Company details for:

Metalmaster Promotions UK Ltd

(0)

Shirburn House,

Oxford Road,

London,

SE19 3JH,

United Kingdom

Quick Links:

About us

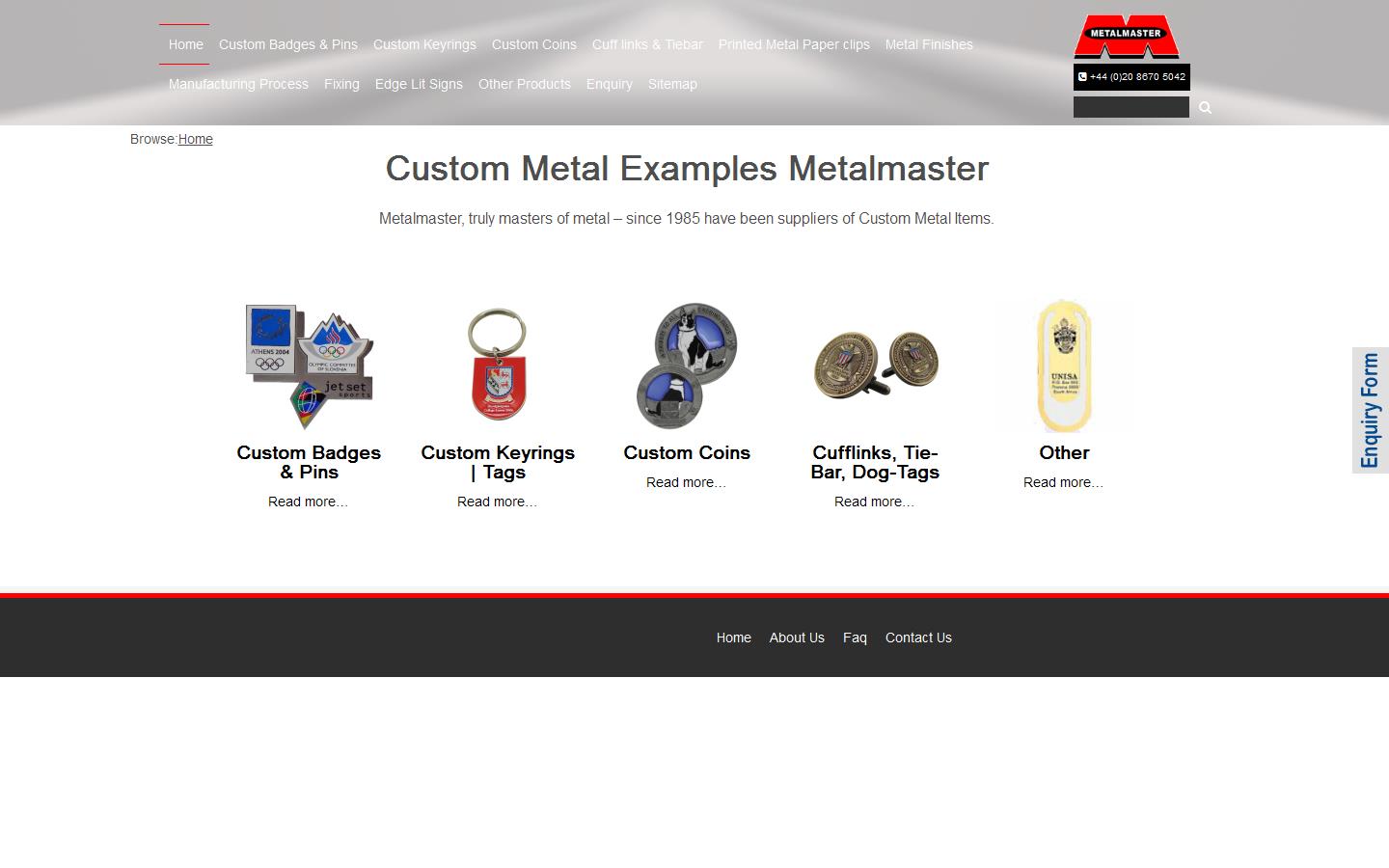

Established in 1985, Metalmaster Promotions are true masters of metal, designing and creating promotional metal items including enamel pin badges and printed badges.

