Company details for:

Riverside Waste Machinery

Unit A,

2 Jubilee Court,

Wath Lane, Copgrove,

Harrogate,

North Yorkshire,

HG3 3TB,

United Kingdom

Quick Links:

Products

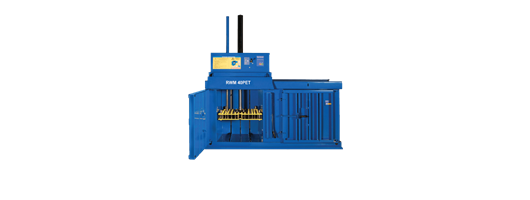

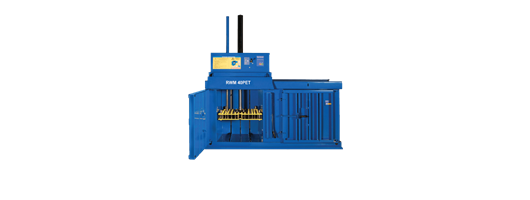

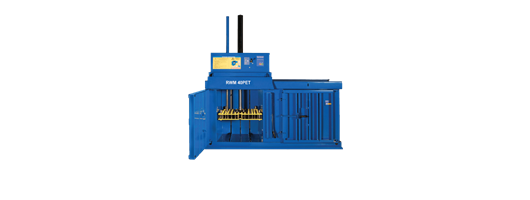

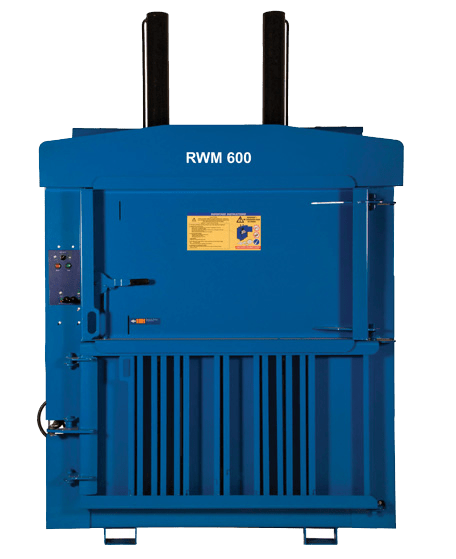

Mid-Range Waste Balers

So, whether you’re looking for a cardboard baler, waste paper baler, or plastic baler, one of these machines could be perfect for you. They are typically used by manufacturers, warehouses, distribution outlets, larger retailers, prisons, hospitals, and bigger hotel chains, but in truth the list goes on.

Heavy Duty Waste Balers

However complex your waste streams we’ll work with you to convert these tough materials into secure, sturdy bales. And like all of the other waste balers within our extensive range, all are available to rent or purchase outright. Simply tell us what works best for you.

Waste Machinery

Compactors

Highly configurable to suit individual requirements, these clever yet compact machines typically offer a hassle-free 4:1 size reduction of dry commercial and industrial waste − perfect for organisations regularly filling skips with their material arisings.

Bag Press

Boasting a small footprint, the bag press is a neat addition to a garage forecourt, hotel, retail outlet, university or small hospitality establishment − to name just a few. Suitable for indoor or outdoor relocation, it is supplied with a 12 month warranty for maximum peace of mind.

Drum Press

Glass Crusher

As with many of our technologies, the primary goal of the RWM Glass Crusher is volume reduction. In fact, with a compaction ratio of 5:1, from bottles to cullet, our clients can reduce the frequency of their glass collections and therefore experience cost savings of up to 80%.

Cardboard Balers

However, to help you with your search, we’ve selected our current most popular cardboard balers, which you can view below.

Plastic Balers

But if you just want to do some of your own research initially, we’ve highlighted some of our most popular solutions for this varied application.

Mill Size Waste Balers

Our robust mill size balers are popular with recyclers and industrial users alike, due to their powerful ability to effortlessly and efficiently convert large volumes of ‘waste’ materials into manageable bales.

Whichever mill size waste baler you choose, you’re guaranteed a robust and long-lasting machine that will reduce the storage, handling and transportation costs of your waste.

Horizontal Waste Balers

Multi-Chamber Waste Balers

Whether you’re looking for a twin baler, or a baling press with multiple chambers, talk to us about the material streams you handle, so we can help you make the best-fit investment.

Compact Waste Balers

You know what they say, great things come in small packages − with impressive press forces, robust component parts and rapid cycle times, these compact balers are impressive little machines perfect for schools, convenience stores, takeaways, offices and more.

PolyPack Waste Baler

Waste Baler Hire

Used Balers

Baling Wire

Baling Twine

Baling Tape

Clear Polythene Sacks

Service & Maintenance

Cost Benefits

Baler Training

But what if operators move on to a new role and leave a skills gap within the workforce? We can train your new recruits!

And what if experienced operators have picked up bad habits or forgotten things along the way? We can provide refresher sessions to ensure nobody cuts corners!

Our courses are quick and cost-effective, yet incredibly thorough. They’ll also be carried out on your site, using your own machine, at a time to suit you. It couldn’t be easier.

Spare Parts

This equates to utmost ease of maintenance for you, low ongoing running costs and only very ad hoc spare parts requirements.

When you do need a spare part, of course, we can help. We keep everything − from rams and motors, to pumps and switches − in stock at our North Yorkshire headquarters. This ensures it can be despatched for nationwide next business day delivery, to reduce any unnecessary downtime that you may otherwise incur.

Baler Refurbishment

At Riverside, we don’t just sell − or offer for hire − brand new waste balers. Our team of highly experienced engineers also refurbish second-hand models, to give them a new ‘lease of life’!

About us

Over the years, the firm has used robust technology to both improve client’s recycling capabilities and boost their environmental credentials. The company specialises in waste balers, baler servicing, baler consumables and associated waste management expertise. We pride ourselves on our ability to make big waste worries small, which is achieved through working closely with clients and meeting their needs.

Since its establishment in 1997, the company has gained a wealth of experience within the waste management industry. It offers a multitude of products and services including waste balers for clients to convert their packaging waste into manageable bales, waste presses for volume reduction of general waste and waste shredders designed to reprocess and re-use industrial wastes and recyclables. Clients include Oaklair Ltd, Duffield Printers, Dee Set Complete Retail, Wester Ross Fisheries, Pirelli, Wood Recyclability, Greyhound Box Ltd, Woolcool, Clark Transport Ltd, SWM, Bird Bros Ltd, EA Tailby Ltd, Momentive, Allpress Farms and many more.

Riverside Waste Machinery offers a vast array of products and services, such as mid-range waste balers, heavy duty waste balers, used balers, waste machinery, compactors, bag presses, drum presses, bin presses, glass crushers, mill size waste balers, cardboard balers, plastic balers, compact waste balers, horizontal waste balers, waste baler hire, operator training, service and maintenance, spare parts, waste handling consultancy, baler refurbishment, multi-chamber waste balers, baling wire, baling twine, baling tape and clear polythene sacks.

Contact the team today for more information.

Images