Company details for:

TM Robotics

Unit 2, Bridge Gate Centre,

Martinfield,

Welwyn Garden City,

Hertfordshire,

AL7 1JG,

United Kingdom

Quick Links:

Products / Services

Shibaura Machine SCARA Industrial Robot Range

THL Range - Energy Efficient SCARA Robots

To bolster the robot’s overall performance, the THL features an aluminium extrusion cross-section, custom designed and manufactured for Shibaura Machine robots. Providing no compromise in strength, the aluminium extrusion is 55 per cent lighter than cast aluminium and its values are calculated precisely to maintain strong mechanical capabilities of the robot arm.

THL300 - SCARA Robots

Each THL offers a payload of 5kg. Cycle times (with 2kg load) are 48s for the THL300 and 47s for the THL400. All THL robots feature a working envelope of 4 axes, with a Z-axis rotation of 360°.

Maximum speeds range from from 5.1m/s to 6.3m/s overall.

THL400 - SCARA Robots

Each THL offers a payload of 5kg. Cycle times (with 2kg load) are 48s for the THL300 and 47s for the THL400. All THL robots feature a working envelope of 4 axes, with a Z-axis rotation of 360°.

Maximum speeds range from from 5.1m/s to 6.3m/s overall.

THL500 - SCARA Robot

Each THL offers a payload of 10kg. Cycle times (with 2 kg load) are 45s for the THL500 and THL600, and 50s for the THL700. All THL Robots feature a working envelope of 4 axes, with a Z-axis rotation of 360º.

Maximum speeds range from 6.3m/s to 7.9m/s overall.

THL600 - SCARA Robot

Each THL offers a payload of 10kg. Cycle times (with 2 kg load) are 45s for the THL500 and THL600, and 50s for the THL700. All THL robots feature a working envelope of 4 axes, with a Z-axis rotation of 360º.

Maximum speeds range from 6.3m/s to 7.9m/s overall.

THL700 - SCARA Robot

Each THL offers a payload of 10kg. Cycle times (with 2 kg load) are 45s for the THL500 and THL600, and 50s for the THL700. All THL robots feature a working envelope of 4 axes, with a Z-axis rotation of 360º.

Maximum speeds range from 6.3m/s to 7.9m/s overall.

THL800 - SCARA Robot

Each THL offers a payload of 10kg. Cycle times (with 2 kg load) are .47s for the THL800 and THL900, and .48s for the THL1000.

All THL robots feature a working envelope of 4 axes, with a Z-axis rotation of 360º with a Z axis movement up to 300mm.

THL900 - SCARA Robot

Each THL offers a payload of 10kg. Cycle times (with 2 kg load) are .47s for the THL800 and THL900, and .48s for the THL1000.

The THL robots feature a working envelope of 4 axes, with a Z-axis rotation of 360º with a Z axis movement up to 300mm.

THL1000 - SCARA Robot

Each THL offers a payload of 10kg. Cycle times (with 2 kg load) are .47s for the THL800 and THL900, and .48s for the THL1000.

All THL robots feature a working envelope of 4 axes, with a Z-axis rotation of 360º with a Z axis movement up to 300mm.

THL1200 - SCARA Robot

Each THL offers a payload of 10kg. Cycle times (with 2 kg load) are .47s for the THL800 and THL900; .48s for the THL1000 and .58s for the THL1200.

All THL robots feature a working envelope of 4 axes, with a Z-axis rotation of 360º with a Z axis movement up to 300mm.

TSL3000E Controller

THE Series: High-Speed SCARA Robots

TH Range: SCARA Robots

6-Axis Industrial Robot Range

Compact yet powerful, 6-axis robots are an ideal articulated robot solution for many industrial manufacturing environments. They provide the optimal combination of flexibility, strength and reach.

As the name suggests, these robots are able to move along six axes, mimicking the movements of a human arm. Each axis represents an independent motion or degree of freedom, which allows the robotic arm to move to a programmed point.

While some robots struggle with dexterous applications, 6-axis industrial robots are suited to precision automation tasks due to their motion control capabilities. These versatile and flexible robots can also be easily reprogrammed for other tasks. At TM Robotics, we can work with you to make adjustments for custom applications.

6-Axis TVL Range Industrial Robots

The TVL industrial robot brands also include an aluminium extrusion cross-section. The design takes inspiration from the Shinkansen bullet train − reducing weight without compromising on strength or performance. This also achieves an impressive 70 per cent reduction in power requirements compared to other robot series

TVL500 6-Axis Robot

This light weight, compact vertically articulated 6-axis robot offers high performance and productivity on all assembly and handling applications. Yet, because of its compact size, it also saves on space delivering all of the functionality that you would insist on from a 6-axis robot, but with a fraction of the expected foot-print within your production line.

6-Axis TV Range Handling Robots

TV1000H - 6-Axis Robot Arm

This 6 axis mechanical desktop robotic arm, can be used in a host of pick and place applications such as machine loading, unloading and assembly applications. Known for its unique design, the TV1000H has a total arm length of 1000mm and a reach of 1090mm contributing to a composite maximum speed of 9.61 meters per second.

