Company details for:

Wilbar Components Ltd

Quick Links:

Products / Services

High Precision Turning

5-Axis Machining

Turnkey Solutions

Toolroom / Ancilliary Equipment

OPTICAL TOOL & CUTTER GRINDER

BRIDGEPORT MILL WITH D.R.O

TOOL & GAUGE VENDING MACHINE

2 x BUNDLE CUT BANDSAWS

VERTICAL BAND SAW

MITRE CUT BANDSAW +/- 90 DEGREES

HYDRAULIC PRESSURE TEST CABINET − UP TO 25,000 PSI STATIC TEST

10 TONNE HYDRAULIC PRESS

ASSEMBLY FLY PRESSES − VARIOUS SIZES AND WEIGHTS

HURCO VMX42SRTi Simultaneous 5 Axis Vertical Machining Centre

X, Y, Z Axis Travel - 1067 x 610 x 610 mm

Max. Weight on Table - 1,360 kg

Max Weight on Rotary/ Trunnion Table - 500 kg

Spindle Nose to Table (Min-Max) - 10 / 620 mm

Table Size - 1,270 x 610 mm

Table Size C - 600 mm dia

B, C Axis Travel - +/- 90°, 360°

Spindle

Max. Spindle Speed - 12000 rpm

Peak Spindle Motor - 36.5 kw @2,900 rpm

Spindle Torque - 118 Nm @ 2,900 rpm

Inspection Equipment

Baty R14 GXL Inspection Shadowgraph Projector

Miyano ABX-64SYY Turning Centre

twin spindle

twin turrets and 2 Y axis.

The ability to machine simultaneously at the left and right spindles using the upper and lower turrets,

both featuring a Y-axis function, means that complete front and back machining of products with

Complex shapes can be accomplished simply and in a short time.

HURCO TM10 Lathe

Distance Between Centres - 735 mm

Swing Over Bed Diameter - 582 mm

Swing Over Cross Slide Diameter - 402 mm

Max. Turning Diameter - 450 (304) mm

Max. Turning Length - 760 (734) mm

Max. Bar Capacity - 81 mm

X, Z Axis Travel - 250 x 790 mm

HURCO VM10 Vertical Machining Centre

X, Y, Z Axis Travel - 660 x 406 x 508 mm

Max. Weight on Table - 1500 kg

Spindle Nose to Table Min./Max. - 101.6 / 609.6 mm

Table Size - 762 x 406 mm

CAD / CAM

3 seats Solid Works − Fully Featured

About us

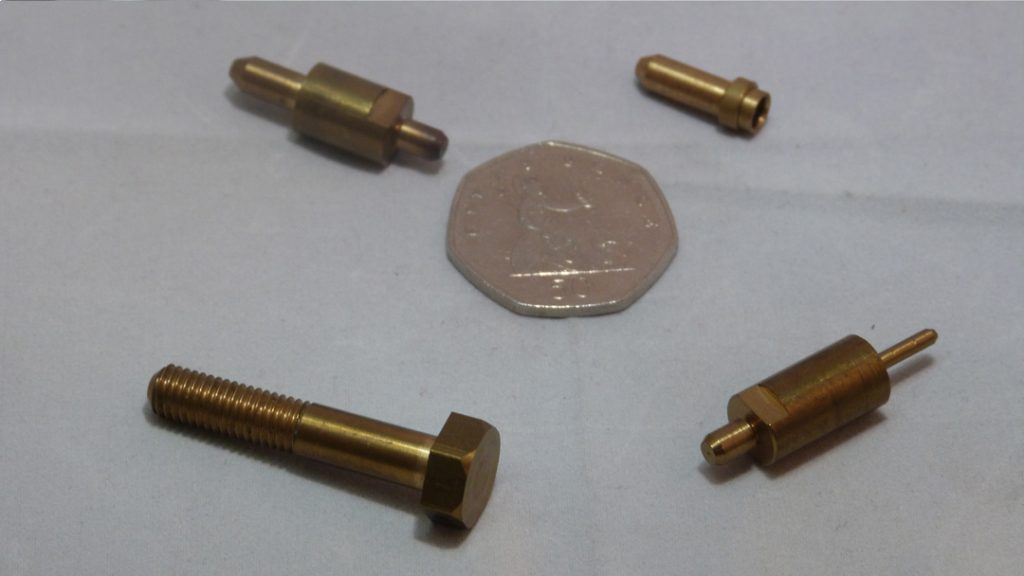

Wilbar Components Ltd, established in 1981, began by manufacturing hydraulic couplings and valves for the agricultural and mobile machinery sectors. As the company grew and thrived, it led to the development of a custom-built facility in Cannock, Staffordshire.

