Company details for:

Newson Gale Ltd

Quick Links:

Products / Services

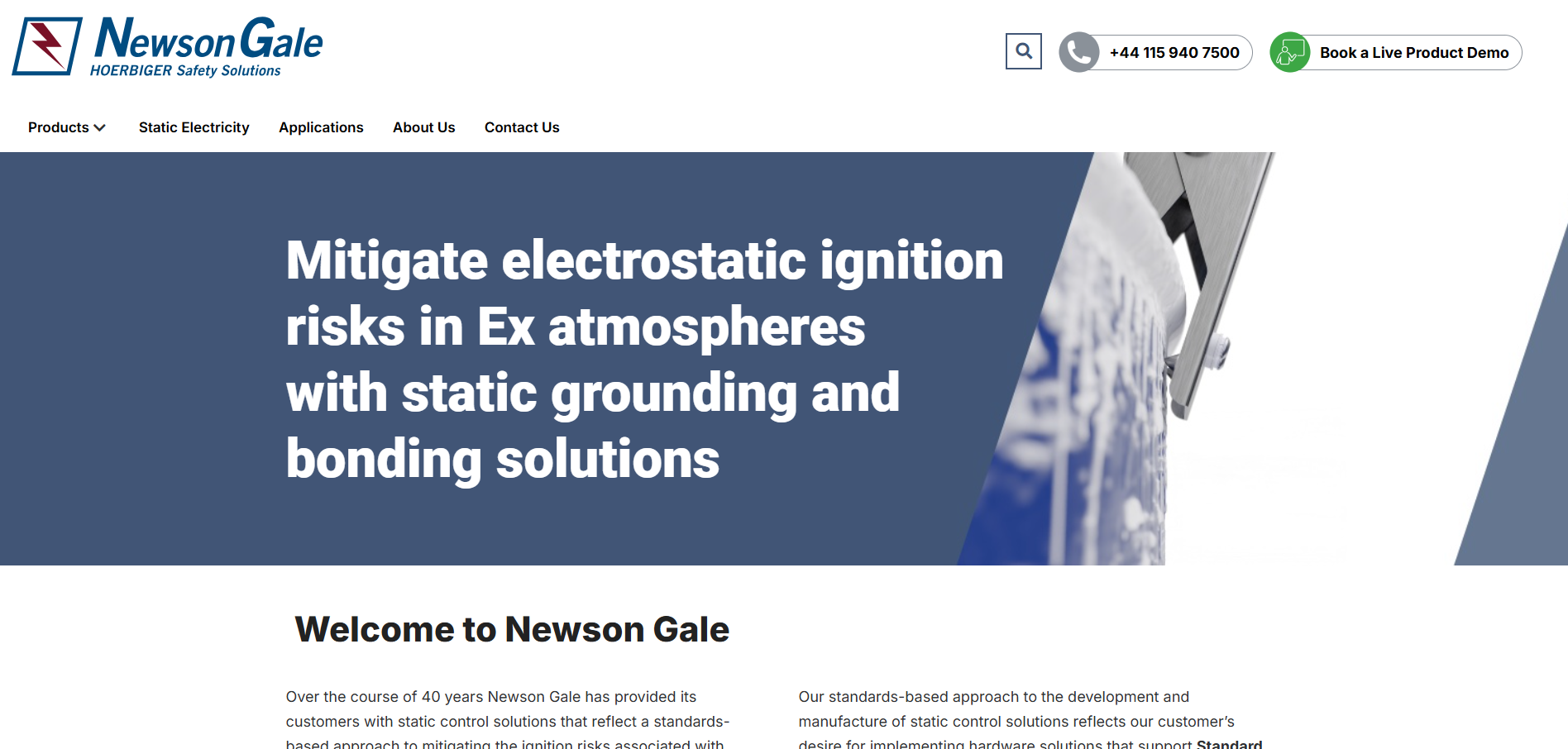

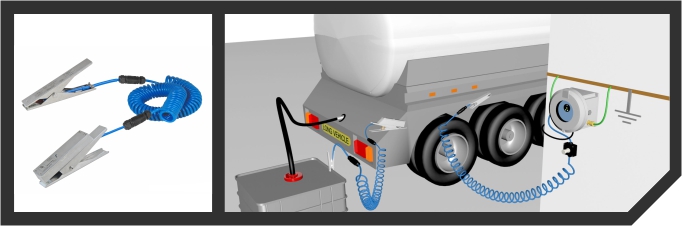

Static Earthing Protection for Road Tankers

The loading and unloading of road tankers with large volumes of flammable liquids and powders generate enormous amounts electrostatic charge which, if left to accumulate on a road tanker, could discharge incendive sparks that exceed the minimum ignition energies of a vast range of combustible gases, vapours and dusts. The ignition of such atmospheres by static electricity can be prevented by ensuring the road tanker has a verified connection to earth.

Earthing the road tanker ensures there can be no build of static electricity on the tank and chassis of the road tanker and the most reliable way of earthing your road tankers is to specify an Earth-Rite RTR.

Mobile Static Earthing System

Vacuum trucks and bulk chemical road tankers, including their hoses and hose connections, are susceptible to static charge accumulation during the transfer of product into or out of the truck’s containment system. This accumulation of static charge is equivalent to a hidden source of ignition and if discharged as a static spark can lead to the ignition of the product or the atmosphere in which the truck and material handling team is operating.

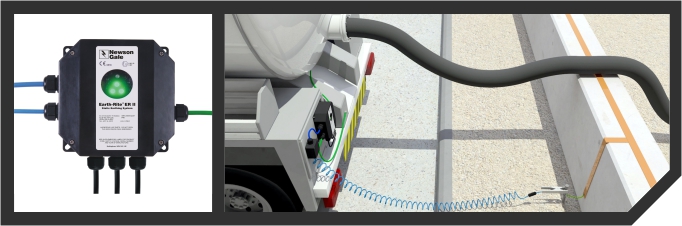

Static Earthing Interlock System

