Company details for:

Western Mechanical Handling UK Ltd

Quick Links:

Products / Services

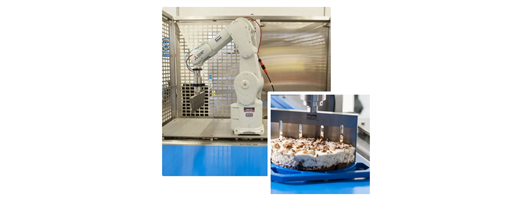

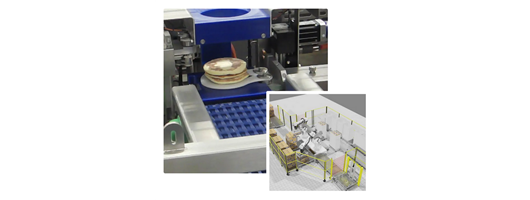

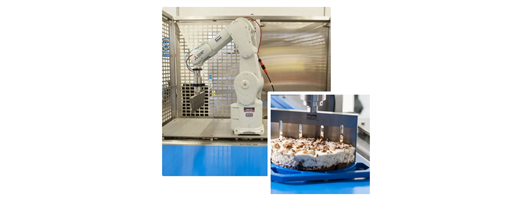

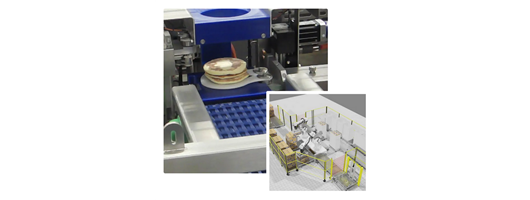

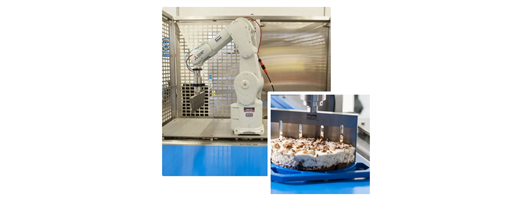

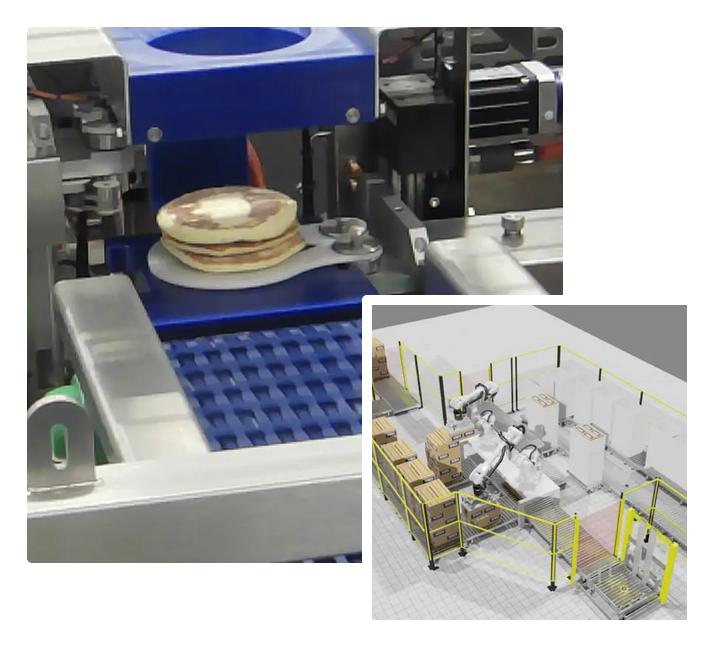

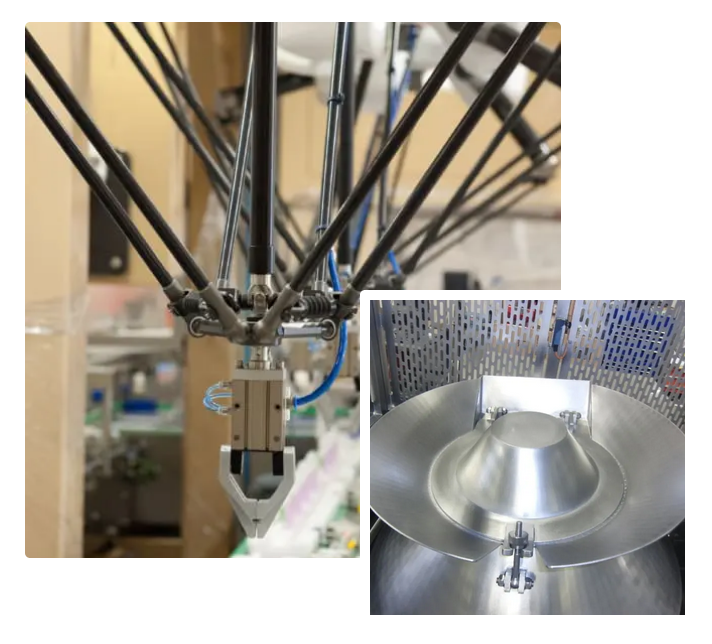

Robotic Solutions

Robotic solutions offer a flexible solution to the automation of repetative production line tasks where multiple product configurations are needed for future proofing your line.

Controls & Automation

WMH Automation provides in-house control system build and design for all WMH mechanical handling and production line equipment and attends on site with WMH systems to ensure systems integrate seamlessly with other line processing equipment. WMH Automation will also carry out commissioning and factory acceptance trials for WMH lines. WMH Automation engineers are also able to provide on-site and remote support for non WMH machinery. For more information or to discuss a specific requirement please email WMH Automation at: automation@wmh-uk-ltd.com

Ready Meal Assembly

WMH Ready meal assembly lines are:

Designed to fit your range of tray sizes

