Company details for:

I.S.T. Pigging Systems

UK Sales Office,

Po Box 172,

Deeside,

CH5 9AN,

United Kingdom

Quick Links:

Products

Pigging Technology “Brilliantly Simple”

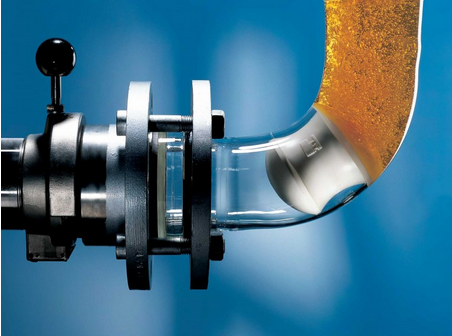

The best ideas are often the most simple. This is just the case with pigging. It was expended more than 45 years ago by I.S.T. "for new branches of industry", and is based on a process which is, in principle, very simple: a shaped plug, the pig, which is driven by a propellant, is used to push out the contents of a pipe. What makes this principle so attractive is that it is suitable for use in various fields: I.S.T. pigging systems can be used to pump, fill, mix and separate large quantitites of substance and also to clean pipes, in an environmentally friendly, efficient and cost-effective way. I.S.T. has taken a brilliantly simpel idea an d developed it into perfect system solutions for all problematic tasks associated with pumping and filling systems.

Stations / Valves

Pipeline Manifolds

Blending Equipment

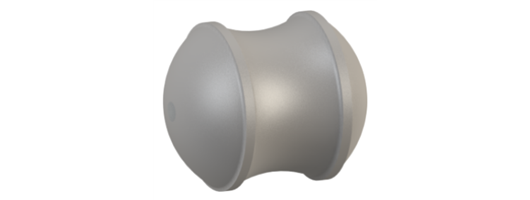

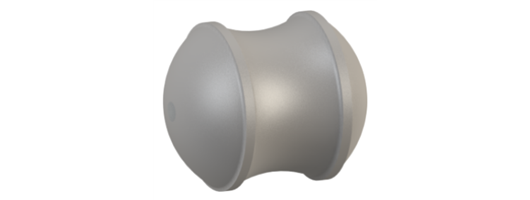

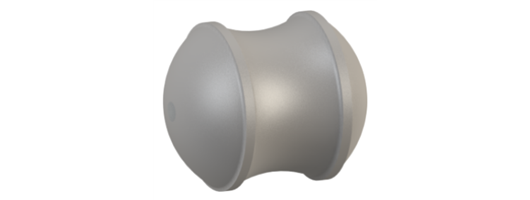

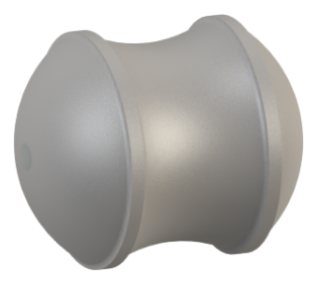

Pigs

I.S.T. pigs are sold only in connection with our valves and systems.

Special Designs

Accessories

T02 - Loading Lance for Tank Trucks & Tank Wagons

The loading lance is equipped with a level control switch. Thus the product is transported back to the tank after loading and overfilling of trucks or wagons etc. is avoided. Due to the fact that the loading arm is fully piggable, it is possible to fill several different products through the same loading arm. Product flow is controlled by a sliding sleeve installed in the loading lance. This sleeve is operated by instrument air (positions open/closed/throttle). In case of emergency air failure, the loading lance is closed automatically by spring.

Indispensable for the use of the loading lance is the piggable loading arm T91.

T50 - Loading Valve

T91 - Loading Arm

T06 - Rotary Manifold: Connects Piggable Pipelines

1 x 6 and 1 x 12: The compact solution for a filling unit. With central outlet and access port

Here's the space-saving and operationally reliable solution for distribution problems: on the I.S.T. rotary manifold 1 x 6 or 1 x 12, fixed I.S.T. sliding couplings are arranged round a central pipe nozzle, from which an 180° elbow projects. Switchovers are performed by rotating this elbow. A pneumatic cylinder activates the locking devices. Sensors ensure accurate positioning. The 1 x 12 rotary manifold operates fully automatically by pneumatic drive or manually. The smaller 1 x 6 model can only be operated manually.

2 x 12: For two filling units. Now with unrestricted rotation

On the fully automatic 2 x 12 rotary manifold, an elbow and an S-pipe rotate on the radius of the I.S.T. sliding couplings. A separate pneumatic motor moves the pipes, the positions of which are monitored by sensors. The control unit co-ordinates all paths of travel. The rotary manifold is protected by a wire mesh guard - or with shatter-proof PMMA type guards on request.