Conductive metal objects like railcars, LACT units, skids and IBCs that come into contact with electrostatically charged liquids can accumulate hazardous levels of electrostatic charge that could discharge static sparks with energies far in excess of the minimum ignition energies of a vast range of combustible gases and vapours. The ignition of combustible atmospheres by static electricity can be prevented by ensuring that such objects are earthed.

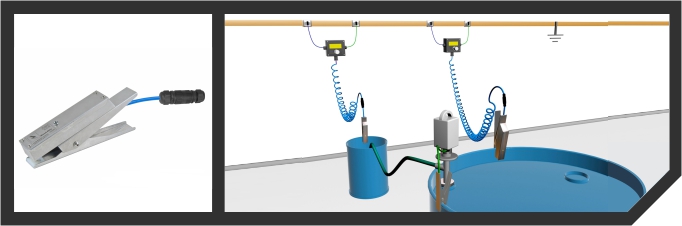

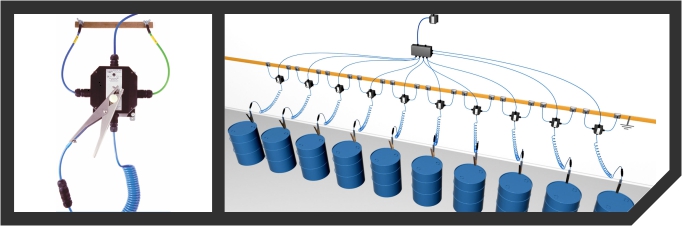

Multi-channel Static Earthing System

To earth and monitor multiple items of equipment at points like multi drum loading stations and mixing stations, IBC loading stations and railcar loading gantries, a large number of conventional static earthing systems would be required to provide protection against incendive electrostatic sparks. In addition to flammable liquid and gas operations, powder processing equipment that typically includes interconnected pipes, fluid bed dryers, hoppers and micronizers would require multiple earthing systems. With the Earth-Rite® MULTIPOINT II up to eight individual items of potentially isolated equipment can be earth monitored simultaneously with a single static earthing system.

Static Earthing for Type C FIBC Bags

To compensate for normal wear and tear on Type C bags it is important to ensure the bag maintains its ability to dissipate electrostatic charges. It is equally important to ensure earthing connection between the bag and plant earth grounding point is functioning correctly.

