Company details for:

Xfurth Ltd

Unit 4,

Firbank Industrial Estate,

Dallow Road,

Luton,

Bedfordshire,

LU1 1TW,

United Kingdom

Quick Links:

Products

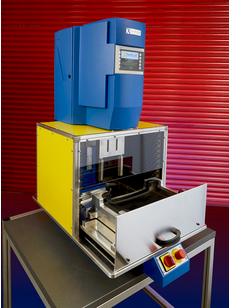

Ultrasonic Welding Machines

Key Points:

Frequency Range: 20kHz − 40kHz

Power Range: 400W − 4000W

Pneumatic Cylinder Range: Ø40 − Ø80mm

'H' frame aluminium casting construction

Rigid dovetail head assembly

Touch screen control interface

Facility to weld and monitor in time, distance, power and energy

99 Program memory

Printout capability of all set parameters or storage of all welded data to PC or network

Option of rocking table (levelling) or sliding table

Standard Options: Linear Encoder, Part Sensing and Part Ejection, Proportional Valves − (more accurate control

of pressure, digitally set via HMI), Facility to monitor all available parameters during the weld cycle, Ability to weld using collapse distance

Easily adapted to suit automated lines

British built and design

Depending on the application, all of our machines can be adapted to suit the majority of customers requirements

Ultrasonic Hand Welders

Spin Welding Machines

Special Purpose Machines

We believe it is imperative to build a relationship with you, our client, and work closely with you so we can fully understand and help you with your design criteria and component specification. With our flexible approach and our combined knowledge we are able to design and build purpose machines, which will meet and exceed your expectations.

Maybe you have no specific criteria. In which case, we can still help you, and you can be confident in our reputation that our engineers will design and build your special purpose machine.

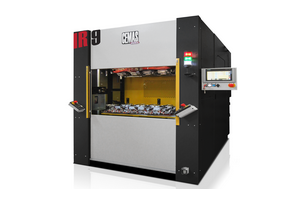

Vibration Welding Machines

The Cemas Elettra range of vibration welders with up to date design and technology can meet a wide range of applications, all backed up by Xfurth sales and service in the UK. Click on the links to view the various sizes of machine in both standard and customisable options, some of which employ dual welding technology for even greater performance and application.

IR & Hotplate Welding

All machines are fully electric providing excellent control on the machine operation during the complete welding cycle. Click on the links to view the range of machines.

Infrared (IR) and Hotplate welding are advanced techniques used in the plastic welding industry. IR welding uses infrared radiation to heat and join plastic components, offering precise control and efficiency, especially for complex shapes. Hotplate welding, on the other hand, utilizes a heated plate to melt the joining surfaces of thermoplastic materials. This method is known for its strong, consistent welds and is suitable for a wide range of applications. Both techniques provide reliable and high-quality joins, making them popular choices in various industrial processes.

Our collaboration with CEMAS Elettra ensures access to the latest advancements in welding technology, keeping your operations at the forefront of efficiency and quality.These fully electric machines ensure unparalleled control throughout the welding cycle, enhancing precision and efficiency. Each machine is designed to meet diverse industry needs, providing solutions for complex welding challenges. To explore our comprehensive range, please click the provided links. Our dedicated customer service team is also available to assist with any inquiries, ensuring you find the perfect machine to meet your specific requirements. This addition aims to emphasize the quality, versatility, and customer support associated with these machines.

Ultrasonic Food Cutting

The oscillating titanium blade offers a nearly frictionless cutting action which is extremely precise, allowing the most delicate or textured of products to be cut neatly and effortlessly, leaving a clean and aesthetically pleasing product. From tray bakes, sandwiches, round cakes to extruded foods, ultrasonic cutting could be the solution to your needs.

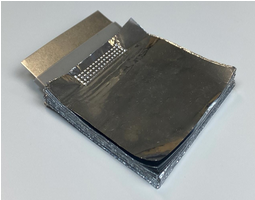

EV Battery Samples & Products

Having been involved in lithium battery welding since 1996, TECH-SONIC has been working with many of the leading EV battery manufacturers of the world over twenty years of operation. With long established expertise in lithium battery welding, TECH-SONIC has been working with these manufacturers on new advanced solutions in welding foil stacks, foil-to-tab, foil-to-busbar, and tab-to-busbar to meet the needs of assembling current and future batteries. With experience in welding materials ranging from aluminum, copper and other non ferrous metals.