T08 - 2 / 2 Way Manifolds

T51 - 1 to 4 / 1 to 8 Manifold

T56 - Piggable Manifold

T57 - Full System Manifold

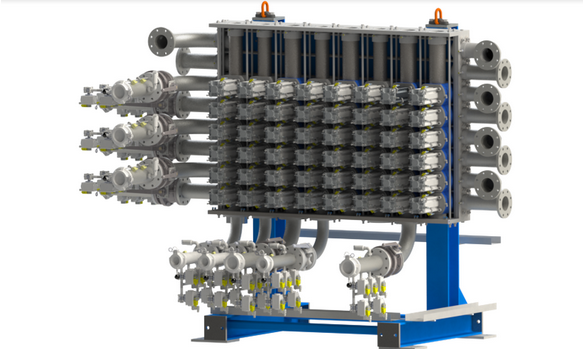

The full system manifold T57 requires no hoses and reliably eliminates product losses and connection errors. It offers maximum safety and extremely straightforward operation for your staff.

This is the first manifold which allows different nominal diameters to be combined in a single design. For example, a piggable DN 50 pipeline can be filled with product next to a DN 100 pipeline and can then be pigged.

With the full system manifold T57 up to 50 transport lines can be connected to up to 20 pigging lines in one module. By attaching several manifold modules to each other, large scale distribution can be achieved.

When filling and pigging take place in parallel, the manifold can open and close the connections independently of each other.

T57-K - Full System Manifold

Technical description: The manifold unit T57-K consists of a matrix layout with a manifold node which is piggable to one side. The upper full system line and the lower pigging line are installed rectangular to each other. In initial state both lines are separated from each other when the manifold is switched. In the manual version the manifold is operated with a hand lever. The manifold can be applied for horizontal and vertical arrangement.

