Company details for:

Team Corporation UK Ltd

Quick Links:

Products / Services

Vertical Vibration Test Systems

Team Application Engineers will evaluate your requirements and determine the appropriate actuator force, stroke and velocity requirements to provide the highest frequency response within your budget constraints. Team vertical vibration test systems are available with an air isolated seismic base that will eliminate low-frequency vibration transfer and allow placement in your test facility with no modifications to the standard industrial floor structure.

Seismic & Earthquake Simulation Test System

By integrating our legendary servohydraulic actuators with our patented T-Film hydrostatic slip table bearings, we’ve created the perfect high-frequency long stroke vertical/horizontal system. With our available trunion mounted actuator system, repositioning from vertical to horizontal axis takes very little time.

Horizontal Vibration Test System

With the modular line of components, Team Corporation can provide you with a system that is best tailored to your test requirements. The actuator force, stroke, and velocity are optimized to provide the highest frequency response within your budget constraints.

Team Corporation horizontal systems are designed to work with almost any off-the-shelf controller and offer the full spectrum of sine, random, sine on random, random on random, or resonant search and dwell control.

Subsidiary Shock Test System

The SSTS has also shown the capability to reproduce the decaying sinusoid that is sometimes measured in the frequency band centered around 60 Hz.

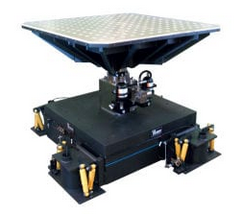

Multi-Axis Vibration Test Systems

Mantis™ 6-DoF Vibration Test System

Through the use of hydrostatic bearing technology pioneered by Team Corporation in the vibration test market, MANTIS™ has the performance to simulate real-world events that were previously unattainable.

Custom engineering is a hallmark of Team Corporation. MANTIS™ can meet a wide variety of testing needs, as it is available in a standardized model and can also be customized to fit special requirements.

RVC 400 Rotary Vibration System

The RVC400 rotary vibration table is an electrically powered device. The basis of the design is a state-of-the-art torsional voice coil directly driving a flexure bearing supported rotary shaft and table. This arrangement provides a very responsive rotating mechanism with virtually no friction yet retains the ability to react off-axis motions with very little deflection. Utilizing rare earth permanent magnets, this rotary drive produces very high torque within a small dimensional envelope.

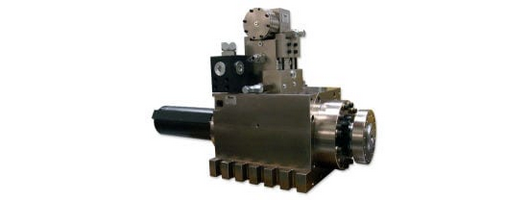

R-10 Series Rotary Actuator

The R-10 series rotary actuators were designed for fatigue testing wherever high torque output with restricted rotational travel is required. The R-10 series has total rotational travel of 100 degrees (+/- 50 degrees). One primary feature of the R-10 series is that they incorporate hydrostatic bearings, which eliminate mechanical wear caused by side or thrust loads − thus ensuring longer life.

Acoustic Noise Generator

Special Project Development

Each large platform system is unique in design and application, and no two systems are alike.

Whether you are developing satellites, spacecraft, or tracked or wheeled military vehicles, Team Corporation has the engineering experience and expertise to meet and exceed your exacting requirements for shock, vibration and acoustic test systems.

T-Film Slip Tables

EX Series Hydraulic Actuators

Team Corporation’s EX Series Actuators are double acting, double ended, hydrostatically lubricated and designed to be stiff both mechanically and hydraulically. This is achieved by using a heavy body cross-section, a large diameter one-piece piston shaft and by keeping the trapped oil volume to a minimum. The actuator piston is internally supported by a thin film of high-pressure oil, commonly referenced as a hydrostatic bearing. This feature eliminates metal-to-metal contact, providing virtually infinite piston life. To provide position feedback, an LVDT (linear variable displacement transformer) is mounted concentrically within the piston shaft.

High Performance Linear Actuator

Linear actuators are the bread and butter of vibration test systems. They provide the force necessary to run a vibration test. All Team Corporation test systems and components are engineered and manufactured in our USA facility.

At Team Corporation, we offer a selection of high performance servo-hydraulic actuators that provide the reliability and accuracy you require. Our actuators are integral to test systems installed around the world, serving various industries, including aerospace, independent environmental testing, and civil engineering.