Self-testing earthing clamp with visual indication

The Bond-Rite CLAMP contains a bright green LED which pulses continuously when it verifies that the resistance between the equipment to be earthed and the site’s verified earth grounding point (e.g. copper bus-bar) is 10 ohms or less.

The pulsing green LED provides process operators with a continuous visual reference point that enables them to monitor the earth status of equipment at risk of accumulating static electricity.

Once connected to equipment the Bond-Rite CLAMP continuously monitors the resistance of the circuit between the equipment and the verified earth point.

Earth Monitoring Clamp With Wall Mounted Indicator

The Bond-Rite REMOTE indicator station houses both the earth loop monitoring circuit and a bright green LED indicator which pulses continuously when it detects that the resistance between the equipment and the site’s verified earth (e.g. copper tape) is 10 ohms or less.

Once connected the Bond-Rite REMOTE continuously monitors the resistance of the clamp’s connection to the equipment.

Self-Testing Externally Powered Earthing Clamp

For process applications that require earthing for more than 6 hours per day, the Bond-Rite® REMOTE EP (EP = Externally Powered) utilises 230V AC or 115 V AC mains power to power the monitoring circuit of up to ten indicator stations.

The external power supply can be located in both hazardous areas (Zone 2/22 − Div.2) and non-hazardous areas. The indicator stations can be mounted in EX zoned / HAZLOC area (Zone 0 / Div.1) or lower.

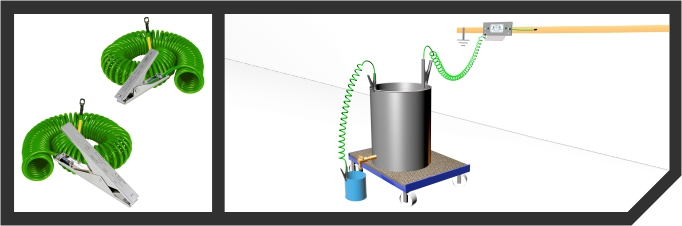

Portable Bonding Clamp With Visual Indication

ATEX / FM approved static earthing clamps and cables

When flammable or combustible products are being handled and processed in hazardous areas it is essential to specify certified equipment that will protect personnel from sources of electrostatic ignition.

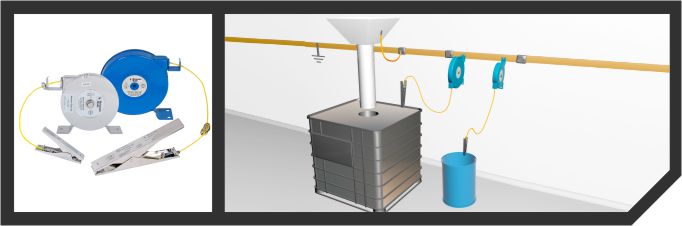

ATEX/FM approved static discharge cable reels

Newson Gale’s “R-series” of static earthing reels offer our Cab-Lite cable housed on automatically retractable cable reel.

Cab-Lite is a 3.2 mm (1/8″) multi-stranded galvanized steel conductor protected by a hi-vis yellow coating and is supplied on the R20, R30 and R50 reels.

Personnel Grounding Strap

Through their own movement people can generate large amounts of static charge if they are not earthed. In some cases, as much as 30, 000 volts can be carried by people who are completely unaware that they themselves are the potential source for an electrostatic spark discharge that could ignite a flammable atmosphere.

If the operating requirements of certain processes cause the loss of direct contact between the operator’s static dissipative safety shoes and the static dissipative flooring of the plant, the VESX45/PGS provides an added layer of protection to ensure the operator is earthed via the plant or bonded to the equipment they are interacting with.

Portable Static Grounding Kit

The portable grounding kit combines multiple shortened earthing rods with surface wire earthing techniques to provide acceptably low resistance for static earthing requirements in field operations.

The flexible array of interconnected earthing rods is inserted into the soil at specified intervals to maximize the capacity to safely dissipate static electricity from mobile trucks, service vehicles and other equipment.