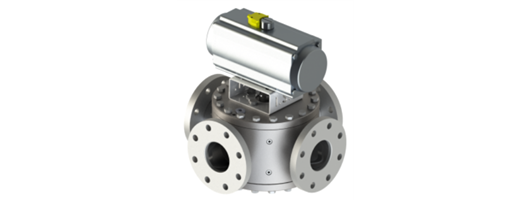

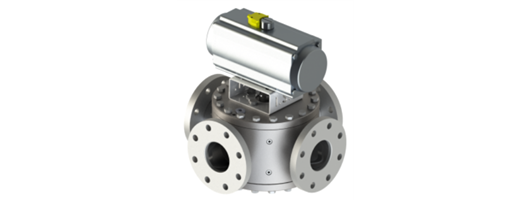

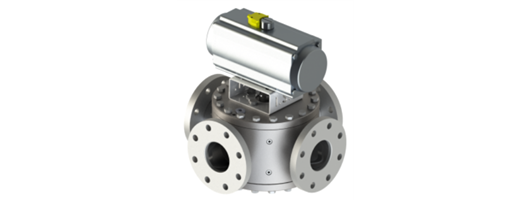

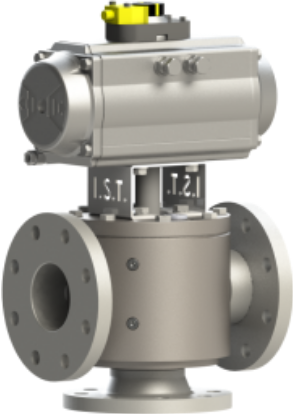

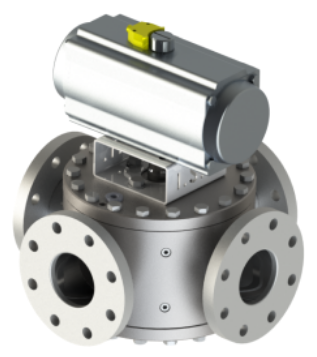

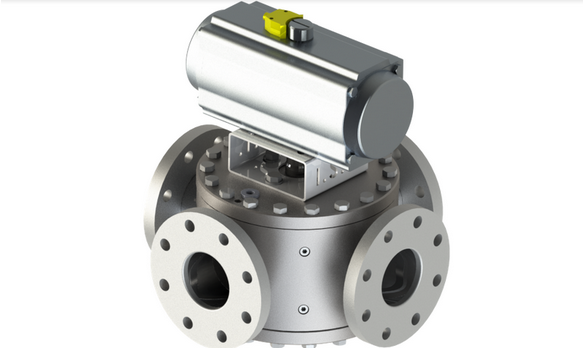

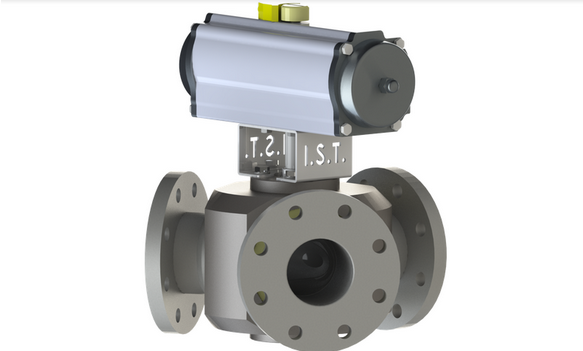

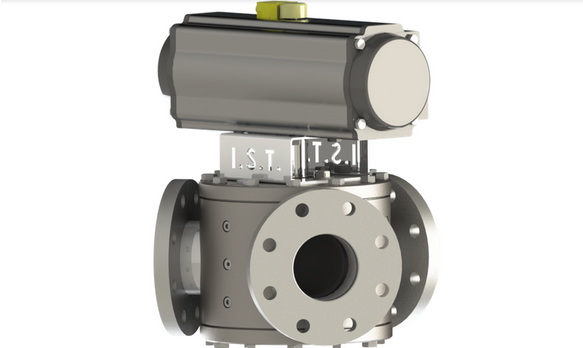

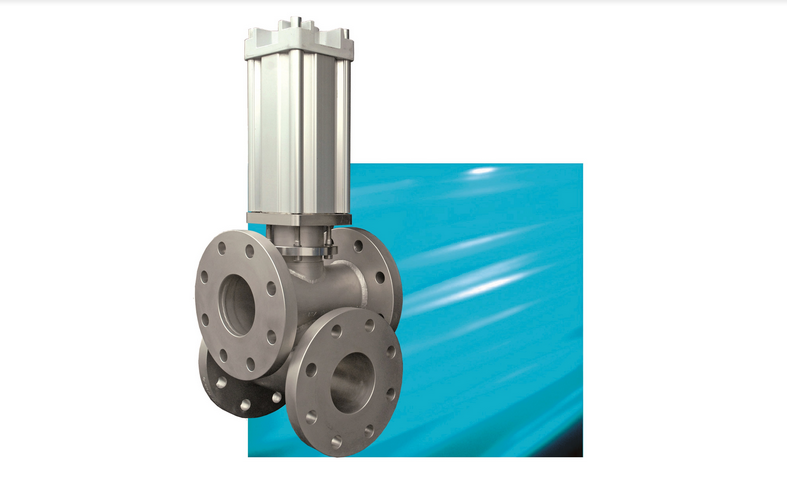

T07 - 3-Way Valve

T41 - 3-Way Valve, Cylinder

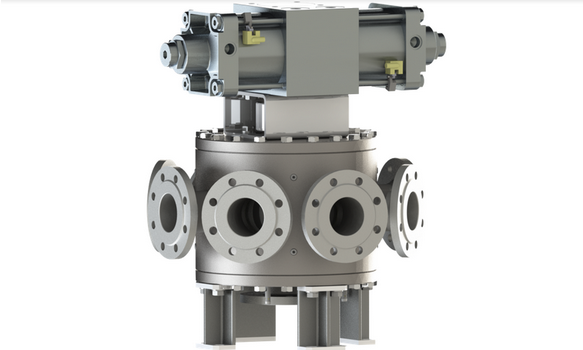

T09 - T-Ring Valve

It can be used either as an independent station or integrated in a distribution assembly. The horizontal plane can be pigged without pockets when the valve is closed. The vertical port can be closed with the ring-shaped seal when necessary.

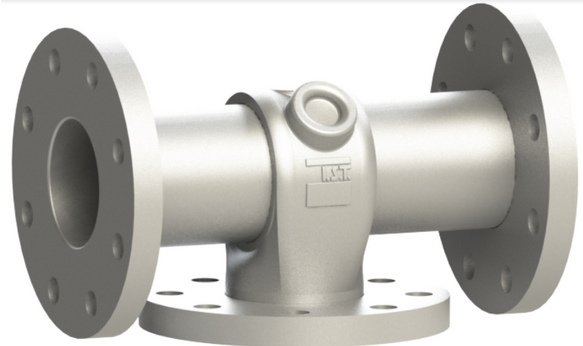

T10 - T-piece

T10.3 & T10.4

For high temperature areas special sensors are also available.

All pig sensors are available for EX and NON-EX areas.

Pigging stations can also be equipped with manual pig locators. With this type of device a tappet is manually pressed into the station, in order to check for the presence of the pig. The tappet is then automatically removed from the pipeline by a spring.

I.S.T. also offers a portable pig sensor pen with which the pig can be detected throughout the pipeline. This method is only applicable for stainless steel pipelines.

