Company details for:

Eclipse Magnetics

Atlas Way,

Atlas North,

Sheffield,

South Yorkshire,

S4 7QQ,

United Kingdom

Quick Links:

Products

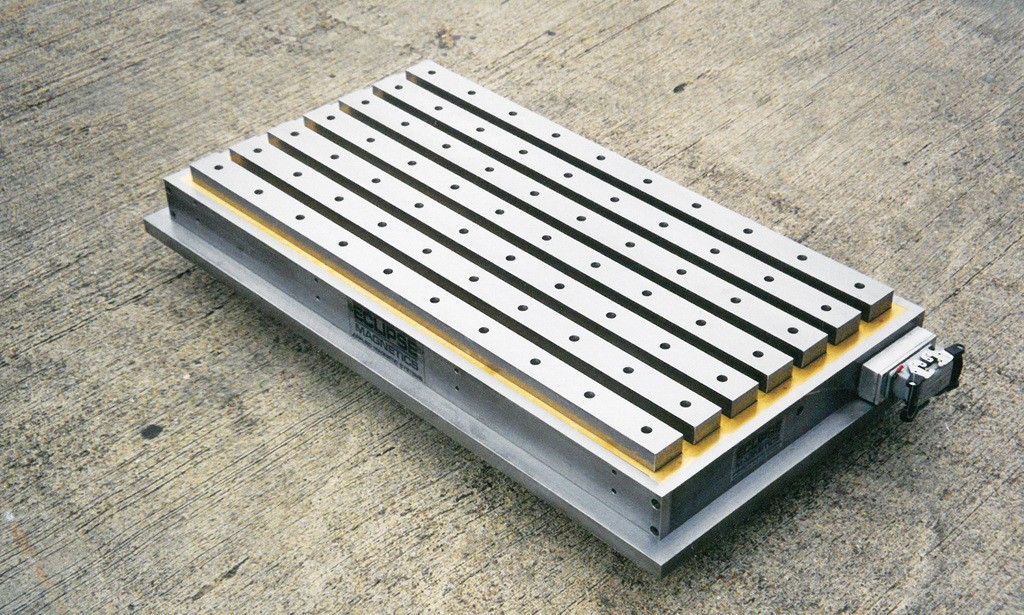

Supermill

The ultimate permanent electro-magnetic chuck for heavy duty milling applications.

Supermill is constructed from solid steel and brass; it incorporates high intensity neodymium magnets to ensure an extremely robust, high performance clamping system. It is ideal for steel plate from 15mm to 300mm thick.

Supermill outperforms traditional clamping systems and other milling chucks, offering several process advantages.

• Instantaneous 10 tonnes ft² of clamping force

• Failsafe magnetic technology - maintains hold even if power is cut

• Maximises feed rates - no time wasted fitting and positioning clamps

• Uniform clamping - eliminates vibration

• 5 side access to the workpiece

• Push button remote control

• Supplied with pole extensions

Circular Premier Chuck

Premium permanent magnetic chucks, ideal for precision grinding, turning and inspection.

Our high performance Premier circular chucks include the high quality parallel pole version. Ideal for holding workpieces on lathes and cylindrical or rotary grinding machines, this range is designed for holding thin ring-shaped components that can be subject to radial distortion.

Key Product Features

• Thick all metal top plate - high accuracy and long lifespan

• High corrosion resistance - resists damage from coolants

• Concentric guide rings - provide positional guide

• Simple on-off switching - removable operating handle

• Variable hold - allows adjustment of position before full hold is engaged

• Failsafe permanent magnetic technology

V Blocks

Ideal for holding cylindrical and other complex workpieces for marking, spark erosion, grinding and measurement.

The 'v' and the base are both magnetic. Both are energised / de-energised at the same time by the toggle switch. Securing the base to any flat ferrous surface and securing the workpiece to the holding area.

