Company details for:

Grade 1 Hire & Sales Ltd

Unit 2-3,

Agecroft Trading Estate,

Langley Road,

Salford,

Greater Manchester,

M6 6JD,

United Kingdom

Quick Links:

Products / Services

Scaffold Boards

Tubes

Double Coupler

Swivel Coupler

Wrapover Coupler

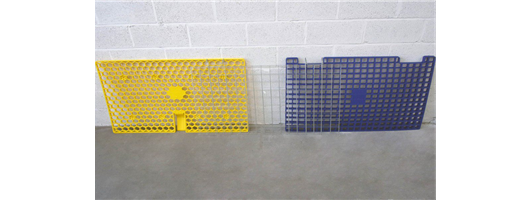

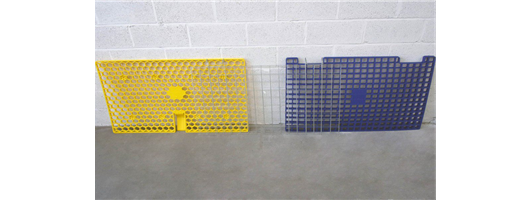

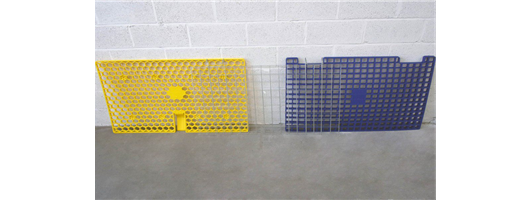

Brickguards

Debris Netting

Sheeting

Scaffold Hook

Signs

Pedestrian Gate

Hoarding Panels

Loose Leg Barrier

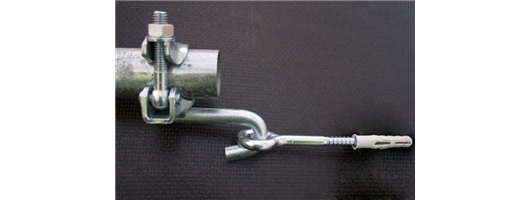

Standard Pipeclamps

Forkheads

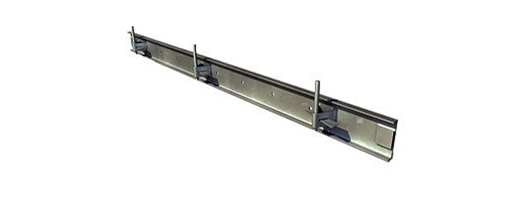

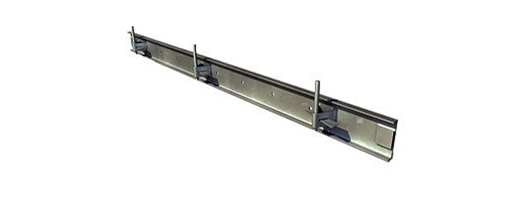

Roadform

Trestles

Top Hopper

Red Hopper

Roof Ladder

Platform Steps

Double and Single width Towers

Podium

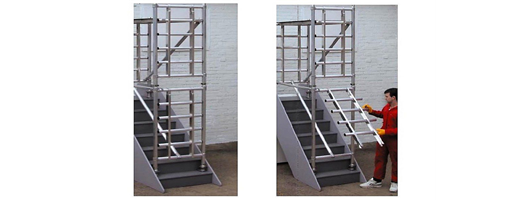

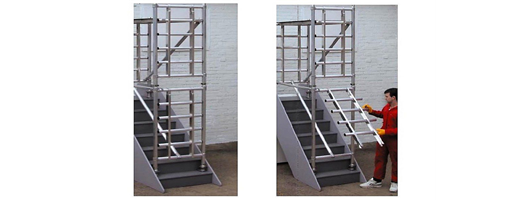

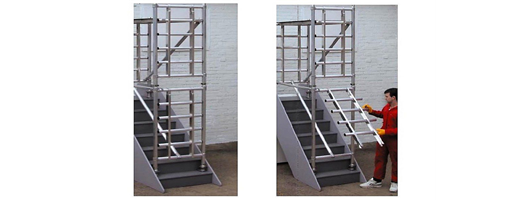

Stairdeck

Guardrails

About us

Offering exceptional customer service from beginning to end and employing a dedicated workforce, we as a company have gained an outstanding reputation over the years for our ability to meet the needs of clients quickly, efficiently and professionally. Whether our customers are looking for scaffold, fencing, ladder, chute, pipeclamp or guardrail solutions, we at Grade 1 are guaranteed to have the perfect fit.

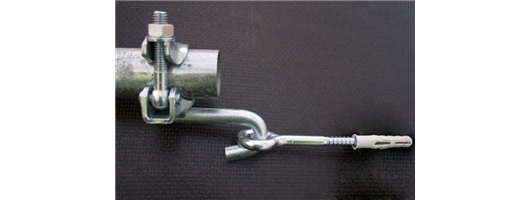

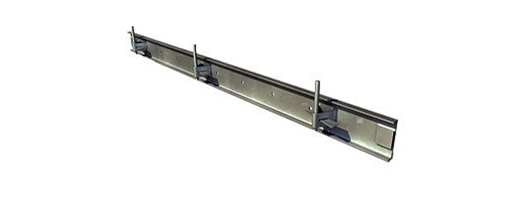

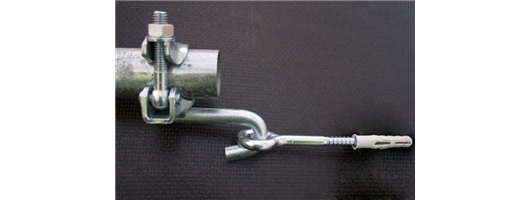

Some of our leading products here at Grade 1 Hire & Sales Ltd include scaffold boards, scaffold tubes, scaffold fittings, scaffold ring and anchor systems, brickguards, debris netting, sheeting, tube end caps, sleeving, doam, loading bay gates, ladder traps, harnesses, scaffold steps, stillages, aluminium beams, vehicle gates, loose leg barriers, fixed leg barriers, plastic barriers, hoarding panels, walkway barriers, security couplers, forkheads, underpinning jacks, trench struts, trestles, rubbish chutes, roof ladders, roof hooks, ladder guards, ladder tags, platform steps, lorry podiums, stairdecks, guardrail systems, stair safety posts and many more.

Over the years, we at Grade 1 have delivered exceptional service to a vast array of clients throughout the UK and beyond. All products and services we provide are designed to be safe and secure, requiring little to no maintenance once installed and coming in a variety of styles depending on the wants and needs of the client. Our impressive selection is available to view online, and we will be more than happy to answer any questions regarding our services.

We primarily cover UK areas such as Manchester, Liverpool, Preston and Bolton, ensuring that customers are always 100% satisfied no matter what.

Images