Company details for:

Teddington Engineered Solutions Ltd

Quick Links:

Products / Services

Metallic Bellows

Rubber Bellows

Flexible Hoses

Fabrication Services

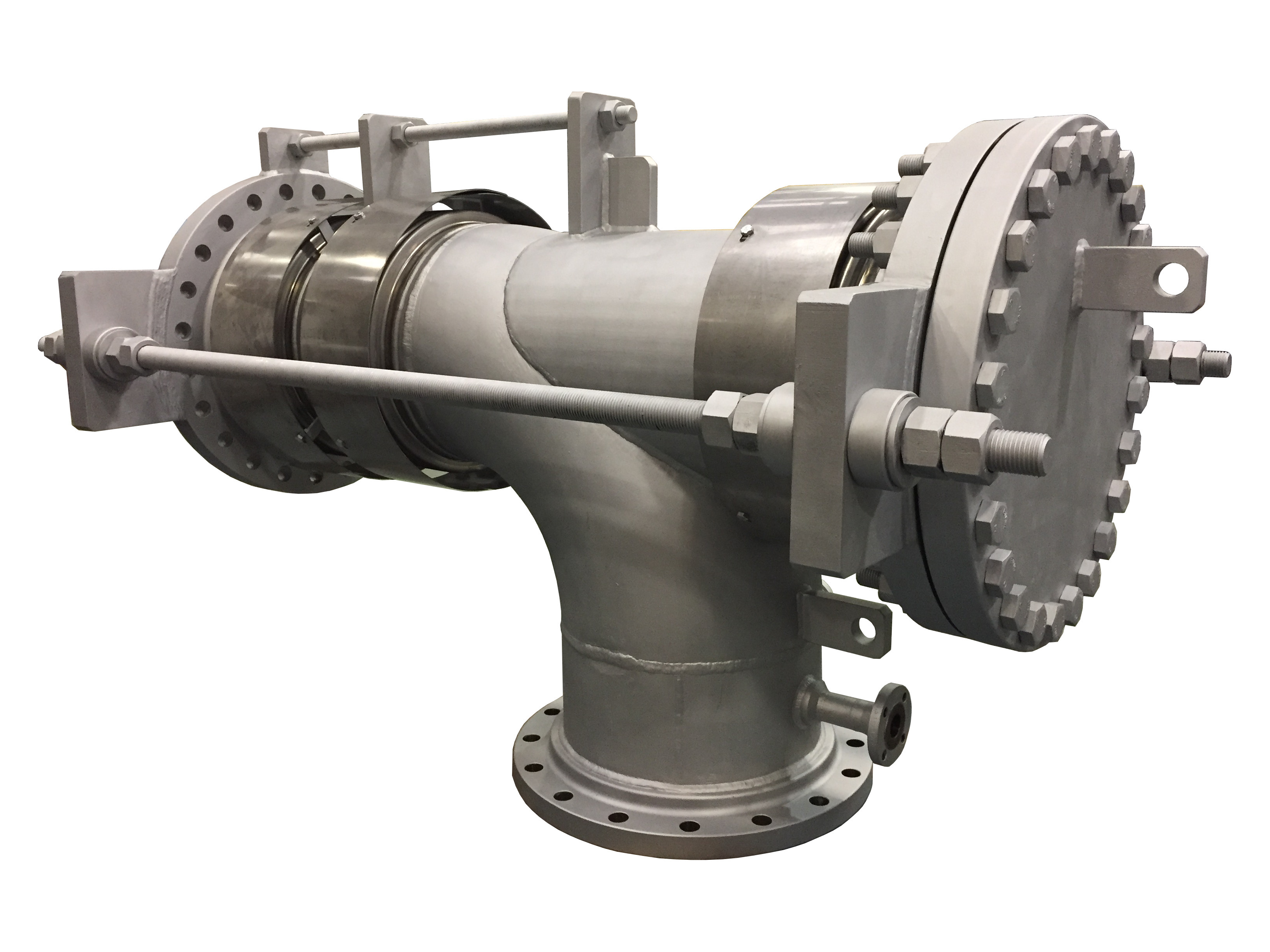

Our dedicated team of Fabrication specialists have over 30 years experience, covering an extensive range of applications. We offer the expert expertise and capabilities to provide a Fabrication solution that will suit your requirements, regardless of the complexity of the project.

Provision of our services is tailored to suit each customer’s needs. Our extensive experience in this field gives us the ability to offer sound advice and an innovative approach to solving individual customer requirements.

Overview:

We offer Fabrication of metallic units with a full range of welding techniques and methods, inwelding in--house machininghouse machiningand testing.

Usage:

Fabrication is used where specialist forming of complexFabrication complexshapes or partshapes part--joining of bellow components are required.

Detail:

We manufacture and supply Fabrication solutions in a variety of materials, including steel, inconel, incoloy, aluminium, titanium, hastelloy and other metals.

NDT Services Division

We recognise that product reliability is of paramount importance to our customers. Our NDT division will give you the confidence and reassurance that you are getting dependable products. Our laboratory facilities include a purpose built radiography compound. We can inspect small or large components, with a sliding roof for accessibility.

Provision of our services is tailored to suit each customer's needs. Our extensive experience in this field gives us the ability to offer sound advice and an innovative approach to solving individual inspection requirements.

Scope of Services

We offer both on and off-shore inspection. We can provide:

- Liquid Penetrant Inspection

- Magnetic Particle Inspection

- Gamma Radiography

- X-Ray Radiography

- Ultrasonic Inspection

- Metascope (Positive Material Inspection)

- Hardness testing of engineered components

- QA/QC Vendor Inspection

- CCTV/ Borescope Inspection

- Eddy Current Inspection

- IRIS Tube Testing

- Tank Floor Testing

- TOFD (Time of Flight Diffraction)

- Automated Ultrasonics

- Rope Access Engineering.

About us

Teddington designs, manufactures and supplies metallic bellows expansion joints, as well as rubber, fabric, and PTFE bellows, with metal flexible hoses and a wide variety of end fittings and precision-machined components.

Teddington has been making bellows since 1927, even lodging the first ever patent for a bellows design in the UK in 1928.

Since then, Teddington has combined with three other formerly independent bellows manufacturers, with experience in the design, application and manufacture of bellows expansion joints.

- Teddington Bellows

- Brockington & Scott

- Vokes GenFlex

- MaxComp

Teddington is considered a world leader in this field and this is recognised by being committee members of the Expansion Joint Manufacturers Association (EJMA). This code is followed by all major expansion joint manufacturers and its role is to develop all future revisions to this world standard.

Teddington has extensive experience in many market sectors, including but not limited to: Aerospace; Automotive & Exhaust Systems; Chemical & Petrochemical Processing; Construction & Building Services; Cryogenic Applications (LNG & PNG); Defence (Land, Sea & Air); Diesel Engines & Generator Sets; District Heating & Cooling; Food Processing, Brewing & Packaging; Fusion Research; Heat Exchangers; HVAC; Hydrogen Research; Instrumentation; Locomotive & Rail Infrastructure; Medical, Pharmaceutical & Healthcare Facilities; Metallurgy, Foundries & Steel Making; Mining & Mineral Processing; Oil & Gas (Down, Mid & Upstream); Power Generation (Conventional, Nuclear, Geothermal) and Distribution; Research Facilities; Shipbuilding, Salvage & Repair; Space Communication & Exploration; Waste & Environmental Management; Water Treatment & Desalination Plants; and still many more.

Images