Company details for:

Welwyn Tool Group Ltd

Unit 2,

Little Mundells Business Park,

Welwyn Garden City,

Hertfordshire,

AL7 1EW,

United Kingdom

Quick Links:

Products / Services

Roof Membrane Welding Hand Tool

Used with the wide range of LEISTER nozzles, rollers and accessories for roof welding, the TRIAC-ST will enable you to weld single ply membrane overlap welds at 20mm and 40mm with materials from manufacturers including Sika/Sarna, Icopal, Protan, Flag, Soprema and Bauder to name a few. The TRIAC ST is the latest hot air tool of choice for professional roof installers worldwide and is available either as a hand tool in a case, or can be purchased as a complete roofing kit to suit your specific needs.

Leister FORTE S3

Key Features

- 650°C Temperature

- Power consumption of 10 kW

- Powerful pallet shrink-wrapping

- Uniform shrinkage

- May be used in confined spaces

- Integrated tool stand

Leister TRIAC AT

Key Features

- Suitable for site work

- Digitally controlled and displayed temperature

- Sturdy but weighing only 1 kg

- Two-component handle grip with optimal centre of gravity

- Quick clean air filters

- Automatic carbon stop and heating element protection

- Available in 120V and 230V

- Takes push fit nozzles

Leister MINOR Mobile Blower

Key Features

- Lightweight and compact

- Powerful

- Suitable for work on construction sites

- Serves as a mobile air supply for the DIODE PID, DIODE S and LABOR S

- Delivering 400 l/min

- Weighing only 1.15 kg

Leister WELDPLAST S2 PVC

The PVC version of the compact hand held extrusion gun with a welding speed of up to 2.7kg/h; the established flagship of the plastic welding range, the Leister WELDPLAST S2 PVC is a truly fantastic hand extruder that will enable you to weld PVC plastic materials as well as HDPE and PP. The PVC version will weld all main thermoplastics as well as handling the corrosive nature of PVC.

Key Features

- Optimised for PVC-U

- Perfect weld seam quality

- Welds PVC-U, PP, PE (other materials on request)

- Heavy Duty Extruder with a welding speed of up to 2.7kg/h

- Welding rod diameter 3 or 4 mm

- Maintenance-free hot-air blower

- Adjustable grip

- Multifunction display

- Weighs 5.8kg

- Power 3kW

Leister WELDPLAST S6

WELDPLAST S6 is the world’s highest rated hand-held extrusion welder. With an output of up to 6 kg/h, it is surprisingly manoeuvrable. It features a brushless, preheat motor, multifunction display and comfortable ergo-grip − making the S6 Leister’s flagship extrusion welder.

Key Features

- Welds PP and PE

- 6 kg output per hour

- Welding rod diameter 4 or 5 mm

- Adjustale control wheel

- Maintenance-free hot-air blower

- Multifunction display

- Material Preheater

- Pre-set Welding Material Profiles

- Weighs 14kg

- Power 4.6kW

Leister TRIAC-AT Plastic Welding Kit (110v)

- Leister Triac AT 110v

- Leister 5mm Nozzle

- Leister Tacking Jet

- Leister 4mm Round Speed Weld Nozzle

- Leister 5.7mm Triangular Speed Weld Nozzle

- Rotary Burr

- Mixed Welding rod

The Triac AT version of the Plastic Welding Kit brings full digital control and the ability to set temperature and blower speeds independently of each other for even better welding control. With a comprehensive suite of diagnostic software the TRIAC AT will show the operator when there is (or isn’t) adequate voltage from the generator to be able to weld plastic effectively; its LCD display will even tell you when it is time for the brushes to be replaced or time for a service! A truly fantastic addition to the Leister range. Available now as a complete plastic welding kit.

Foam Cutter AZ TC20 Hotknife

- easy operation by safety push button

- adjustable power regulation

- rapid blade heat up

- overheating protection

- easily change blade functionality

- LED function control and much more.

The AZ TC 20 Hotknife / Foam Cutter is suitable for the following materials:-

- Foam cutting

- Plexiglass cutting

- Tyre cutting

- Rubber cutting

- Styrofoam cutting

- Rope cutting

- Polystyrene cutting

- Plastic cutting

Leister Vacuum Pump 120v

Leister VARIMAT V2

The Leister Varimat V2 is the successor to the longstanding and established Varimat V and introduces even faster welding speeds of up to 12 metres per minute, as well as the ability to store user settings for pre-programmed material profiles using its innovative e-drive system.

The Varimat V2 operates on-site using the 230v feed from a 7.5KVA − 10KVA generator and will weld overlaps of 40mm on the roof as recommended by the single ply membrane material manufacturer.