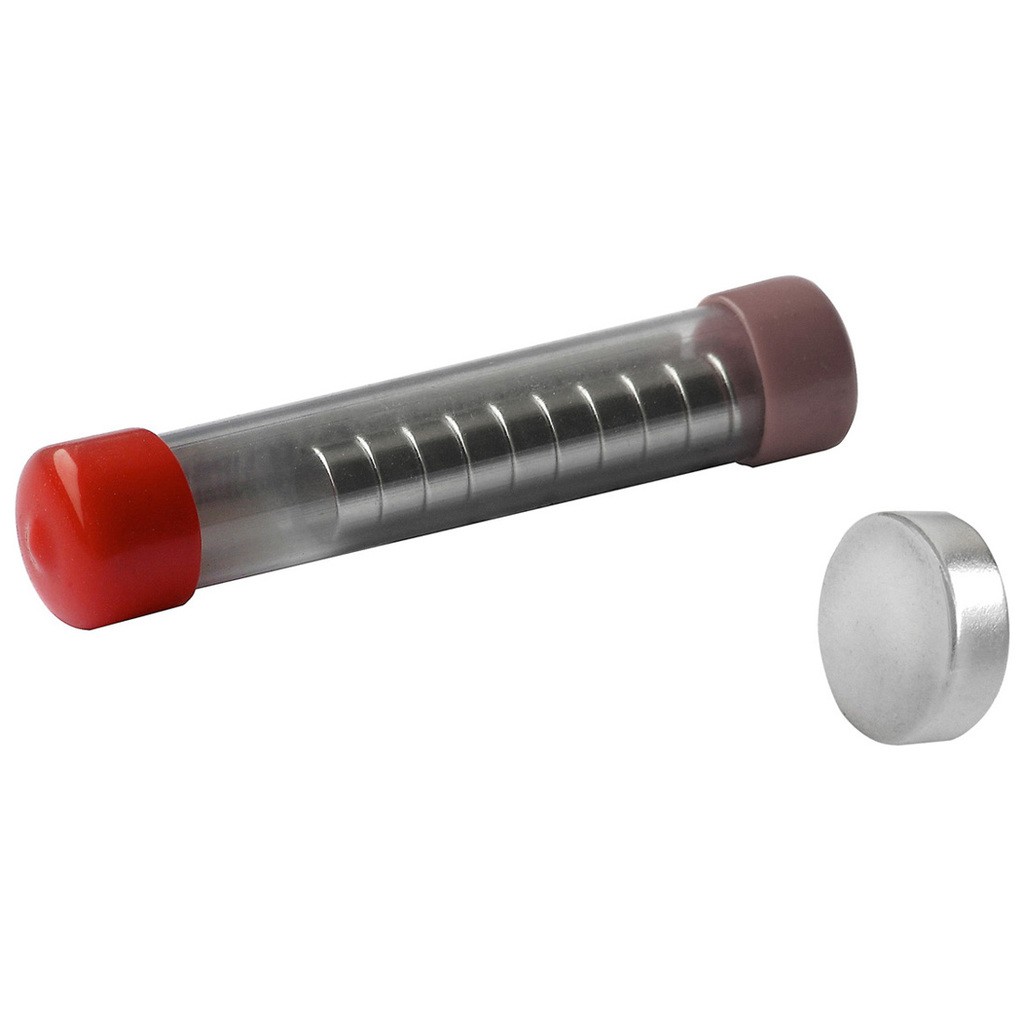

Neodymium Disc Magnets

• Strongest magnetic performance

• Nickel plated

• N35 grade material

• 80°C max operating temperature

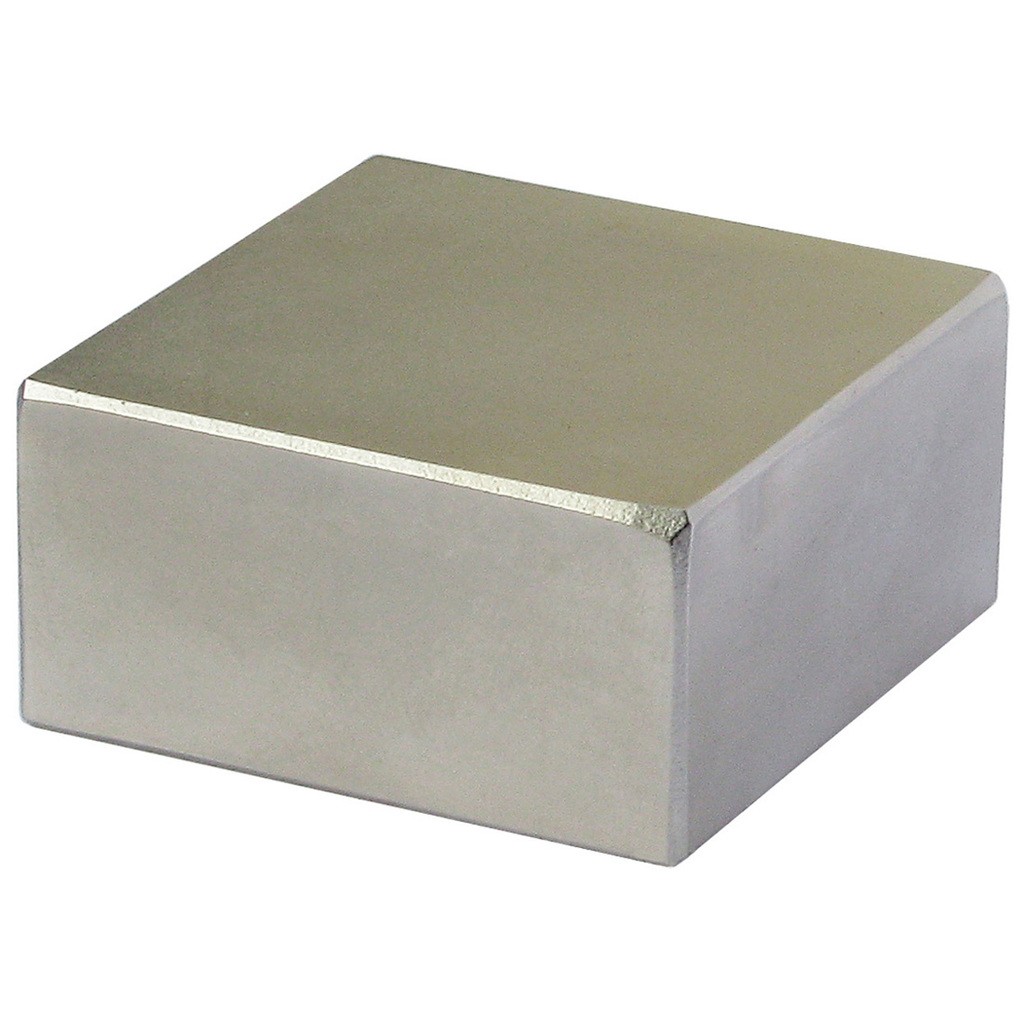

Neodymium Block Magnets

• Strongest magnetic performance

• Nickel plated

• N35 grade material

• 80°C max operating temperature

Ferrite Disc Magnets

• 250° maximum operating temperature

• Excellent resistance to corrosion

• High resistance to demagnetisation

Magnetic Sweeper

• Attracts potentially dangerous or damaging ferrous items e.g. nails, pins, staples

• For easy clear of work areas, floors, sports pitches or car parks

• With adjustable telescopic handle

• Handle mounted quick release mechanism releases debris collected

Gauss Meters

• Digital hand held Gauss meter for checking magnetic flux

• Supplied with 2 probes (Transverse TX and Axial AX)

• Measurement units , Gauss, Tesla, Oersted and Ampere meters

• Batter powered (includes 4x1.5v batteries

Magnetic Tool Racks

• Neatly secures and holds tools in the workshop, garage or kitchen utensils

• Contains 2 powerful magnetic bars with a rubber strip.

Baking Tray Handling Systems

Pneumatically activated systems for fast and efficient tray or bread tin handling in bakeries.

Baking tray or bread tin loading and unloading from conveyors is arduous and time consuming process especially when done manually. Our pneumatically activated magnetic handling system is the ideal solution for efficient automated tray storage systems.

They are widely used, worldwide, to lift different bread tins, straps, bun trays and lids. Systems are available for handling single tins or up to 16 straps in a single lift. It allows sets of straps to be handled, off loaded and stacked into secure areas or placed onto the in feed conveyor.

Battery Activated Magnetic Lifter

Combines the power and ease of operation of an electro-magnet with the safety, the convenience and flexibility of a permanent-magnet lifter.

