Company details for:

Plastics By Design

2 ,

Dial Close,

Seend,

Melksham,

Wiltshire,

SN12 6NP,

United Kingdom

Quick Links:

Products

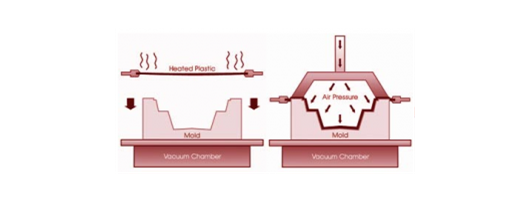

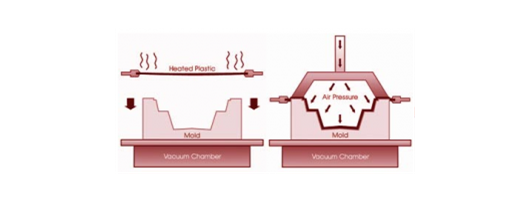

Vacuum Forming

The benefit of plastic vacuum forming is its versatility. It offers a good price, performance and rate of production. Prototypes can be created promptly and properly. These are used to prove components before full production tooling is needed.

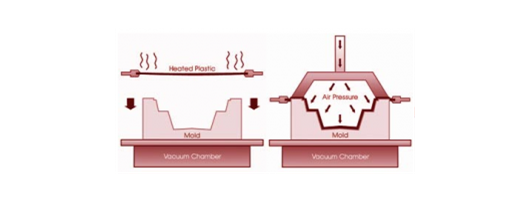

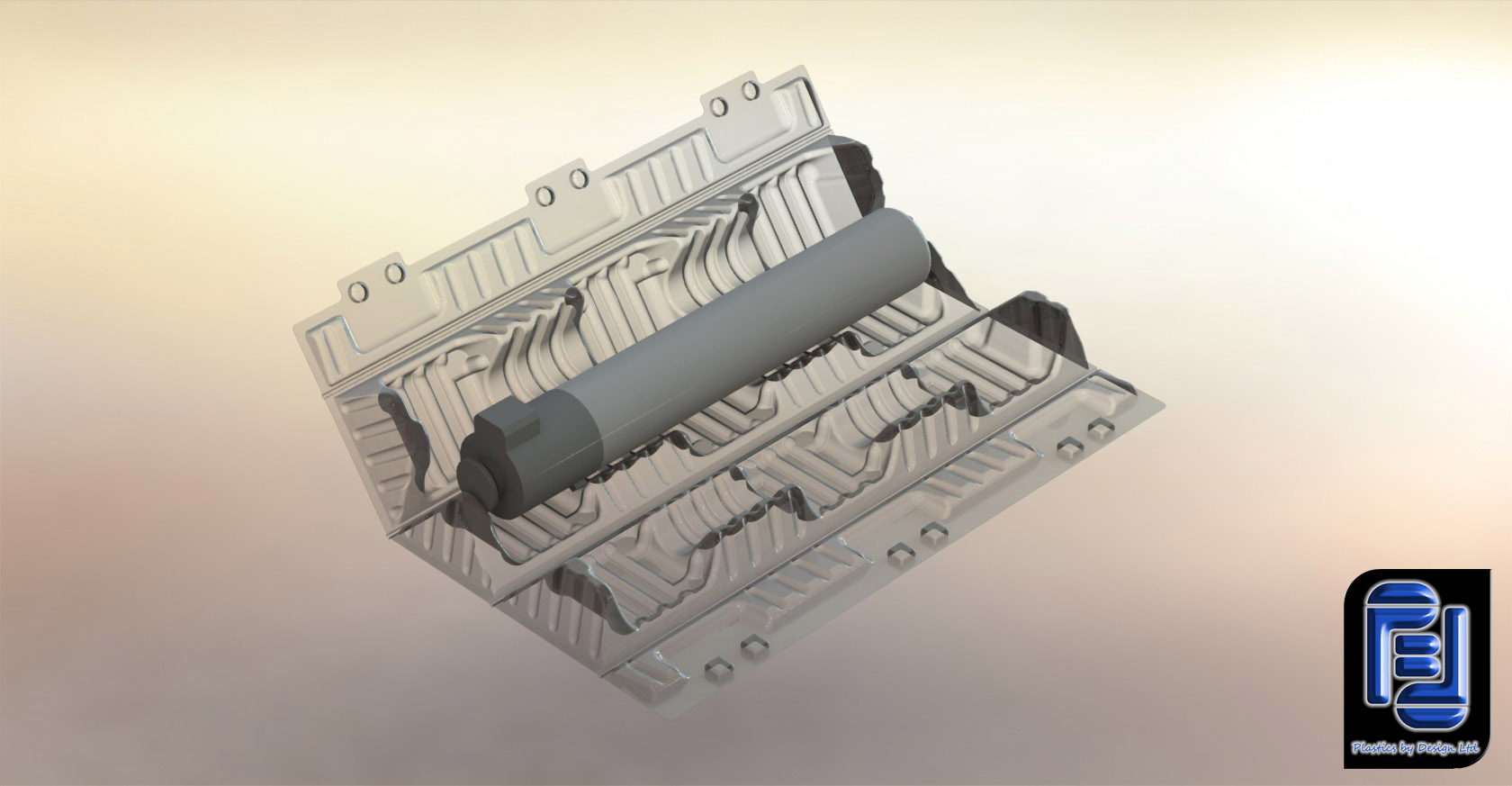

Pressure Forming

With conventional vacuum forming, the components are formed by creating a vacuum on the mould side of the sheet. The air pressure is 14.7 extra pounds per square inch (PSI). This is the theoretical maximum forming stress readily available with vacuum forming.