Key Features

- Slimline design allows welding up close to edges

- Welds PVC, TPO, ECB, EPDM, CSPE

- Welds up to 12 metres/minute

- Guide bar for ergonomic handling

- Maintenance free blower for lower servicing costs

- No shrinking of insulation due to integrated air dam

- Uniform welding results

- Press & turn controls with saved settings

- Constant drive & regulated electronics

- Requires only one user to efficiently weld seams

- Power up to 5.7kW

- Weight 35kg

- Temperature range between 100 − 620ºC

Hot Wire Cutter AZ ZTS-24

The ZTS-24 hotknife / hot wire cutter is the tool for heavy duty users who require constant use. It combines the functionality of the smaller ZTS-20 hot knife foam cutter, but in a more robust, durable and secure heavy duty model, still offering rapid blade heat up and ease of use.

You will need to use this unit in conjunction with the GG2 Hot Knife Controller (which we also supply).

Leister HOT-JET S

Key Features

- Weighs just 600g (0.6kg)

- Stepless electronically controlled temperature

- Stepless electronically controlled air flow

- Ultra compact design

- Built-in stand

- Low noise

- Compatible with a wide range of nozzles

Leister GROOVER (120V/230V)

The Leister Groover cuts welding grooves into thick, tough floor coverings made of PVC-P, PE and linoleum with ease. The GROOVER glides on three rollers and cuts a uniform grooving depth even at high speeds.

Key Features

- Cuts all types of floor coverings

- Adjustable guide roller for tracking accuracy

- Easy and safe to use

- Reduced dust particles with included dust bag

- Able to cut close to floor edges

Leister TRIAC-ST Floor Welding Kit (230v)

- Leister Triac ST 230v

- Leister Feed Roller

- Leister 5mm Nozzle

- Leister 5mm Round Speed Weld Nozzle

- Spatula/ Crescent Knife

- Leister Speed Grover

- Spatula Guide

Used in multiple applications the Leister TRIAC-ST will enable you to weld vinyl & safety flooring with a professional finish. The Leister TRIAC-ST Flooring Kit includes all the necessary accessories to be able to weld floor vinyls in the most cost effective way. Fundamentally based on the TRIAC-ST the kit includes the hot air tool of choice for trades professionals worldwide.

Leister FUSION 3

The plastic extruder ideal for working on fabrications where materials are on the ground, saving the operator having to bend down to weld. It’s ‘no nonsense’ plug-in and weld capability means you will get the job done at speeds of up to 3.5kg/h.

Key Features

- Welds PE/ PP

- High performance extruder

- No fuss Plug-in & Weld functionality

- Easier on the operator’s back!

Leister Weldplast S2 PVC

The PVC version of the compact hand held extrusion gun with a welding speed of up to 2.5kg/h; the established flagship of the plastic welding range, the Leister WELDPLAST S2 PVC is a truly fantastic hand extruder that will enable you to weld PVC plastic materials as well as HDPE and PP.

TRIAC-ST GEOTEXTILE WELDING KIT-BASIC (110V)

Leister Triac ST 120v

Leister 40mm Silicone Roller

Leister 40mm Wide Slot Nozzle

Used in multiple applications the Leister Triac-ST will enable you to weld all types of geo-textile membranes where overlap welding is required at the industry standards of either 30mm or 40mm. The Leister Triac-ST Basic Geo-textile welding Kit includes the necessary accessories to be able to weld roof membranes in the most cost effective way. Fundamentally based on the TRIAC-ST the kit includes the hot air tool of choice for professionals worldwide.

Leister GEOSTAR G5 Wedge Welder

This is the machine the GeoTextile market has been waiting for; the next generation Concord machine!

Since Concord was integrated into LEISTER in 2012 LESITER has been working on developing technology to produce a new machine for welding materials 0.8mm to 3.0mm; HDPE, as well as welding PP, LDPE, TPO, FPO, PVC-P.

The GEOSTAR is the result of prior Concord innovation combined with the latest LEISTER pedigree & Know-How.

Key Features

- Digital display shows actual welding pressure, heat output & speed

- Easily adjusted for different material thicknesses

- Welds up to 12 metres/min

- Up to 2800W of heating power

- Welds materials from 0.8mm to 3.0mm thick

- Wedge exchange in less than 1 minute!

Leister VARIANT-T1 (Tape)

Designed with the aim of increased productivity when manufacturing items such as lorry side curtains and tarpaulins, marquees and other PVC coated materials, the Variant T1 will weld at up to 18m/min, almost twice the speed of the existing machine. A key new feature is the ability to view all angles of the welded seam during the welding process; a critical part of the new machine. This ensures that the operator has full control over the final result of the item being manufactured, ensuring maximum quality of the finished product.The Leister Variant T1 boasts an impressive welding speed of up to 18 metres per minute, combined with a slim, study and compact design.

Key Features:

- User friendly display plus storable welding parameters

- Fast & accurate welds up to 18 Metres per minute

- Digital ‘e-drive’ operation

- New guide roller keep tape taut to the final cm

- Dual-action − easily converted from 50mm to 25mm tape

- Kits available to convert Overlap to TAPE version

Leister SEAMTEK 36

A recent addition to the textile welding range, the SEAMTEK 36 guarantees great flexibility. With its easily configurable, modular construction and wide range of pressure rollers and nozzle widths, the SEAMTEK 36 guarantees the greatest flexibility. The ingenious tape guiding system makes it easy to position material and keep it taut throughout for wrinkle free and precision welding. The pedestal, included in the SEAMTEK 36 Base version, is the workhorse of the system. Together with one of three additional modules almost every plastic weld technique is possible.

