business model to deliver on all of these reasons. We have rental equipment to temporarily cover breakdowns and for seasonal equipment which isn’t needed for 12 months of the year. Alternatively, if you’re just looking to spread the costs or for R&D purposes, we’ll have the solution for you.

We have designed our solution so that we can look after every type of customer, no matter the size and we treat all customers with the same dedication and professionalism as you would expect when purchasing such service; no job is too big or too small.

We have built our hire business to be able to accommodate any customer in England, Wales and Scotland.

About us

Part of the larger Summit Systems Group, with division in plastics automation, premium recycling machinery and raw material recycling services, Summit Process Cooling specialises in the supply and/or installation of specialist’s temperature control and process cooling equipment for multiple industries such as plastics, industrial, medical, and food and beverage. Our customers are mainly end user manufacturing facilities but also OEM, FM, and M&E. We mainly supply within the UK but do also have some customer over-seas.

We are known for providing our clients with well-engineered, cost-effective cooling equipment that is specifically design to meet their exact requirements. We offer an extensive range of dry air coolers, heat exchangers, pump stations, chillers and adiabatic coolers that are highly recommended by our loyal customer base.

With over 30 years’ experience within the industrial process cooling sector, Summit Process Cooling supply both nationally and internationally, while offering competitive pricing on all products we provide. Our cooling equipment is widely recognised for industrial quality, reliability and efficiency, as well as extended warranties and specialist advice and support from our team of our fully-qualified cooling engineers.

Established in 1991, formerly as Total Process Cooling, before joining the Summit System Group in 2018, our company reputation is built upon satisfied customers who have praised our services for being flexible, effective, and professional. Our technical product knowledge has allowed for better client relationships and therefore better results, leading to our company becoming widely recognised within the current marketplace. We are fully committed to ensuring that clients receive outstanding service from start to finish, and are more than happy to offer any advice or support on a vast array of products and services we provide.

Here at Summit Process Cooling, we offer an impressive range of products including small duty air cooled chillers, medium duty air cooled chillers, high duty air cooled chillers, oil chillers, air blast coolers, flatbed adiabatic coolers, premium adiabatic coolers, open cooling towers, closed cooling towers, free cooling systems, pump stations, sealed dual pumpsets, open dual pumpsets, brazed plate heat exchangers, shell and tube heat exchangers, gasketed plate heat exchangers, cabinet coolers, energy saving solutions and many more.

Images