• Lifts up to 3000Kg (1250Kg round profile), quickly and safely

• Battery only required to activate the lifting magnet

• Energy efficient - no power required to maintain the lift

• Permanent magnets ensure failsafe operation

• Push button or optional remote control

• 3:1 lift safety factor guaranteed

• Access only required to one face of the load

• Re-chargeable batteries included

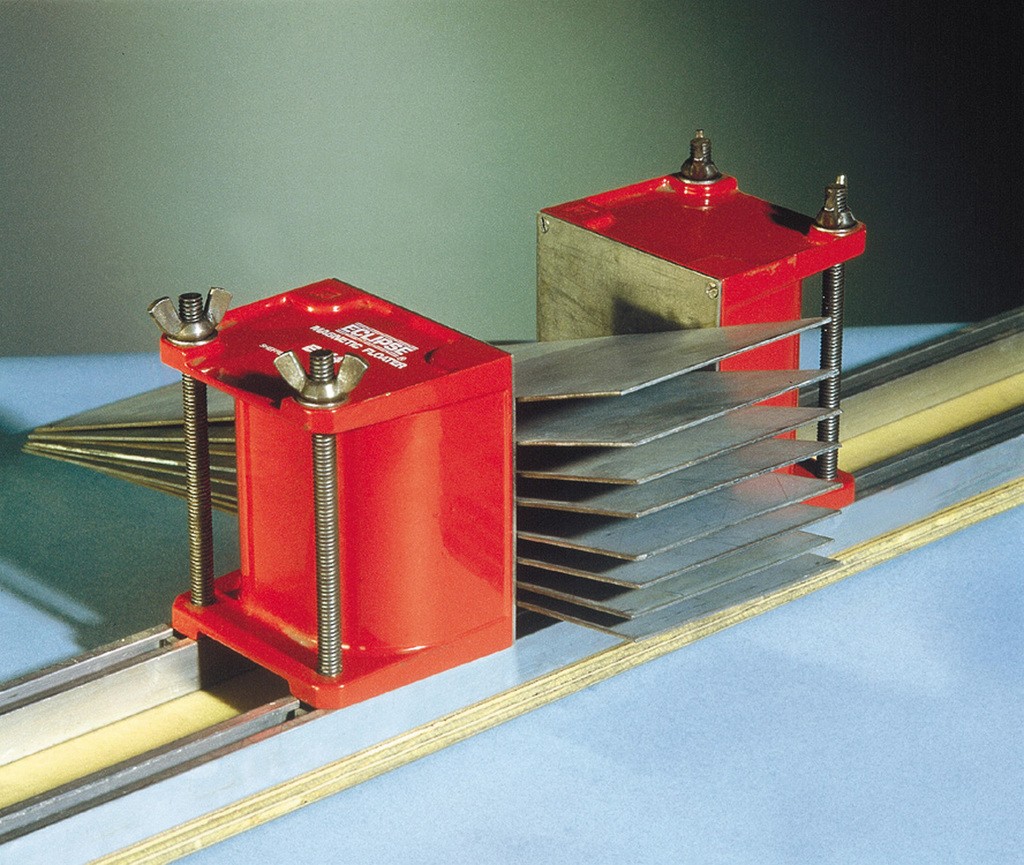

Magnetic Sheet Floaters

Safe and efficient removal of single steel sheets or pressings from a stack.

Our magnetic sheet separators aid efficient lifting by separating the top item from a stack of sheet steel or pressed products from the rest of the stack ready for automated or manual removal.

• Typically separate materials from 0.2mm to 3mm thickness

• Accommodate virtually any shape or size material

• Prevent lifting of 2 sheets together

• Switchable units available for high speed/high volume production lines

• Feature high intensity permanent magnets

Micromag

Micromag is ideal for single cell machines and smaller wash stations. The manual clean magnetic filter can be easily installed on new or existing equipment. With a high intensity magnetic core and patented fluid flow path, Micromag ensures removal of almost 100% of ferrous contamination.

• Patented design

• High collection capacity relative to size

• Non-block design

• Easy clean

• Compact design

• No reduction in pressure or flow

• Rapid return on investment

Filtramag+

Filtramag+ magnetic filter is the ultimate in filtration technology, its' high intensity magnetic cores make it 100% effective for use with materials which have lower magnetic permeability such as tungsten carbide and cast iron. With a stainless steel construction, Filtramag+ is ideal for use in harsh chemical environments and wash systems.