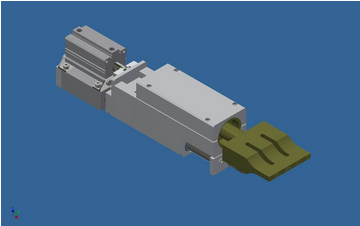

Ultrasonic Tooling

In addition to tooling for welding purposes we are also able to manufacture ultrasonic tooling used for food/textile cutting, metal welding and sonication of solutions.

We also design and manufacture jigs and fixtures to retain and support the components during the welding process.

With over 30 years’ experience, and a team of expert engineers, we provide unparalleled expertise in plastics welding technologies.

Please contact us on 01582 368257 for more information on any of our welding services. One of our team of experts will help you with the advice you need.

Plastic Welding Consultancy & Design Services

From product concept through to production we can offer the complete service on weld joint design, weldability of materials, through to prototype welding trials and machine concept and design.

With our in house design team and testing facilities we can work with you to optimise your product design to encounter the most seamless transition into full production. Our team of professional designers and engineers will be with you every step of the way, and are always on hand to answer any questions you may have.

Using the latest CAD design software we are able to read all forms of 3D CAD files, ensuring a quick response to your enquiry.

For more information on our design consultancy, please call 01582 368257.

Contract Welding

It offers customers an alternative to committing themselves to purchasing equipment; it can also be useful for short term increases in production capacity.

Xfurth's contract welding and assembly service caters to low volume production and prototype work, providing a flexible solution for businesses. By opting for this service, customers avoid the financial and logistical burdens associated with acquiring and maintaining specialized welding equipment. This is especially beneficial for companies that encounter sporadic demands or require welding services for specific, short-term projects.

Furthermore, Xfurth's expertise in this field ensures high-quality results, regardless of the complexity or uniqueness of the project. The team is equipped with advanced technology and has a wealth of experience in handling a variety of materials and welding techniques. This versatility makes them an ideal partner for industries ranging from automotive to aerospace, where precision and reliability are paramount.

Plastic Welding Machine Repairs & Breakdowns

Your business is very important to us. We pride ourselves in providing you with exceptional customer service and care, be it with the replacement of spare parts, in house servicing or onsite support. Our team of engineers are available to assist and support you.

Alongside the service and support we offer on our range of equipment, we can also service and support on the Herfurth range of machines and equipment, as well as equipment supplied by other manufacturers.

Please contact us on 01582 368257 or fill out our enquiry form for more information.

Equipment For OEMs

The flexibility of this equipment, alongside our engineering experience means we are confident we have the solutions to your machine building requirements.

We can supply CAD data of our standard equipment which offers you the chance to quickly establish the suitability for your system. If something customised or special is needed we are more than happy to discuss this to find you a solution.

Xfurth can supply equipment to be built into automated assembly line or customer own equipment.

Please contact us on 01582 368257 for more information.

Plastic Welding Services for the Automotive Sector

At Xfurth our team of qualified engineering specialists have more than 90 years’ experience providing cost-effective solutions to businesses in the automotive industry.

Different welding applications require different approaches. For automotive businesses, you will typically need a combination of ultrasonic welding systems, infrared welders, vibration welding machines and hybrid solutions.

Plastic Welding Services for the Plastics Manufacturing Sector

At Xfurth we help you rise to the challenges of your business by providing a dynamic range of cost-effective and powerful welding technologies. How you approach plastic welding depends on the size, nature and shape of your components. For every application there is an appropriate welding technology that will give you a perfect weld. You may need to use ultrasonic welding, vibration welding, infrared welding, or combination of different technologies.

We use our decades of engineering experience to understand the problems faced by your business and suggest personalised solutions to get you the weld you need.

About us

Xfurth Ltd stands as a prominent manufacturer and supplier of plastic welding machinery and equipment in the UK.

We manufacture and provide a wide array of thermoplastic welding machinery and equipment, focusing on ultrasonic welders (both standard and specialised), spin welders, infrared and hot plate welders, vibration welders, as well as ultrasonic tooling across various frequencies. We also offer location fixtures and servicing for our equipment.

With our extensive expertise in welding and joining technologies, we have successfully expanded our services internationally across Europe, the USA, and beyond. With over 30 years of experience collaborating with clients worldwide, we are dedicated to providing top-notch service, assisting your company in achieving commercially viable solutions to your plastic welding and joining challenges.

Our Products Include:

Plastic Welding Machines

Our ultrasonic machines have evolved over time, drawing from our extensive and professional experience. They incorporate a range of features designed to offer you a high level of reliability, stability, and user-friendliness.