Being a metal master, we can create bespoke promotional metal items with different enamel decorations and a whole range of electroplating metal finishes to create wonderful quality and long lasting promotional items that can be kept.

Custom Pin Badges

Metalmaster Promotions core product range includes custom designed badges and pins using different enamel decorations and electroplated finishes to suit individual styles and tastes.

Hard Enamel Badges − Cloisonné on Copper

Perfected by the Chinese many many years ago, the concept of the hard enamel badge is to make prestige ornaments that are used as collectables. The hard enamel surface is like a glass like material making the pin or badge last for a lifetime allowing them to kept as a collectible.

Synthetic Enamel Badges on Copper

Synthetic enamel is a modern day substitute to hard enamel. The synthetic enamel process provides a top quality finish and has a much broader range of colours available. Stone polishing gives the metal item a recognizable flat shiny surface.

Soft Enamel Badges on Copper

Soft enamel is another substitute to real Cloisonné and probably used the most. Soft enamel differs by the colouring technique. The colours do not completely fill the cavities and the metal borders are much more visible. The soft enamel process is also frequently used for metal items with no colouring and with 3D relief.

LED Flash Pin Badges

Ideal for special events the LED flashing pin and badge can be used for sports events as they are great for attracting attention. They can be made with stamping or printing processes.

Offset Printed Pins & Badges

The offset printing process enables Metalmaster to print designs with gradiant colours such as photos, paintings, lithographies etc. The offset printing industry resolution standard is 125 lines per inch, Metalmaster can achieves 250 lines per inch resolution on prints. An epoxy coating will be applied to enhanced protection

Laser / Silk Screen Printed Pins

Laser printing and silk screen printing is generally carried out on a flat metal base with aluminium and brass materials. Each colour would be applied one at a time as a print. Metalmaster’s pins and badges are printed using these methods using spot colours − a precise and identifiable number of colours which do not require any plating. An epoxy coating should be applied to protect the print. This process is also known in Europe as "Serigraphy".

Being a metal master, we can create bespoke promotional metal items with different enamel decorations and a whole range of electroplating metal finishes to create wonderful quality and long lasting promotional items that can be kept.

Custom Pin Badges

Metalmaster Promotions core product range includes custom designed badges and pins using different enamel decorations and electroplated finishes to suit individual styles and tastes.

Hard Enamel Badges − Cloisonné on Copper

Perfected by the Chinese many many years ago, the concept of the hard enamel badge is to make prestige ornaments that are used as collectables. The hard enamel surface is like a glass like material making the pin or badge last for a lifetime allowing them to kept as a collectible.

Synthetic Enamel Badges on Copper

Synthetic enamel is a modern day substitute to hard enamel. The synthetic enamel process provides a top quality finish and has a much broader range of colours available. Stone polishing gives the metal item a recognizable flat shiny surface.

Soft Enamel Badges on Copper

Soft enamel is another substitute to real Cloisonné and probably used the most. Soft enamel differs by the colouring technique. The colours do not completely fill the cavities and the metal borders are much more visible. The soft enamel process is also frequently used for metal items with no colouring and with 3D relief.

LED Flash Pin Badges

Ideal for special events the LED flashing pin and badge can be used for sports events as they are great for attracting attention. They can be made with stamping or printing processes.

Offset Printed Pins & Badges

The offset printing process enables Metalmaster to print designs with gradiant colours such as photos, paintings, lithographies etc. The offset printing industry resolution standard is 125 lines per inch, Metalmaster can achieves 250 lines per inch resolution on prints. An epoxy coating will be applied to enhanced protection

Laser / Silk Screen Printed Pins

Laser printing and silk screen printing is generally carried out on a flat metal base with aluminium and brass materials. Each colour would be applied one at a time as a print. Metalmaster’s pins and badges are printed using these methods using spot colours − a precise and identifiable number of colours which do not require any plating. An epoxy coating should be applied to protect the print. This process is also known in Europe as "Serigraphy".