Over the years, our expanded machine capacity has enabled us to provide high-quality sub-contract services to a wide range of industries, building strong partnerships with several major companies in the process.

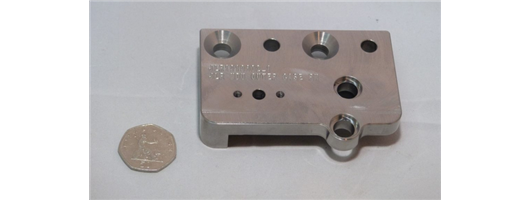

Our extensive in-house expertise enables us to manufacture customer parts to precise specifications, ensuring timely delivery with every order. We adhere to a fully documented Quality System that provides complete traceability to raw materials. Each project undergoes thorough documented inspections at every stage of the manufacturing process.

Our Services Include:

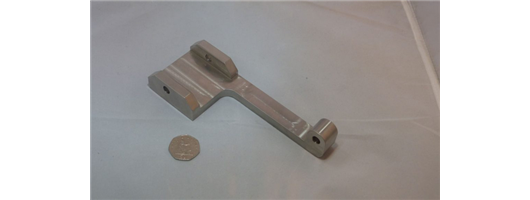

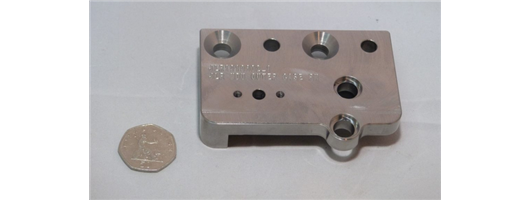

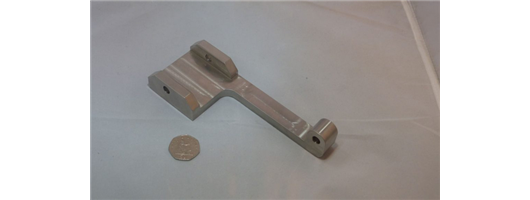

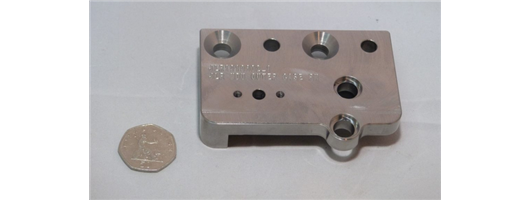

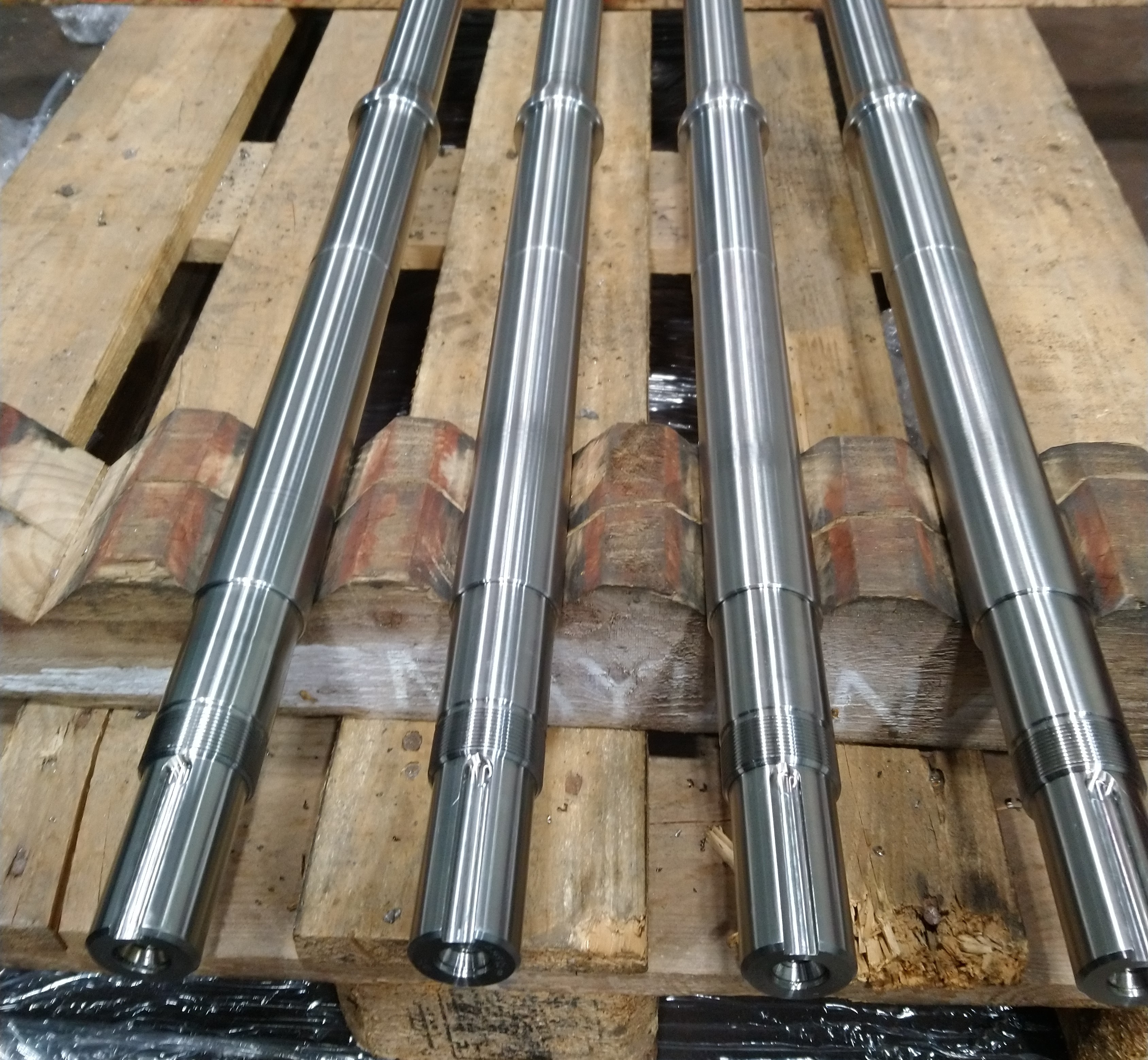

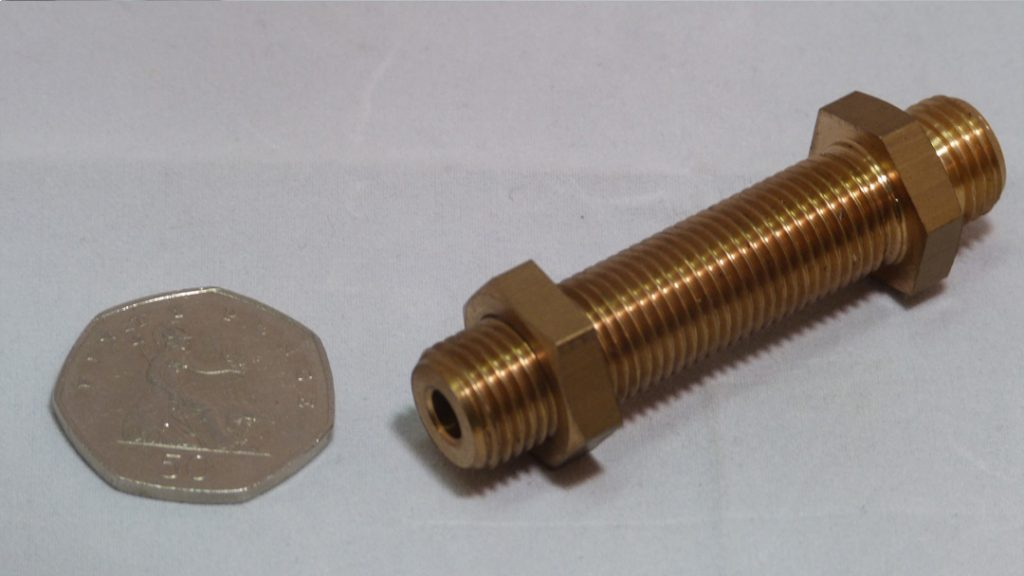

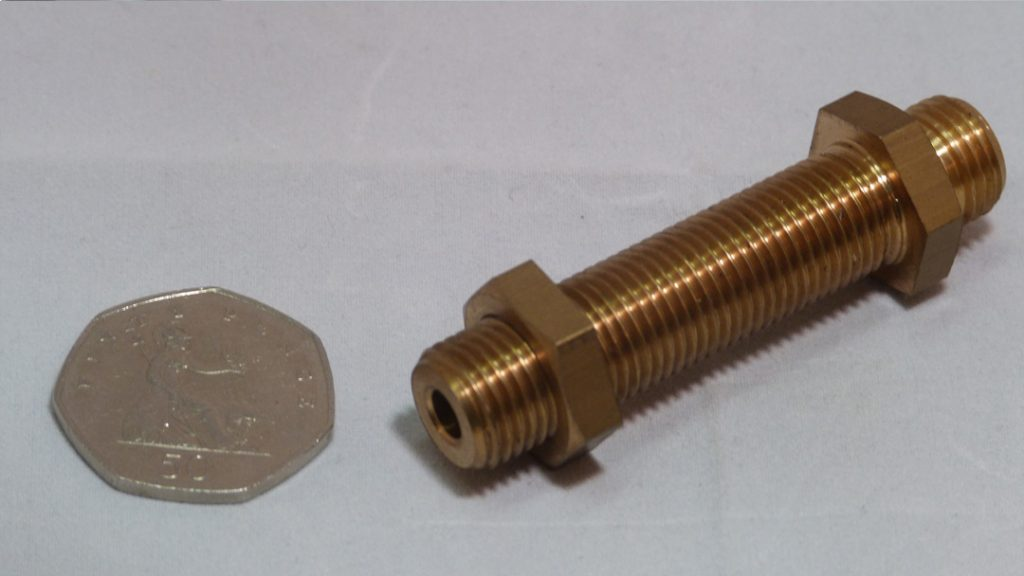

High Precision Turning

With advanced CNC machinery and a highly skilled team, we provide precision-engineered parts that meet the most exacting specifications.