Single or twin lane configuration

Continuous or indexing operation

Fitted with electrical and pneumatic service outlets

Outfeed lane merging option

Touch-screen menu driven operator control

Grilling & Browning Systems

WMH inline industrial grilling units are designed to add colour to the top of ready meals and convenience foods without increasing the core temperature of the product. The specialised infrared heater panels provide even consistent heat across the width of the grill and the quick reaction time enables panels to be at optimum operating temperature almost instantaneously.

All WMH inline grill units as designed to suit the specific browning requirements of your product and the required throughputs for the line. Prior to specifying a unit WMH will carry out extensive product trials both at their test facility in Callington and onsite at your factory to determine the best size machine to achieve the required throughput and colouration of the product.

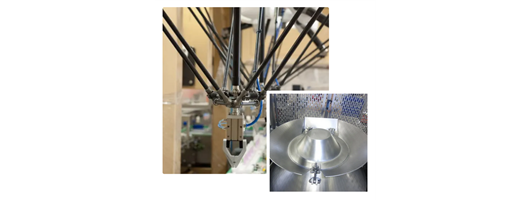

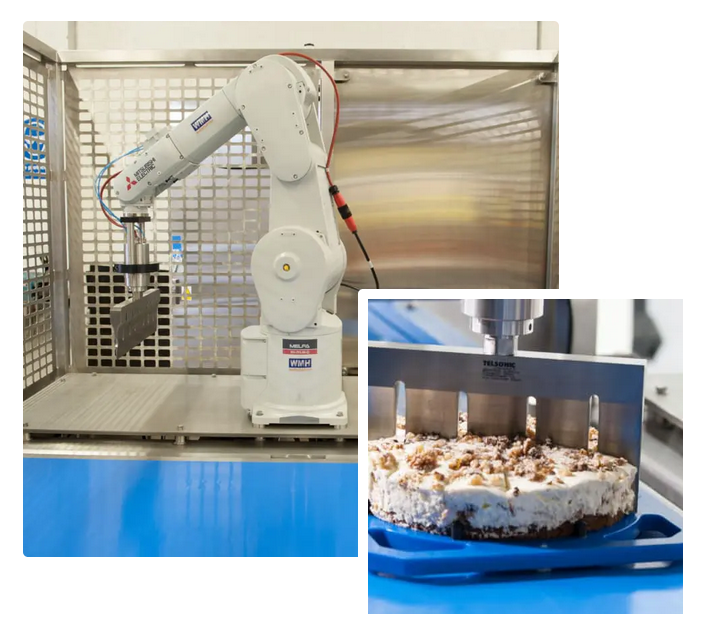

Ultrasonic Cutters

Whether you are looking for a compact standalone unit for batch production or a fully automated inline solution the WMH flexible ultrasonic cutting range has a model to suit our requirements.

