Company details for:

Titan Enterprises

Unit 2,

5A Coldharbour Business Park,

Sherborne,

Dorset,

DT9 4JW,

United Kingdom

Quick Links:

Products / Services

Atrato® Inline Ultrasonic Flow Meters

Process Atrato® Ultrasonic Pulse Flow Meters

MetraFlow® Ultra-Pure Water PFA Ultrasonic Flow Meters

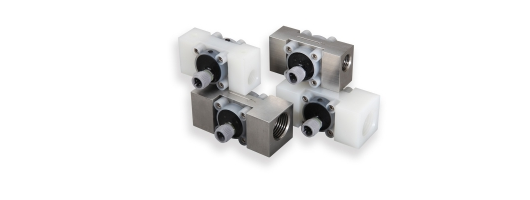

OG1 Oval Gear Positive Displacement Flow Meters

OG2 Oval Gear Positive Displacement Flow Meters

OG3 Oval Gear Positive Displacement Flow Meters

OG4 Oval Gear Positive Displacement Flow Meters

OG5 Oval Gear Positive Displacement Flow Meters

OG6 Oval Gear Positive Displacement Flow Meters

OG7 Oval Gear Positive Displacement Flow Meters

Metra-Clear Oval Gear Positive Displacement Flow Meters

NSF Approved 800-Series Turbine Flow Meters

NSF Approved Beverage Flow Meters

800-Series Low Power Turbine Flow Meters

900-Series Turbine Flow Meters

1000-Series Turbine Flow Meters

FT2 Optical Detection Turbine Flow Meters

FT2 Hall-Effect Detection Turbine Flow Meters

Pulsite® Solo Rate & Totaliser Battery Powered Display

Pulsite® Link Pulse & Analog Converter

About us

With over 40-years experience in flow meter innovation - Titan Enterprises Ltd are a leading UK-based design, manufacturer and supplier of high-performance liquid flow measuring solutions.

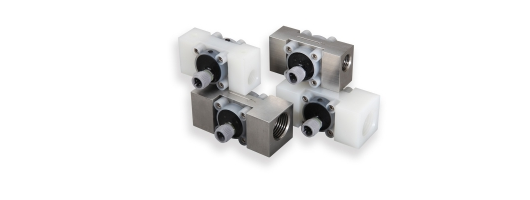

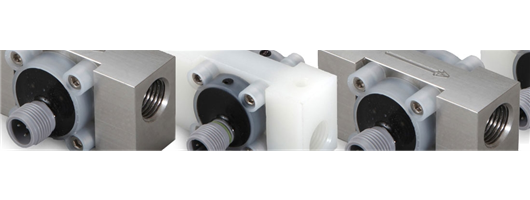

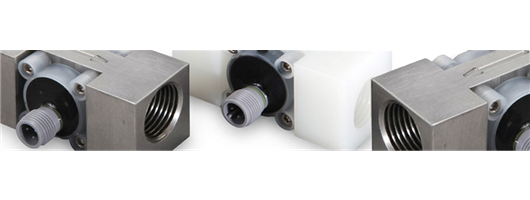

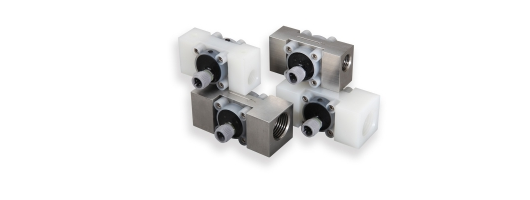

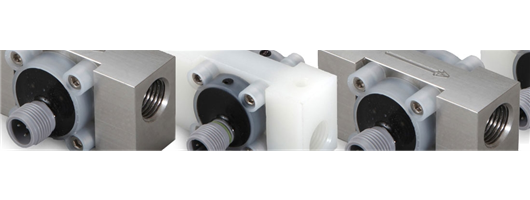

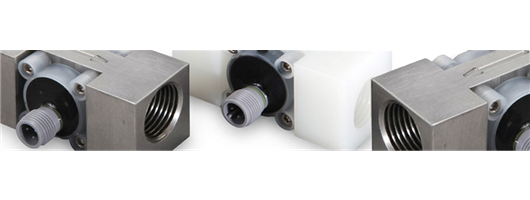

Titan’s Atrato® and Metraflow® ultrasonic flow meters, Oval Gear flow meters and the low flow Turbine flow meters and instrument range meet the requirements of broad industrial process applications. Our knowledgeable team can offer either an off-the-shelf meter or fully bespoke OEM flow system solution designed for a particular application or to work within customer-specific equipment.

Titan delivers innovative flow measurement solutions into a broad range of sectors, including medical, pharmaceutical, industrial, oil and petrochemical, food and drink, and laboratory. Utilizing the latest technology and collaborative partnerships, Titan’s innovation challenges conventional flow meter thinking to provide solutions for commercial, industrial and domestic markets.

With wide flow ranges, chemically inert and robust materials, and reliable high performance, Titan’s flow meters are ideal for process applications from viscous materials to drink dispensing and aggressive chemicals.

Titan’s company philosophy of “pushing the envelope by trying to do things a little different and better” has resulted in sales of over 2 million flowmeters and components into 50 countries worldwide and a repeat purchase percentage of 95%.

For higher volume users, we can tailor flowmeter design and materials to match customers’ exact application requirements. The resultant device, unique to the OEM application, still benefits from Titan’s modern manufacturing methods to ensure a competitive OEM solution. From an initial concept, Titan offers a complete service from budget costings through prototypes to full production.

All flow meters produced by Titan are designed and manufactured to ISO9001 and calibrated, if required, to an uncertainty of ±0.25%. We produce chemically resistant, high accuracy flow meters that are not only competitively priced but engineered to give long-term reliable performance.

The value of a flow meter cannot be judged by price alone. Often in industrial applications the reliability of a product far outweighs the initial purchase price, as “down time” is extremely expensive. At Titan we endeavour to produce devices that are inherently reliable and manufactured using the latest and most economical production techniques.

Typical Applications Overview

- Flow Batching

- Engine test metering

- Oil and petrochemical flow measurement and metering

- Hydraulic fluid measurement and metering

- High viscosity fluid measurement and metering

- OEM equipment

- Chemical plant measurement and metering

- Hazardous areas (simple apparatus)

- Laboratory use

- Cooling equipment and systems measurement and metering

- Food and drink dispensing

- Semiconductor plant

Images

Articles / Press Releases

Reviews

Trade Associations