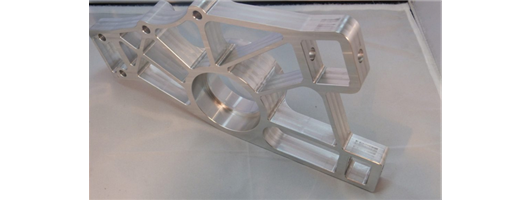

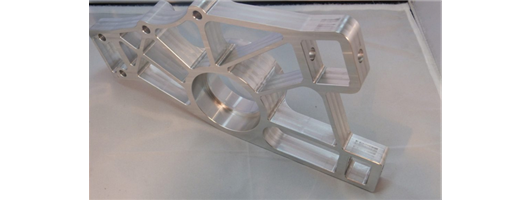

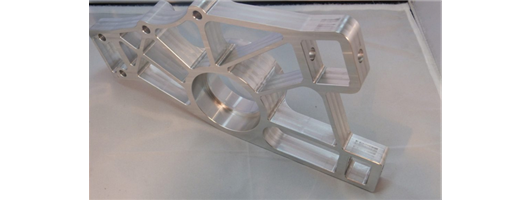

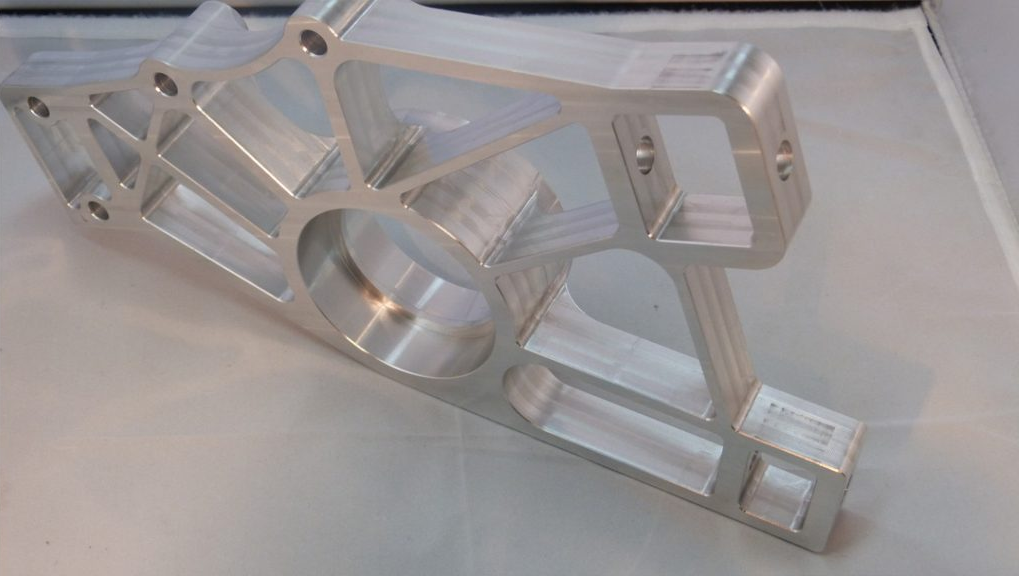

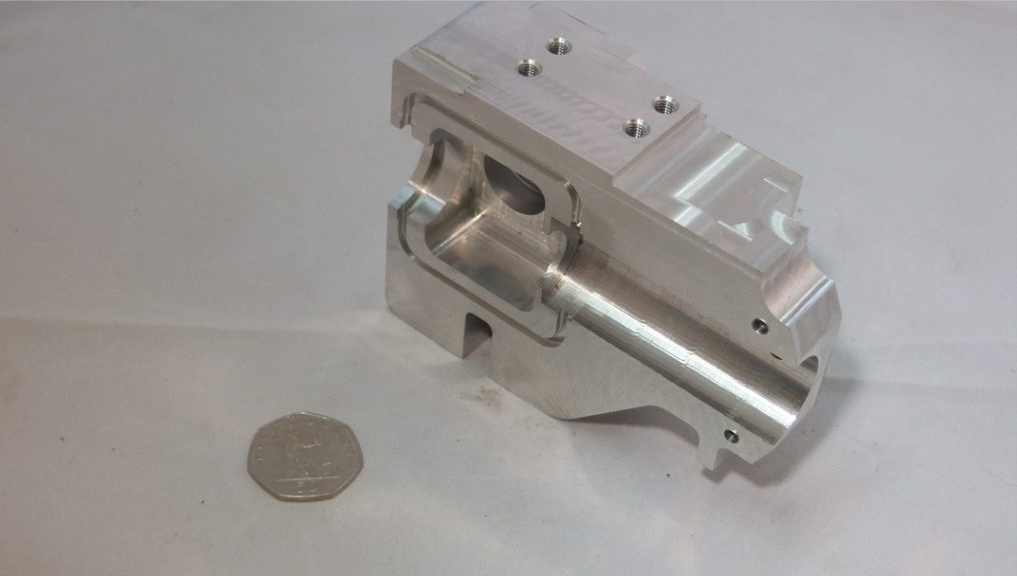

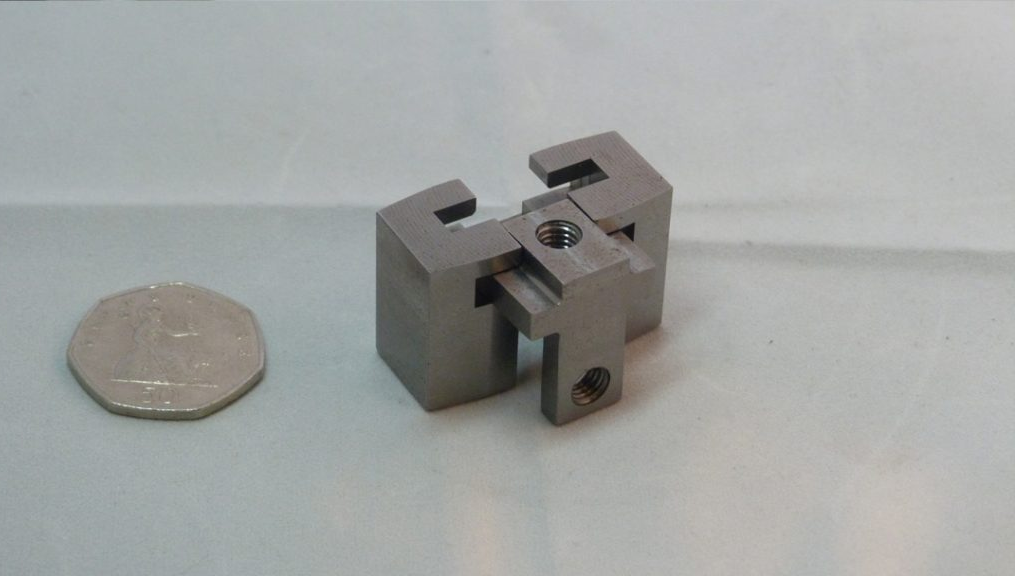

5-Axis Machining

Our advanced equipment enables us to machine complex parts with remarkable precision, minimising setup times and enhancing efficiency.

Turnkey Solutions

We offer complete turnkey solutions that manage every phase of your project, from the initial concept to final production. Our integrated services encompass design, manufacturing, assembly, and quality assurance, ensuring a smooth process and timely delivery. Whether you require precision-engineered components or entire systems, we customise our approach to fit your specific needs.

The synergy of our highly skilled and dedicated team, along with our continuous investment in cutting-edge equipment, allows us to deliver the quality and service needed by various research and manufacturing companies in today's highly competitive market.

In addition to manufacturing products for numerous prominent hydraulic companies, we provide sub-contract machining services across various industries, including petrochemical, electrical, medical, aerospace, marine, and automotive sectors. We also offer turnkey solutions for several machinery manufacturers.

Wilbar Components is a fully integrated, quality-driven manufacturing company. We are dedicated to continuous improvement and maintaining the high standards of service and product quality that our clients expect.

Images