Developed over a number of years in close cooperation with Mitsubishi Electric Automation and Telsonic Ltd, the WMH range offers a reliable and flexible solution to your cutting requirements that will enhance the quality of your product and reduce the cost of product wastage.

Oven Loading / Unloading

Working with large bakeries WMH has developed oven loading and unloading systems for a range of product formats from pies and quiche in foils, to individual sausage rolls and pasties and baking trays of batter puddings and strap tins of bread and cakes.

Running at speeds of 5000 units/hour WMH oven loading and unloading systems will gently handle and collate even the most delicate products and transfer them from assembly line to oven and beyond without damage to ensure your line runs efficiently with optimum product loading to achieve the maximum throughput for your production line.

WMH works closely with the supplier of your oven to develop a solution that best suits your product and production requirements.

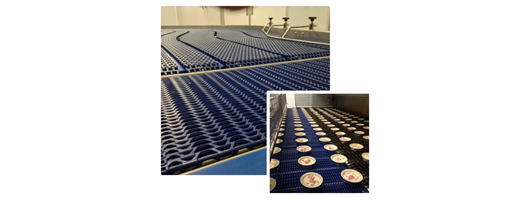

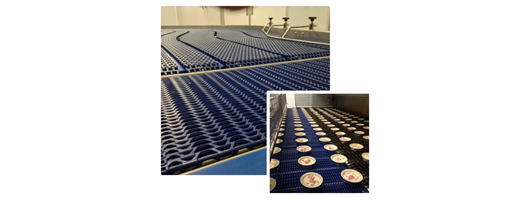

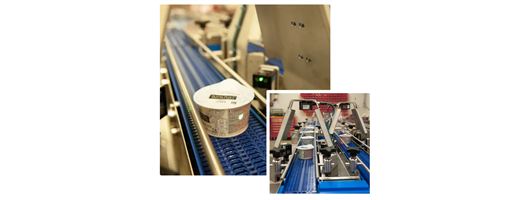

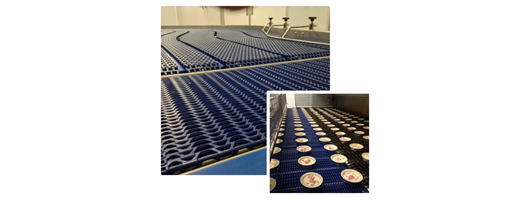

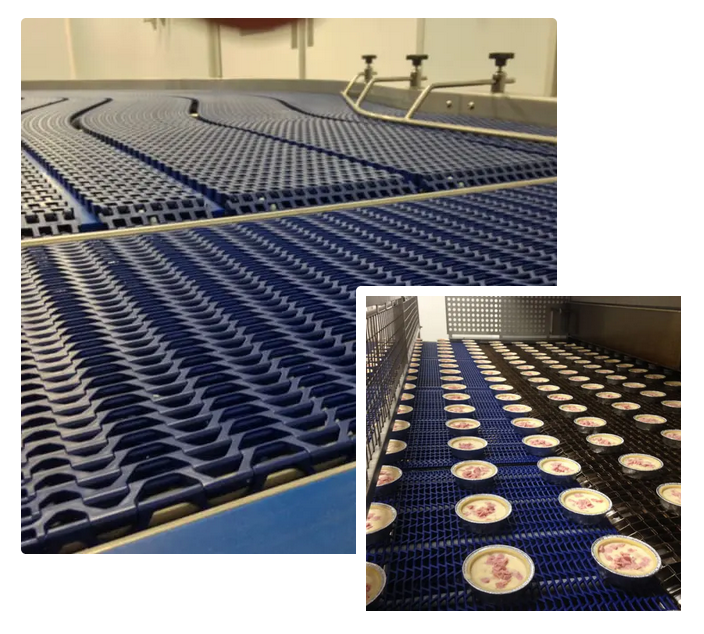

Chiller Loading / Unloading

WMH provides spiral freezer and chiller loading and unloading systems to large commercial bakeries. Systems are designed to handle many formats of product from chilling of freshly baked goods to freezing of ice cream.

