Company details for:

EPS Watermains

Merefarm Business Complex,

Red House Lane,

Hannington,

Northamptonshire,

NN6 9SZ,

United Kingdom

Quick Links:

Products

Water Mains Replacement

Small Footprint Domestic Directional Drilling

This method involves drilling a pilot borehole along a predetermined bore path. The hole is then enlarged following the path set by the pilot bore, this is known as back reaming. Then the product pipe is pulled in behind this.

Pipe sizes range from 25mm to 225mm with distances up to 90m installed in one shot. Directional drilling uses a small footprint with no need for deep excavations and operates through various ground types.

Domestic Moling

This method involves excavating pits at intervals for the mole to be placed. The mole is then entered into the earth on the horizontal face at the bottom of the pit. Destination pits of similar proportions are also dug, and this is where the mole emerges. The mole itself is a steel cylinder, it works as a pneumatic cylinder with pulsed compressed air causing the head of the mole to repeatedly hammer against the soil in front of the mole. The mole displaces the soil creating a bore for the new services to then be pulled through. This reduces the installation time, disturbance and cost.

Pipe sizes range from 25mm to 150mm with distances up to 20m installed in one shot (absolute perfect ground conditions).

Water Leak Detection & Pipe Tracing

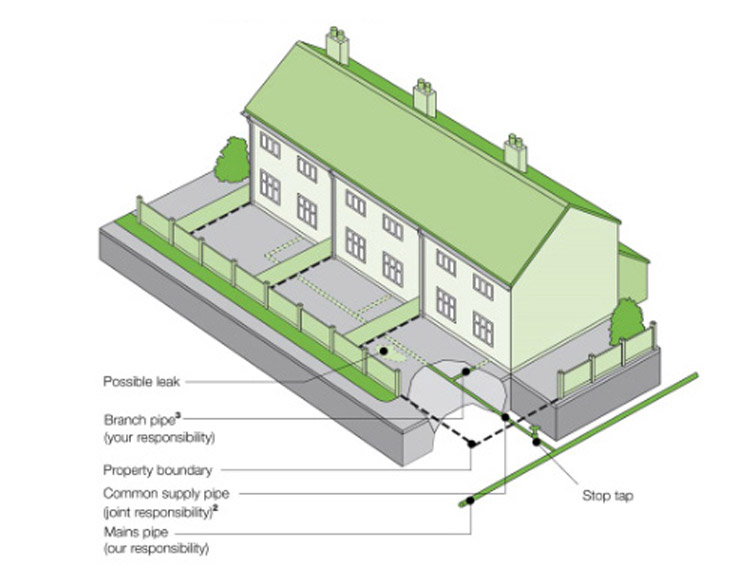

Even when water rises to the surface, it does not necessarily mean the leak is located at this point, as water tends to find the easiest route of escape. It is important to recognize that leak detection is not an exact science and it is not always possible to locate some leaks using listening devices alone - it may be necessary to excavate.

Leaks from plastic pipes are harder to locate as they are quieter than those from metal-based pipes and therefore the sound is more difficult to detect. In addition, property owners do not always have accurate records of the route of their supply pipes and any alterations that may have taken place. In some instances, it may be necessary to carry out excavation work to narrow down the length of supply pipe to pinpoint the leak.

Common Water Supply Pipe Work

Find & Fix

Directional Drilling

This method involves drilling a pilot borehole along a predetermined bore path. The hole is then enlarged following the path set by the pilot bore, this is known as back reaming. Then the product pipe is pulled in behind this.

Pipe sizes range from 25mm to 355mm with distances up to 200m installed in one shot. Directional drilling uses a small footprint with no need for deep excavations and operates through various ground types.

Small Footprint Commercial Directional Drilling

This method involves drilling a pilot borehole along a predetermined bore path. The hole is then enlarged following the path set by the pilot bore, this is known as back reaming. Then the product pipe is pulled in behind this.

Pipe sizes range from 25mm to 225mm with distances up to 90m installed in one shot. Directional drilling uses a small footprint with no need for deep excavations and operates through various ground types.

Commercial Moling

This method involves excavating pits at intervals for the mole to be placed. The mole is then entered into the earth on the horizontal face at the bottom of the pit. Destination pits of similar proportions are also dug, and this is where the mole emerges. The mole itself is a steel cylinder, it works as a pneumatic cylinder with pulsed compressed air causing the head of the mole to repeatedly hammer against the soil in front of the mole. The mole displaces the soil creating a bore for the new services to then be pulled through. This reduces the installation time, disturbance and cost.

Pipe sizes range from 25mm to 150mm with distances up to 20m installed in one shot (absolute perfect ground conditions).

Pipe Bursting

Feasibility Studies

We conduct underground infrastructure surveys during the project design stage to ensure appropriate measures are taken to avoid any service conflicts. We use the latest radio-detection cable locators and ground penetrating radar (GPR) to confirm and complement existing drawings and other records prior to development and excavation operations.

Mains Laying & Diversions

About us

As a trenchless technology leader, we partner with domestic clients, businesses, and contractors nationwide to install underground pipes, ducts, and cables. Our fast, efficient, and comprehensive services minimise disruption while addressing all your installation needs−from planning, searches, and licensing to drilling, installation, and final reinstatement.

Trenchless technology is widely regarded as one of the most efficient methods for installing pipes and ducts. It offers a cost-effective and environmentally friendly solution, with minimal impact on landscapes and the surrounding environment.

Our Services Include:

Pipe Repair

At EPS, we are committed to providing the ideal solution for your needs. Our FIND & FIX service specialises in localised repairs for burst water mains, ensuring efficient and effective results.

Leak Detection & Pipe Tracing

Our engineers are highly trained and experienced in utilising a variety of leak detection tools and techniques.

Mains Laying & Diversions

EPS provides a full range of services for repairing, laying, and diverting large-diameter water mains (2” and above) located on private property.

Moling

Impact moling offers an affordable and eco-friendly approach to a wide range of underground installation projects.

Water Mains Replacement

Streamline water main replacements and reduce costs with EPS's cutting-edge trenchless techniques.

With successful projects on main roads, motorways, SSSIs, railways, rivers, canals, military bases, nuclear facilities, and sports venues like Donnington Park, EPS Trenchless Installations has a proven history of delivering major underground installation projects.

Whether you need new services installed or existing ones upgraded, EPS Trenchless Installations offers a range of customised solutions to suit your needs.

Images

Reviews

Trade Associations