• Patented design

• Unique Dual Flow Technology TM - maximises collection capability

• Removes both magnetic and non-magnetic contamination - optional mesh strainer

• High flow capability

• Non-block design

• Easy clean

• Stainless steel construction

• No reduction in pressure or flow

• Rapid return on investment

Automag

The Automag magnetic filter is a fully automated unit which is ideal for 24/7 machining operations. With high contamination collection capacity and an ability to handle high flow rates, Automag is widely used on high volume production lines.

• Patented design

• Unique Dual Flow Technology TM - maximises collection capability

• No user intervention required

• Suitable for harsh chemical environments

• PLC compatible

• Ultra-fast automated cleaning

• No reduction in pressure or flow

• Rapid return on investment

• Flow rates up to 10,000 litres per minute (using multiple units)

Automag Skid

• Unique Dual Flow Technology TM - maximises collection capability

• No user intervention required

• Suitable for harsh chemical environments

• PLC compatible

• Ultra-fast automated cleaning

• No reduction in pressure or flow

• Rapid return on investment

• Built in fluid recovery system

• Flow rates of up to 1800 litres per minute

High Intensity Liquid Filter

The housing comprises a vessel, magnetic lid assembly and band clamp, which secures the unit together. The filter is available in two versions, single wall and double wall (jacketed for heated pipelines).

The filter can be used in any line that processes liquids at all viscosity levels and can be installed at any angle from vertical to horizontal. A common installation location is tanker loading and discharge to inspect outgoing and incoming materials.

The filter can be supplied to suit various processing volumes, pressures, temperatures and specifications.

Magnetic Rods

This item can be supplied with blank, tapped or studded ends for ease of installation. Rods are 25.4mm (1") in diameter. Magnetic Rods are particularly useful for those engineers who wish to build their own separator units or have severe space restrictions and are not able to accommodate a conventional unit. All product contact parts are manufactured using 316 grade stainless steel.