Our solutions seamlessly convey your products from oven to freezer and or freezer to packing line. WMH takes care to gently collate or lane products across the chiller belt. This ensures your line runs efficiently with optimum product loading. Maintaining the maximum throughput for your production line.

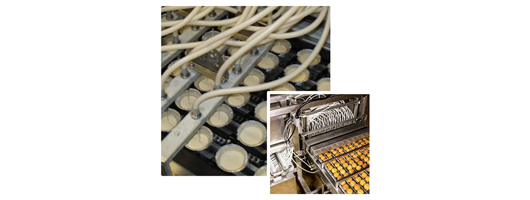

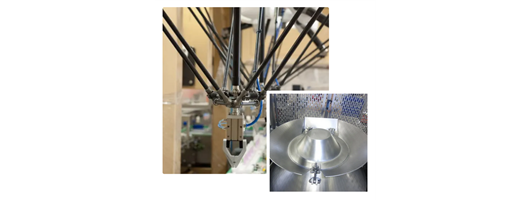

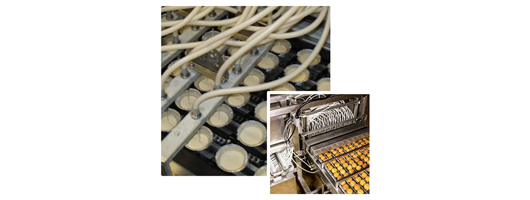

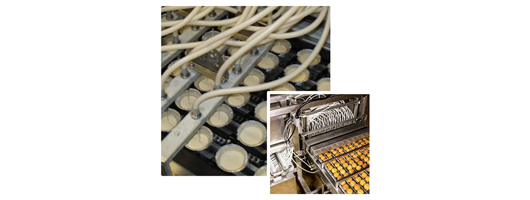

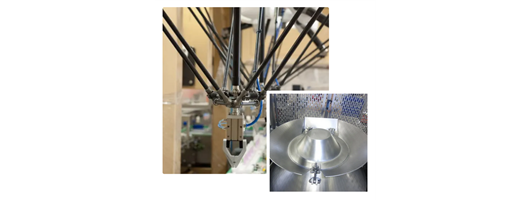

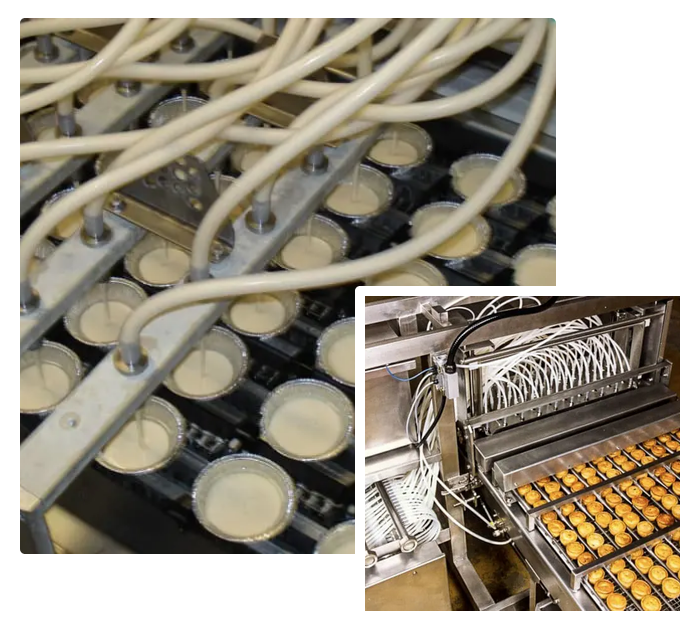

Product Depositing

WMH hygienic multi-lane depositing systems are designed for liquid depositing of hot or cold sauces at high throughputs and with great repeatable accuracy. Our depositors can be supplied as standalone mobile units or can be fully integrated into the production line.

Systems range in size from single pumps with six chambers up to multiple pumps linked together each with up to 32 chambers, and can be stand-alone units or inline systems incorporated into long production lines depositing many products per cycle.

