Company details for:

Tascomp Ltd

Quick Links:

Products / Services

Tascomp

As the developers of the software we have full control of its functionality and capabilities, and can customise it to meet the specific requirements of our customers.

We offer a range of products including the Prodigy SCADA HMI system for monitoring, control, and automation. We also offer solutions like PlantRun, which improves manufacturing efficiency, and PAMS, an alarm management system for airports. Our in-house development team enables us to tailor their software to meet specific client needs, offering exceptional flexibility and ongoing support to ensure your systems optimisation.

PlantRun - Machine Downtime Monitoring

PlantRun is a production monitoring system designed to help manufacturers gain real-time insights into their operations. By connecting directly to your machines, PlantRun automatically tracks key performance indicators including utilisation, production counts, OEE, cycle times and downtime. This data is recorded on a central server and made available on dashboards you can access from any device, whether it's a PC, Tablet or Smartphone.

From insight to impact, PlantRun fuels you with the data required to force positive change in your manufacturing processes.

With PlantRun you instantly see how your site is performing. If a machine is running slowly or suffering unplanned downtime, you will know straight away, helping you to minimise costly lost time, improve machine efficiency, and reduce waste.

PlantRun doesn’t just collect data — it also provides the tools to help you understand it. With PlantRun you can set up alerts to notify you of production problems as they happen, track trends over time, and integrate with third party systems (ERP/MES, CMMS, WMS, etc) to truly connect your factory.

Prodigy - Industrial Automation Software

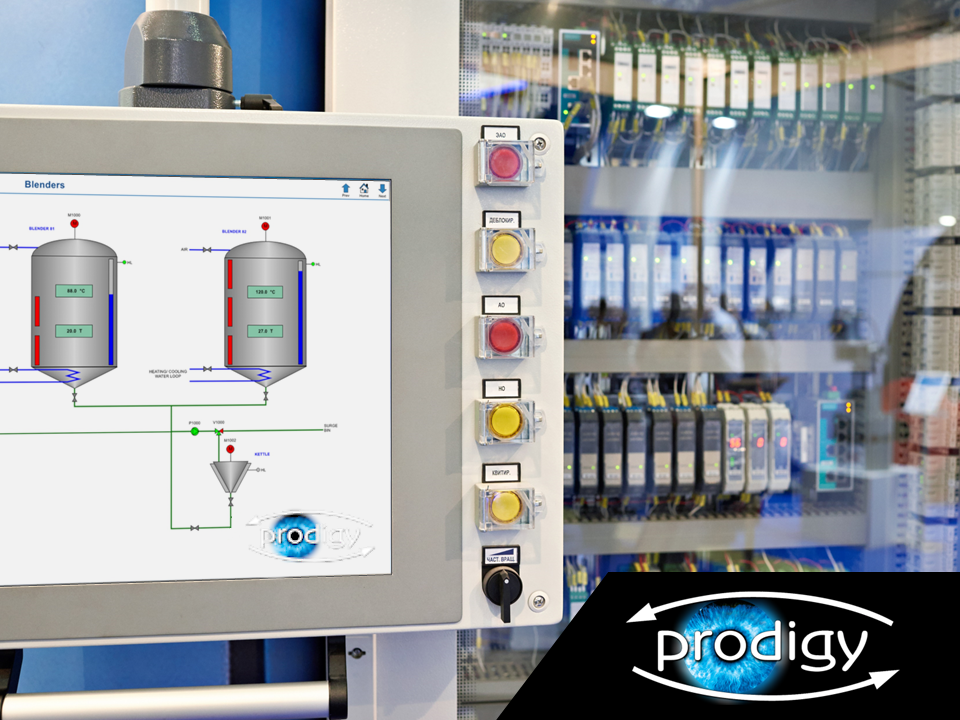

Prodigy SCADA is proven in use in a diverse range of applications and industries around the world.

Built on forty years experience of systems integration it is the software that countless companies rely upon for the smooth and efficient running of their day to day operations.

Highly flexible and versatile, Prodigy SCADA offers the ideal industrial automation solution and can be used for any level of monitoring, control and automation application.

Prodigy has been developed on the back of a vast range of monitoring, control and automation systems in the UK and overseas. For a flavour of Prodigy’s capabilities you can read summaries of real industrial applications.

PAMS - ATC Alarm Management

PAMS functionality is based on systems designed by us that have been installed and proven in a commercial airport environment since 2003 and are now used at airports across the United Kingdom and overseas.

The system provides Engineering, Maintenance and ATC with a cost effective, state of the art solution for alarm management, which gives instant alarm notification and recording of user response, overall status for all monitored systems and services.

OEM SCADA - HMI Software

Our OEM Software, based on Prodigy SCADA - HMI and its class leading range of facilities, provides a fast and economical way to have a ready made industrial control and monitoring software for resale.

Any level of specialised functionality can be incorporated to meet customer application requirements. The use of flexible licensing allows custom licenses to be created that closely match these facilities with the OEM application. This makes them very cost effective for OEM's because they do not pay for facilities they will not use. Further saving can be made by purchasing licenses in bulk and activating them as and when they are needed.

We provide a complete service of SCADA, HMI design and development to meet your needs like on going technical support, training etc.

Many companies have now taken advantage of this service - use the side menu links to view some recent projects. If you have an OEM SCADA or custom HMI application please contact us for an informal talk about how we can help you with your project.

Manufacturing Information Systems

Machine monitoring is a broad term that means different things to different people. We have over 30 years expertise in applying software solutions to machine monitoring applications and we will be pleased to discuss your requirement whatever it is.