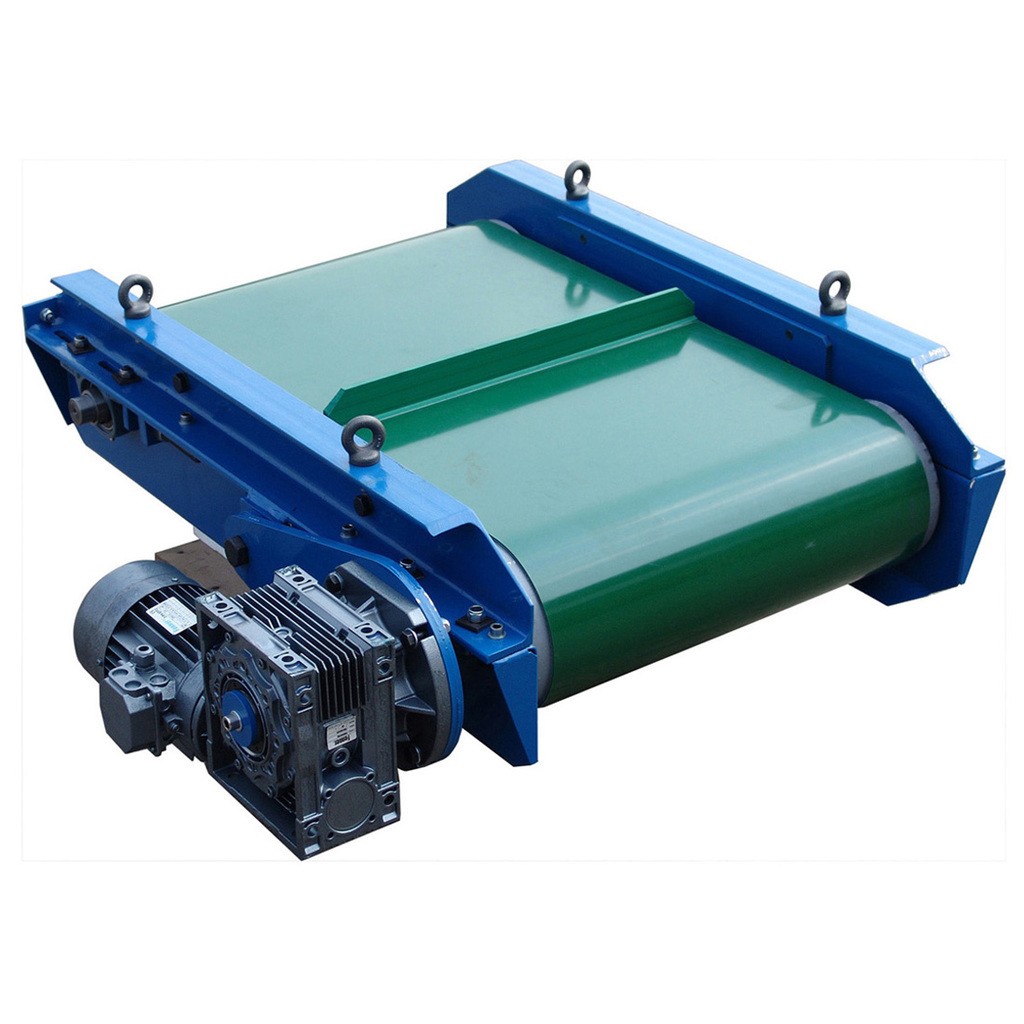

Magnetic Overband

Large permanent magnetic packs generate deep penetrating magnetic flux fields that attract and remove tramp ferrous items from the process.

This unit is considerably cheaper to purchase and run than electro-magnetic units, the only power consumption is for the geared drive.

When considering installation points it should be noted that steel belt support rollers will need to be changed to non-magnetic ones due to possible flux field absorption.

The Overbands are ideal for conveyable products such as wood chip, biomass, recyclables, aggregates and minerals.

Sieveguard Vibratory Sieves

Essential for the sifting, grading and screening of food, chemical and pharmaceutical ingredients entering process lines.

An integral magnetic grid ensures that any ferrous particles carried in ingredients are removed before they can enter your process line.

Screen and seals can be damaged and fragments can enter your product. Our screen and seals are metal detectable so contaminated product can easily be rejected in process.

Fully constructed from highly-polished hard-wearing 316 stainless steel.

TMD Tunnel Metal Detector

The detection head is filled with silicon beads and resin to reduce any potential external anomalies and ensure consistent performance is achieved.

These units are supplied with the Interact+ electronic control system which can store the number of activations and the date and time those activation occurred. This enables the unit to be utilised as part of a companies HACCP system.

With over 200 sizes available in our standard range we are confident that there is a size to suit your application. If we don't have the correct size for you we'll build one to exactly suit your requirements.