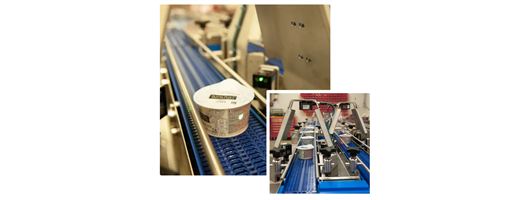

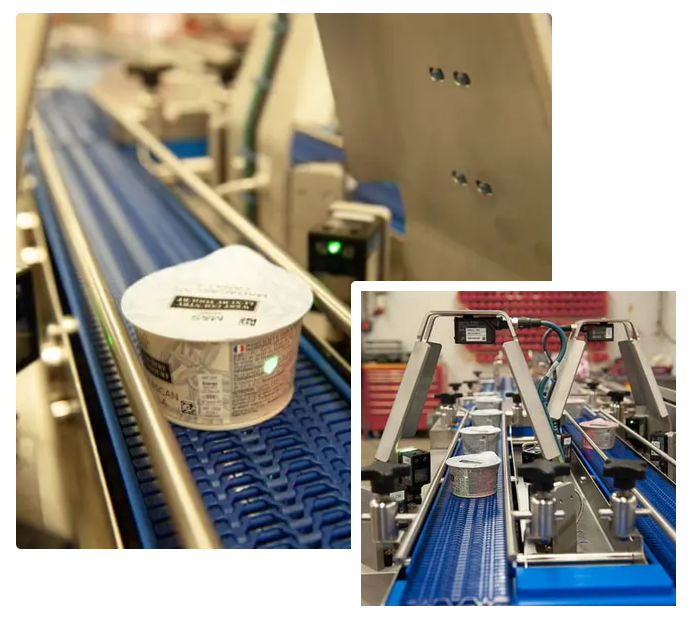

QR Code Scanning

Working with major suppliers WMH has developed a QR code scanning system to enable producers to check and verify QR codes between products and their lids. Using groups of cameras the system generates a 360 degree view of the product to ensure codes are viewed no matter the orientation of the product.

Output data can be used to flag or reject mis-matched products to minimise the risk of product defects which can lead to costly product recalls.

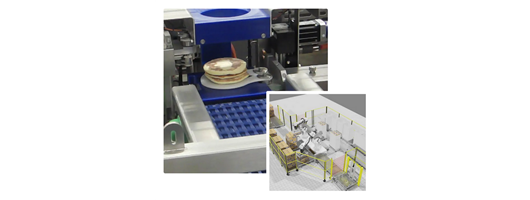

Packing Systems

Finished products require careful handling to ensure the best quality product reaches the consumer. WMH has developed a range of packing systems to suit various product packing requirements.

Whether your line requires a fully automated robotic pick and place system or lower cost alternative with operator intervention WMH will be happy to provide a cost effective solution tailored to your specific product and production requirements.

Platforms & Stairs

Inline automation solutions inevitably lead to personnel access issues, to mitigate this WMH supplies bespoke access steps, walkways and platforms to minimise inconvenience to workers and to maintain safe access and egress routes for daily operation and emergency escape routes.

WMH access solutions are designed in-house in Callington and provide safe personnel access routes. WMH platforms and walkways are designed with all the hygiene features demanded of a wash-down food production or clean room production environment.

Where access is required over unwrapped food products our access walkways and steps are designed to ensure debris is contained on the walkway and any washdown water is safely contained and drained away from the production line below.

Special Purpose Machinery

WMH develops special purpose machinery tailored to customers often unique product handling and processing requirements. If you have a complex handling issue that you are looking to automate then WMH may be able to help.

WMH engineers will work with you to develop a solution utilising a range of tools from layout drawings and 3D models, visal simulations and trial rigs and mock ups to prove the process prior to development of the final production unit.

Pharmaceutical Applications

Working with major blue-chip pharmaceutical companies WMH have developed high-tech handling solutions to a range of handling requirements. As a design and build company WMH is happy to work in partnership with clients to develop specialist machinery for very specific handling needs.

As with all our food handling equipment WMH prides itself on designing and building high quality machinery that is robust, hygienic and flexible and adaptable to changes in production requirements.