Paperless Manufacturing

Organisations collect data, whether it is operational or regulatory, not for the data itself but for the information the data can provide. Whether data is collected and stored to paper or transcribed to software the following problems are suffered:

• Inaccuracy

• Cost

• Lack of Visibility

• Data islands

OEE Monitoring & Improvement

All too often the very collection of performance data is the root cause of this failure.

Manual OEE data collection increases administration costs and introduces data inaccuracies. This results in poor quality information or it could be delivered too late to be of maximum benefit. It also costs staff time when they could be doing more value added work. (Try a simple calculation of the cost based on time taken and average salary - you might be shocked how much it is costing per year)

Machine Downtime Reduction

To combat these issues, companies must focus on minimising unexpected downtime through proactive maintenance and monitoring.

Improving Shopfloor Visibility

Real-time data gives visibility into the manufacturing process, allowing issues to be identified rapidly. By leveraging real-time analytics, manufacturers can categorise scrap and rework, track defects, incorporate quality metrics and continuously improve processes. The result is faster response times, increased productivity, reduced costs and higher quality products.

Automatic Test Sequence

By automating the testing process, we enable manufacturers to streamline operations, minimise human error and achieve consistent quality control.

Our tailored systems can be customised to meet specific product requirements and integrate seamlessly with existing production lines. With a focus on innovation and excellence, we empower companies to deliver high-quality products while optimising their end-of-line testing processes for maximum efficiency.

Process Control & Automation

To further support your system in your operations, we have a dedicated UK based team of engineers and programmers meaning you have access to real-time support from experts who understand the Prodigy system.

Proof of Process Reports

Prodigy's reports can combine alarm histories with batch details and any number of processes into a trend on a single page reports, expressing a permanent record for the industry, with easy configurability and full control over the report layout.

Downtime Monitoring

Prodigy can provide you with the information on what the error is and the reason for the loss of production. Alarms can be implemented to alert when errors are detected to immediately alert your staff for that rapid response to ensure operations are resumed as quickly as possible.

Batch & Recipe Handling

This includes recipe storage, automatic form filling, automatic batch creation and monitoring and proof of process reporting.

Recipe data is a collection of control setpoints that define the parameters required to make a specific product or to control a specific process. Prodigy allows any number of such recipes to be created and called up via user defined forms.

Alarm Management System

In the event of an operational system developing a fault, an alarm condition is triggered on the PAMS Site System and this is displayed at one or more locations. All alarm statuses are available to engineering and typically a defined, more critical subset is made available to Air Traffic Control (ATC) operators. This allows minor alerts and degraded states to be acted upon by engineering staff without impacting on the ATC operations.

Remote Tower Alarm

This minimises the need for remote sites to be fully manned when there is no air traffic and cost savings from reduced manning requirements for both ATC and engineering.

Commercial Airfield Systems Monitoring

Sitting at the heart of many airports, PAMS monitors the status of everything from radios and ILS, to the fibre network infrastructure. In the event of an issue, the usual reporting through PAMS Workstations and optional beacons is expanded to include the Saab Digital Tower system - allowing airports to maximise their capacity.

Military Airfield Systems Monitoring

Our advanced monitoring systems offer real-time visibility into critical infrastructure, including runways, taxiways, and support facilities, ensuring that all components function optimally and comply with strict military standards. By integrating cutting-edge technology and data analytics, we enable military personnel to detect potential issues proactively, manage maintenance schedules effectively and ensure readiness for flight operations.

Our tailored solutions are designed to withstand the unique challenges of military environments, providing reliable performance even in demanding conditions. With a commitment to excellence and a focus on mission success, we are dedicated to supporting the operational integrity of military airfields around the globe.

Digital Hub & Satellite Towers

For a visual view of this, view our website to see this formatted as a diagram.

About us

Prodigy powers several specialised systems, including PlantRun, which integrates hardware and software to help manufacturers improve operations by monitoring production at the asset level. Additionally, PAMS provides centralised alarm management for airfield ground systems.

Other key solutions include Prodigy-ET, designed for engineering test automation and data acquisition, and OEM SCADA, offering customised HMI software development services tailored to specific industry needs.

Our Solutions Include:

Prodigy - HMI SCADA Industrial Automation Software

Prodigy HMI SCADA industrial automation software, developed and fully supported in the UK, has been successfully utilised across a wide variety of industries and applications worldwide.

Machine Downtime, Machine Utilisation and Downtime Systems

PlantRun OEE, machine downtime, and manufacturing information systems provide manufacturers with precise real-time production performance data, enabling them to optimise efficiency, boost output, and increase profits.

PAMS - Alarm Management for Airport Ground Based Systems

Advanced systems for monitoring airfield ground-based services, covering Air Traffic Control (ATC), Communications, Navigation and Surveillance (CNS), UPS, and meteorological equipment.

Test Automation Software - Prodigy-ET

Prodigy-ET is a comprehensive industrial test automation and data acquisition software suite trusted by leading manufacturers for automated product testing.

OEM SCADA Software and Custom HMI Design and Development

If you need software for new product lines, to update outdated systems, or to enter new markets but lack the time or resources to develop it from the ground up, our OEM SCADA-HMI software provides the perfect solution.

We are proud of the high-quality support we offer for our products.

Depending on the product, our software and systems are available through multiple channels, including a network of resellers, distributors, systems integrators, and direct sales to end users.

Images

Videos

Articles / Press Releases

Brochures

Trade Associations