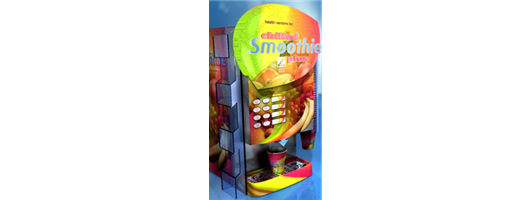

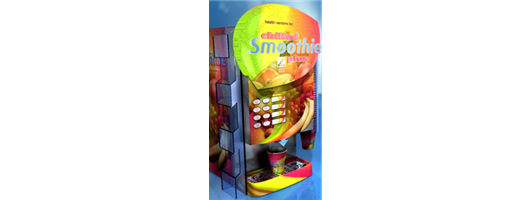

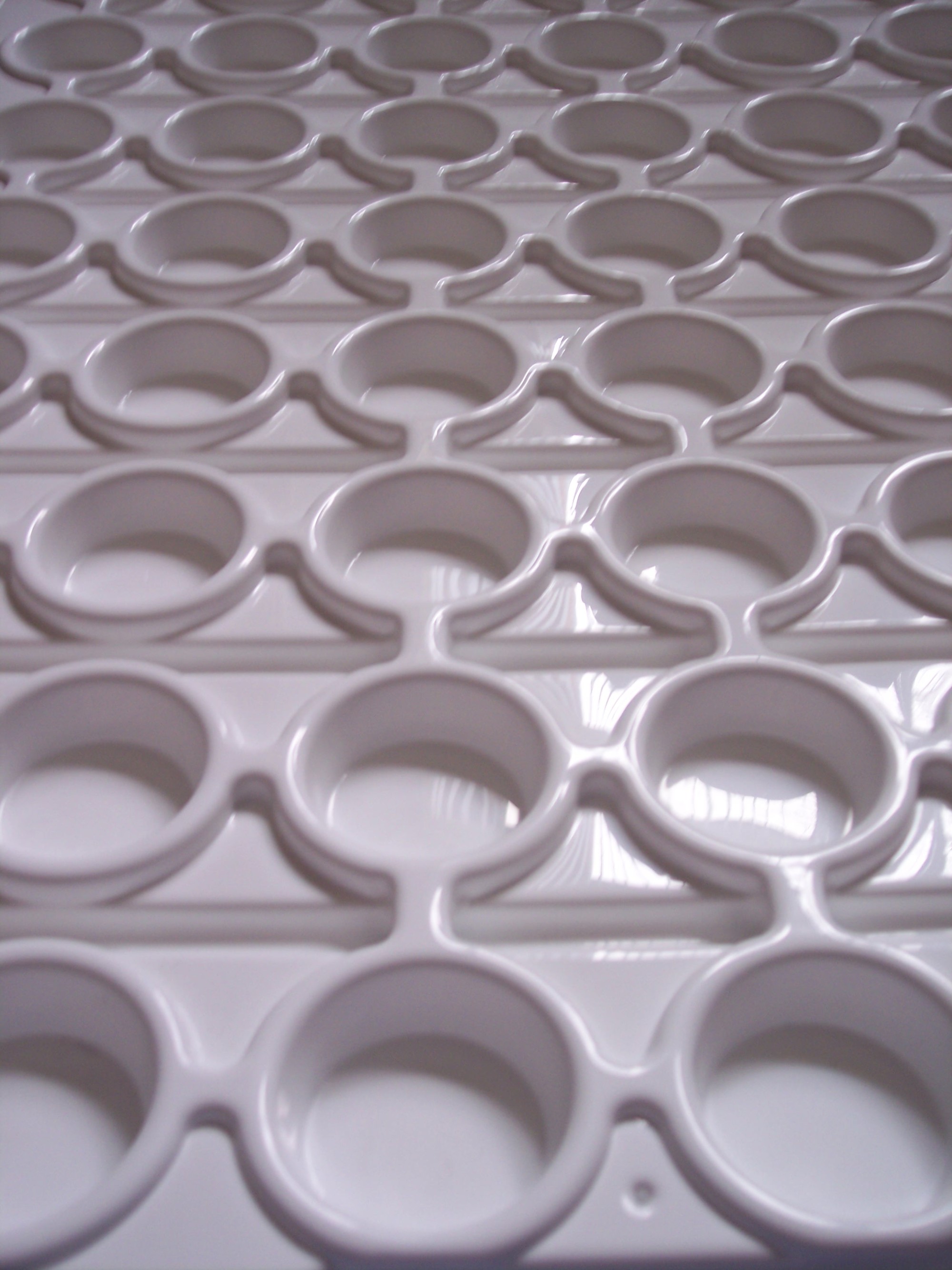

Protective Packaging

We have a comprehensive customer service to target the best price, design, unique solutions, product loading and transportation for every client’s project.

Design & Innovation

Plastics by Design currently supply into a variety of market sectors with differing packaging formats.

Working closely with our customers and their machinery suppliers we can develop cost effective bespoke solutions for non-food and food requirements.

