Company details for:

Texcel Technology

Parkside Works, Thames Road,

Crayford,

Dartford,

Kent,

DA1 4SB,

United Kingdom

Quick Links:

Products / Services

Electronic Design & Product Development

Even if you only have a concept, we can work with your team to develop this into a specification which includes circuit design, firmware, PCB layout, prototyping and final production.

Electronics Procurement

We also hunt down obsolescent parts through our international network of specialist suppliers and where appropriate offer alternative components with the support of our design team. If necessary, we can trace components using our sophisticated integrated materials management software.

The combination of our technical and procurement expertise means we can guide you on the selection of components that will be both functionally suitable and readily available.

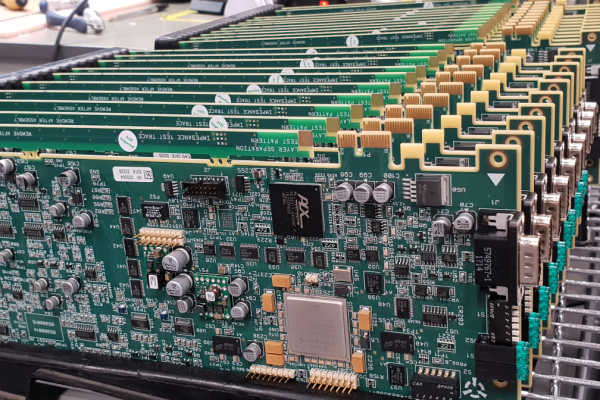

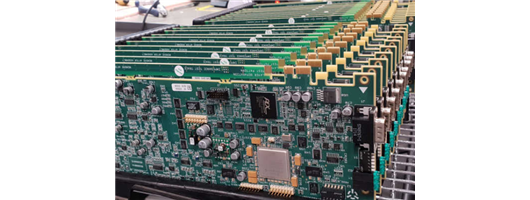

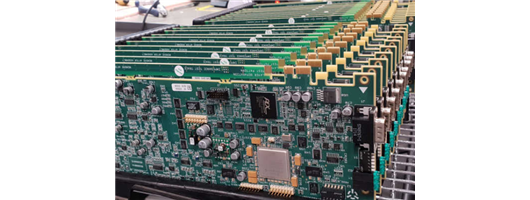

PCB Assembly

We have made significant investments into automated PCB assembly equipment, and support solder, through-hole and mixed assembly processes.

Electronic Manufacturing

Our facility is approved to ISO9001 and ISO 14001 standards and our workmanship standards to IPC610.

We also have global reputation for the design and manufacture of electronic products that are used in the subsea and marine industries.

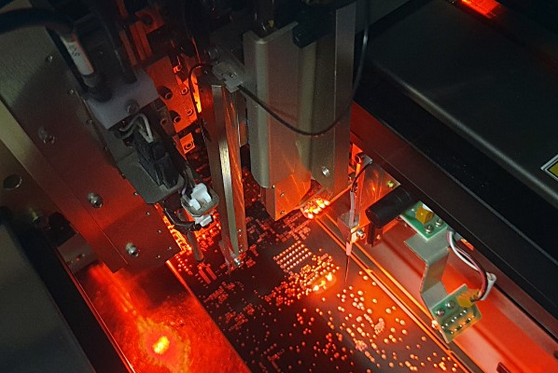

Electronics Testing & Inspection

Each board is carefully inspected by our dedicated inspection team using Automatic Optical Inspection (AOI) machines and flying probe testers. We test PCBs to component level, and all wiring is fully inspected and tested. Flash testing and earth- bonding tests can also be undertaken where required, with boundary scan testing when designed into the target assembly. Our team can conduct complex PPM and DPMO (defects per million opportunities) analysis to improve our processes and your products.

Full Turnkey Solutions

We can provide everything from basic PCB design and manufacture through to complete product assembly including testing, inspection and product packaging.

We can assemble complex mechanical systems with embedded electronics and then test them.

In addition to a dedicated account manager, you will have the full support of our design and production engineering team throughout the design and production process. We encourage communications across all functions as this results in smoother more efficient project management process and reduced time to market, which is critical for new product introductions.

About us

Our facility is certified to ISO9001 and ISO 14001 standards, and we adhere to IPC610 workmanship standards.

Texcel is globally recognised for designing and manufacturing electronic products for the subsea and marine industries. When partnering with us, you gain access to competitive pricing, flexible delivery options, rapid prototyping, and stocking arrangements tailored to your project. Our dedicated NPI team ensures a seamless transition from low to high-volume production, while maintaining open and transparent communication across all departments.

Our Services Include:

Electronic Design & Product Development

Our multi-skilled design engineering team collaborates closely with you to create feature-rich, high-quality, cost-effective solutions with repeatable production processes.

Electronics Procurement

Our highly skilled procurement team excels in sourcing components, which benefits our customers by speeding up the time to market for new product launches.

PCB Assembly

Effective PCB design is crucial to new product development. By working with us, you gain access to our technical experts, who bring extensive experience in PCB design and assembly. We encourage you to collaborate with them, as their advice can often enhance your design and help reduce overall costs.

Electronic Manufacturing

We provide a full spectrum of Electronics Manufacturing Services, from design and procurement to PCB assembly, testing, and complete turnkey solutions.

Electronics Testing & Inspection

Each board undergoes thorough inspection by our dedicated team using Automatic Optical Inspection (AOI) machines and flying probe testers. We perform component-level testing on PCBs, with all wiring being fully inspected and tested. Flash testing and earth-bonding tests are available as needed, along with boundary scan testing if integrated into the design. Our team also conducts detailed PPM and DPMO (defects per million opportunities) analysis to enhance both our processes and your products.

Full Turnkey Solutions

We offer a full range of services, from basic PCB design and manufacturing to complete product assembly, including testing, inspection, and packaging.

The company fosters strong customer relationships by promoting direct communication across all departments. We understand that each client has unique needs and provide tailored services in design support, production, and logistics.

We source components globally, with our procurement team excelling at securing parts for clients to ensure timely delivery, thanks to our strong partnerships with suppliers.

We take pride in delivering a service that is both professional and personalised for our customers.

Images

Brochures

Reviews

Trade Associations