Company details for:

HSM UK Ltd

Unit 14,

Attwood Road,

Zone 1,

Burntwood,

Staffordshire,

WS7 3GJ,

United Kingdom

Quick Links:

Products

Accessories for Document Shredders

On this page you can find everything you need for continuous operation of HSM document shredders:

Reusable plastic bags for document shredders

Cardboard boxes for collection and convenient disposal of shredder material

Special lubricating oil for cutting heads, a lubricating and cleaning oil for maximum service life and consistently high cutting capacity

Practical accessories for your HSM document shredders

Vertical balers

The HSM baling presses series has many advantages:

Excellent price/performance ratio

Performance according to your needs − with a wide variety of models

Optimal bale dimensions and bale weights − for perfect truck utilisation and saving of transport costs

User-friendly operation

High degree of flexibility − press programs for cardboard and foil can be selected

Long service life thanks to innovative control concept

Available in different configurations

Energy efficient and quiet

Horizontal Baling Presses

The baling presses of the HL series feature low overall height and a large loading aperture, facilitating handling of these materials by the user.

The advantages of the horizontal baling presses at a glance:

Pressing power of 80 kN to 400 kN

Bale weight of up to 600 kg

Large loading aperture, low overall height

Press ram moves horizontally, compresses against a counterplate

Loading: manual or automatic

Bale strapping: manual, with polyester tape or wire (HSM HL 3521)

Also suitable for bulky material

Channel Baling Presses

The advantages of the channel baling presses at a glance:

Application areas: disposal companies, processing industry, trading, logistics, central depots, paper industry, printing plants, distribution centres

Suitable for the following materials: cardboard, paper, foil, DSD, PET, composite materials and more

loading: mostly continuous feeding on a variety of systems (such as conveyor belts, fork lifts, suction units, etc.)

Fully automatic compression and strapping of bales

Up to 1500 kN pressing power

Baling weight up to 1250 kg

All feed techniques possible

Innovative detailed solutions bring crucial benefits

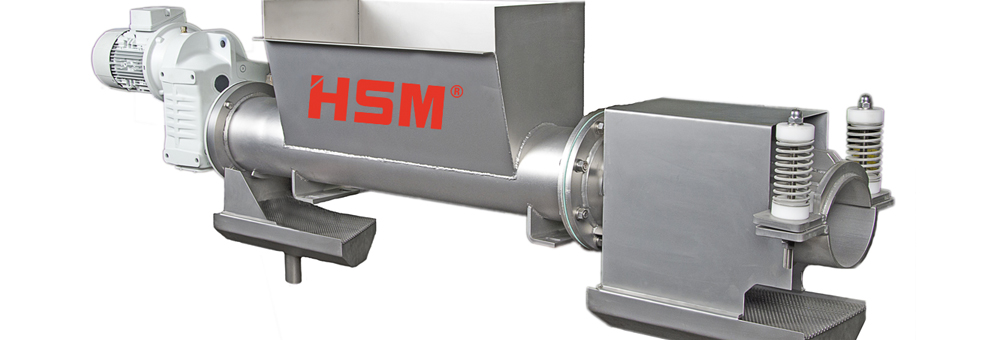

Dewatering Presses

Dewatering presses for the food and beverage industry.

The HSM URP-S universal recycling presses are completely manufactured from stainless steel wherever technically possible and are specially designed for emptying, compressing and conveying incorrectly filled or expired disposable packages. One crucial advantage of these presses is that they enable the product emptied from the packages to be re-used, either as rework, as fuel for biogas plants or for producing animal feed. Depending on the product and the type of packaging, the presses can extract up to 98% of the content. The presses are available in four sizes, which means HSM can offer a solution for practically any size of company. A wide range of optional accessories means they can be used for extracting both liquids and pastes in many different application areas, including the food, beverage and cosmetics industries, as well as disposal companies and biogas plant operators, etc.

We offer a selection of these presses on mobile trailers for rent. The mobile presses give you the opportunity to test the capabilities of our machines on site with your own products. We would be happy to visit you and demonstrate our presses or carry out trial runs.

The HSM label presses are mainly used in breweries and bottling plants. They remove water and suds from washed labels, compact them and convey them out of the bottle washing plant.

Briquetting Presses

No strapping of the briquettes needed

Briquetting density of approx. 400 kg/m³ (PET/UBC) and approx. 760 kg/m³ (aluminium beverage cans) thanks to multistage compaction

Driving power through a highly efficient and lowmaintenance PowerPack

For continuous loading

Optimal pressing plate guidance

Robust construction made of wear-free steel

Consumables for Baling Presses

Barrel Press

In addition, this barrel press features the following characteristics:

Short cycle times and simple operation

Very sturdy and powerful

270 kN pressing power

Suitable for light metal and rolling hoop drums

Also available in EEx-proof version according to EX II Gcb IIBT3

High throughput capacity − up to 50 barrels per hour

With sump tray for residual fluid

Front inspection window

Cardboard Perforators

The HSM cardboard perforator is the perfect solution for all dispatching and warehouse areas. It perforates or pads out used boxes and transforms them into new packaging material for universal use. That saves money and is a meaningful and practical contribution towards environmental protection at the same time.