Ultrasonic Cutting Machines

Ultrasonic food cutting is emerging as a significant sector within the dynamic food manufacturing industry. The industry's fast-paced, low-waste demands have prompted an increasing number of manufacturers to adopt ultrasonic cutting in their food production processes, aiming to minimise waste.

Ultrasonic Metal Welding

TECH-SONIC is the pioneering manufacturer behind the development of Closed-Loop Control Ultrasonic Welding, a cutting-edge servo-controlled ultrasonic metal welding process. This innovative technology, especially beneficial in spot welders for EV battery assembly, integrates the latest advancements in ultrasonic welding, servo control, user-friendly microprocessor control, and load cell force feedback. The result is a fully digital welding process, setting new standards in precision and performance.

Our Services Include:

Ultrasonic Tooling

We specialise in the design and production of a diverse range of ultrasonic tools (sonotrodes/horns) spanning frequencies from 15kHz to 40kHz, compatible with all machine makes. Our tools are crafted from aluminium, titanium, or hardened steel, and we offer expert guidance on selecting the most suitable material for your specific application. In addition to welding tools, we manufacture ultrasonic tooling for food/textile cutting, metal welding, and solution sonication. Furthermore, we design and fabricate jigs and fixtures to securely hold and support components during the welding process. With over three decades of experience and a team of skilled engineers, we deliver unmatched expertise in plastics welding technologies.

Plastic Welding Consultancy & Design Services

In addition to manufacturing and supplying plastics welding machines and joining technology, we provide professional in-house design consultancy services. From initial product concept to production, we offer comprehensive support on weld joint design, material weldability, prototype welding trials, and machine concept and design. Leveraging our in-house design team and testing facilities, we collaborate with you to optimise your product design for a seamless transition into full-scale production. Our team of experienced designers and engineers guides you through every stage and is readily available to address any inquiries. With access to the latest CAD design software, we can swiftly respond to your needs and work with all forms of 3D CAD files.

Contract Welding

Xfurth provides a contract welding and assembly service tailored for low-volume production and prototype projects. This service offers customers an alternative to investing in equipment purchases and can be particularly beneficial for short-term increases in production capacity.

Plastic Welding Machine Repairs & Breakdowns

Xfurth's Plastic Welding Machine Repairs and Breakdowns Service provides specialised assistance for the maintenance and repair of plastic welding equipment. With a dedicated team of skilled technicians, this service aims to minimise downtime caused by machine breakdowns. Their swift response and focus on delivering high-quality repair work help uphold the reliability and performance of the welding machines, ensuring uninterrupted operation for clients' projects.

Equipment For OEMs

Xfurth offers a diverse array of equipment, providing OEMs, system builders/integrators, or customers with tailored engineering solutions and automated functionality. Control of this equipment can be managed through a supplied system or integrated into existing systems. The adaptability of our equipment, combined with our engineering expertise, instils confidence that we can meet your specific machine building needs. We can provide CAD data for our standard equipment, allowing you to promptly assess its suitability for your system. Should you require customised or specialised solutions, we are eager to collaborate and find the ideal solution for you. Xfurth can supply equipment for integration into automated assembly lines or customer-owned machinery.

Xfurth originated from the former team of employees of Herfurth UK after its closure in 2002. Acknowledging the outstanding reputation and distinctive service provided by Herfurth UK to its customers over 18 years, the former employees recognised a demand for the ongoing availability of the products and services previously offered to the industry. Xfurth Ltd was established to fulfil this demand and continue serving the industry with the same level of excellence.

Since its establishment, Xfurth has consistently enhanced its plastic welding technologies, equipment, and services, solidifying its position as a market leader in thermoplastic welding technologies. Additionally, Xfurth has maintained its commitment to supporting and servicing equipment, machines, generators, transducers, and tooling formerly supplied by Herfurth UK, allowing former customers to sustain the working relationships established with familiar individuals from Herfurth UK. As one of the leading suppliers of plastics welding, cutting, and joining systems in the UK, Xfurth's ability to design and manufacture its own products has propelled it to become the foremost UK manufacturer of plastics welding machines, ensuring its sustained growth over the past 16 years. With a global customer base, Xfurth has expanded its reach to become a recognised industry brand internationally.

At XFurth, we lead the way in delivering state-of-the-art plastic welding machines and equipment, crafted with precision. We are dedicated to nurturing lasting relationships with our clients. Your inquiries and feedback are essential, guiding us in refining our offerings in the thermoplastic welding industry.