WMH understands the demands of a clean room environment and designs all machines to be cleanable and where possible minimises the areas where build-up of debris can occur, with sloping surfaces and spacing off of bearings and joining brackets and support frames.

Betavac Vacuum Sealers

The world’s choice in cheese packaging systems

For over three decades, the BetaVac design has earned the trust of the dairy industry, renowned for its durability and reliability. WMH are pleased to able to supply and support these machines across the UK and Europe.

With installations spanning the globe, BetaVac has become a trusted partner for some of the most prominent names in the dairy sector.

The versatile BetaVac range is capable of packaging:

- 20lb/10kg cheese blocks

- 40lb/20kg cheese blocks

- Cheese offcuts

- Other loose products

- Additionally, it is well-suited for packaging meat and other perishable items.

BetaVac Key Features

- Advanced Connectivity: Ethernet communication enables seamless data capture and integration with other plant systems.

- Low Maintenance: Rugged stainless-steel components minimize upkeep costs.

- User-Friendly Design: The fully automatic pneumatic belt tensioner simplifies cleaning and belt replacement.

- Enhanced Operator Comfort: Soft vent vacuum valves and a silencer reduce noise exposure for better operator well-being.

- Customizable Configuration: Seal bars can be left-handed, right-handed, or both, to suit your layout needs.

- Reliable Operation: Auto-calibration runs via the HMI (Human-Machine Interface) whenever elements are changed.

- Effortless Diagnostics: The HMI displays fault areas on a circuit diagram when the temperature controller detects alarm conditions.

- Flexible Options: Explore the range of BetaVac models by downloading the brochure for more details.

About us

Western Mechanical Handling UK Ltd (WMH) designs, builds and supports production line automation machinery for the food and pharmaceutical industries. Based in Cornwall, South West England, this family owned business has been helping food producers automate and streamline their production processes for nearly 50 years.

Bespoke Automation

If your production process has a problem WMH can design and manufacture a bespoke solution. If you have large pieces of capital equipment that need linking together to make a production line WMH should be your go-to provider for a truly bespoke solution that will stand the test of time and adapt to meet the ever-changing demands of a busy production facility.

While all our solutions are bespoke, designed to meet the exact needs of our clients our products have core values which have been honed and developed over time to provide our users with cost effective, reliable and innovative solutions which will stand the test of time.

Turnkey Solutions

WMH is proud to offer turnkey solutions based on sound engineering principles. WMH offers a complete end to end package from initial concept design, through manufacture, wiring and programming to installation, commissioning and after sales service and spares support. Our machines are manufactured at our purpose-built facilities in Cornwall where raw metal is transformed into working machines.

Building Long-Term Relationships

At WMH aim to we aim to build long-term relationships with our clients so that we can help you grow and develop. We want to be able to support you long term so you know if you need to modify or upgrade your line at any time WMH will be there to support you. We have several sites still using machinery installed over thirty years ago, doing the job they were designed for. WMH has supported this customer over the years by supplying spare parts as needed and hope to be able to provide them with a new line when the time arises. Another client has completed a phased upgrade of their depositing and oven loading systems. WMH was able to retrofit the latest pressure-less collation systems into the existing oven loading system to improve flexibility, throughput and product quality. This was coupled with an upgrade to the drives on their 20-year-old depositing systems to add servo drives for improved accuracy.

Increasing Productivity and Quality

Working with WMH can help you increase your production throughput and quality, as has been the case for a small manufacturer of tray-bake cakes. Installation of a WMH cutting cell has enabled them to scale up production to meet demand without the need to expand their workforce. A side benefit of this added automation has been to improve the aesthetic finish of the product and reduce breakages

Core Areas of Expertise

WMH has a number of core areas of expertise into which most projects fall. However when more specialised solutions are required, WMHs design engineering team have the engineering expertise to develop novel solutions from scratch. Some such projects include: stacking pancakes, collating yogurt sticks, loading cheese into crates and counting and packing bacon rashers.

- Assembly Lines

- Depositing Systems

- Oven Loading and Unloading Systems

- Spiral Chiller/Freezer Loading and Unloading Systems

- Grilling and Browning

- Ultrasonic Cutting Machines

- End of Line Packing Systems

- Tray and Box Handling and Palletising Systems

- Farmhouse Cheese Making Equipment

Images