From waste to packaging material: worn-out cardboard boxes are transformed into high-quality packaging material

Specially hardened cutting rollers ensure absolutely precise cutting

Trimming and padding in a single operation

High-quality packaging material

PET Bottle Compactor

Perforation of full PET and carton based packaging

Containers emptied by up to 98 %

Optimum removal of any remaining liquids using the 4 shaft technology

Low space requirement,

Both manual and automatic filling possible

Cutting unit made of specially hardened steel, durable and robust − for a long life-cycle

Intake shafts ensure that the PET bottles are fed reliably into the cutting unit

Specific discharge system for liquids via hose or pump

Easy to clean due to inspection flap

Ideal as complement to the HSM Baling presses

Shredder baler Combinations

The shredder-baler combinations feature the following characteristics:

Special hardened solid steel cutting rollers: hardwearing, impervious and highly durable

High user safety through safety bar on the loading table

Powerful motors with chain drive, guaranteeing reliable operation with maximum throughput

Crusher Baler Combination

Low space requirement

Manual and automatic filling possible

Crusher rollers made of specially hardened and ground steel, impervious and sturdy − for a long service life

Scraper system removes the compressed plastic bottles reliably from the

crusher rollers

Dosing shaft with several paddles ensures that the PET bottles are reliably fed to the rollers

Automatic photoelectric control of the pressing process

Display to indicate “bale ready”

Manual, 3-fold strapping with continuous polyester strap

Multilevel Shredder Systems

DuoShredder 5540.2: the two-stage shredder system with a throughput of up to 350 kg/h

DuoShredder 5750: the two-stage shredder system with a throughput of up to 800 kg/h

TriShredder 6060: the three-stage shredder system with a throughput of up to 2500 kg/h

Label Presses

In the hydraulic label presses of type PE, compacting anddelivering of the medium takes place by a plunger. Thedegree of compaction and dewatering can be adjusted by atime in the control. The longer the press plunger is in thefront position, the stronger the medium will be compressedand dewatered.

The removed labels are taken up cleanly by the cleaningmachine, pressed and conveyed drop-free into a container.By means of a hydraulic cylinder, the volume of theunpressed labels is reduced to 30%, the freeness valuethereby amounts to more than 70%. The pressed-outalkaline solution is collected and then pumped back intothe cleaning machine. Several label discharges are collectedtogether on a conveyor belt.

Performance features:

Two different executions are provided:PE-G − galvanized steel and PE-S− stainless steelEach in the following different sizesPE 200 / PE 250 /PE 300

Your advantages at a glance

High degree of compression (dewatering)

Washing liquid recycling = cost saving

Reduction of waste management costs by reduction of volume and weight

Rugged construction = low wearing

Insusceptible at glass crushing

Low maintenance

Reduction of internal transport and waste disposal costs

Simple integration into the overall system of the washing plant

Free choice of location by optional feeding through conveyor

Directly under the label exit

Screw Label Presses

The screw label presses of type SEP-S are only offered instainless steel execution. They are especially suited forbottle-washing machines with several label discharges.

Through an electromechanically functioning screw thevolume of the unpressed labels is reduced up to 30%. Thelabels are drained off at the same time. The pressed-outalkaline solution is collected in a separate collecting pan.From there it is pumped back into the cleansing plant orused again in another process.

In case of several label sweeps the machine is equippedwith corresponding material funnels through which thelabels reach the screw area of the press.

Your advantages at a glance

Reduction of waste management costs by reduction of volume

Suitable for several label discharges

Place saving mountable − compact hanging

Low maintenance

Simple integration into the overall system of the washing plant

Simple overcoming of long distances

PET / UBC Bottle Crusher

This HSM solution reduces the space requirement for returned containers to approx. 25 to 30 percent of the original volume, thus also reducing the time required for disposal.

The special roller system perforates and crushes the containers. The sidewalls mesh into each other, making the reduction in volume permanent. Crushing features an additional advantage: Deposit plastic bottles and cans are reliably invalidated.

Universal Recycling Press

The HSM Universal Recycling Press serves to empty,compact and transport incorrectly fi lled or expired disposable packagingas beverage cans, pressurised cream dispensers, tin cans,soft packaging, synthetic packaging and bottles fi lled with beverages,cream, yoghourt, ice cream, soups, puddings and mixedorganic wastes such as fruit, vegetables, pasta, etc.The pressed out materials (e.g. superimposed food, incorrectly fi lledpackagings etc.) come through a receiving hopper in the press.

The contents are collected and the remaining packaging is compressedand ejected. The liquid and pasty contents are eitherreprocessed as a rework in the bottling plants (highest value) orprocessed into animal food or used as feedstock in a biogas plant.The medium is pressed out, compacted and transported by meansof a hydraulically operated press plunger. The necessary counterpressure on the medium being pressed is created by a hydraulicallyoperated slider in the press pipe.

The press plunger presses the medium into the press pipe andagainst the slider in an adjustable number of traverses. The organicingredients escape through holes in the press pipe. After theadjustable traverses, the slider opens and the compacted materialwhich consist out of the empty packaging of organic wastes isejected by the press plunger. The pressed out liquid ends in a collectingbasin which is installed below the press and will be pumpedthrough an existing pump into a container or a channel.

About us

Our products can be used to destroy a variety of personal items such as CD’s, DVD’s. floppy disks, ID cards, USB sticks, film or foil and even hard disks. They are suited for use in the office and home.

HSM UK Ltd have graded our shredders to help you decide which one provides the right security for your application whether it be a Doctor’s office, Advertising agency, Store cards, Development department, Government agency or IT department. Small particles for applications which require higher security and strips for applications which require lower security. Please visit our website for more information.

HSM UK Ltd bailing presses are the ideal solution for compressing any waste material into manageable and easily transported bales with materials compressed by up to 95 per cent! We have a bailing press to suit all needs. They also save you money and help the environment.

HSM UK Ltd Cardboard Perforators transforms used boxes into new packaging material for dispatching and warehouse areas. The new high quality packaging is suitable for universal use.