Performing to a maximum cycle time of 0.9 seconds, and repeatability of ±0.03mm and a maximum payload of ten kilograms, this robot can offer our customers that additional flexibility required in certain applications.

6-Axis TVM Range Robots

The TVM robot’s lightweight design is improved by the addition of an aluminium extrusion. This section of the robot is up to 55 per cent lighter than the usual cast aluminium. From a production perspective, reduced weight reduces the overall cost of production and components, further improving the costs associated with this machine.

Controllers & Options

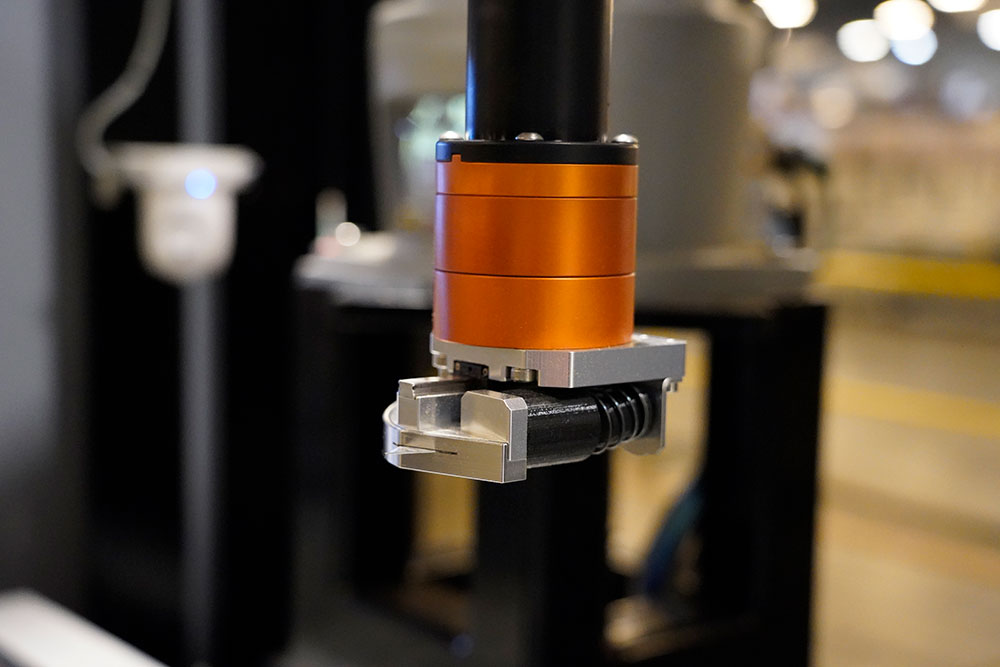

TSVision3D − 3D Vision for your Industrial Robot

3D vision allows robots to account for unforeseen variables in their work environment, to complete more than one task without reprogramming and to be used in a broader range of applications. It's ideal for uses where objects aren't uniform or lack CAD data, like fruit or vegetables. 3D vision eliminates the risk of error due to object location and improves robot flexibility and speed compared to "blind" robots in pick and place tasks.

Easy to Program Robot Training

We also provide various levels of training, from basic robot programming to more advanced courses. In fact, our advanced training programs include operating the Shibaura Machine built-in PLC, taking advantage of conveyor tracking functionality, field bus communications and applying vision systems to robotics applications.

Robot Programming Software

When combined with TM Robotics training options, the outcome is a simple, cost effective and easily controlled installation.

THE400 - SCARA Robot

Accurate movement trajectory with high speed operation and high load performance.

The THE400 offers a cycle time of 0.39 seconds (with 2kg load). Maximum load of 5kg.

THE600 - SCARA Robot

Advancing from the specifications of the existing THE400 SCARA, the THE600 has been developed to meet growing demand for fast-cycle automation. The THE600 model includes improvements in synchronised control and tracking precision.

The THE600 is compact in design and offers improved high speed, with 60 per cent higher payload capacity than competing SCARA models in the same price range, making it the price-to-performance leader.

THE800 SCARA Robot

THE1000 - SCARA Robot

As the largest model in the range, the THE1000 has a maximum payload of up to 20kg, making it suitable for assembly processes that carry larger components. Among the possibilities of the THE1000 is electric vehicle battery assembly, but it can be used in almost any application. Smaller models include the THE400, THE600 and the THE800.

TS5000 Controller for Easy Robot Programming

Compared to previous controllers, the TS5000 offers a three times faster position cycle for better synchronisation and control. Plus, with dedicated ports for status feedback and control, additional ports for priority communication like vision interfacing, and eight additional ports for non-protocol communication − four times as many as the previous model − the TS5000 is designed for use in today’s smart, connected factories.

Injection Moulding Machines

The product range includes the full scope of the all-electric SXIII injection moulding machine series − an enhanced performance model from Shibaura Machine, with significantly faster injection speeds than traditional moulding equipment. You can view the full range of SXIII injection moulding machines here.

Automated Box Opening Robots

About us

Images