Key Features

- Suitable for seam or tape welding

- Handles overlap, butt joints, hem pipe, tape and prayer welds

- Test program to optimise welding parameters

- Easy to access welding process

- Quickly changeable accessories for many applications

Leister LHS 15 Classic Process Heater

Power consumption: 0.55 to 0.8 kW (120V and 230V respectively);

Heating power: not adjustable

Detection of heating element and device overheating: Y with alarm output

Max. air outlet temperature: 650ºC

Max. air inlet temperature: 65ºC

Max. ambient temperature: 65ºC

Max. inlet pressure: 100 kPa

Weight: 0.48 kg

Min. air flow: (see graph)

Leister SILENCE Industrial Process Blower

Technical data: SILENCE

Design: radial blower

Frequency: 50Hz or 60Hz

Air flow (20 °C ) l/min: 4,700 @ 50Hz, 6,000 @ 60Hz

Static pressure: 1.0 kPa @ 50Hz, 1.4 kPa @ 60Hz

Max. ambient temperature: 60°C

Max. air inlet temperature: 200°C

Noise emission level: 61 dB(A)

Environmental protection (IEC 60529): IP 54

Outside diameter air inlet: ∅ 80mm

Outside diameter air outlet: ∅ 60mm

Weight: 9.0 kg

Comes with or without cable

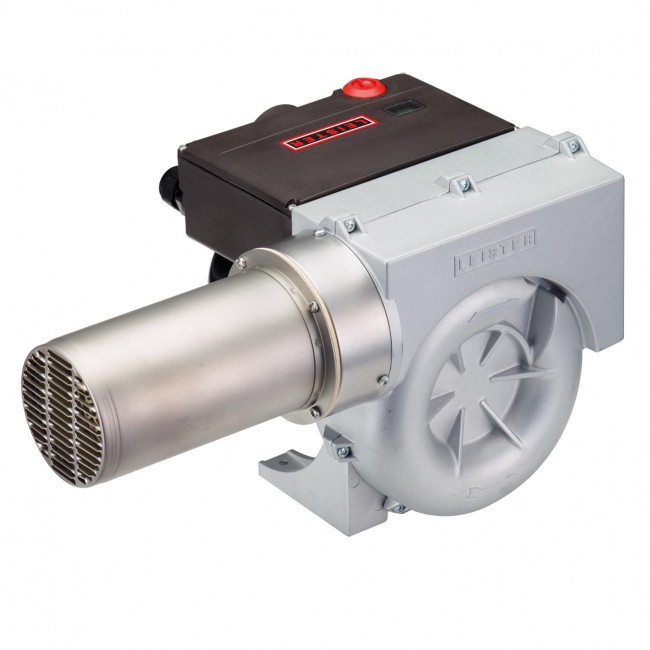

Leister VULCAN Industrial Process Hot Air Blower

remotely through a standard analog interface.

Technical Data: VULCAN SYSTEM

Frequency: 50 − 60 Hz

Heating power steplessly adjustable with potentiometer: Y

Standard control interface through a 4 − 20 mA or 0 − 10 V signal: Y

Integrated power electronics: Y

Protection against heating element or device overheating: Y

Brushless blower motor with FC control: Y

Alarm output: Y

Integrated temperature control: Y

Integrated temperature probe: Y

Display for showing the setpoint and actual values: Y

Max. air outlet temperature °C: 650

Max. air flow l/min (20 °C) 3 × 230 V~: 850 (50Hz), 1500 (60Hz)

Max. air flow l/min (20 °C) 3 × 400 V~ / 3 x 480 V~: 950 (50Hz), 1700 (60Hz)

Static pressure kPa: 3.1 (50Hz), 4.0 (60Hz)

Noise emission level db (A): 65

Weight (kg): 9.3

Power consumption: 6 − 11 kW

Leister KSR Controller

Leister DSE Three Phase Controller

Leister DSE Three Phase Controller is the power electronics module to digitally regulate the LE 5000/10000 series of non-electronic air heaters. Available in versions for use with a potentiometer or the KSR DIGITAL temperature controller.

About us

The LEISTER plastics welding product range includes extruders, hand tools, hot knives, repair kits and tensiometers.

The LEISTER vinyl floor welding product range includes flooring kits, hand tools and welding machines.

The LEISTER roofing membrane product range includes hand tools, hot knifes, roofing kits, roofing machines and tensiometers.

The LEISTER banner welding product range includes automatic machines, hand tools, hot knives and repair kits.

The LEISTER vehicle repair product range includes hand tools and repair kits.

The heat shrink product range from LEISTER includes hot air hand tools and blowers.

Welwyn Tool Group also distribute LEISTER products including hot air welding products for civil engineering and industrial heaters & blowers for process applications including curing, drying, heating, melting, shrinking and sterilisation.

Images