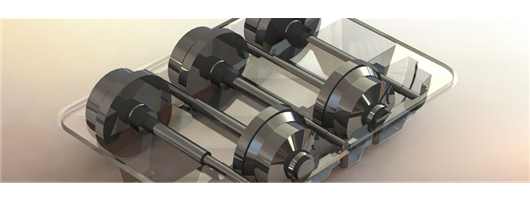

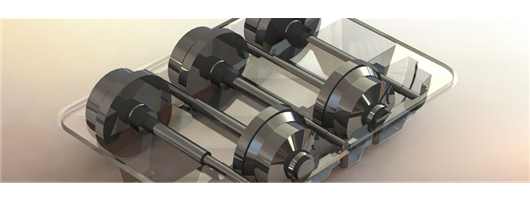

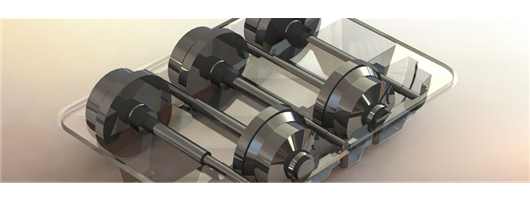

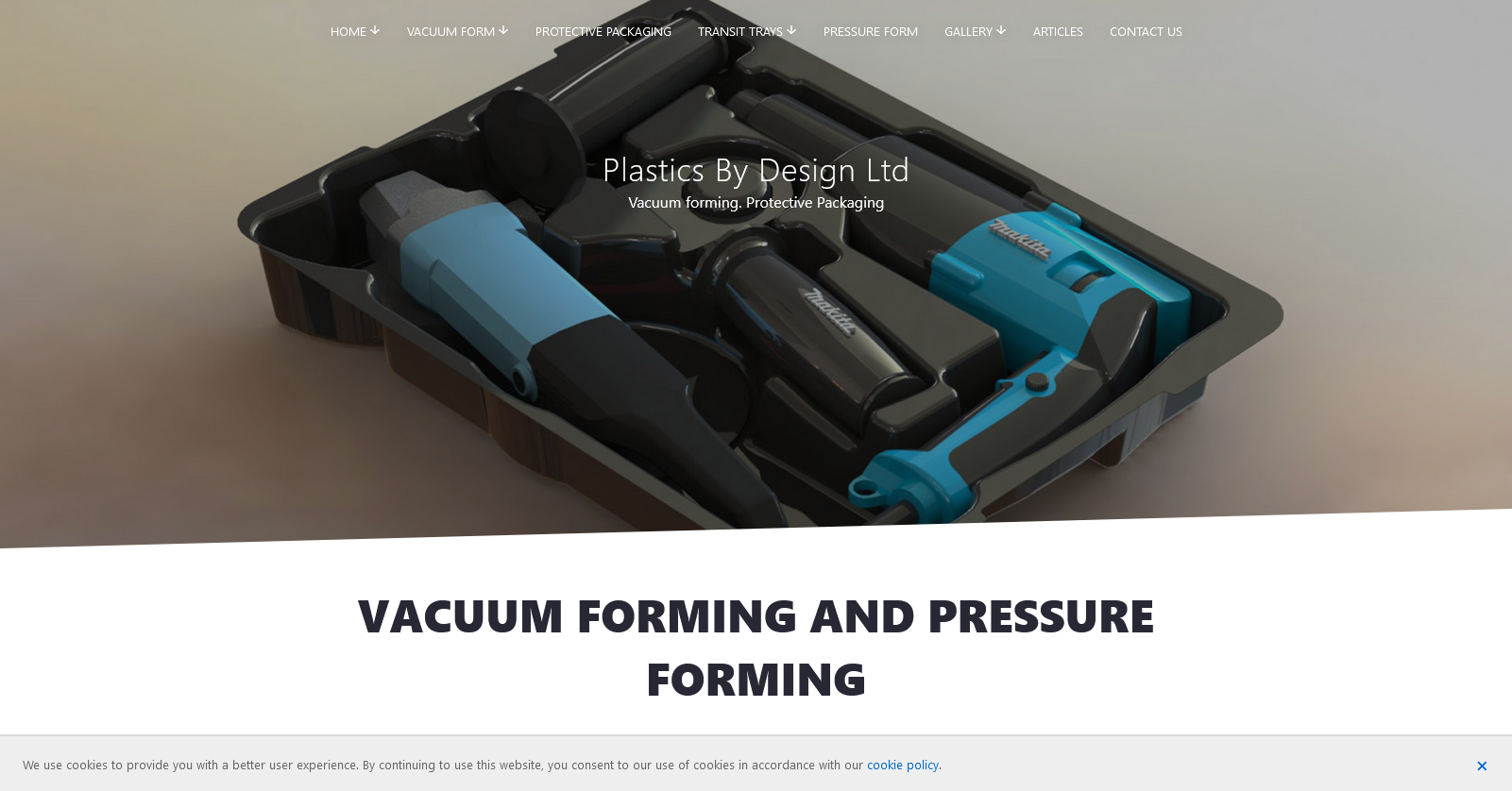

Transit Trays

Transit trays are designed to offer maximum protection to the un-packed item. They are usually used for automotive/electrical/electronic components. These are also used throughout to food, cosmetic and clinical applications.

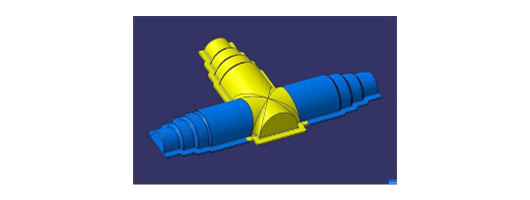

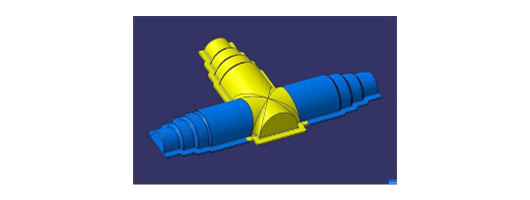

Bespoke Vacuum Forming

About us

Based in Wiltshire, our company has gained an outstanding reputation within the plastics thermoforming industry, which we have achieved through hard work and determination over the last two decades. We offer a friendly and reliable service from beginning to end, which customers have praised over the years for being effective, professional and efficient.

Since establishment, we as a company have developed a wide range of services and processes, some of which include vacuum forming, pressure forming, tool making, protective packaging, standard packs, twin sheet moulding, silk screen printing, injection moulding, rapid prototyping, CNC trimming, foil block printing, plastic fabrication, 3D forming and hot line bending. Our level of experience has allowed for our company to become the number one supplier of high quality thermoformed plastics and components across the UK and beyond.

Here at Plastics by Design, we take the customer’s initial design and transform it into a reality. From initial concept through to production, we help clients every step of the way, ensuring that they receive the best possible service on the market. We take great pride in our friendly and helpful approach at all times, which has helped our business grow in size and reputation. Our thermoformed plastic solutions are cost effective, easily installed and can be utilised across a variety of industries and sectors.

We at Plastics by Design believe that the key to success is maintaining relationships with customers as this allows for exceptional service from start to finish. We work closely with customers to ensure that their requirements are met quickly and efficiently.

We have enhanced thousands of projects across the nation and continue to extend our services beyond the UK. Our in-house design team are able to utilise the latest design technologies when manufacturing these solutions and are able to satisfy the needs of clients all over the world.

Images