Head Expanders

For projects requiring extreme stiffness and cross axis control, Team Corporation manufactures specialty guided head expanders to accommodate large payloads. Our extremely rigid and custom-designed head expanders are ideally suited for spacecraft component and satellite testing utilizing servohydraulic or electrodynamic shakers.

Hydraulic Power Supplies

Each Team Corporation hydraulic power supply is sized specifically to accommodate the pressure and flow requirements of our high-performance servovalves. Many of our hydraulic power supplies are available with an optional quiet motor and pump assembly.

Hydrostatic Pad Bearings

Specialty pad bearings with larger force ratings and greater angular rotations may be available depending upon your application requirements.

V8 & T8 Hydrostatic Bearings

T-8 and V-8 hydrostatic bearings are designed for use with electrodynamic and servohydraulic shakers with a maximum 2 in. (50 mm) of stroke.

Hydrostatic Spherical Couplings

Single and Double pivot couplings are available, in either 0.5 degree or 6 degree configurations. Our double pivot couplings allow for angular and lateral misalignment. Each spherical surface is hydrostatically lubricated for extremely high stiffness, zero backlash, and infinite life.

HydraBall Hydrostatic Bearing Ball Joint

The HydraBalls’ smaller package and revolutionary design eliminates pin shear associated with typical clevis pin assemblies. There are no high-pressure seals to wear out or cause friction to compromise test results. The Team HydraBall requires only 0.2 gpm (.751 lpm) of oil at 3,000 psi (205 Bar).

Torsional Vibration Table

About us

Team Corporation UK Ltd specialises in the design, construction, and delivery of advanced single and multi-axis vibration and shock testing systems, along with associated components.

Team Corporation provides a diverse array of solutions tailored to meet your vibration testing system needs. Our precision-engineered test systems and components ensure precise results, empowering you to create more resilient products. With our trusted components, you can conduct highly effective testing and evaluation, facilitating quality control and identifying potential performance concerns with precision.

Our Products Include:

Vibration Test Systems

Our vibration testing systems play a vital role in guaranteeing the integrity and reliability of your product. We provide a diverse array of products to cater to an extensive range of vibration testing requirements, encompassing single and multi-axis systems, as well as acoustic sound generation. Our expertise enables us to identify and tailor custom vibration testing solutions precisely suited to your specific applications.

Vertical

Vertical vibration testing systems are engineered for conducting tests that demand high force, extended stroke, or exceptionally low-frequency capability.

Horizontal

Our horizontal vibration test systems outperform the competition. They incorporate our high-performance T-Film™ bearings into the slip table offering unmatched test article guidance and support.

Multi-Axis

Team Corporation's multi-axis vibration testing systems replicate real-world vibrations, offering simulation capabilities ranging from two to six degrees of freedom.

Rotary

Team Corporation's rotary systems are especially beneficial for torsional vibration testing and product development purposes.

Slip Tables

Utilising multiple bearings to fully support and guide the slip plate provides exceptional dynamic stability and damping, leading to improved test outcomes.

Actuators

Team Corporation's fatigue-rated actuators have proven their reliability in numerous applications across a wide spectrum of demanding operational environments.

Head Expanders

Team Corporation's conventional and guided head expanders are meticulously crafted to provide optimal dynamic response while minimising mass and weight.

… And more.

Team Corporation will collaborate closely with you to comprehend your needs and preferences thoroughly. We will present a system tailored to meet these requirements while adhering to your limitations. Our approach ensures transparency regarding the pros and cons of the proposed system, equipping you with the insights needed to make well-informed decisions. By sharing our expertise with the test engineers who specify and utilise your system, we aim to optimise performance, minimise expenses, and expedite the delivery of your system.

Team Corporation has a rich history of innovation, from pioneering hydraulic shakers to unveiling the first 6-degree-of-freedom systems. Over the years, we have introduced a multitude of innovations to the field. Our solutions have been developed for a diverse range of applications, including vibration testing of armaments, missiles, automobile components, vehicles, communication satellites, various types of instrumentation, military and civilian aircraft components, as well as shipping containers.

Challenge us with your requirements. Reach out to Team Corporation today to discuss your future test system needs or to request service or preventative maintenance for an existing system. We eagerly anticipate the opportunity to collaborate with you.

Images