Company details for:

GenHeat

Unit 21, Park Farm Business Park,

Skeffington,

Leicestershire,

LE7 9FN,

United Kingdom

Quick Links:

Products

Benefits of Preheating

The moving parts in an engine, like bearings, crankshaft, connecting rods, camshaft, etc., wear out the most when they are cold. This wear is significantly reduced at higher temperatures. Therefore preheating your engine protects the engine from wear.

Increased Sustainability

As stated above, preheating your engine minimizes engine wear, which extends the service life of the engine. Preheating also has a positive effect on the life of liquids and batteries. Liquids age quicker at extreme temperatures or extreme temperature differences. Preheating results in a more stable temperature, which makes the liquids last longer. The charging capacity of a battery is also affected by extreme temperatures. When the battery is kept at a constant temperature the charging capacity remains intact longer.

Better for the Environment

Next to increased sustainability, preheating results in more environmental benefits. Most fuel is consumed when starting the engine and bringing the engine to operating temperature, and a cold engine emits more harmful substances compared to a warm engine. A preheated engine consumes less fuel and releases less emissions, making preheating beneficial for the environment.

Cost & Time Savings

A preheated engine is less sensitive to wear and therefore requires less maintenance, which results in lower maintenance costs. In addition, a warm engine consumes less fuel, which reduces your fuel costs. By preheating your engine you eliminate the engine warm-up time. You can immediately use the full engine power, without the risk of wear. This is essential for e.g. emergency power supplies, sprinkler systems, ambulances, rescue services, etc.

Coolant Heaters

Other coolant preheaters make use of the thermosiphon process for heat transfer. These heaters warm up the coolant and circulate it through the engine by thermal convection.

Fuel & Oil Heaters

Circulation & Tank Heaters

PowerHeat Preheaters

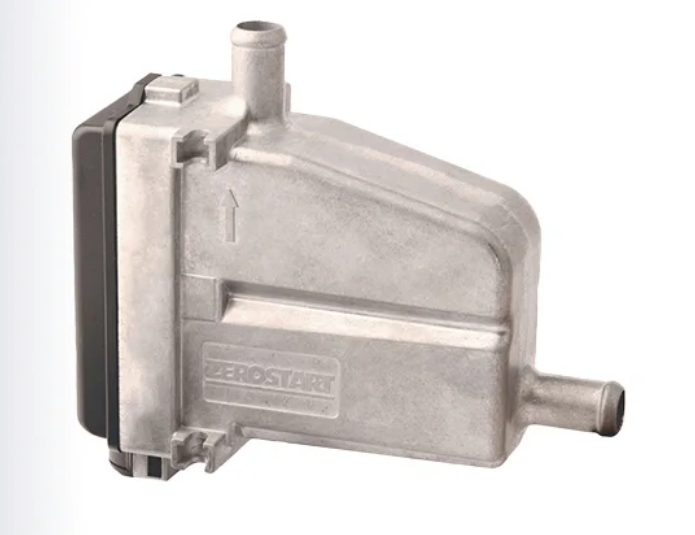

PowerHeatis the new style (engine) pre-heater. The compact design, in combination with the chosen materials, integrated pump, adjustable thermostat and all required control and safety features, makes it an exceptional high quality heater.

The heat exchanger is based on a die-cast tubular component in aluminum with a large heating surface. The heating element is embedded in aluminum during the die-casting process so therefore completely corrosion proof and not in direct contact with the coolant or liquids. This means a more effective heating and no negative side effects for the coolant or liquids. In addition the Aluminum AS13 is finished with a Teflon coating.

Phillips & Temro Preheaters

Circulation tank heaters provide pre-heating for dependable engine starts in all temperatures by circulating warmed coolant through the engine. The tank heater reduces the time needed to reach operating speed, and enhances immediate full-load acceptance. The temperature is controlled by a regulating thermostat. Circulation tank heaters are especially suitable for power generation applications

Calix Mini Plugs

Calix Automatic Battery Chargers

Calix Insertion Heaters

TopStart / Carlor Preheaters

The TopStart (bio) diesel & oil is an electrical preheating system with a circulation pump to heat the (bio) diesel, engine oil, or hydraulics oil. It is universal, reliable, easy-to-install and maintenance-free. Preheating helps to save fuel, decrease pollution, reduce engine wear and prevents difficult cold starts. The TopStart (bio) diesel & oil is ideal for use in large equipment and large gensets.

The Battery Bank will be Launching Soon

Do you want to discuss your Battery requirements? Send us your details and we will call you back.

About us

We provide heating solutions for diesel, fuel, coolant, engine oils, hydraulic oils, other industrial liquids, batteries, cabins, and more. Our systems enhance engine starting, reduce wear, lower fuel consumption, extend battery life, and minimise environmental impact.

An engine preheater warms the engine and maintains a stable starting temperature while it’s not in use. An engine heater can heat the engine's coolant and circulate it through the engine. This transfer of heat can occur in two ways: through a built-in circulation pump that moves the heated coolant, or via a thermosiphon or immersion heater that relies on natural convection to circulate the coolant.

Types of Preheaters Include:

Coolant Heaters

Coolant heaters warm the engine by heating the coolant and transferring that heat to the engine. Some use an electric circulation pump, known as forced flow or circulation heaters, to evenly distribute heat by pumping the coolant through the engine. Other coolant preheaters utilise the thermosiphon process, which relies on thermal convection to circulate the heated coolant through the engine.

Fuel & Oil Heaters

At low temperatures, paraffin wax in diesel fuel can begin to gel, leading to solidification and obstructed flow. This prevents the fuel from reaching the engine, causing significant issues. Oils can also experience increased viscosity in cold weather, reducing their flow to engines and hydraulic systems. These problems can be avoided with fuel and oil heaters, and at GENHEAT, we provide a range of heaters from various brands.

Circulation & Tank Heaters

In addition to enhancing sustainability, preheating offers significant environmental benefits. A substantial amount of fuel is used during engine start-up and reaching operating temperature, and a cold engine produces more harmful emissions than a warm one. Preheating reduces fuel consumption and lowers emissions, making it environmentally advantageous.

In addition to coolant heaters, we offer forced circulation heaters, thermosiphon heaters, and direct immersion heaters for warming (bio) fuels and (engine) oils.

Interested in discussing your preheater needs? Share your details with us, and we’ll get back to you.

Images