Company details for:

Master Bond Inc

(3)

154 Hobart Street,

Hackensack,

New Jersey,

07601,

United States

Quick Links:

About us

With over 3,000 formulations, Master Bond Inc is a leading manufacturer of epoxies, silicones, polyurethanes, polysulfides, UV cures and other specialty adhesive systems.

We also offer custom formulations to meet the performance properties required for your specific application. Many of Master Bond’s products meet NASA, UL, USP and FDA certifications for low outgassing, flame retardancy, biocompatibility and food compatibility.

Products

Master Bond’s vast product line features the most reliable adhesive, sealant and coating compounds to improve production efficiency and ensure high end results. Our product line consists of:

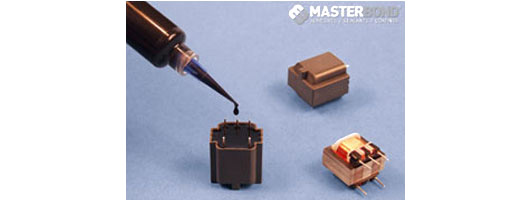

• One and Two Part Epoxy Systems

We offer an extensive line of one and two component epoxy adhesives, sealants, coatings, potting/encapsulation compounds and impregnation resins.

• One and Two Part Silicone Systems

Our specially formulated silicones feature a unique combination of flexibility and high temperature resistance.

• UV Curable Systems

Master Bond’s UV curable systems offer excellent adhesion to glass, metals, ceramics, rubbers and most plastics.

• LED Curable Systems

Master Bond light curable adhesives offer consistent long-term durability and reliability. They also feature outstanding optical transmission properties.

• Polyurethanes

These polyurethanes are especially useful when strength, flexibility and abrasion/chemical resistance properties are required.

• Polysulfides

Our elastomeric compounds are 100% reactive and are designed to cure at ambient temperatures or at slightly elevated temperatures.

Supreme10HT

One part epoxy system, cures at 250-300°F, featuring high shear and peel strength. Superb temperature resistance. Serviceable at cryogenic temperatures.

EP21TDC/STwo component, silver filled epoxy system with a convenient one to one mix ratio and very low volume resistivity.

MasterSil 711

Exceptionally fast setting, high performance, non-corrosive silicone rubber.

UV15

Low viscosity, rigid UV curable system with superb thermal stability. Also capable of spin coating.

LED401LV

One part, low viscosity, optically clear system. Fast curing with a high bond strength. Superior dimensional stability.

Properties

Master Bond’s products are formulated to meet the most demanding application requirements. Our epoxy adhesives feature an extensive variety of superior performance properties including:

• Chemical Resistance

These compounds are used in chemical processing plants, chemical piping and tanks, medical devices and many other applications.

• Curing Properties

Master Bond products feature a variety of different curing processes that vary in cure speed, section thickness capabilities and preparation requirements.

• Electrical Properties

Master Bond adhesive systems feature outstanding electrical conductivity and electrical insulation properties based on your application requirements.

• Low Outgassing

We have developed a line of specialty adhesives that have passed NASA low outgassing specifications and exceed the ASTM E595 test requirements.

• Mechanical Properties

Specific grades maintain superior bonding strength even upon exposure to wear, corrosion, extreme temperatures, vibration, impact and shock.

• Optical Properties

Many of our compounds maintain superior light transmission, even upon exposure to chemicals, heat and other adverse environmental conditions.

• Strength Properties

Master Bond’s advance polymer systems feature superior strength properties including: compressive strength, flexural strength, peel strength, shear strength, tensile strength.

• Thermal Properties

These epoxy adhesive formulations withstand temperatures as low as 4K and as high as 600°F.

Applications

Master Bond’s high performance polymer compounds are used in advanced manufacturing applications. Our products are specially developed for high end applications that require:

Industries Served

Many world leading companies rely on Master Bond’s adhesives, sealants and coatings for the manufacturing of their products. Our epoxy adhesive compounds are used throughout a wide range of industries including;

Certification

Our extensive product line includes a variety of compounds that pass strict testing requirements for the following specifications:

Master Bond also offers numerous packaging options to speed productivity, minimize waste and save energy.

Master Bond's technical team has over 35 years of experience and understands the unique needs of each and every application. We provide personal one on one assistance and can recommend a compound custom formulated to meet your requirements. Furthermore, we will guide you from the design stage through the manufacturing process to ensure optimal results that will meet your needs.