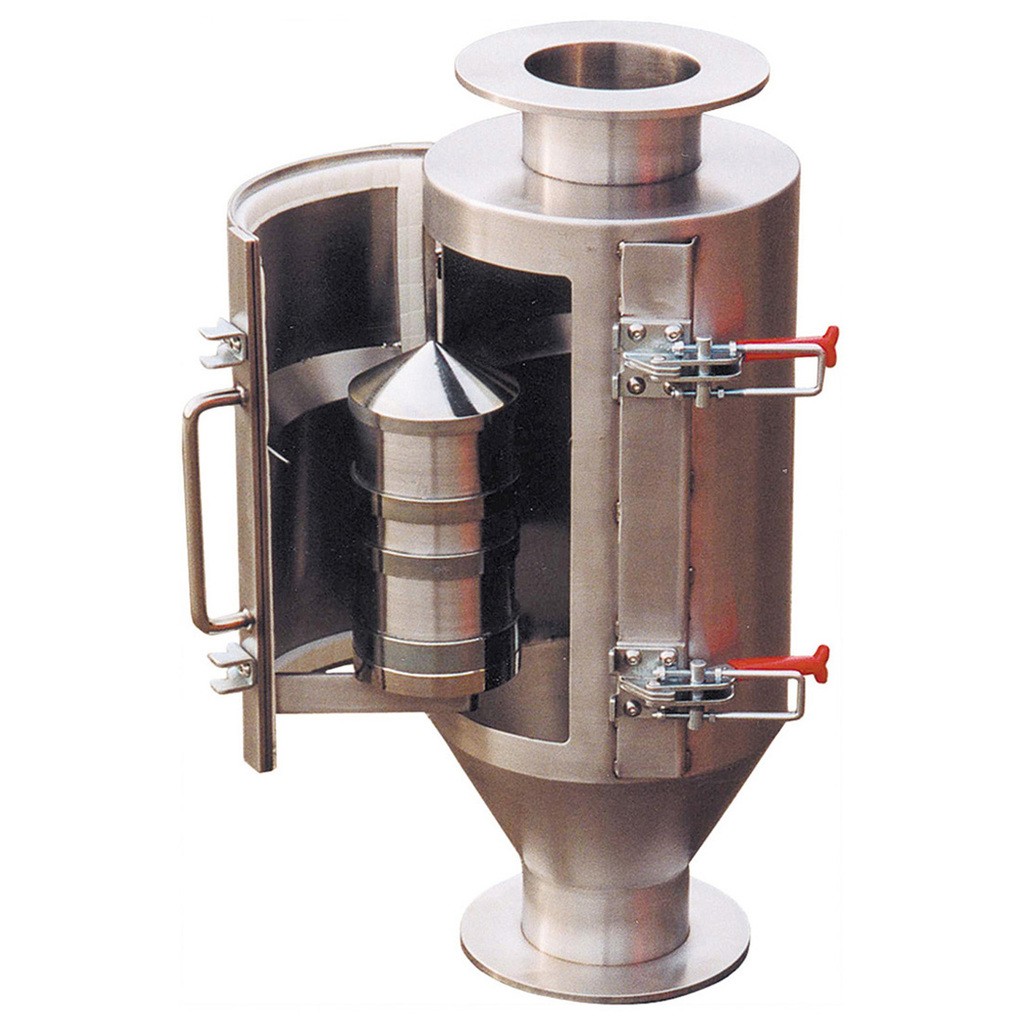

Housed Bullet Magnet

The unit is designed to prevent tramp iron from damaging expensive process machinery such as blenders, granulators, mixers and screw feed conveyors.

A high intensity magnetic bullet element is centrally mounted within a stainless steel housing. The design ensures that product flow is unaffected by the magnetic element.

The bullet element incorporates high intensity rare earth magnetic material which generates deep penetrating magnetic flux fields which ensure contamination is captured. The angled nose cone assists in maintaining product integrity and full flow during processing.

All dry powders and granular type materials can be processed through the unit. Electrical safety interlocks can be fitted to the magnetic packs to stop the process should they be accidentally opened.

Magnetic Grids

Contamination such as rust,stainless steel scrapings and wear from machinery are often too small to be detected by a metal detector, but is easily removed by these highly efficient grids.

The product flows throught the grid. Any contamination is immediately attracted to the grid's powerful magnetic rods. The contamination is pushed to undersides of the rods, where it is securely held, out of the way of the wash-off effects of continuous product flow.

The grids require no power and no maintenance (except for cleaning) and are quick and easy to install. Once the grid is in position you know it's working.

Grids are available in a vast range of standard sizes and 3 magnet strengths (standard for coarse ferrous contamination, high and super-high for micron sized and para-magnetic contamination).

We also supply custom designed and engineered grids to suit your specific requirements.

All product contact parts are manufactured using food quality 316 grade stainless steel and fully sealed.

Supplied with test certificates. Magnetic performance is guaranteed.

Magnetic Trays

Heavy Duty Variable Magnetic Clamp

• Powerful ferrite magnet material gives 40kg of clamping force

• Ideal for angles from 45 to 90°

• Marked at 15° increments to aid positioning

• Non-magnetic case stops attraction of stray ferrous materials

About us

Our brands include Artemis, Automag, BoilerMag, Filtramag, Micromag, Optimag, SieveGuard & Ultralift Plus.

Eclipse Magnetics serve worldwide markets with innovative value adding solutions such as industrial filtration, foreign body removal, customised magnetic assemblies, lifting and handling, workholding, workshop tools and heating system filtration.

Eclipse Magnetics have a track record of producing high quality products backed by a commitment to total customer service, and a wealth of in-house manufacturing and value-adding finishing operations. Their technical application teams also have considerable expertise in applied magnetic technology, thus ensuring most of their products are market leading innovations. All manufacturing is carried out under an ISO 9001 quality management system and appropriate industry directives.

The company’s head office and technical centre is based in Sheffield, UK. They also have dedicated offices based in Canada, China and France. In addition they have a network of technically trained distribution partners to provide local support.