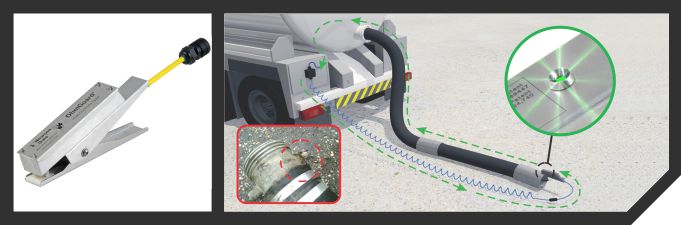

Intrinsically Safe Hose Continuity Tester

The OhmGuard verifies that the electrical conductivity of the hose is functioning correctly, thereby ensuring static electricity is not permitted to accumulate on the metal components of the hose and eliminating the risk of a fire or explosion caused by the discharge of a static spark.

The OhmGuard is easy to operate, does not require any specialist driver training and will indicate, within seconds, if the hoses are safe to use. The driver simply connects the OhmGuard’s cable to a junction box situated on the truck and connects the OhmGuard clamp to the last hose coupling as illustrated. The green LED housed in the OhmGuard will pulse continuously if the hose has an electrical continuity of less than 100 ohms with the truck.

Static Dissipative Footwear Tester

International Standards (detailed below) recommend regular testing of static dissipative footwear. The Sole-Mate provides a time efficient and cost effective method of ensuring personnel operating in hazardous areas are wearing static dissipative shoes that are capable of preventing electrostatic charge accumulation on their bodies.

The Sole-Mate tests the condition of the shoes by measuring the resistance of the electrical loop through the operator and their footwear. If the resistance of the shoes is too high, the Sole-Mate will indicate that the shoes have failed the test via a red lamp and buzzer alarm. If the shoes pass the test a green lamp will indicate to the operator that the shoes are fit for purpose.

Equipment commissioning and maintenance service

Our CompEx® certified engineers will ensure your Newson Gale equipment is installed and maintained in accordance with the equipment’s instruction manual.

This is critical to ensuring the equipment has been installed in accordance with the ATEX and IECEx requirements laid down in EN and IEC standards for the safe installation and operation of electrical equipment in EX zoned areas.

About us

With over 40 years’ experience in developing unique solutions for the mitigation of electrostatic hazards, Newson Gale Ltd have enough knowledge and skill to fully comply with International Standards, Guidance and/or Recommended Practices. Based in Nottinghamshire, our company has a broad range of static earthing and bonding solutions available to customers that are cost effective and offer flexible installation and maintenance. Our main goal as a company is to mitigate the risk of static ignition ensuring the safety of both people and plant.

Here at Newson Gale, we understand that the accumulation of static electricity must be avoided at all costs in any industrial environment as this can result in fires and/or explosions. Over the years, our team of experienced engineers has expanded greatly, offering new and innovative ideas that can create a safer and more productive working environment for all employees. Collectively, our company has a universal knowledge of IEC, Cenelec, API and NFPA codes of practice, which are related to controlling the ignition of static electricity.

Newson Gale Ltd cater for a number of industries and sectors throughout the UK and beyond, such as chemical and petrochemical, food and beverage, paints and coatings and pharmaceutical. Our loyal customer base has praised our fast and efficient service over the years for being reliable and fully committed to reducing the risk of hazards in the workplace. We offer a full range of bespoke brands that have been utilised in many organisations across the country, including our Earth-Rite® range of static ground monitoring and interlock systems, the Bond-Rite® range of self-testing static grounding clamps with visual indication and monitoring, the Cen-StatTM range of static earthing clamps, cables, and personnel safety equipment together with our Earth-SafeTM equipment commissioning and maintenance service.

First established in 1982, our company has ensured that all products and services fully meet customer, contractual and regulatory requirements, which has inevitably led to a rapid growth in reputation and positive working relationships with varying individuals. At Newson Gale are fully committed to maintaining excellent quality, ensuring that each employee understands and appreciates the importance of long-term customer satisfaction. As a company we continuously invest in future development and technology to ensure the safety of our customers.

Images

Brochures

Reviews

Trade Associations