We also offer custom formulations to meet the performance properties required for your specific application. Many of Master Bond’s products meet NASA, UL, USP and FDA certifications for low outgassing, flame retardancy, biocompatibility and food compatibility.

Products

Master Bond’s vast product line features the most reliable adhesive, sealant and coating compounds to improve production efficiency and ensure high end results. Our product line consists of:

• One and Two Part Epoxy Systems

We offer an extensive line of one and two component epoxy adhesives, sealants, coatings, potting/encapsulation compounds and impregnation resins.

• One and Two Part Silicone Systems

Our specially formulated silicones feature a unique combination of flexibility and high temperature resistance.

• UV Curable Systems

Master Bond’s UV curable systems offer excellent adhesion to glass, metals, ceramics, rubbers and most plastics.

• LED Curable Systems

Master Bond light curable adhesives offer consistent long-term durability and reliability. They also feature outstanding optical transmission properties.

• Polyurethanes

These polyurethanes are especially useful when strength, flexibility and abrasion/chemical resistance properties are required.

• Polysulfides

Our elastomeric compounds are 100% reactive and are designed to cure at ambient temperatures or at slightly elevated temperatures.

Supreme10HT

One part epoxy system, cures at 250-300°F, featuring high shear and peel strength. Superb temperature resistance. Serviceable at cryogenic temperatures.

EP21TDC/STwo component, silver filled epoxy system with a convenient one to one mix ratio and very low volume resistivity.

MasterSil 711

Exceptionally fast setting, high performance, non-corrosive silicone rubber.

UV15

Low viscosity, rigid UV curable system with superb thermal stability. Also capable of spin coating.

LED401LV

One part, low viscosity, optically clear system. Fast curing with a high bond strength. Superior dimensional stability.

Properties

Master Bond’s products are formulated to meet the most demanding application requirements. Our epoxy adhesives feature an extensive variety of superior performance properties including:

• Chemical Resistance

These compounds are used in chemical processing plants, chemical piping and tanks, medical devices and many other applications.

• Curing Properties

Master Bond products feature a variety of different curing processes that vary in cure speed, section thickness capabilities and preparation requirements.

• Electrical Properties

Master Bond adhesive systems feature outstanding electrical conductivity and electrical insulation properties based on your application requirements.

• Low Outgassing

We have developed a line of specialty adhesives that have passed NASA low outgassing specifications and exceed the ASTM E595 test requirements.

• Mechanical Properties

Specific grades maintain superior bonding strength even upon exposure to wear, corrosion, extreme temperatures, vibration, impact and shock.

• Optical Properties

Many of our compounds maintain superior light transmission, even upon exposure to chemicals, heat and other adverse environmental conditions.

• Strength Properties

Master Bond’s advance polymer systems feature superior strength properties including: compressive strength, flexural strength, peel strength, shear strength, tensile strength.

• Thermal Properties

These epoxy adhesive formulations withstand temperatures as low as 4K and as high as 600°F.

Applications

Master Bond’s high performance polymer compounds are used in advanced manufacturing applications. Our products are specially developed for high end applications that require:

- Bonding

- Sealing

- Coating

- Potting and Encapsulation

- Impregnation

Industries Served

Many world leading companies rely on Master Bond’s adhesives, sealants and coatings for the manufacturing of their products. Our epoxy adhesive compounds are used throughout a wide range of industries including;

- Aerospace

- Electronic

- Medical

- OEM

- Oil and Chemical Processing

- Optical

Certification

Our extensive product line includes a variety of compounds that pass strict testing requirements for the following specifications:

- NASA low outgassing

- USP Class VI

- FDA CFR 175.300 and CFR 175.105 specifications

- UL 94V-0 and UL 94V-1 for flame retardancy

- RoHS standards

- Halogen free

Master Bond also offers numerous packaging options to speed productivity, minimize waste and save energy.

Master Bond's technical team has over 35 years of experience and understands the unique needs of each and every application. We provide personal one on one assistance and can recommend a compound custom formulated to meet your requirements. Furthermore, we will guide you from the design stage through the manufacturing process to ensure optimal results that will meet your needs.

Images

Articles / Press Releases

Brochures

Reviews

Trade Associations