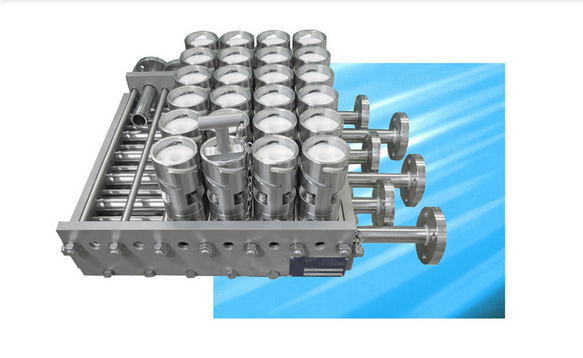

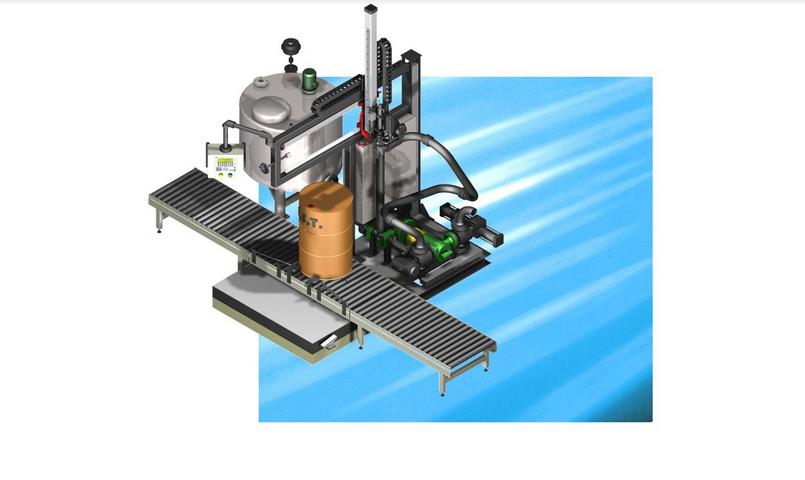

T45 - Simultaneous Metering Blender

The general principle of operation for the SMB is as follows: Operator provides production data (such as: product name / code, type, blend size, and tank destination etc) to the SMB control system.

The SMB control system will then automatically dose all required raw material components according to the customer's specific blend formulation (recipe), in following three stages: First stage is an initial dosing and transfer of the main blend components base oils and additives, followed by a final dosing and transfer of the remaining base oil. This dosing sequence ensures that optimum pigging results are achieved, with respect to cross-contamination between subsequent SMB blends.

The pigging system is directly integrated in the SMB. Thus the connecting pipelines and the basic isolation valves can be emptied without residues.

The non piggable areas such as flow meters / counters are emptied according to a progammed procedure and rinsed with base product. Now the system is completely emptied and the next process can be prepared.

T65 - DDU: Drum Decanting Unit

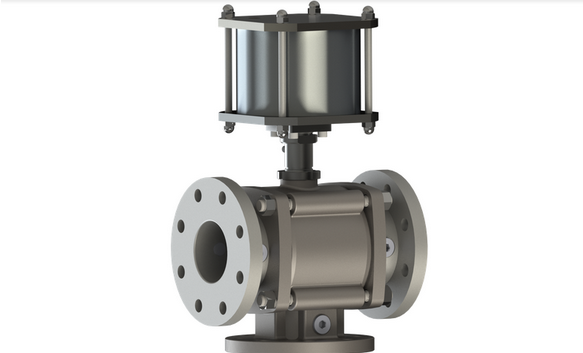

T43 - Plunger Valve

T16 - Pig Launching & Receiving Station

About us

Pigging technology of high quality and competence has been our specialty since 1981

Pigging technology leader

More than 40 patents cover pigging applications

Pigging technology that is 100% customer-specific

A medium-sized company, we offer quality products, innovative strength, flexibility, and service readiness. Over the past few years, we have continuously expanded our production facility. With our expertise in special valves and distribution technology, we are able to meet the needs of each individual customer.

Mr. Hubert Skibowski founded the company in Hamburg in the seventies as a planning office. As a result of technical possibilities and market demands, the planning office developed and produced pigging systems. In addition to the lubricating oil and chemical industries, many systems were developed for the food and paint industries.

Among today's leading industrial pigging companies is I.S.T.

We offer a comprehensive range of services in pigging technology, from individual components to innovative complete solutions. In industrial plants around the world, our systems contribute to their economic and environmental efficiency. We also offer our customers a global sales and service network.

We aim to further enhance customer satisfaction through continuous innovation of our product range.

I.S.T. Offers:

- Our company designs and manufactures pigging valves, piggable manifolds, and pigging systems

- The pigging system is capable of withstanding pressures up to PN 40 and temperatures up to 200°C

- Standards for quality according to ISO 9001 and Pressure Equipment Directive, module H

- Easy-to-maintain manifolds and valves

- Pigging equipment for potentially explosive atmospheres that is ATEX-compliant

Images